Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Minimize color mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

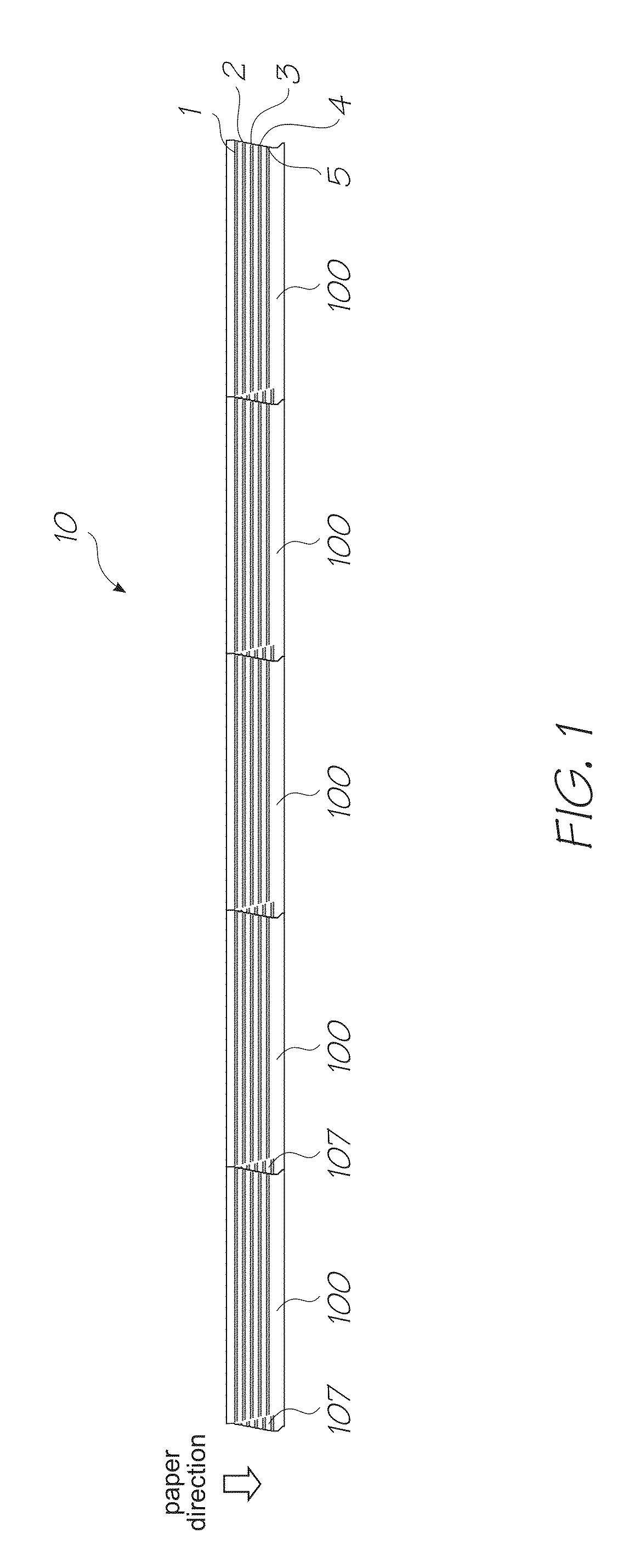

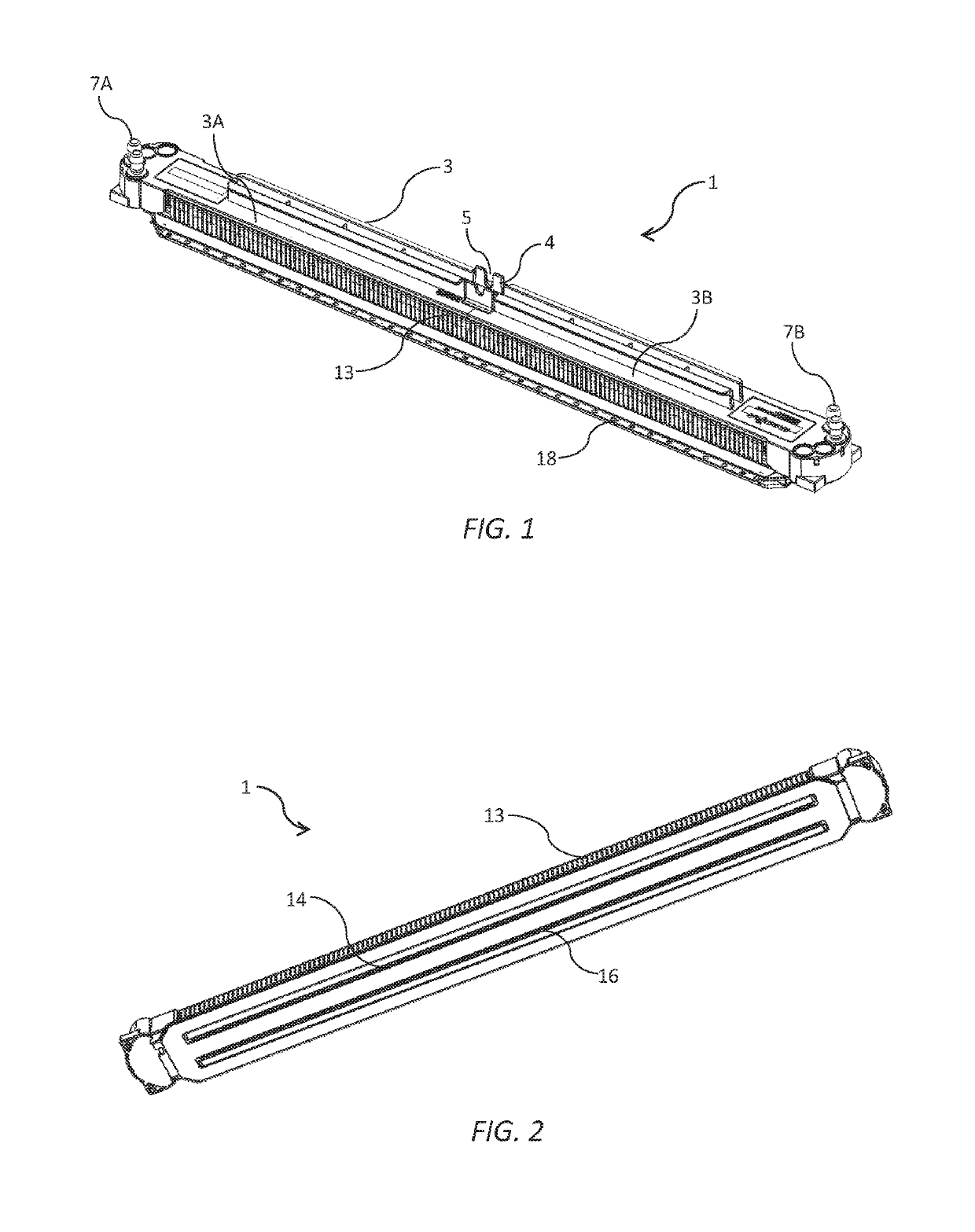

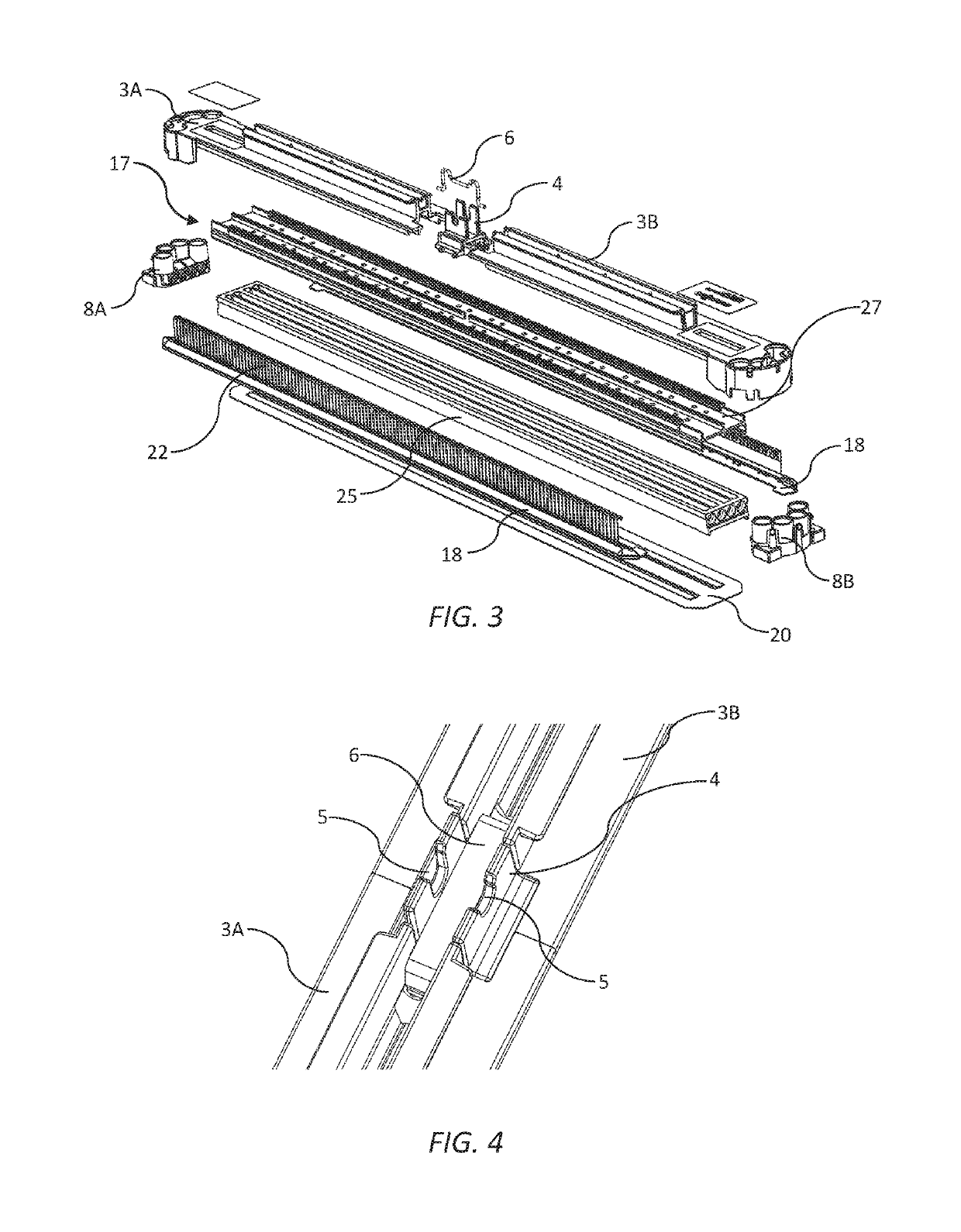

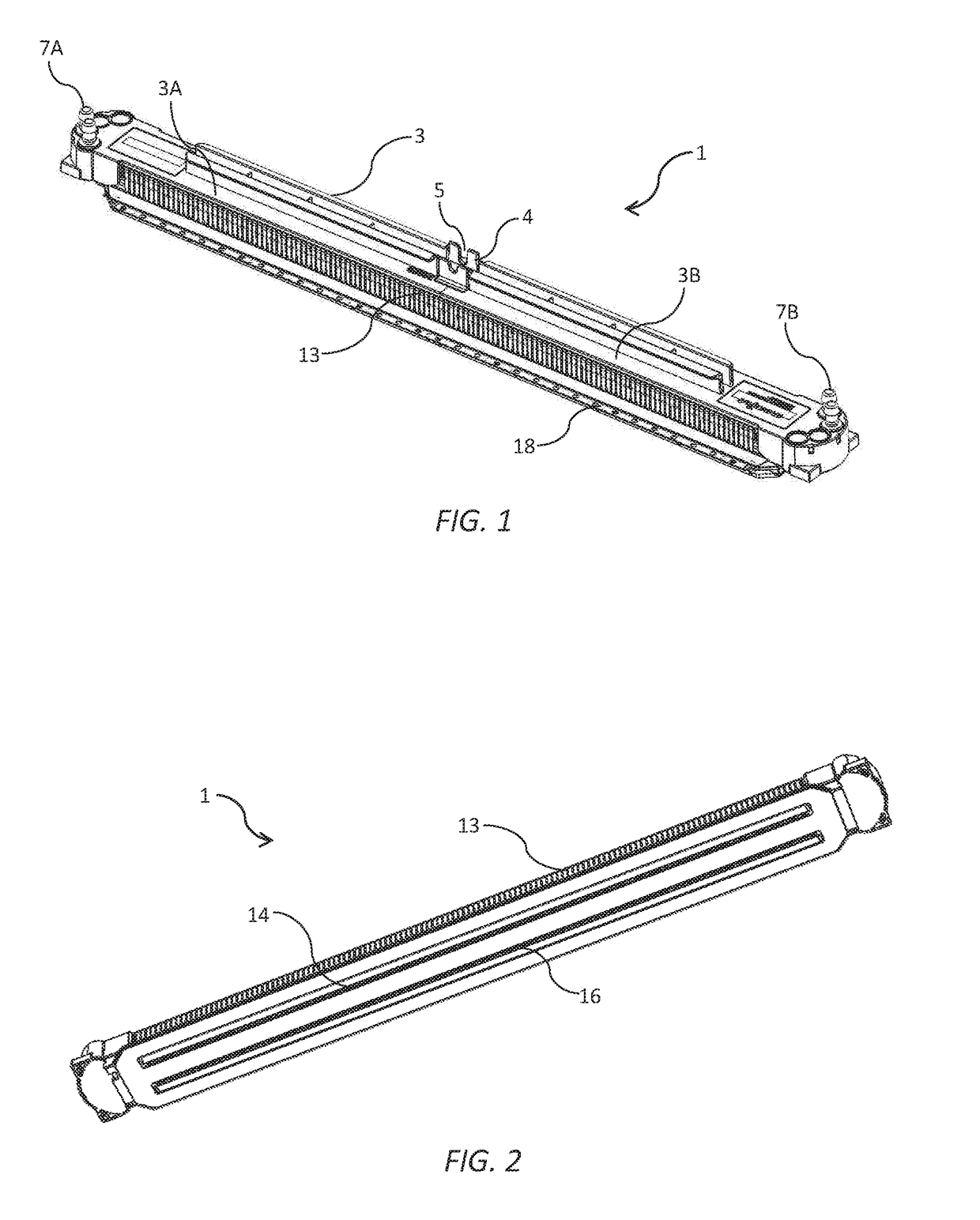

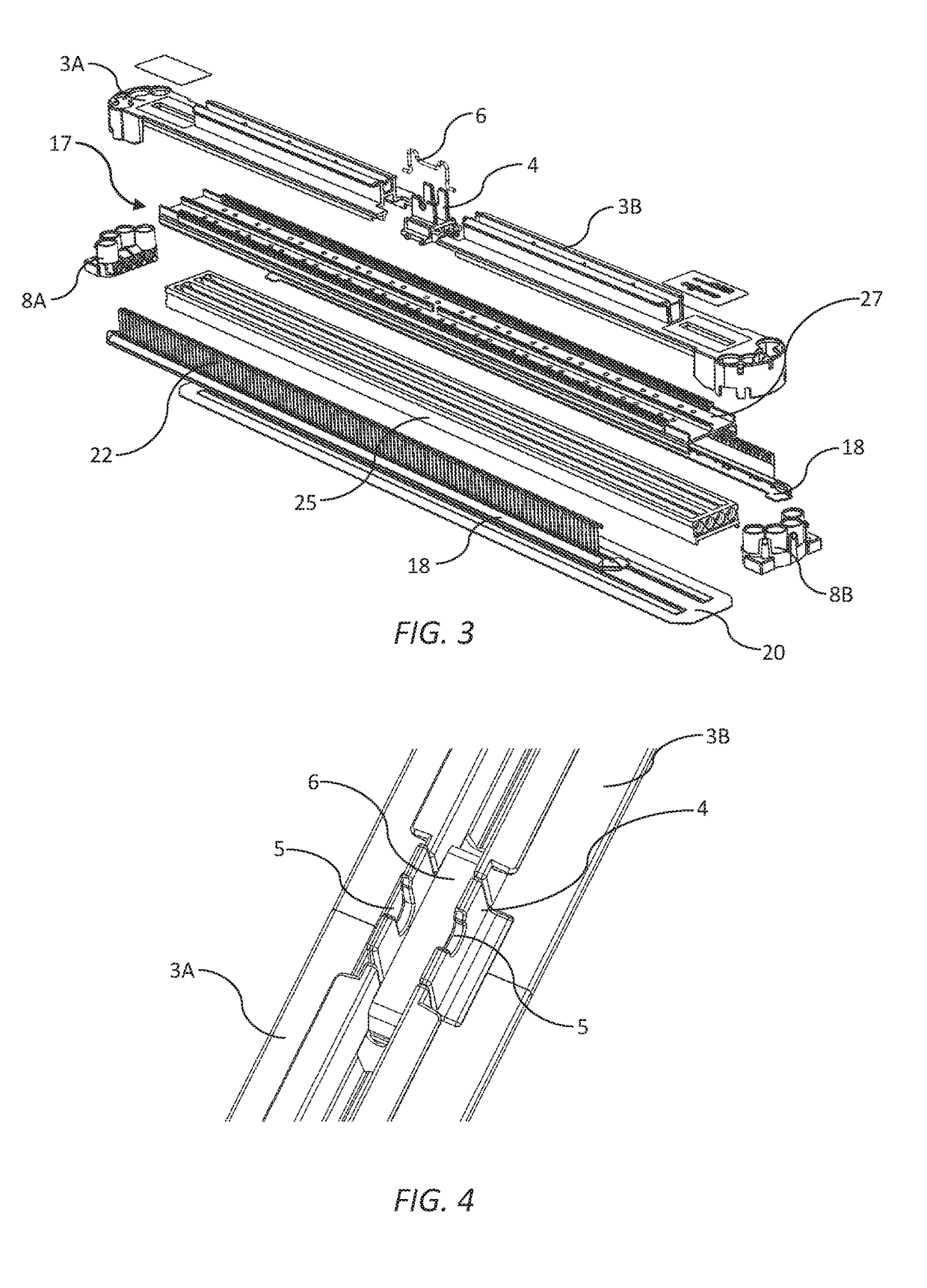

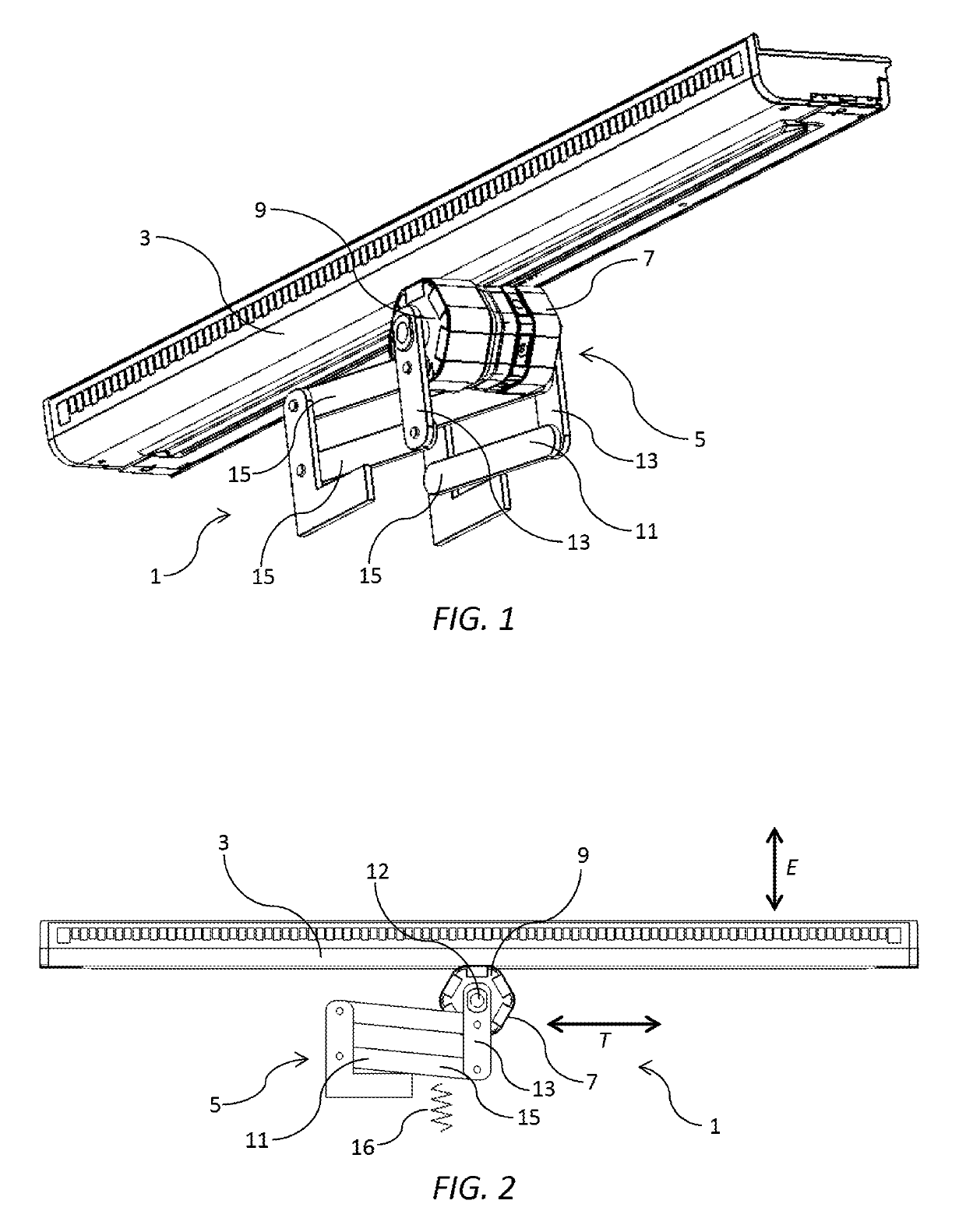

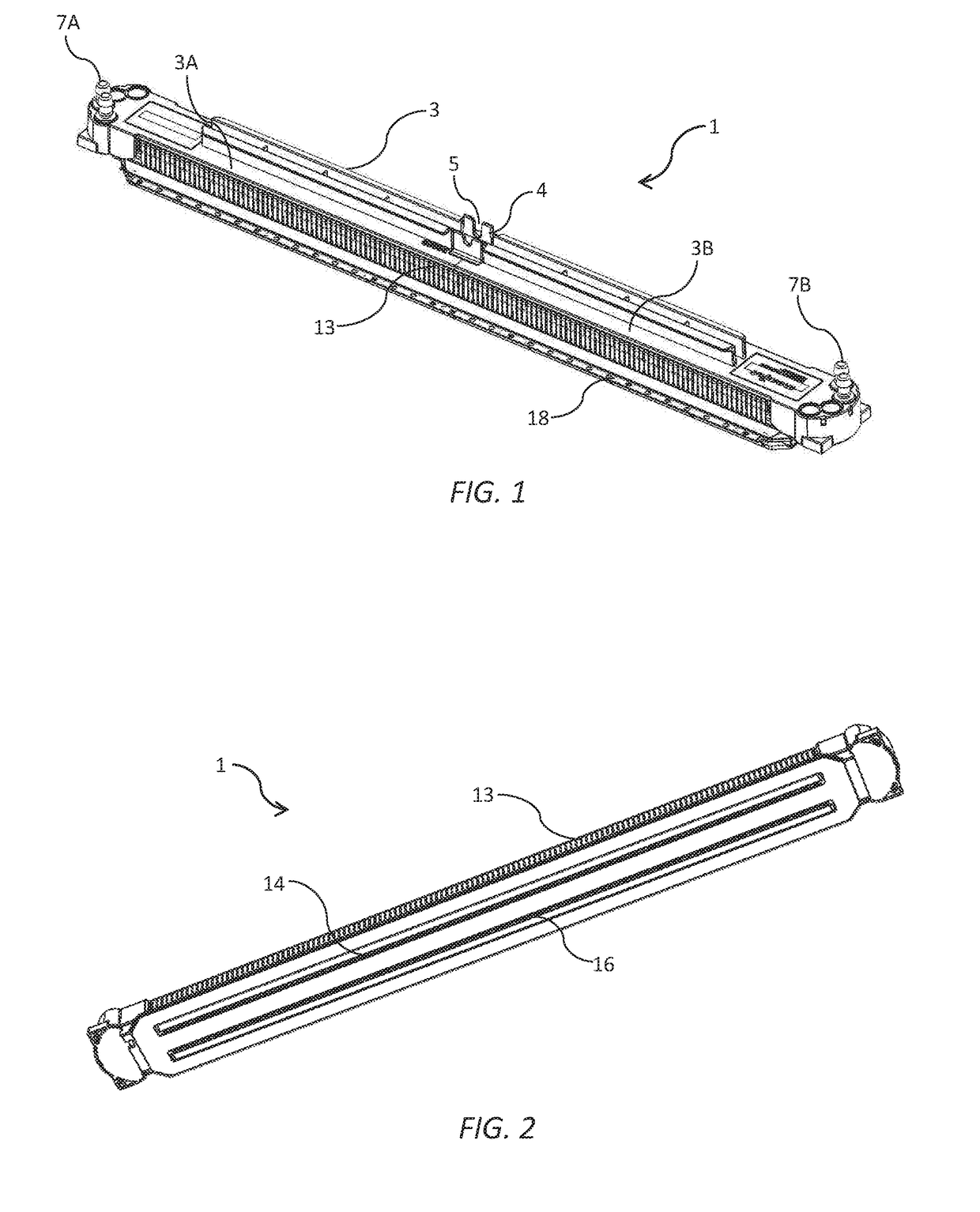

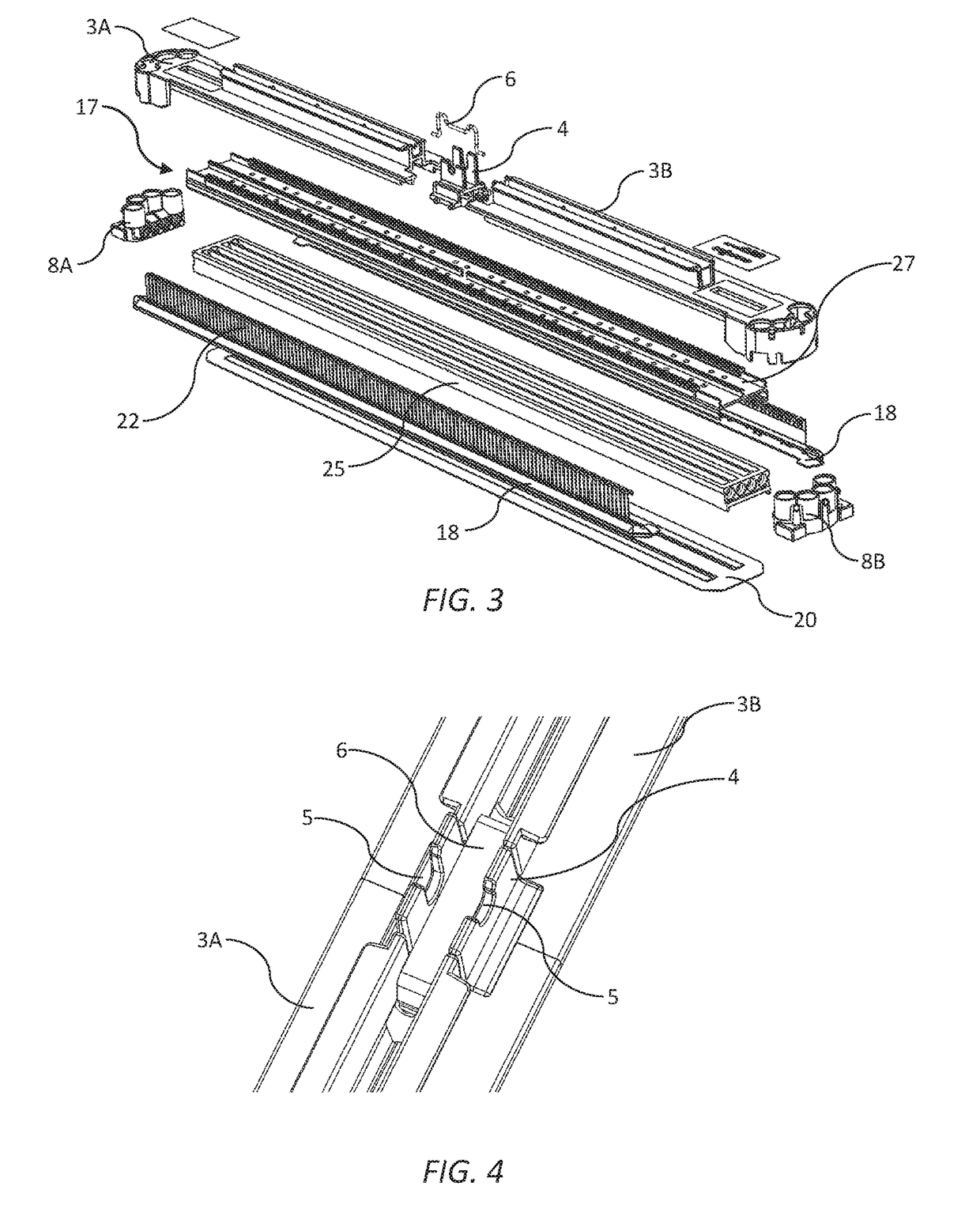

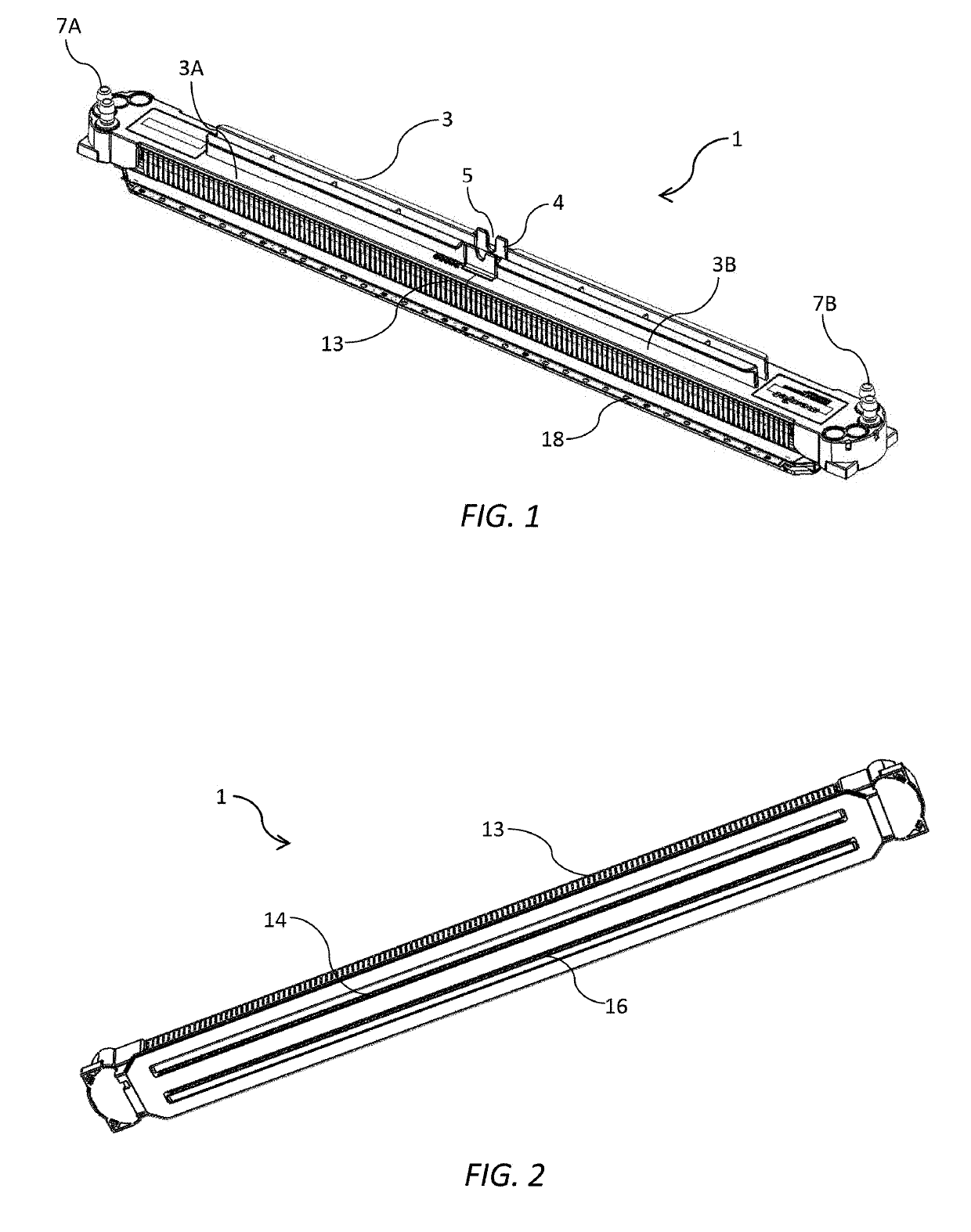

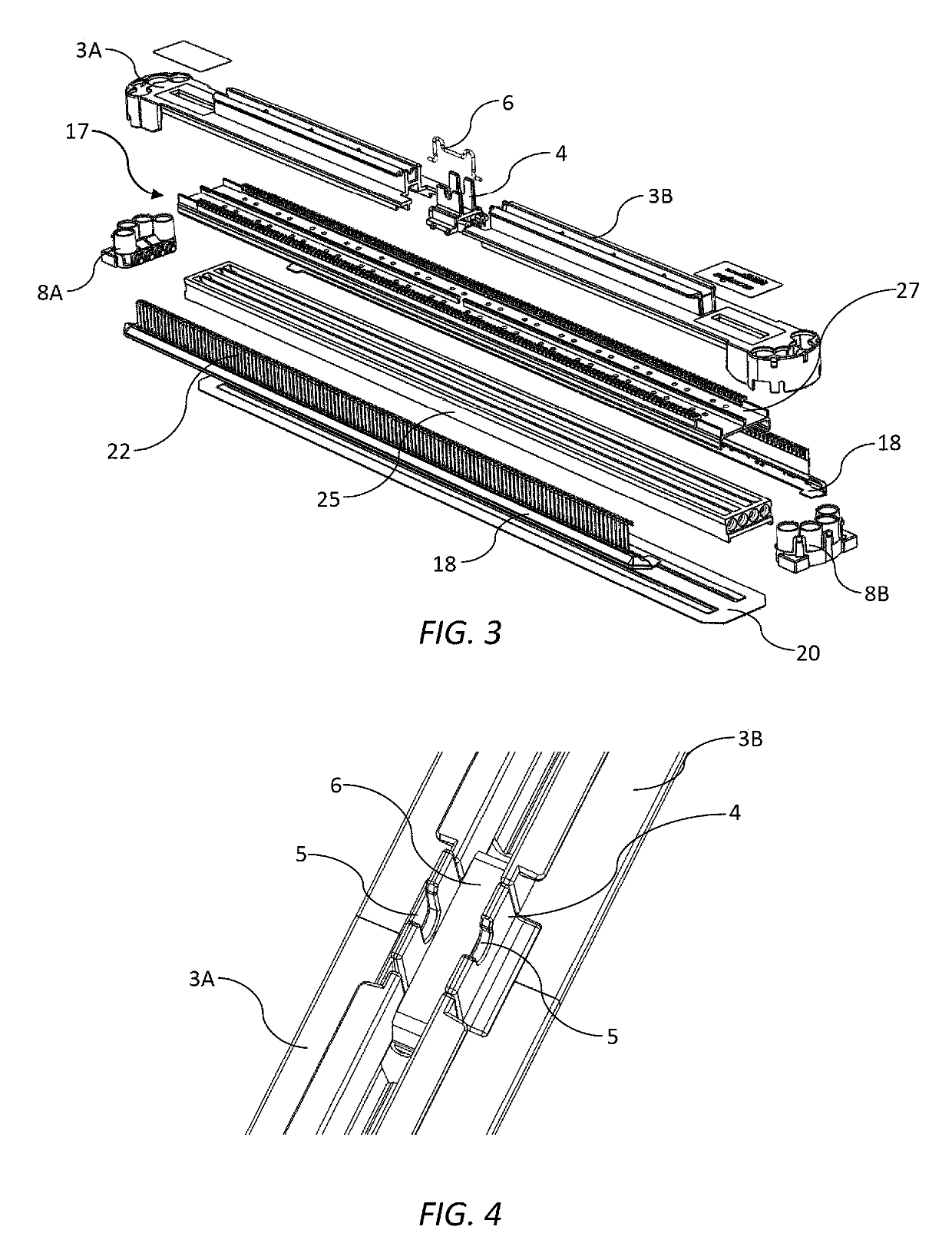

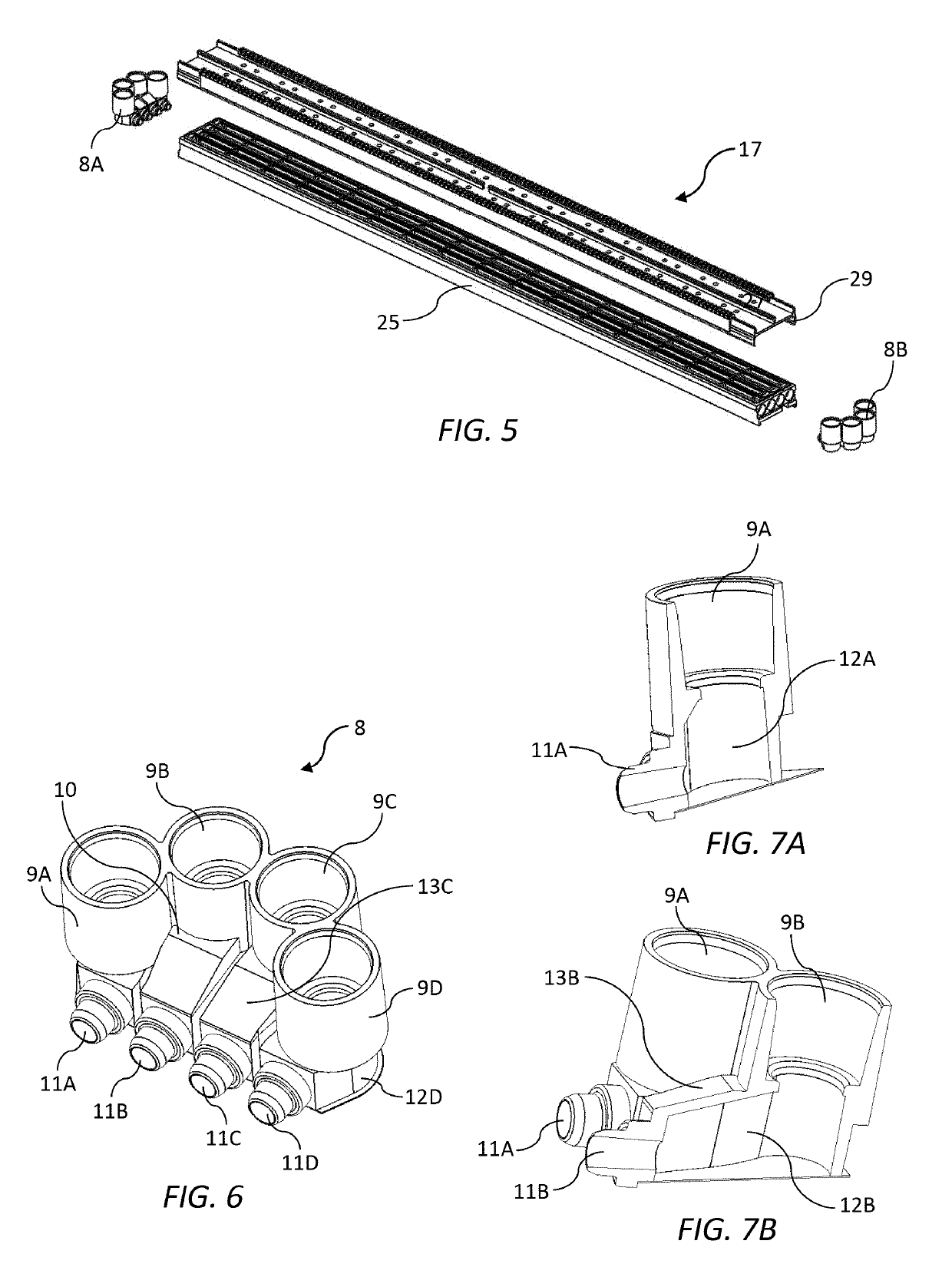

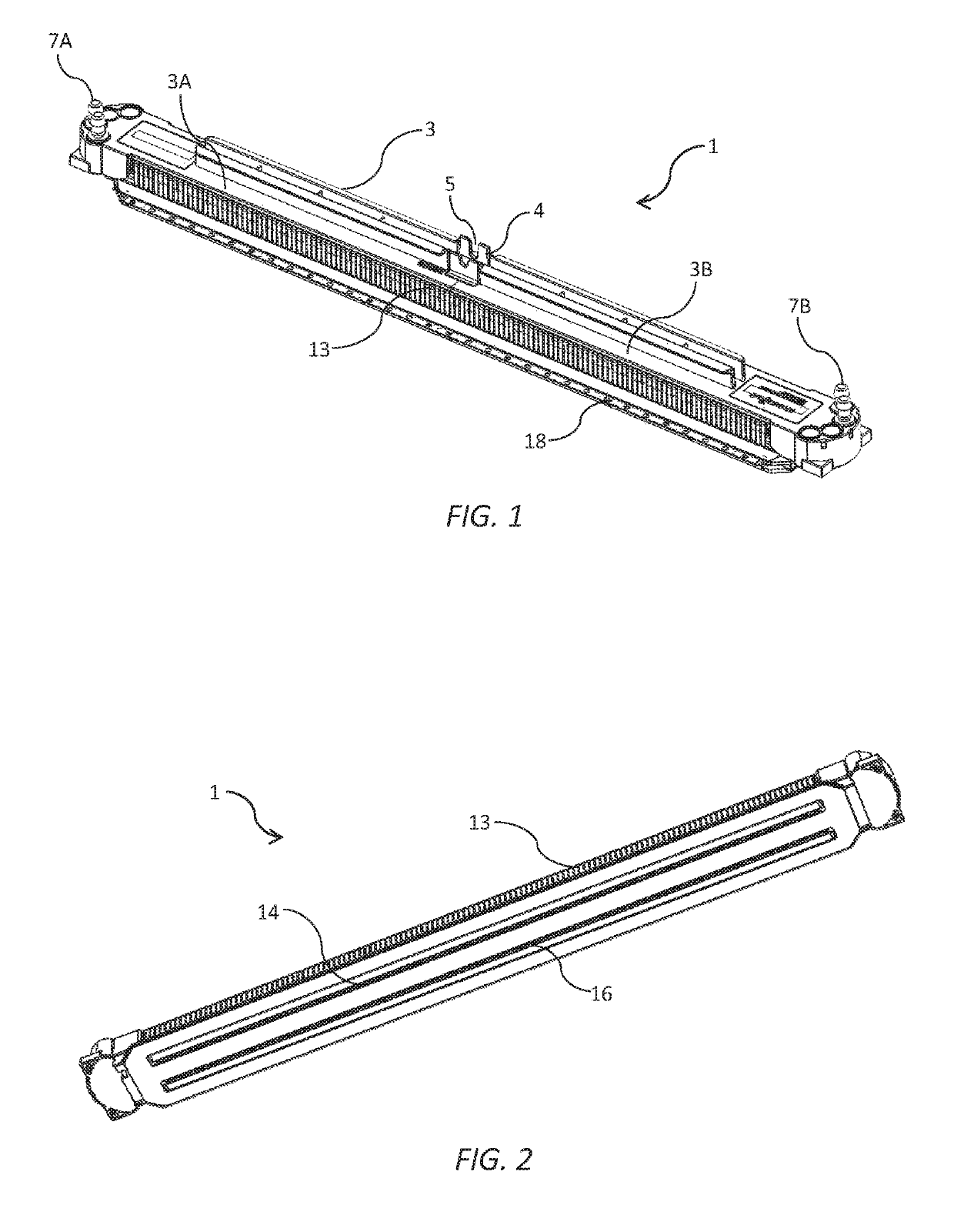

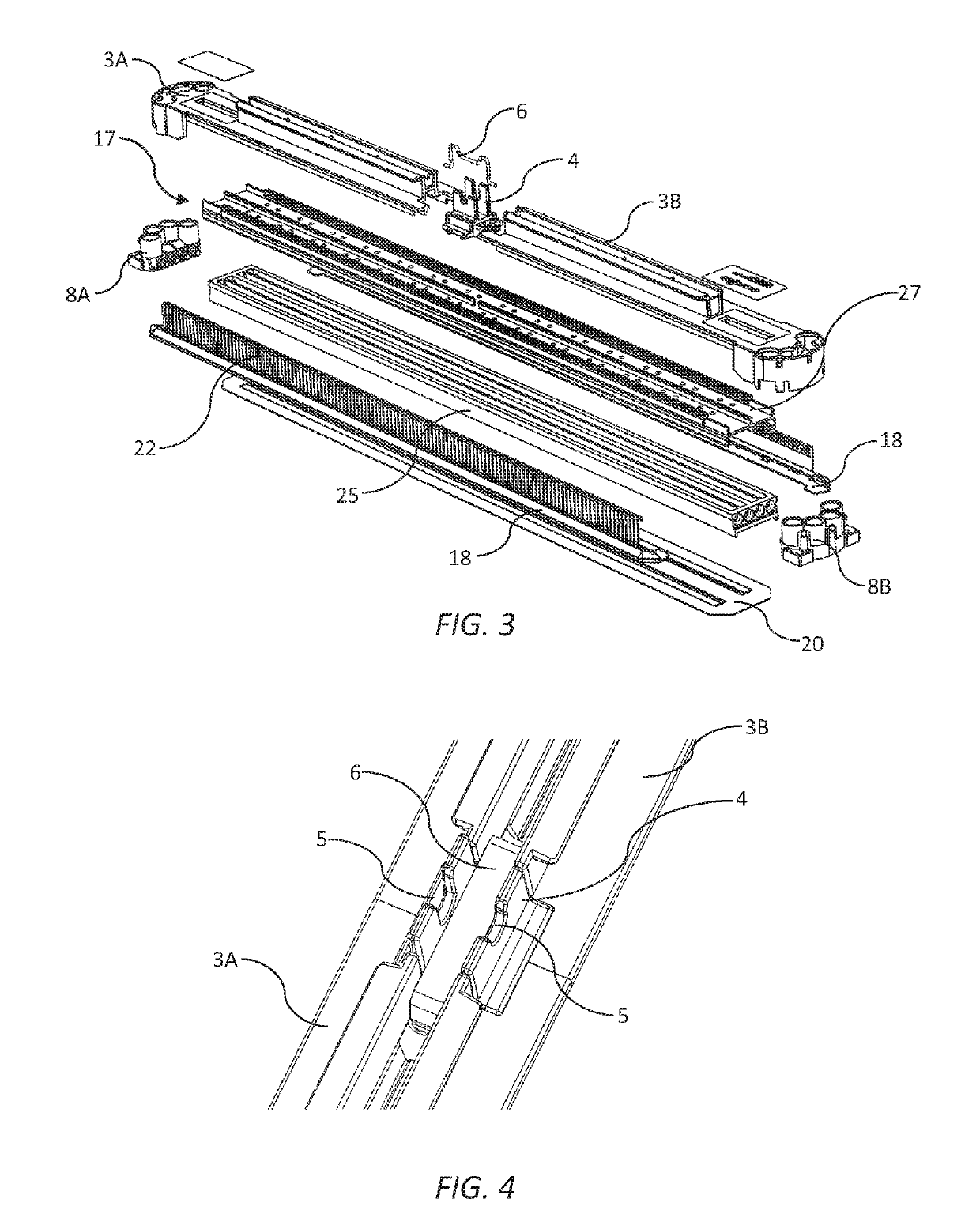

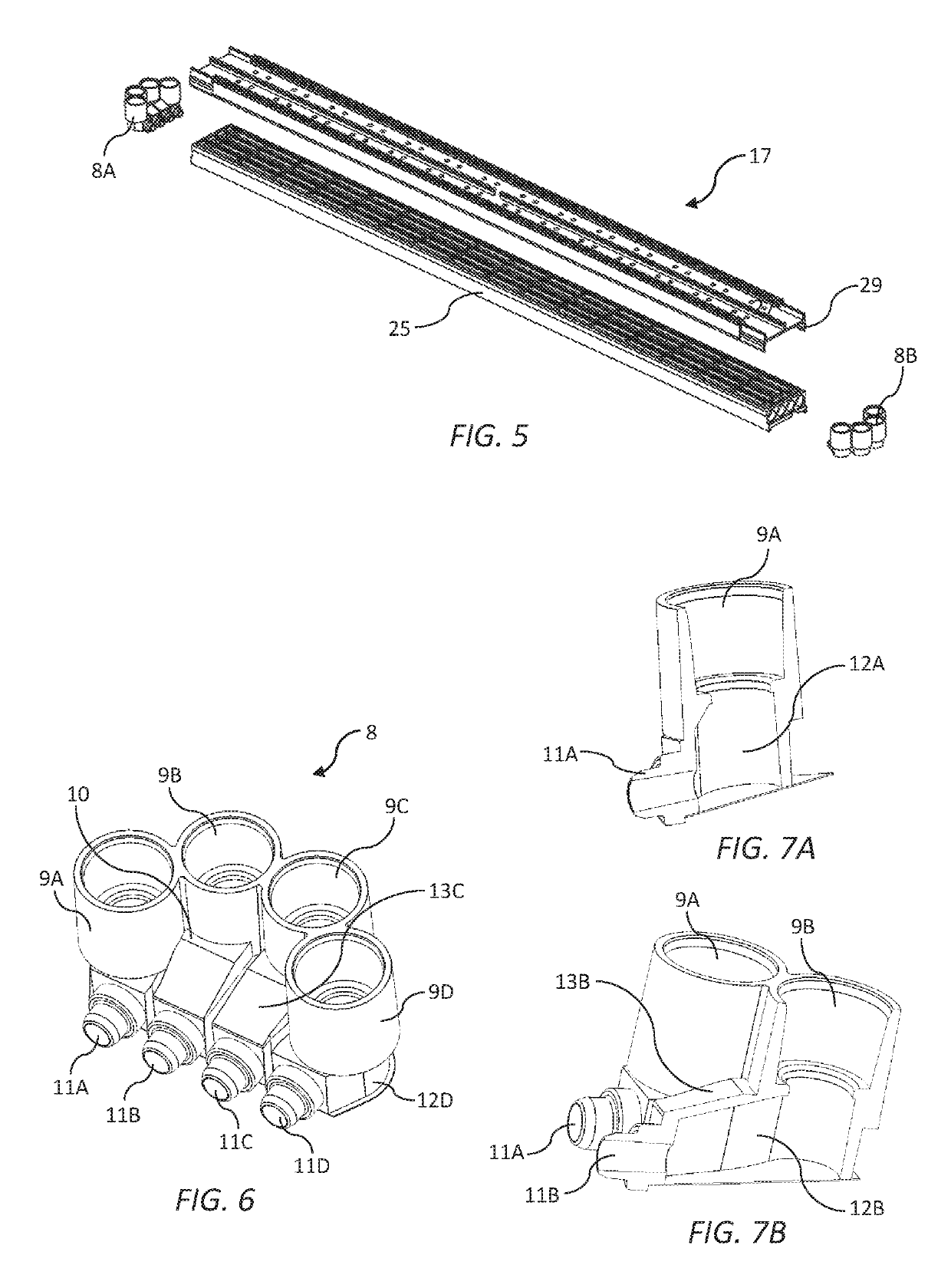

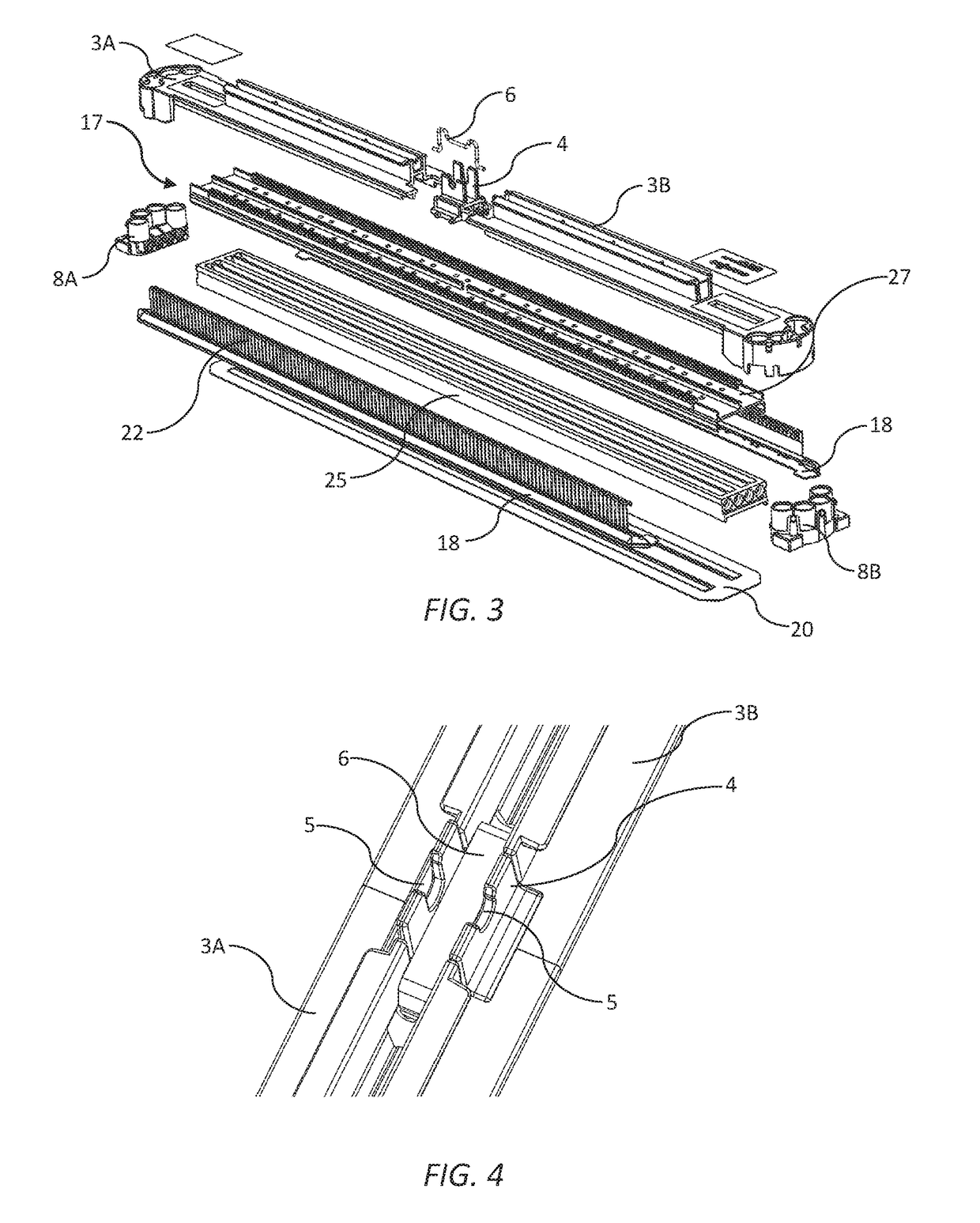

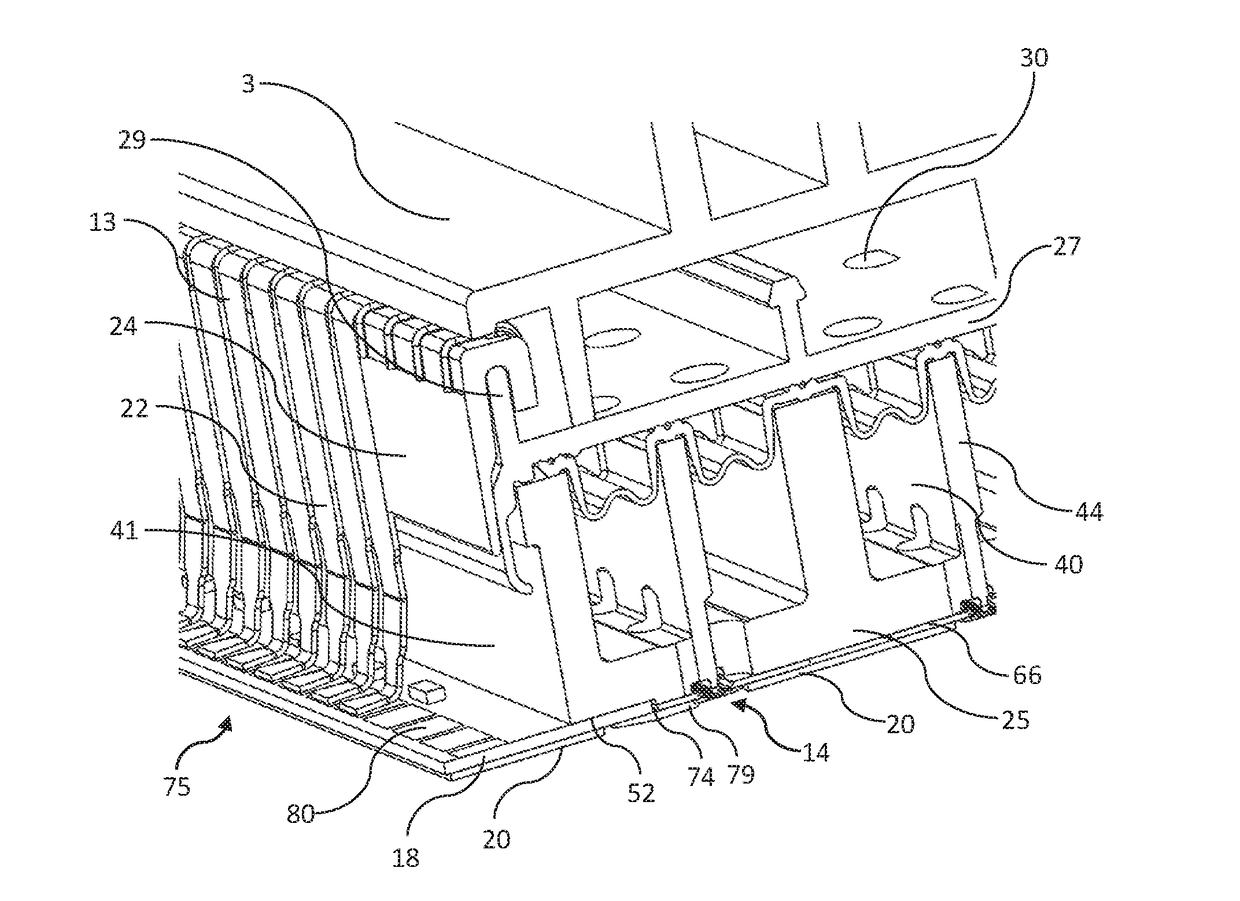

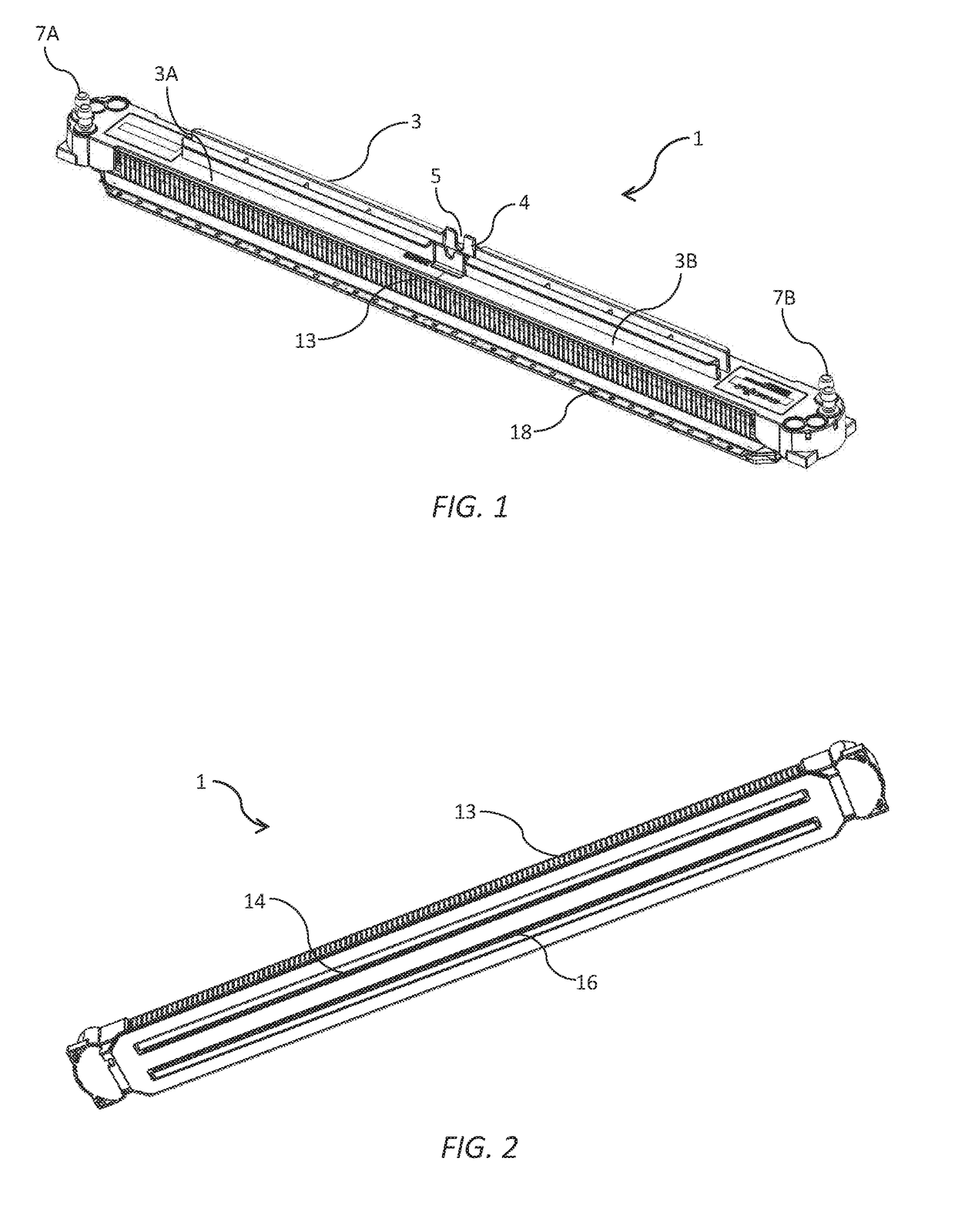

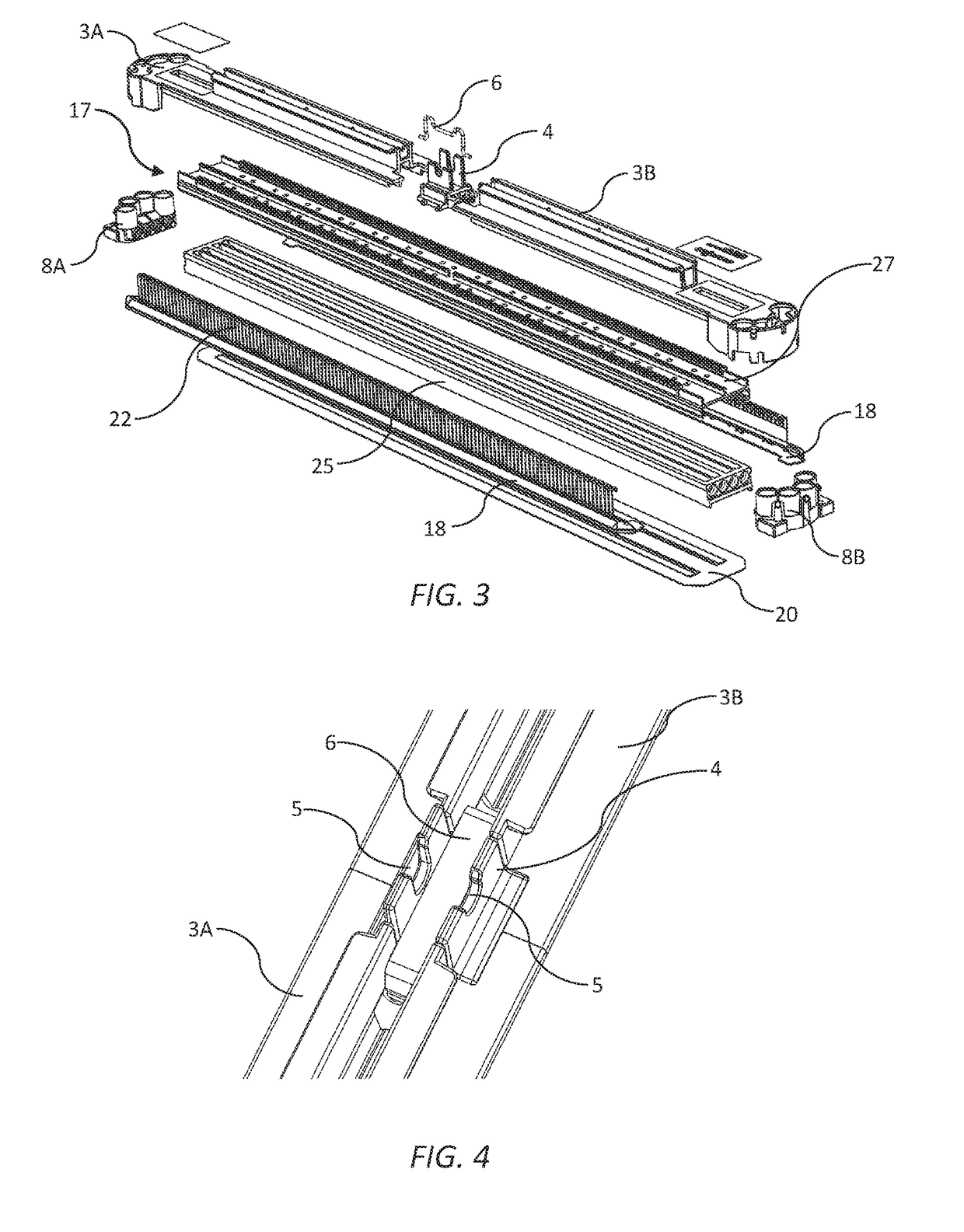

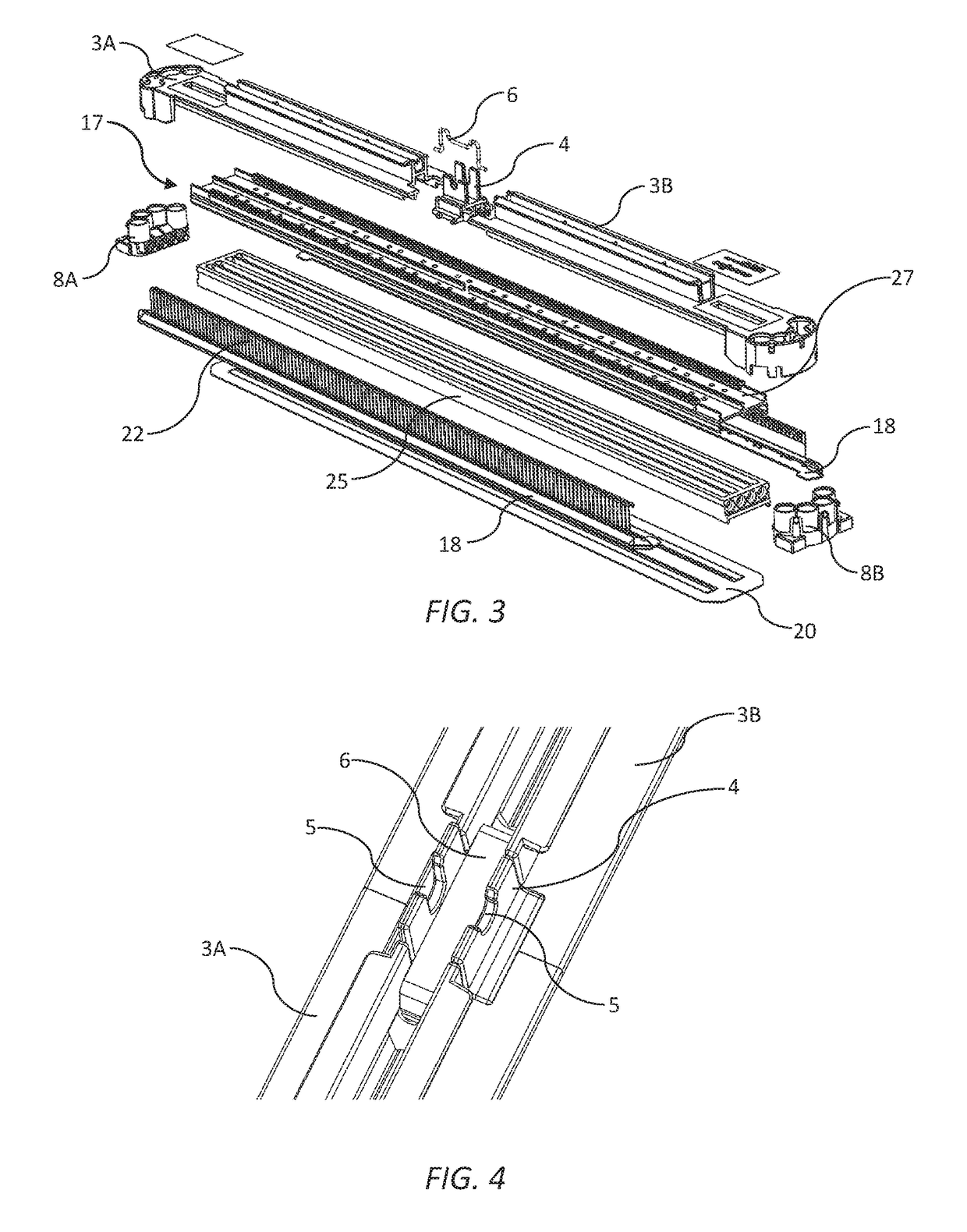

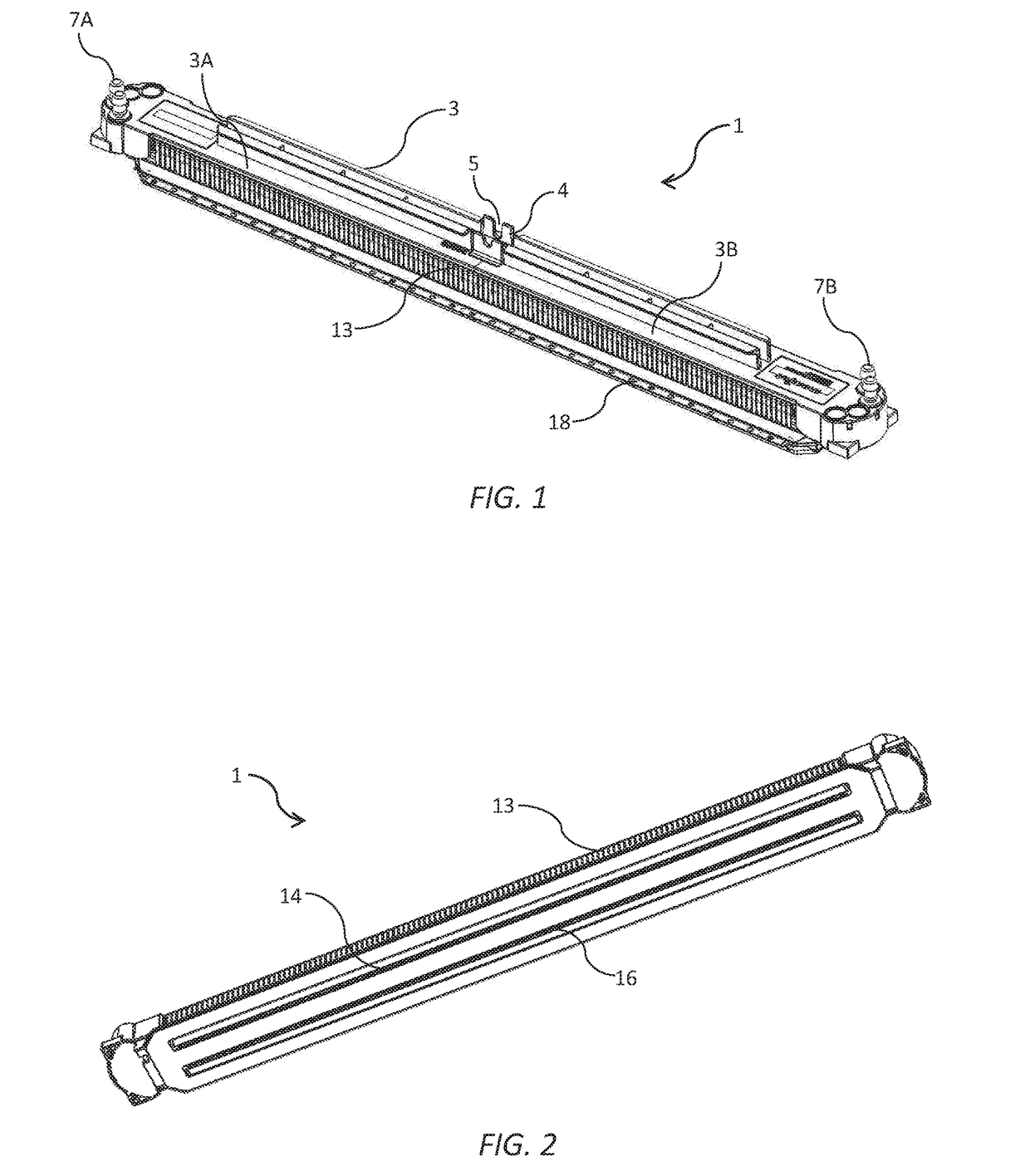

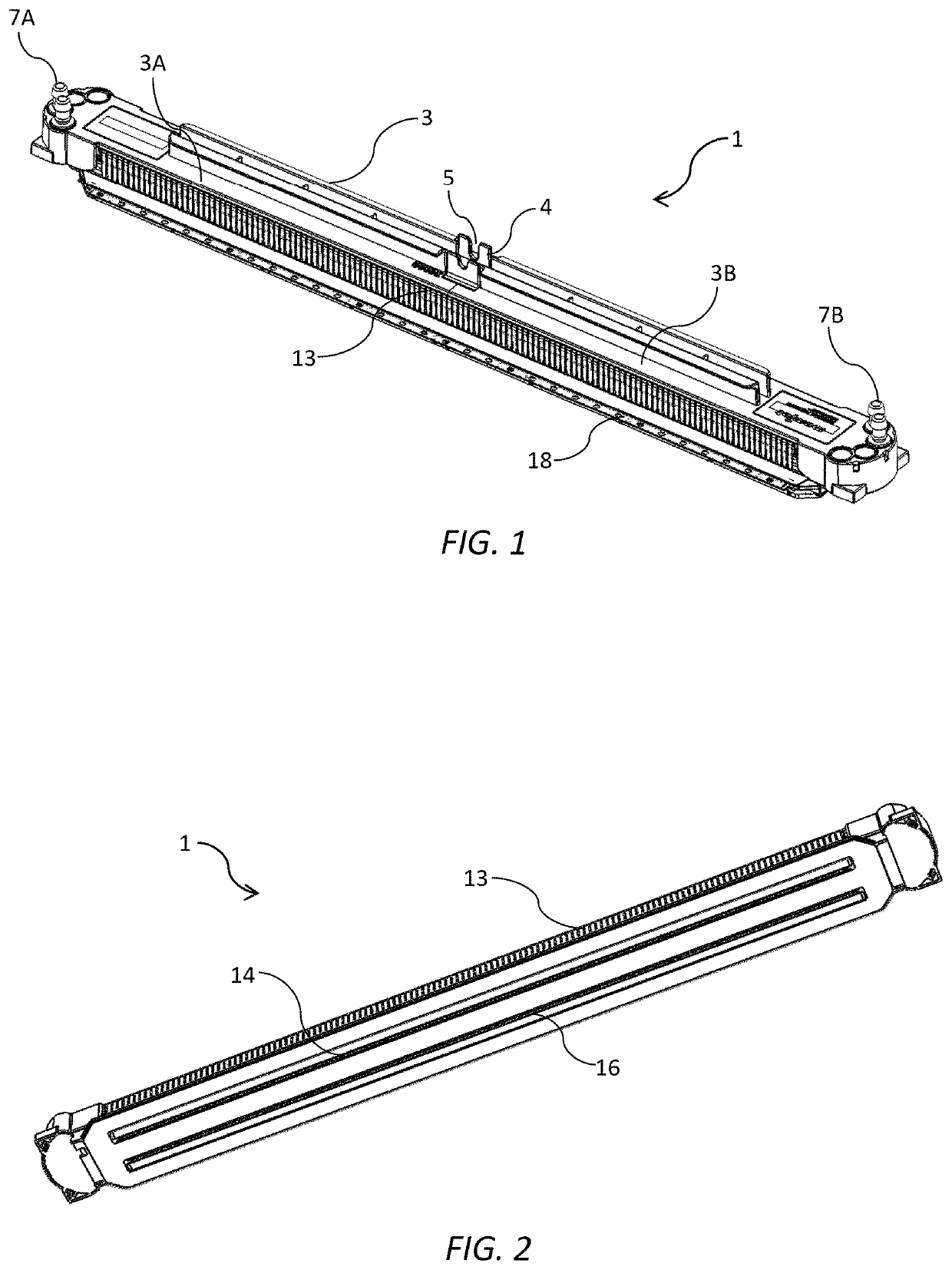

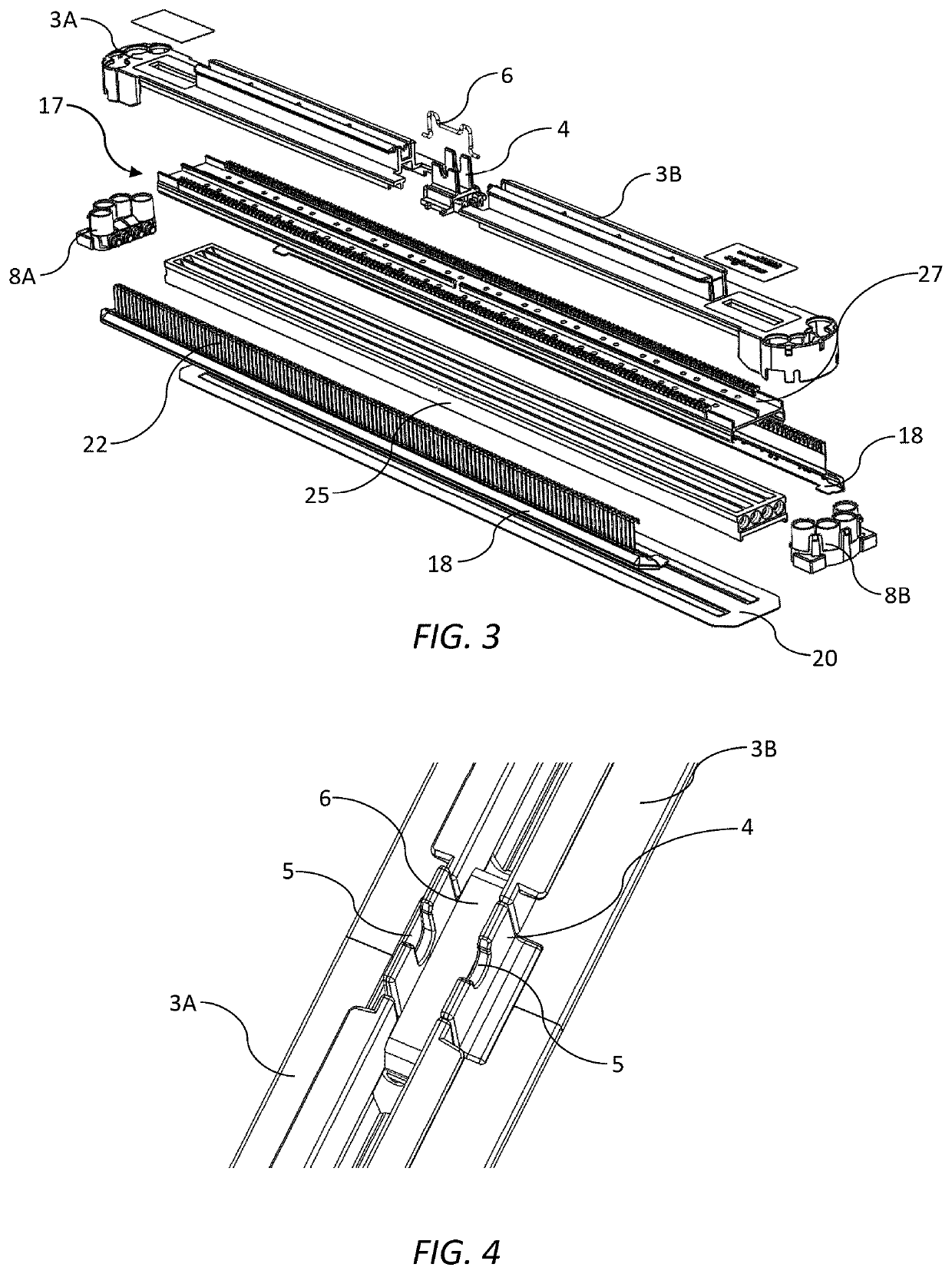

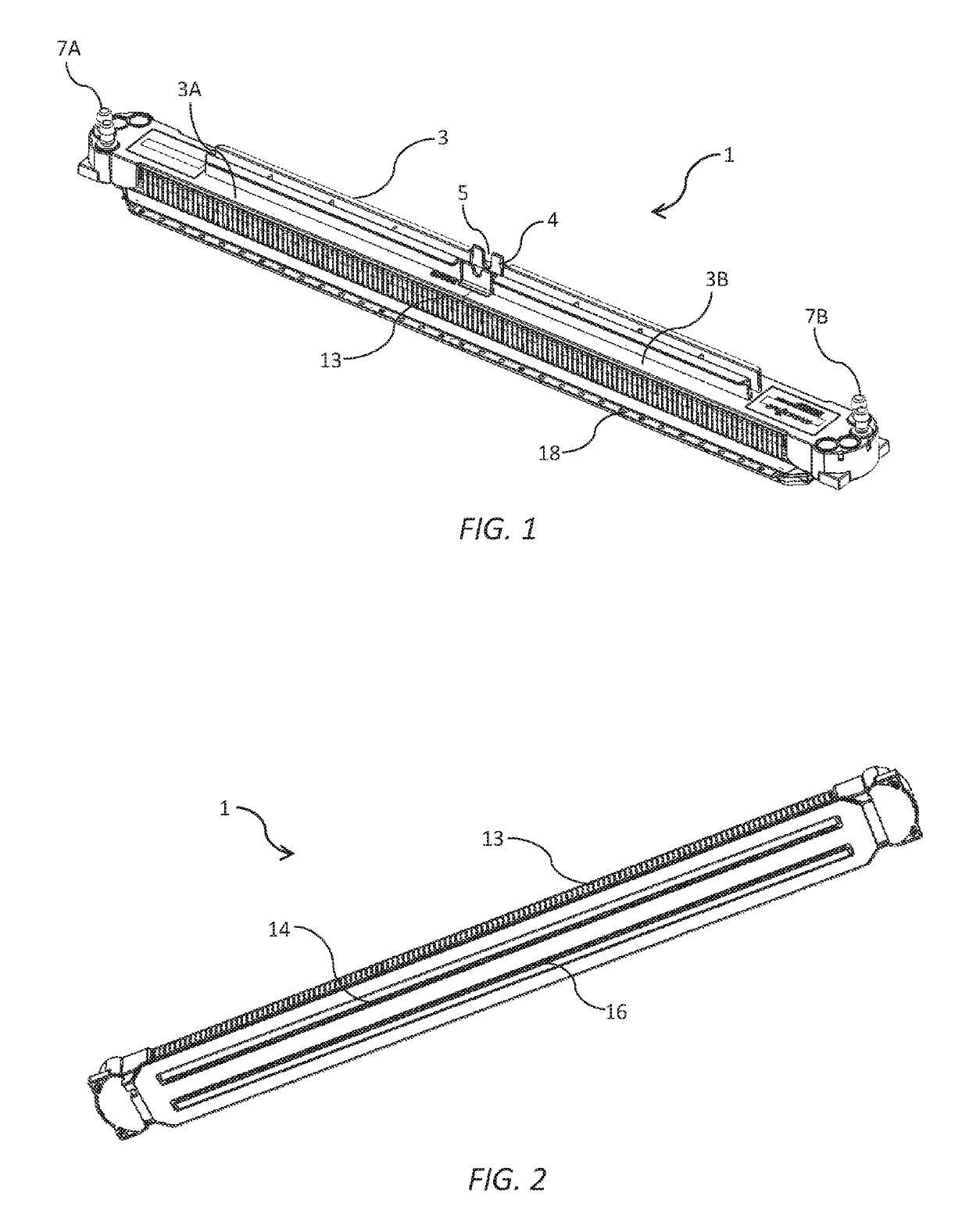

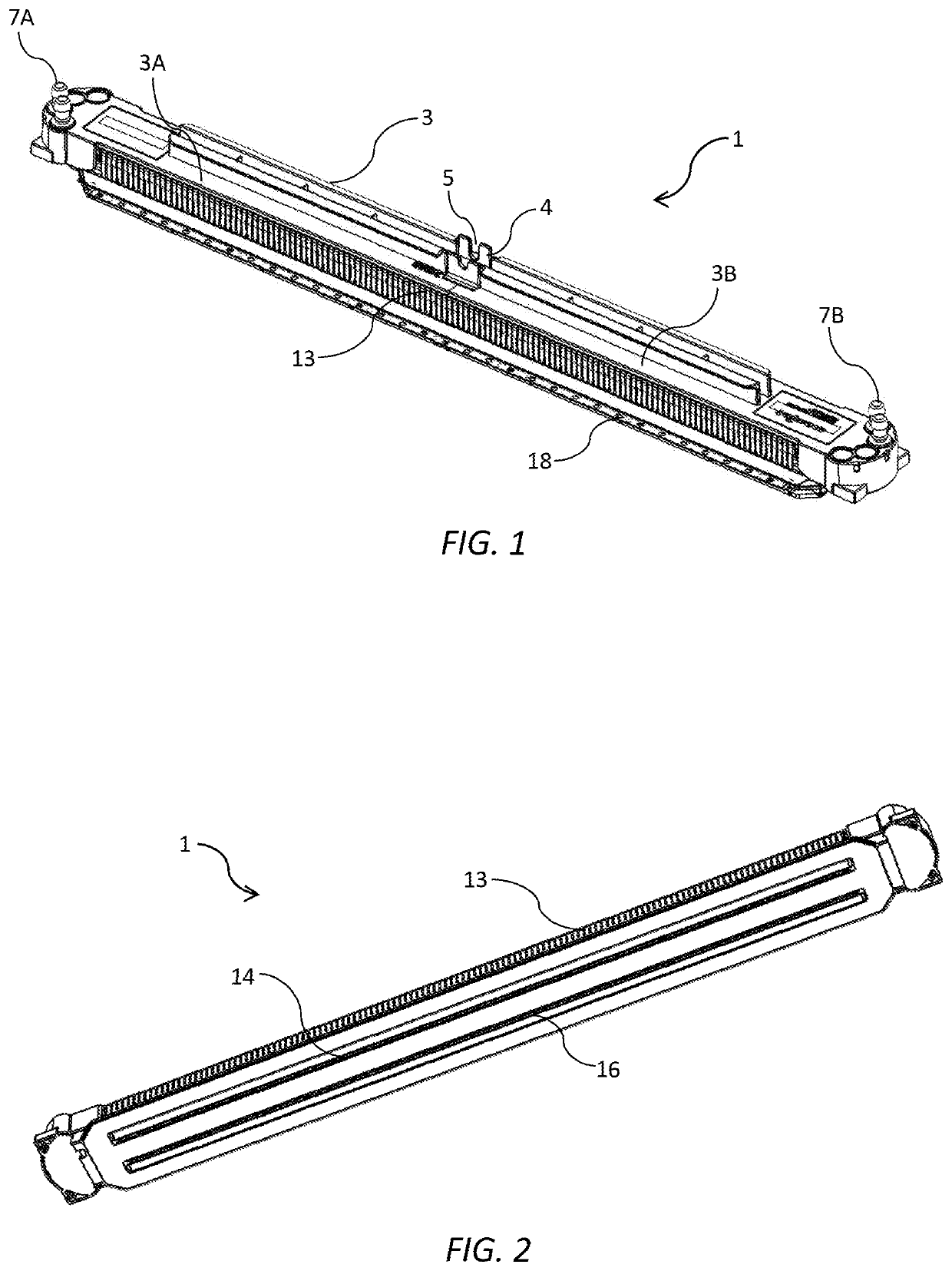

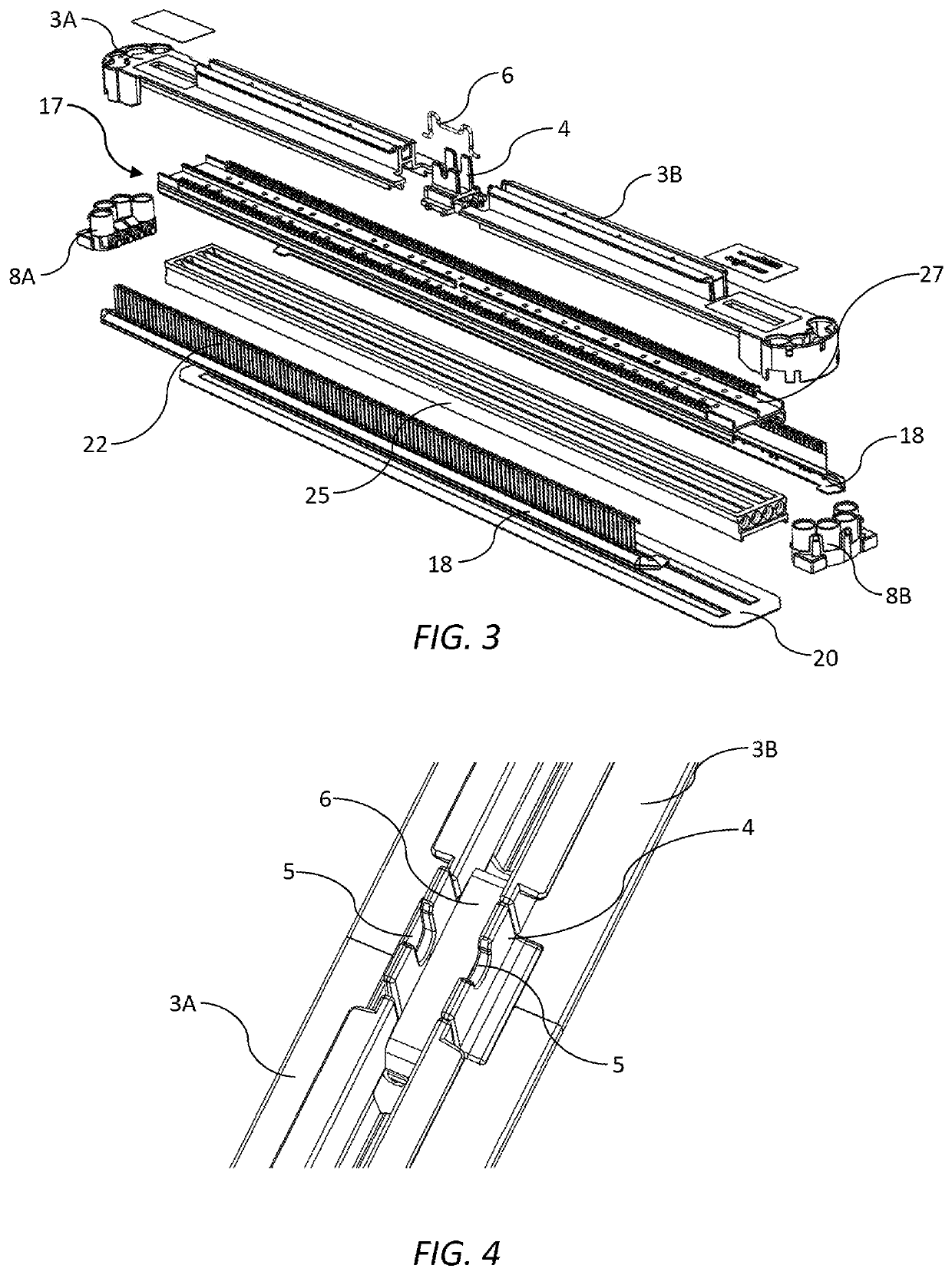

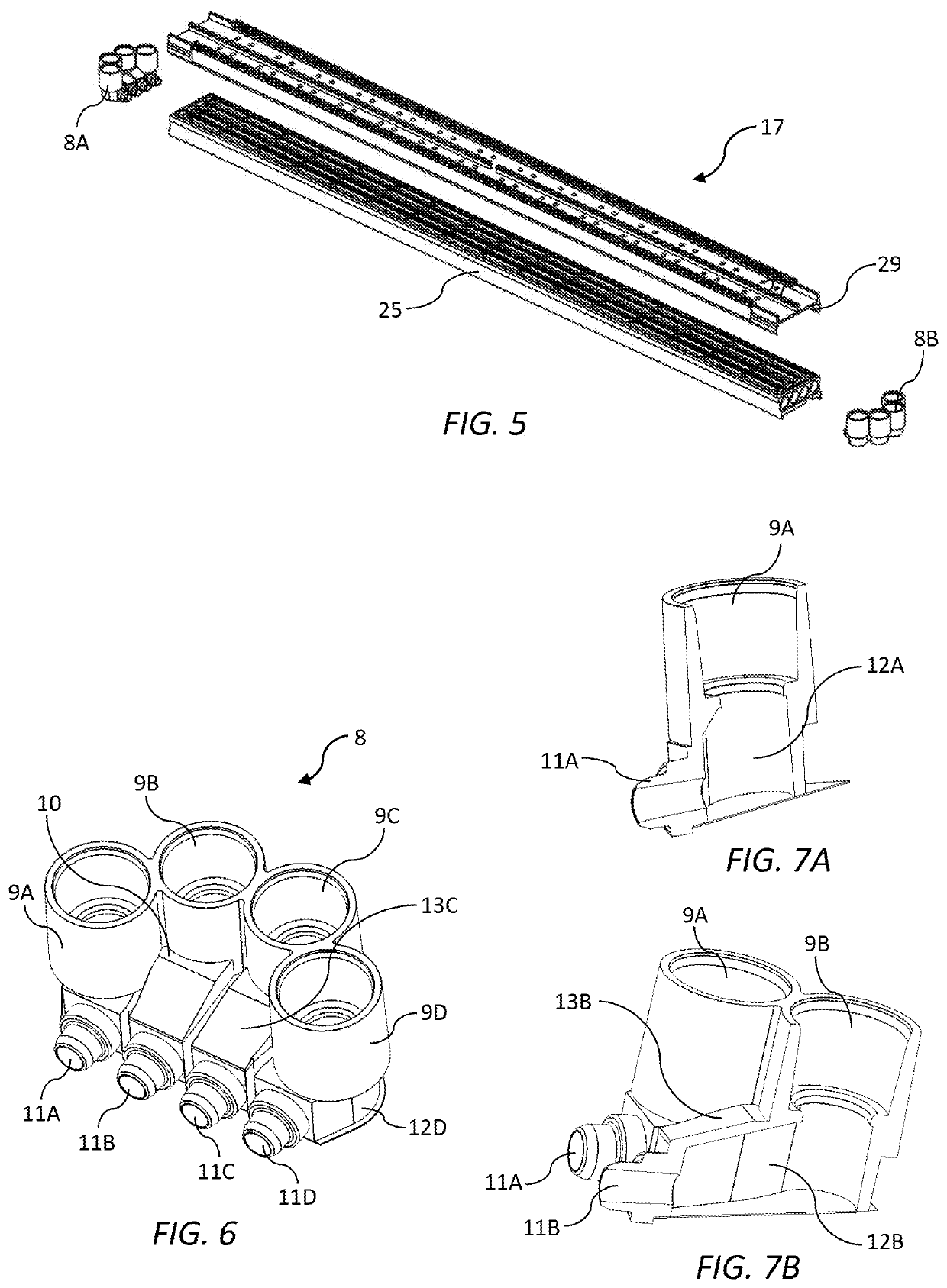

Inkjet printhead for full color pagewide printing

ActiveUS20180222198A1Increase distanceMinimize color mixingInking apparatusPower drive mechanismsEngineeringMechanical engineering

Owner:MEMJET TECH LTD

Method of fabricating suspended beam in a MEMS process

InactiveUS7303930B2Prevent backflowMinimize color mixingInking apparatusSemiconductor/solid-state device manufacturingEngineeringSubstrate surface

A method of fabricating a suspended beam in a MEMS process, said method comprising the steps of:(a) etching a pit in a substrate, said pit having a base and sidewalls;(b) depositing sacrificial material on a surface of said substrate so as to fill said pit;(c) removing said sacrificial material from a perimeter region within said pit and from said substrate surface surrounding said pit;(d) reflowing remaining sacrificial material within said pit such that said remaining sacrificial material contacts said sidewalls;(e) depositing beam material on said substrate surface and on said reflowed sacrificial material; and(f) removing said reflowed sacrificial material to form said suspended beam.

Owner:MEMJET TECH LTD

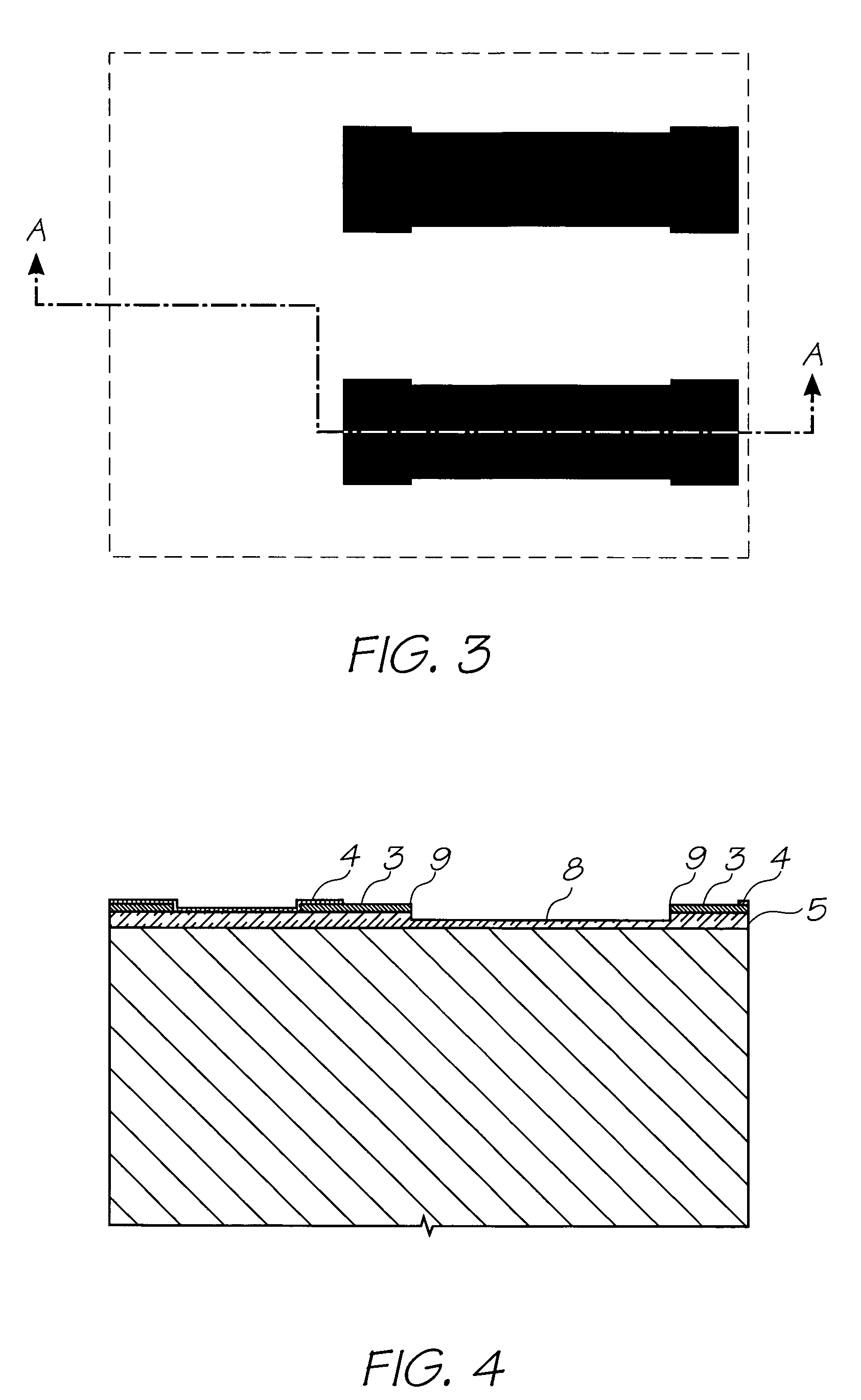

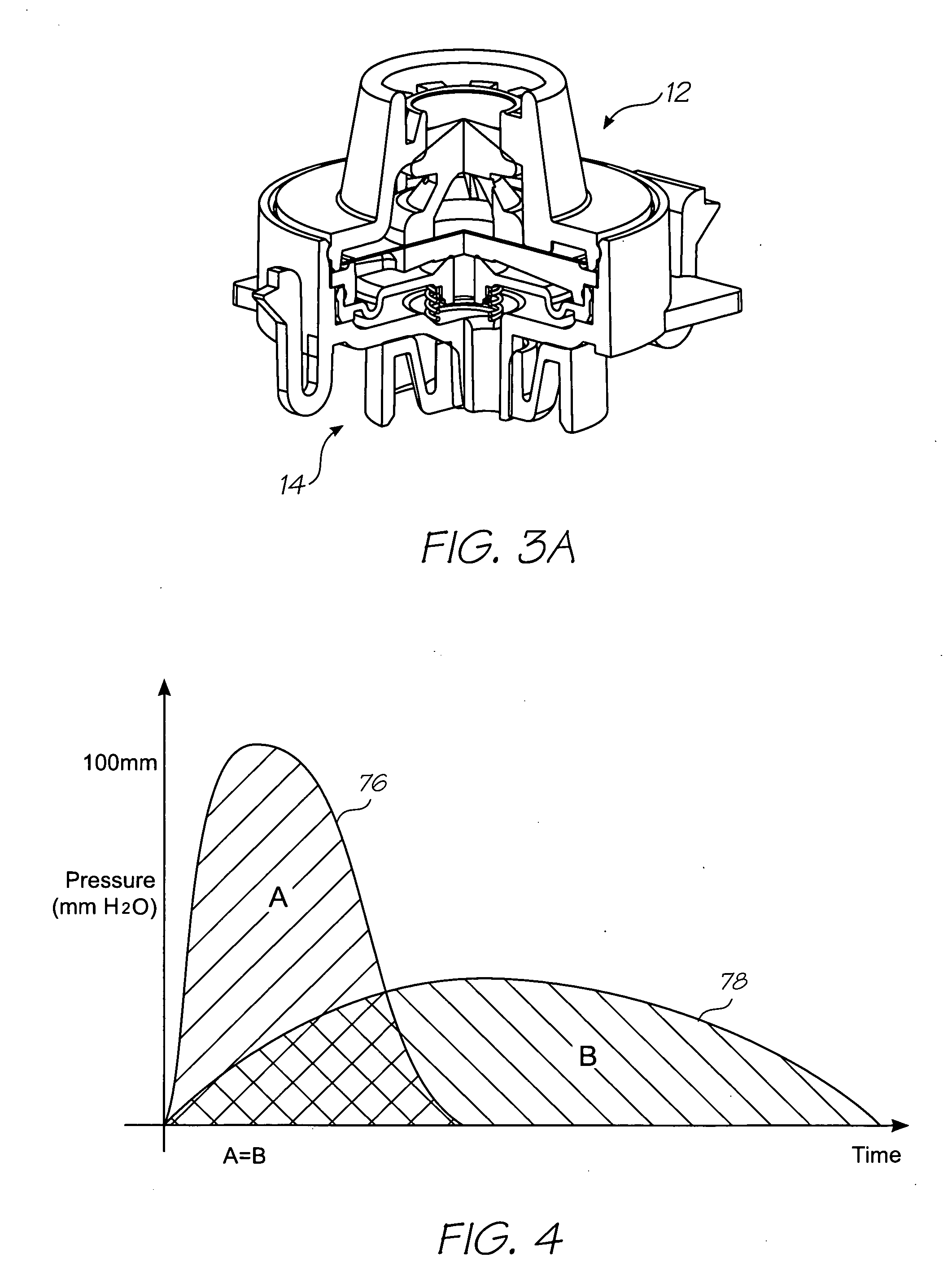

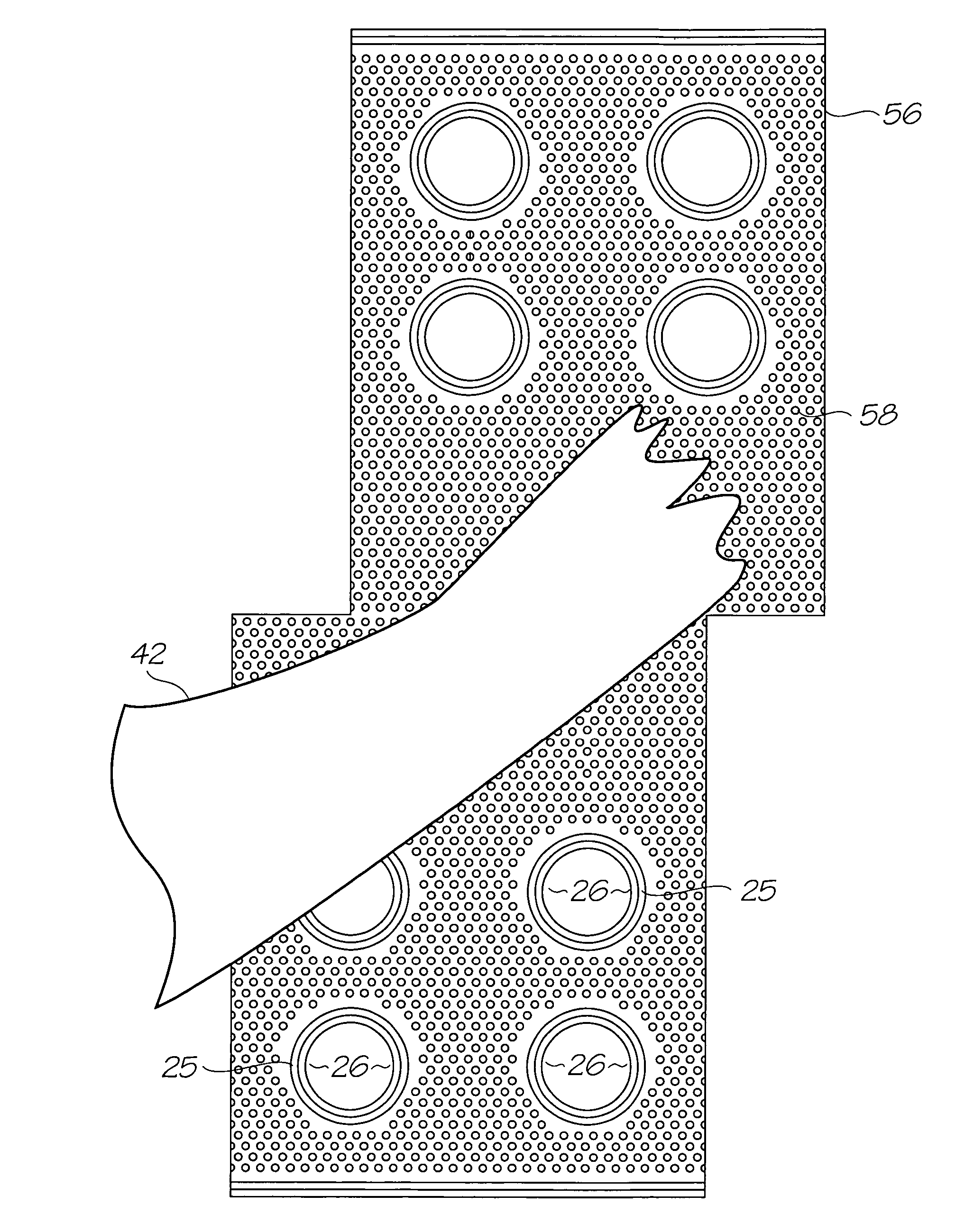

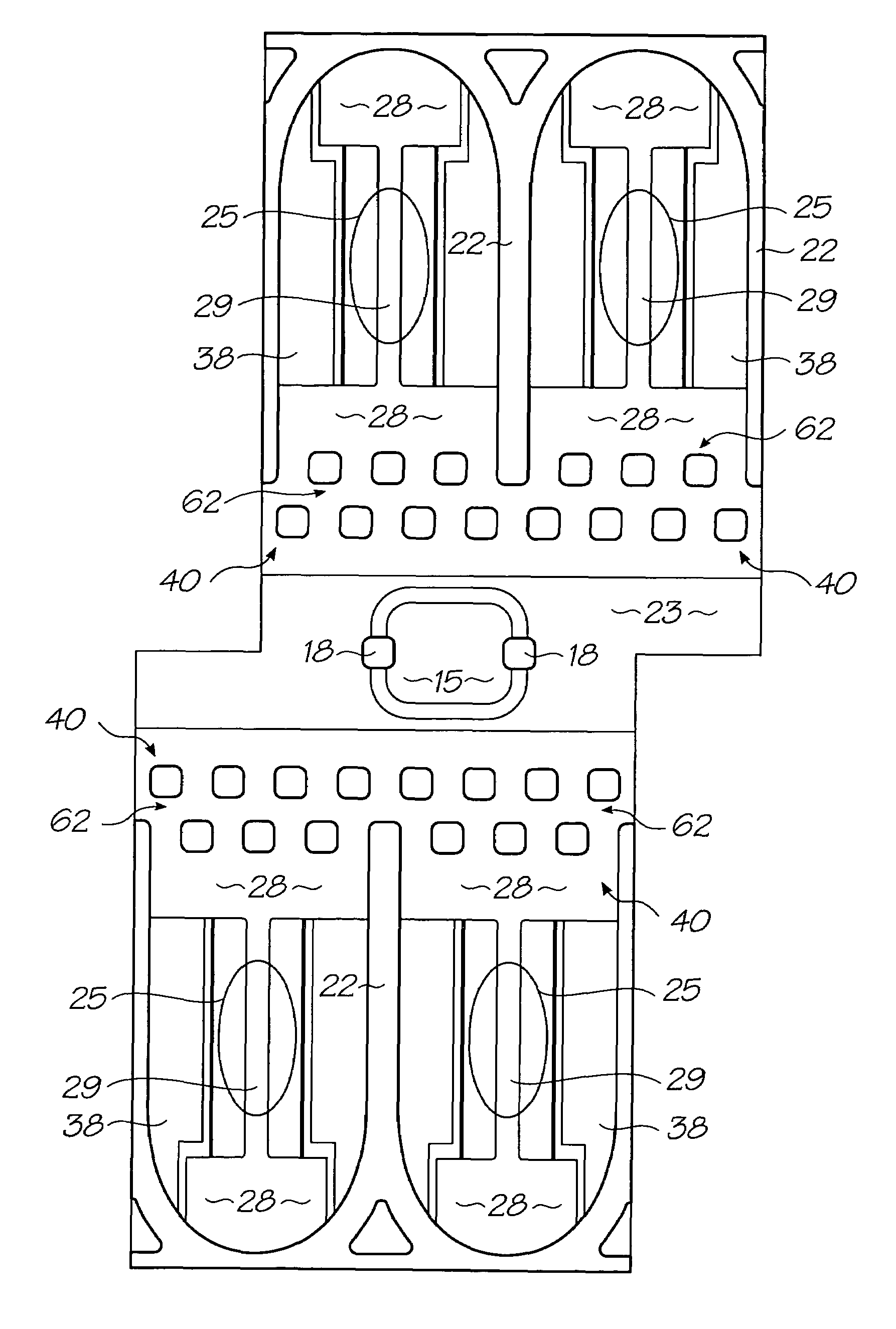

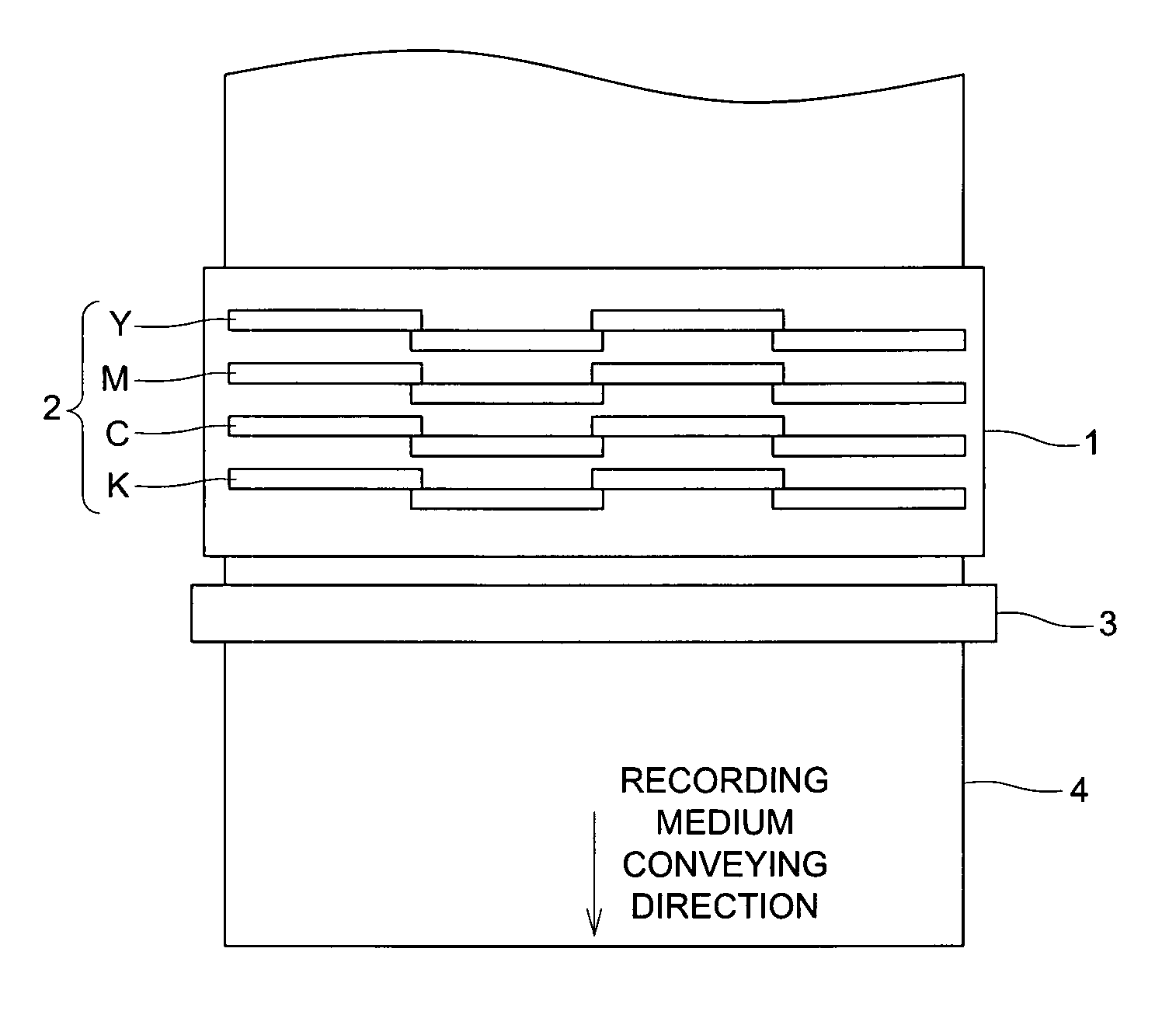

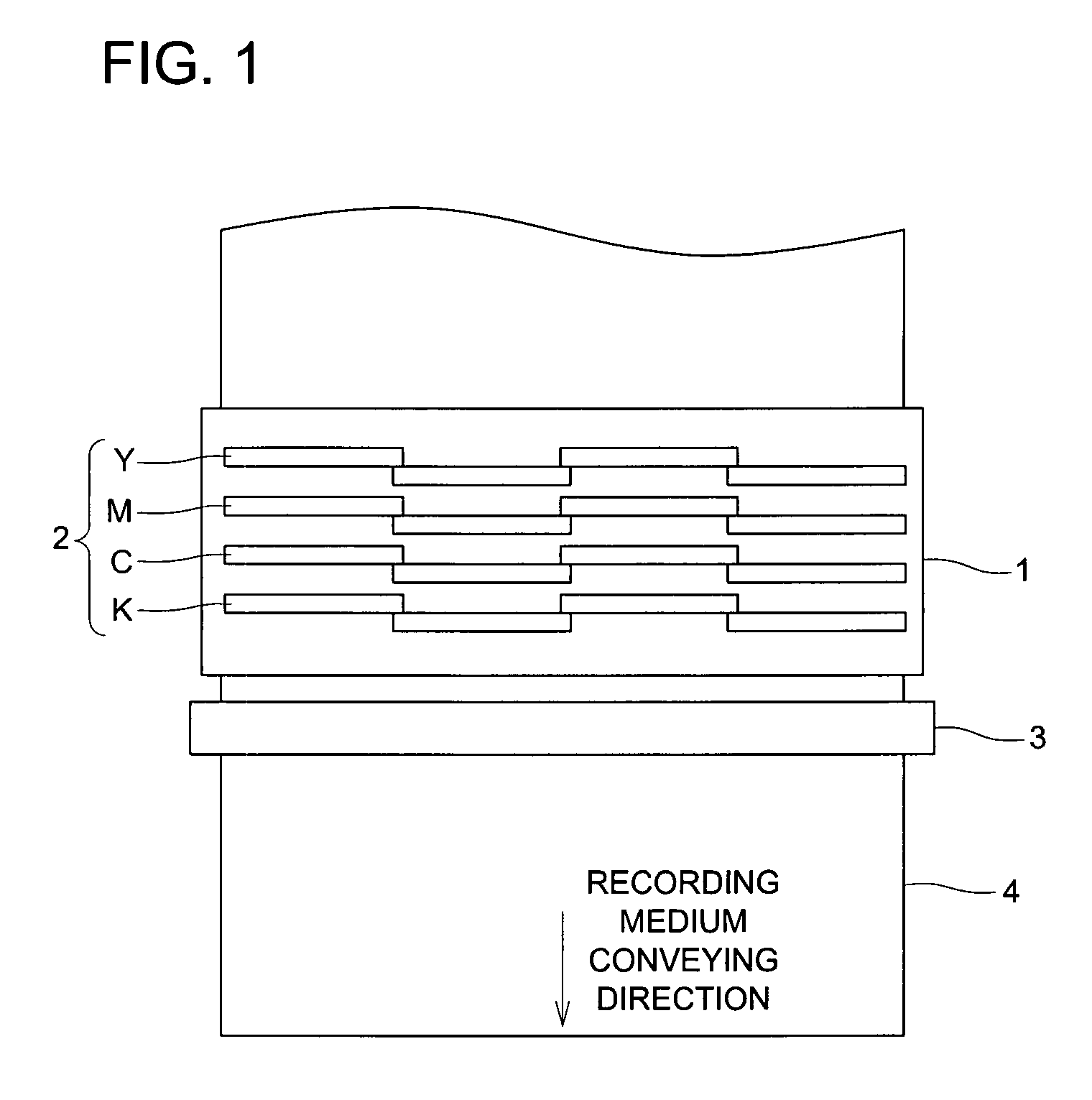

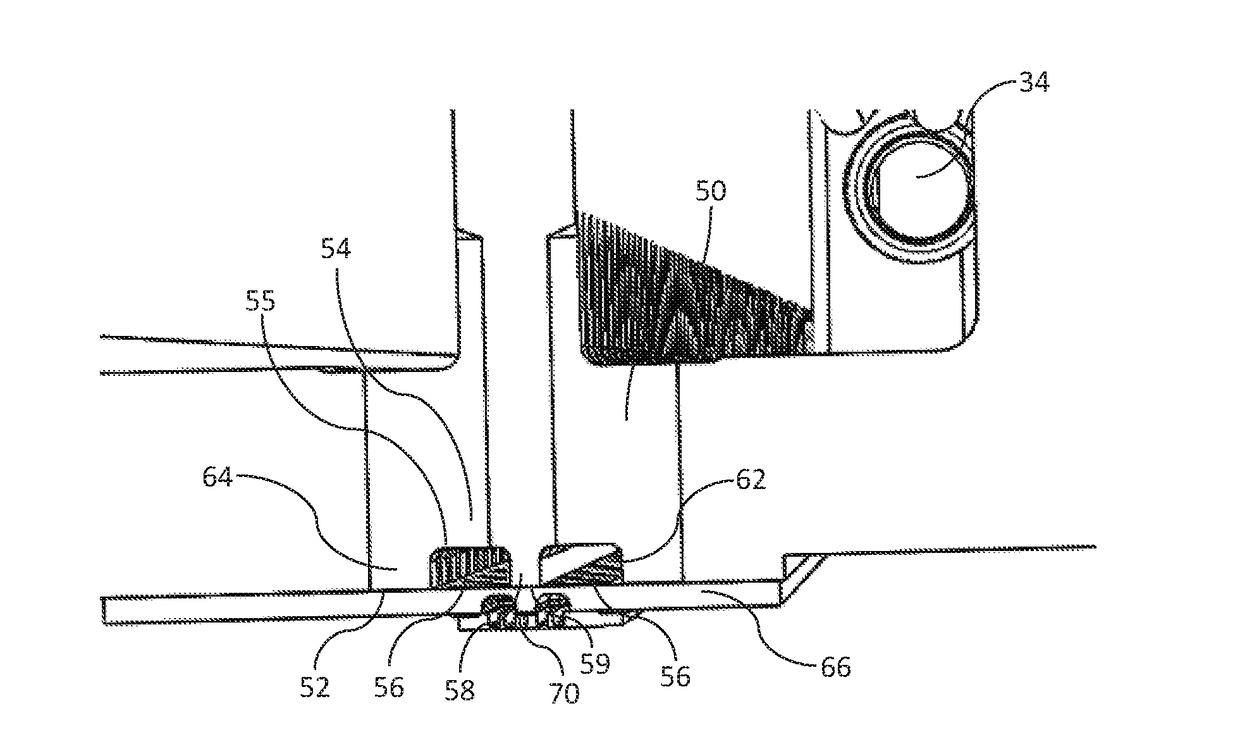

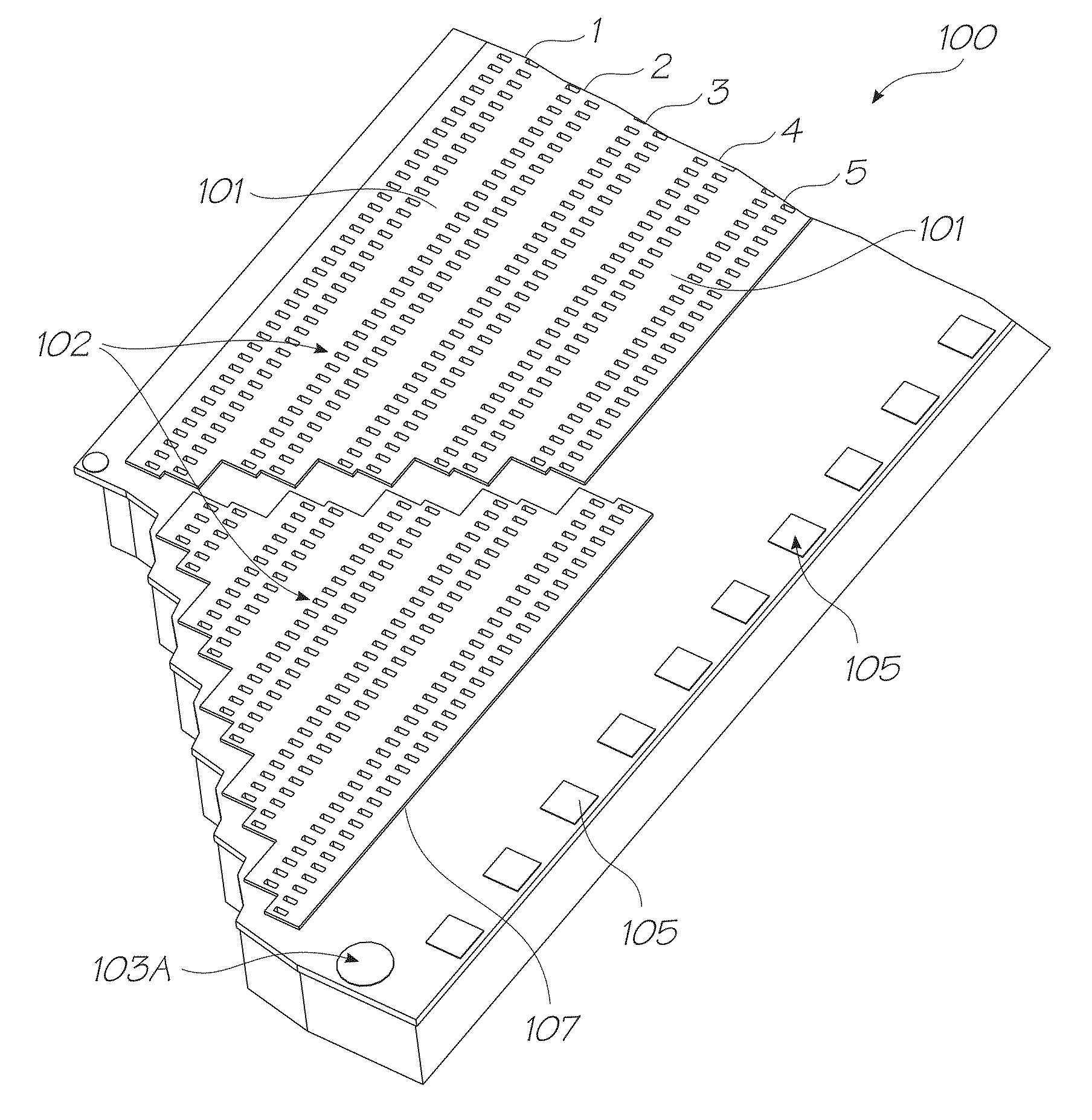

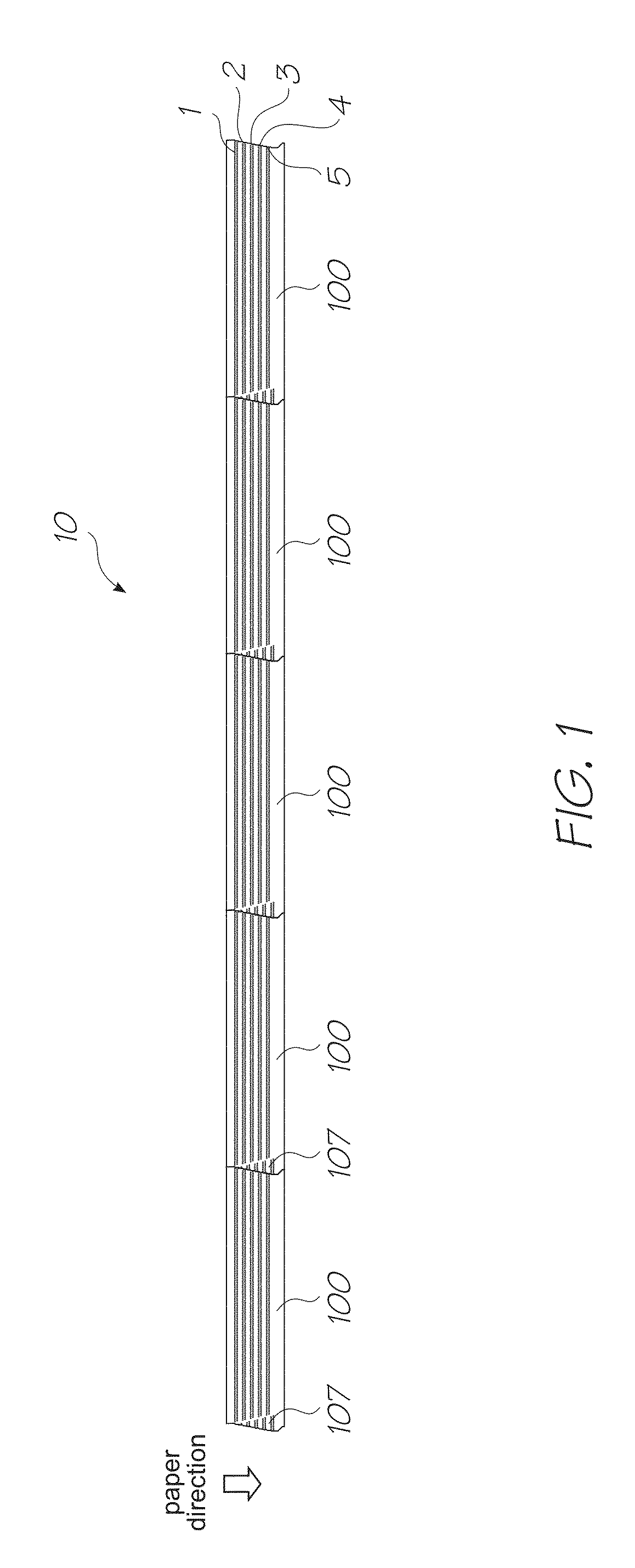

Printer for minimizing adverse mixing of high and low luminance inks at nozzle face of inkjet printhead

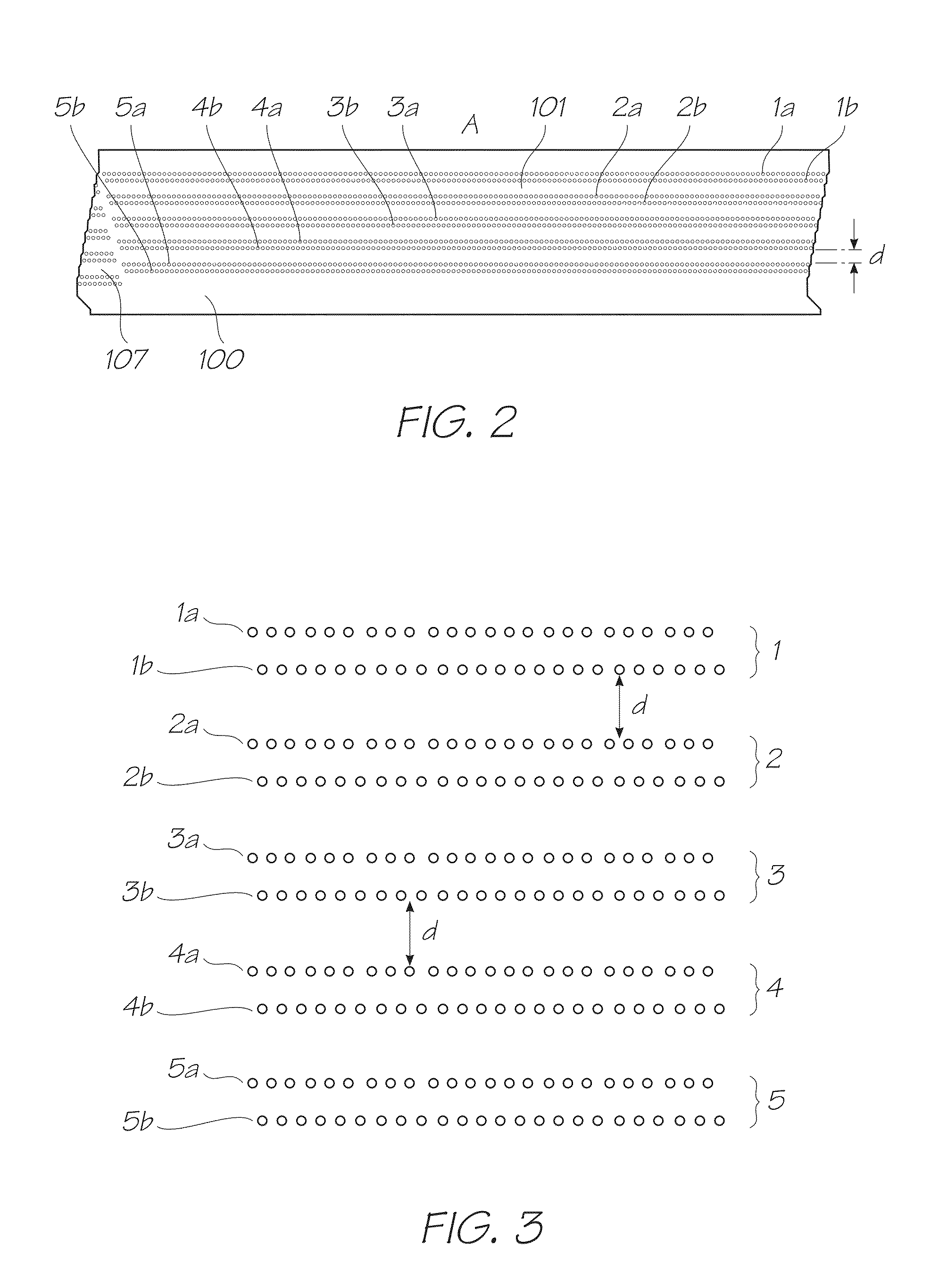

ActiveUS20130070024A1Suitable for useMinimizing adverse color mixingInking apparatusInksEngineeringColor plane

An inkjet printer includes an inkjet printhead having a plurality of color planes for ejecting a plurality of different inks. Each color plane has a nozzle row defined in a nozzle face of the printhead and each nozzle in a respective color plane is supplied with a same ink. The printhead is plumbed such that a first color plane ejecting a first ink having a relatively low luminance is sandwiched between second and third color planes ejecting respective second and third inks having a relatively high luminance A plurality of ink reservoirs are in fluid communication with the printhead, the ink reservoirs containing the first, second and third inks. An amount of surfactant in the first ink is at least 0.4 wt % greater than an amount of surfactant in the second and third inks.

Owner:MEMJET TECH LTD

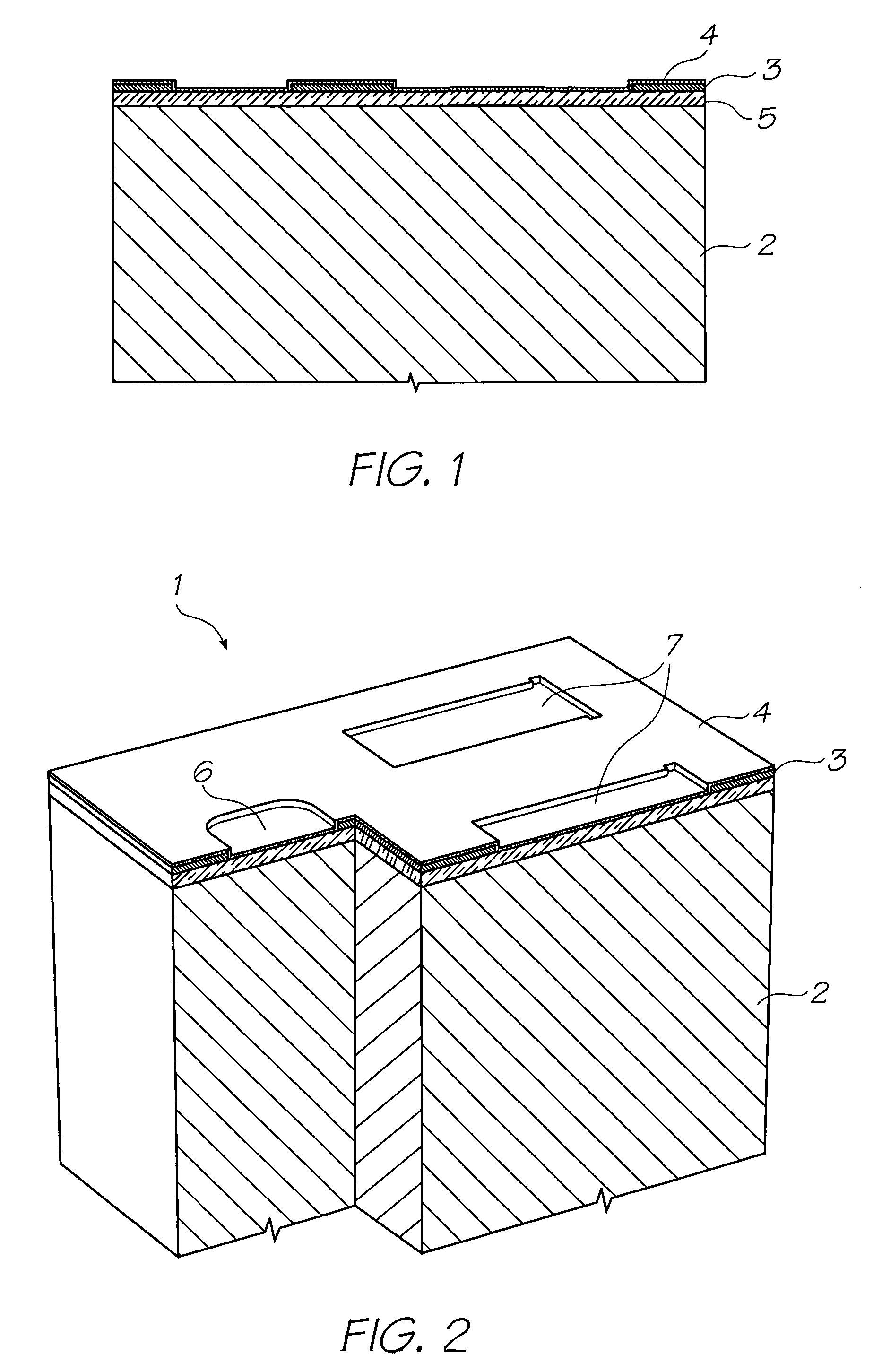

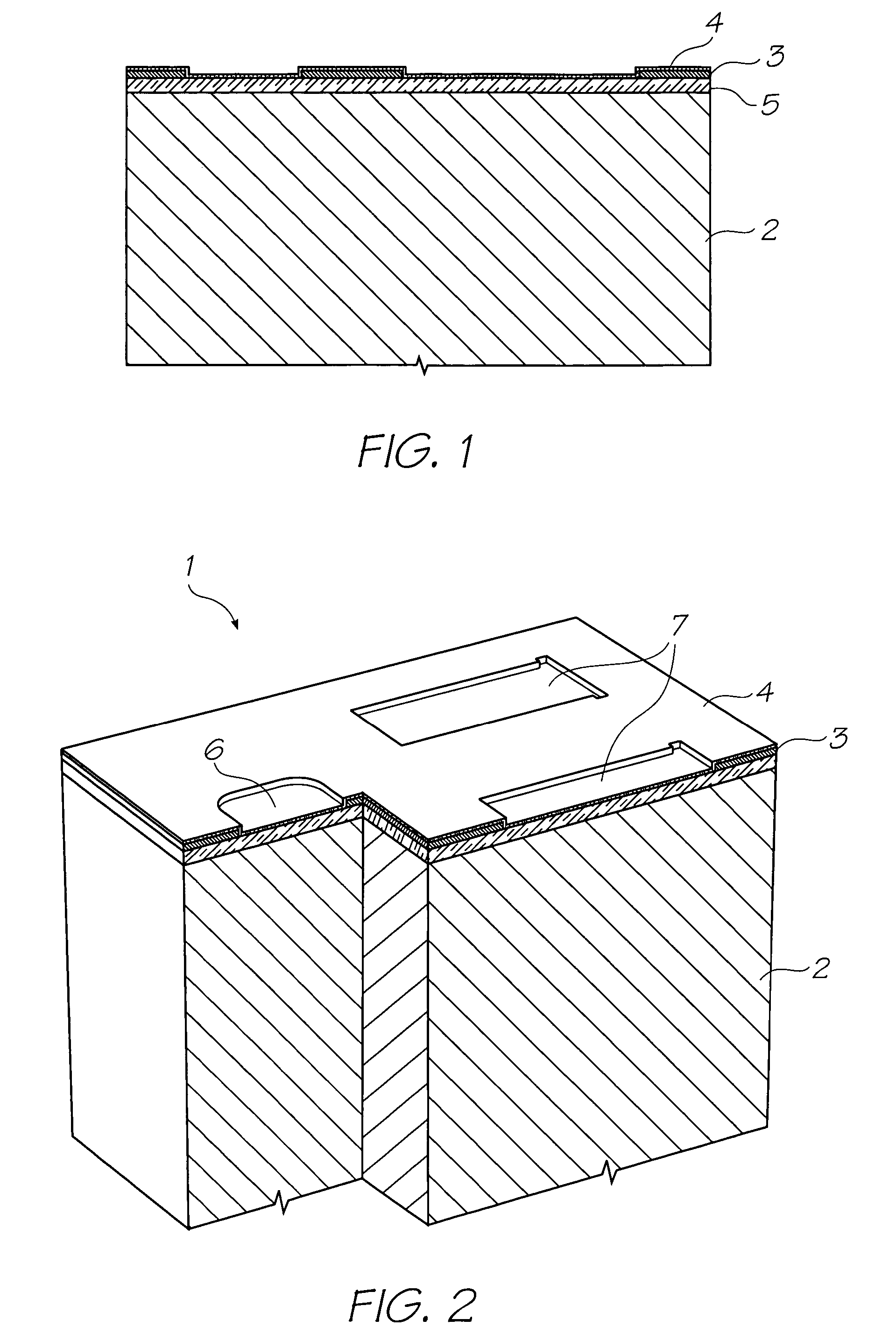

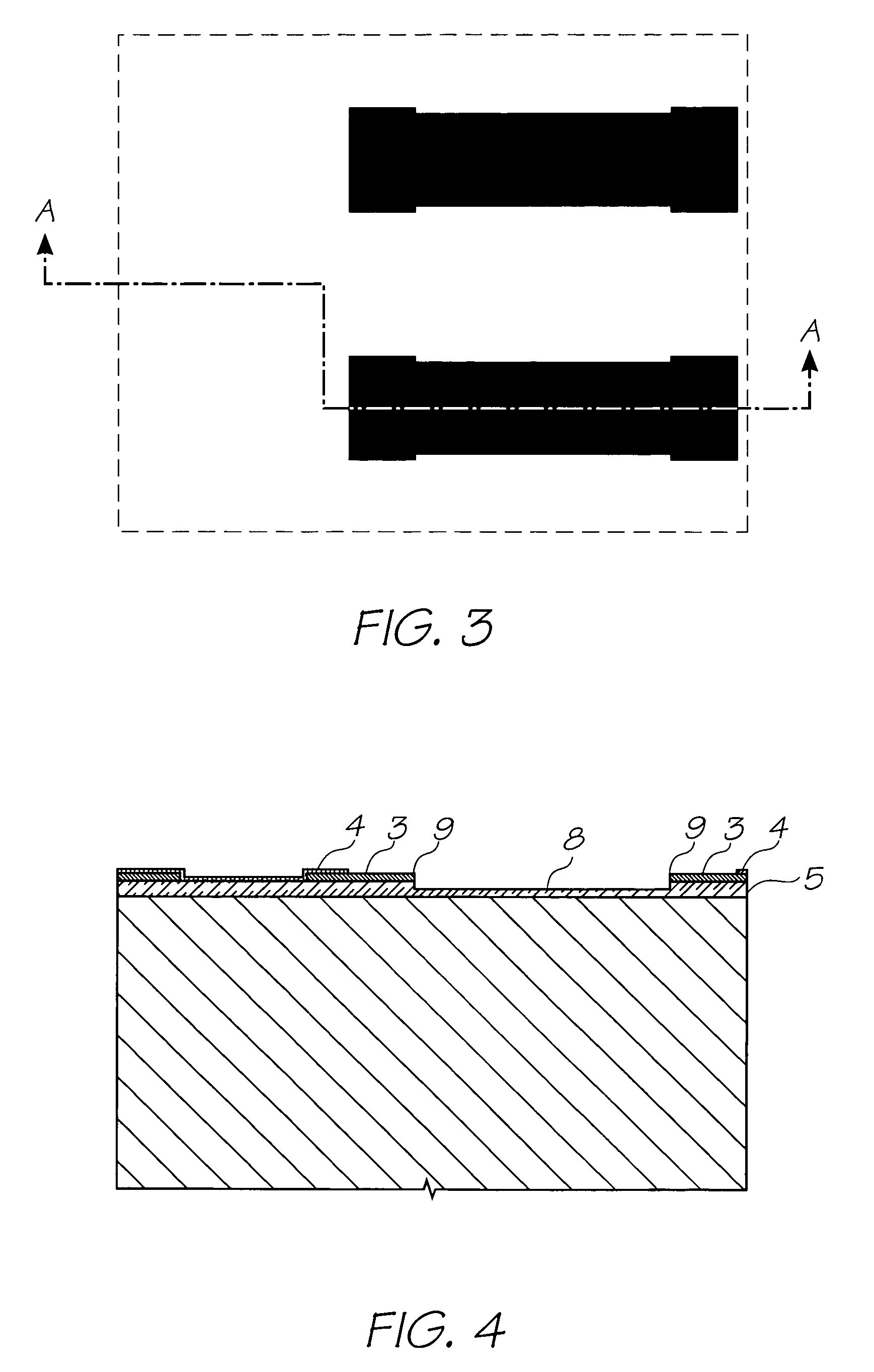

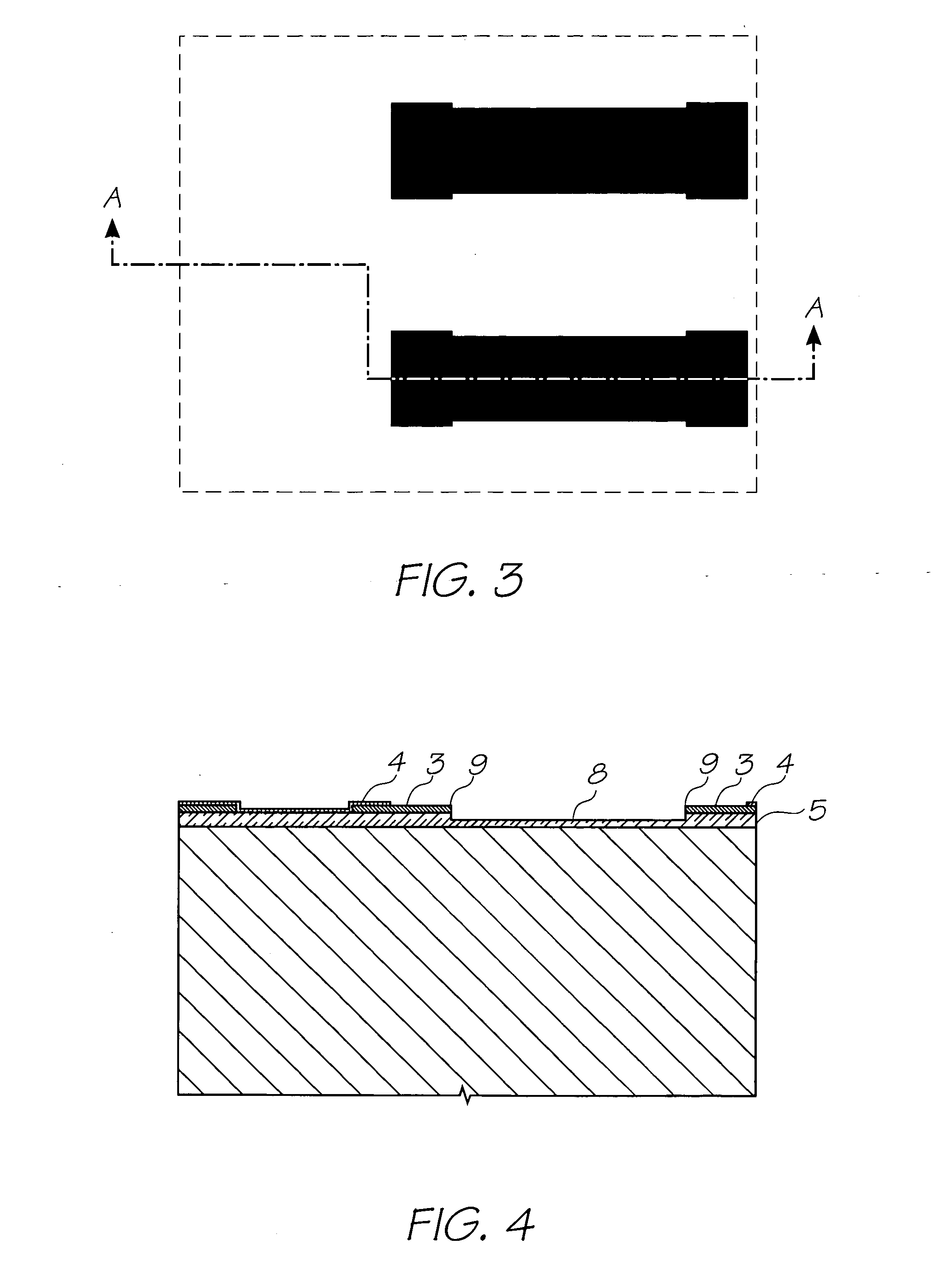

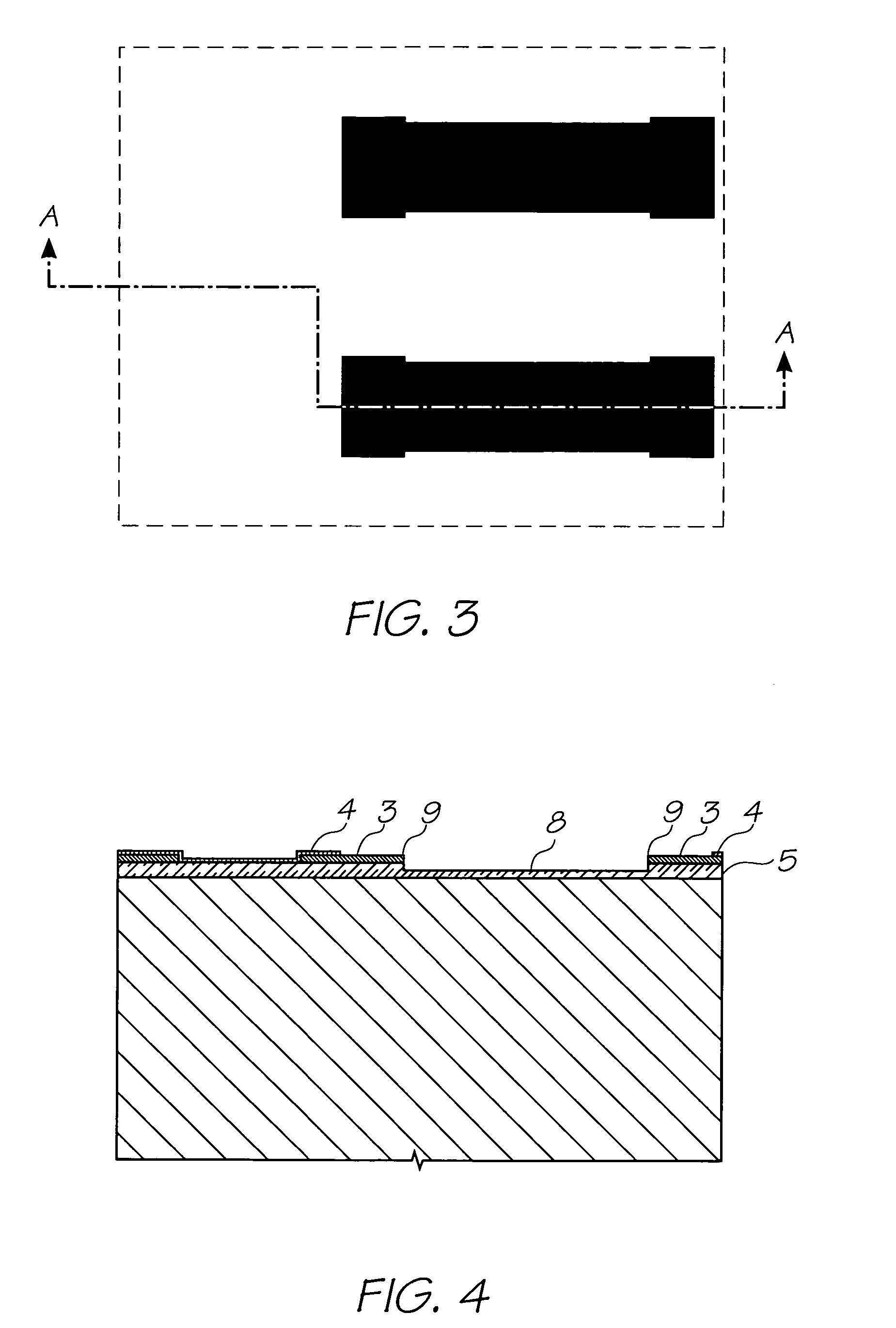

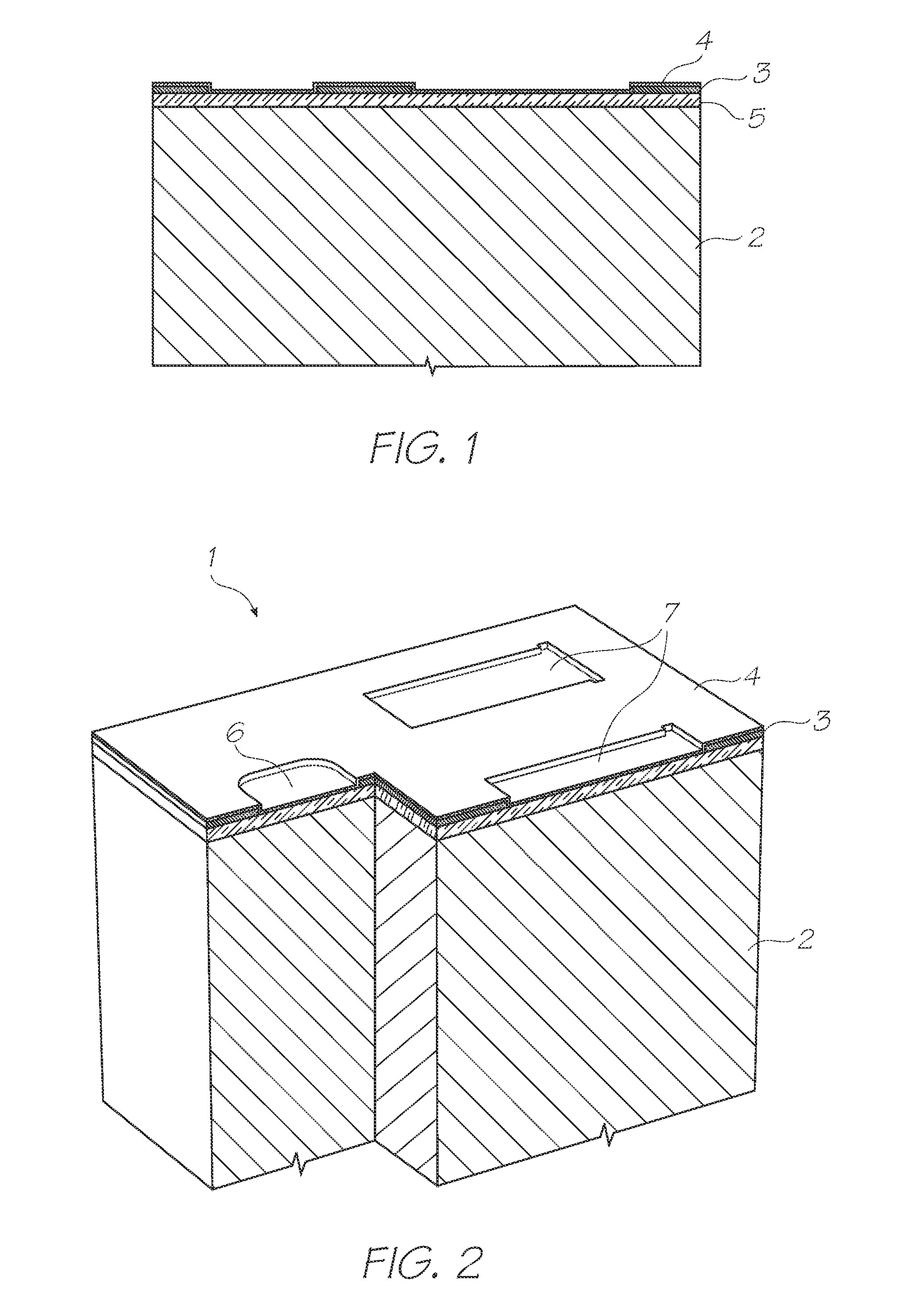

Method of forming low-stiction nozzle plate for an inkjet printhead

InactiveUS7464465B2Prevent backflowMinimize color mixingPrinted circuit assemblingRecording apparatusEngineeringStiction

A method of forming a low-stiction nozzle plate for an inkjet printhead, said nozzle plate having a plurality of nozzle apertures defined therein, each nozzle aperture having a respective nozzle rim, said method comprising the steps of:(a) providing a partially-fabricated printhead comprising a plurality of inkjet nozzle assemblies sealed with roof material;(b) etching partially into said roof material to define simultaneously said nozzle rims and a plurality of stiction-reducing formations; and(c) etching through said roof material to define said nozzle apertures, thereby forming said nozzle plate.

Owner:SILVERBROOK RES PTY LTD +1

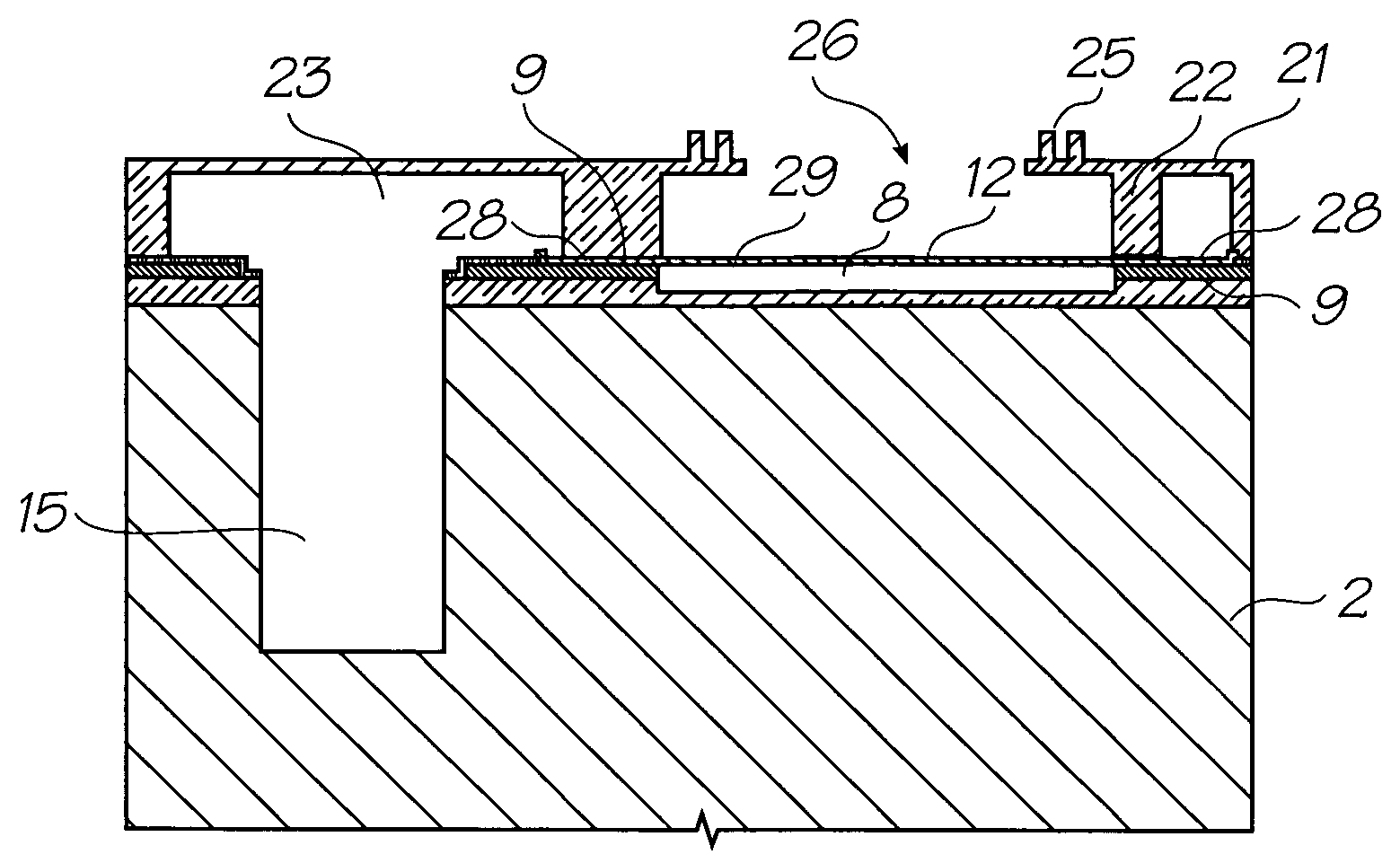

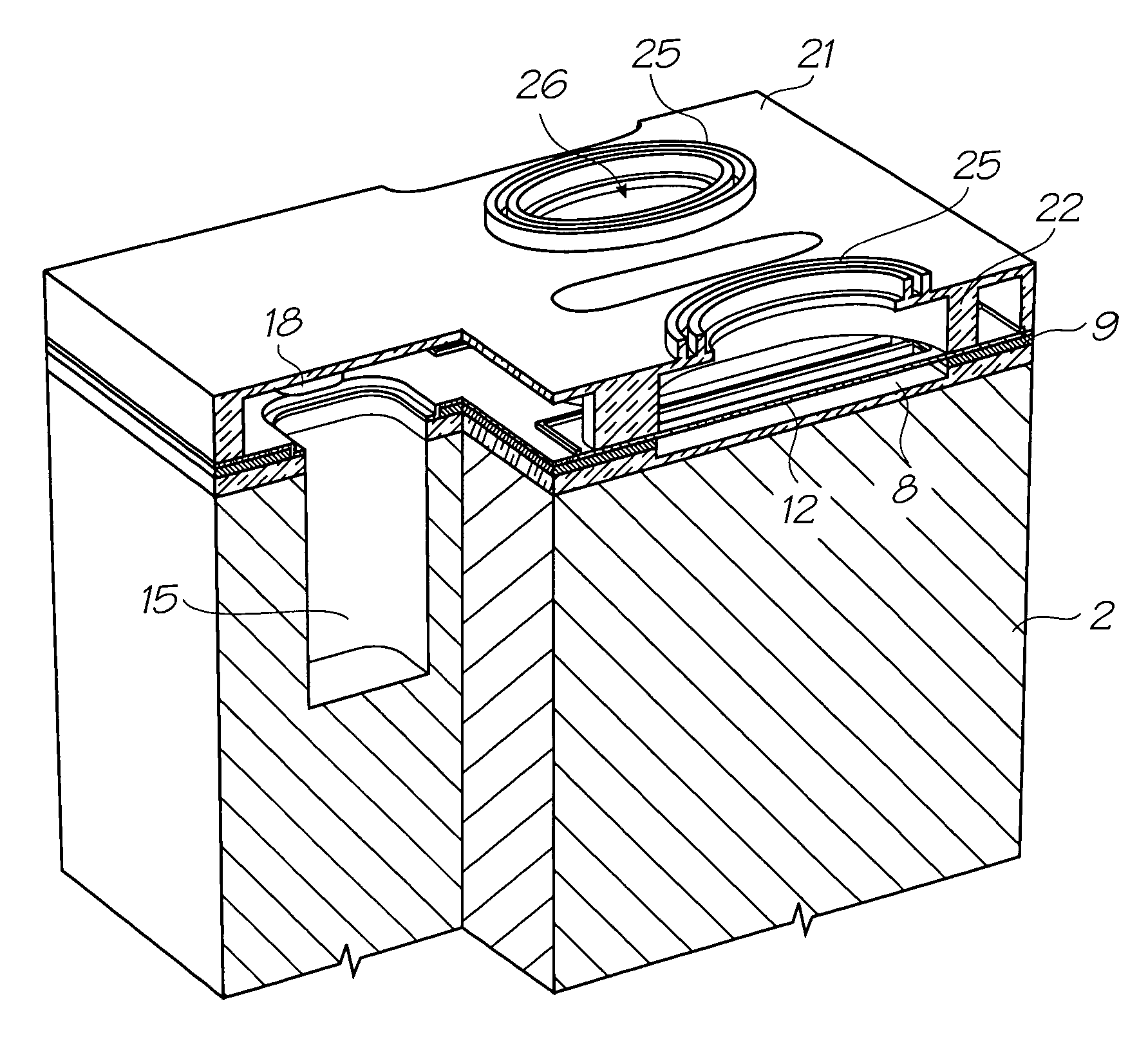

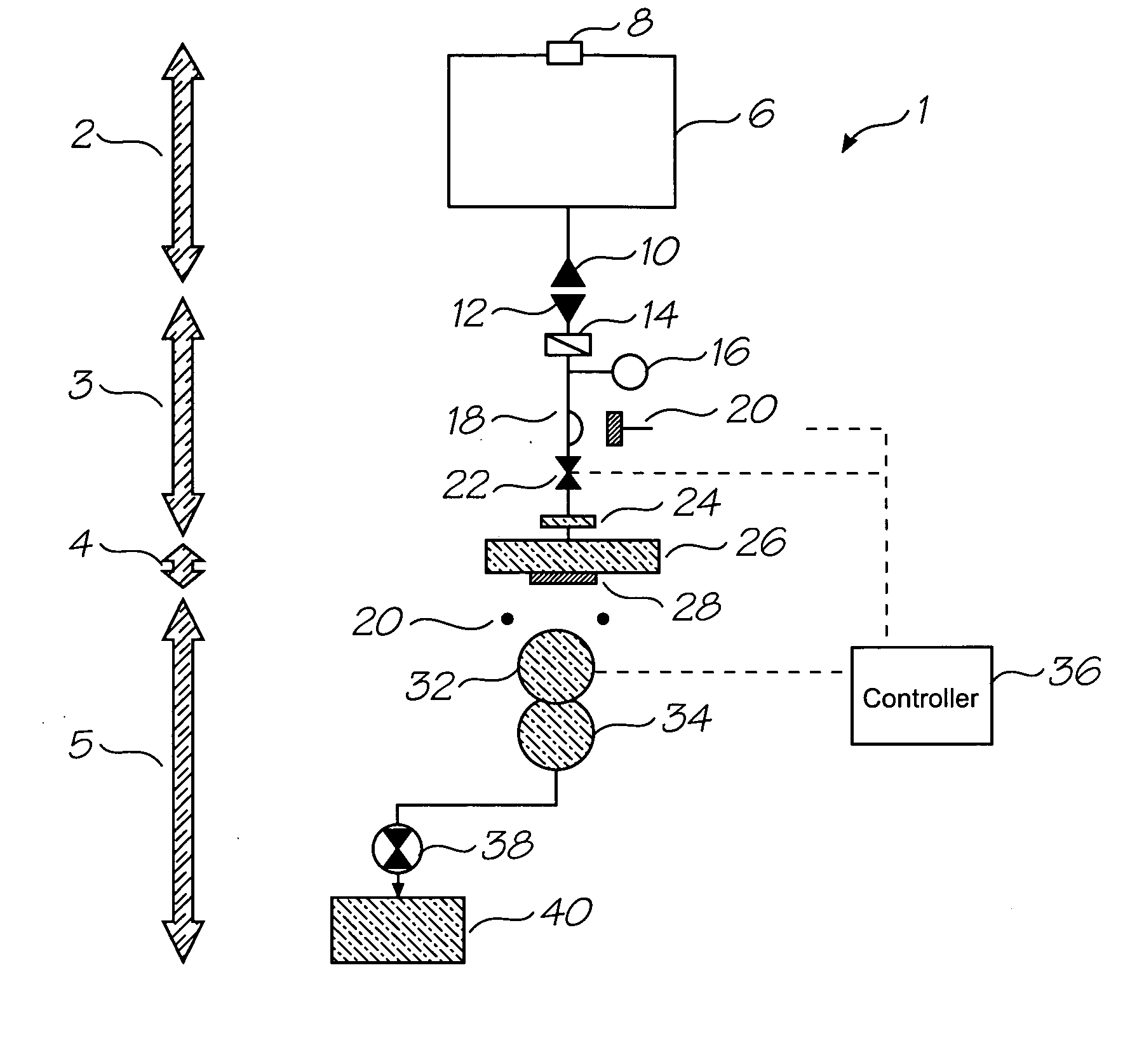

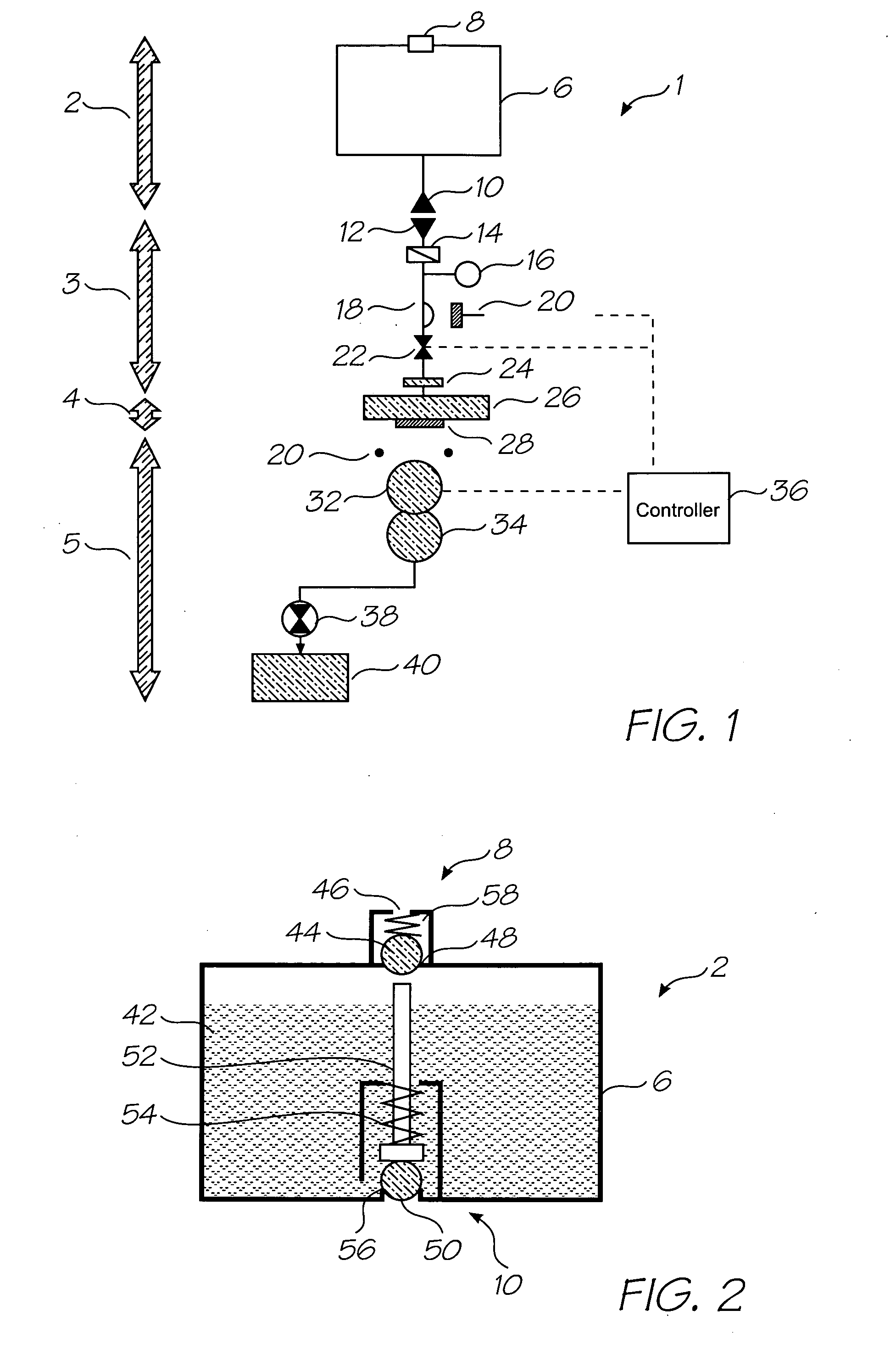

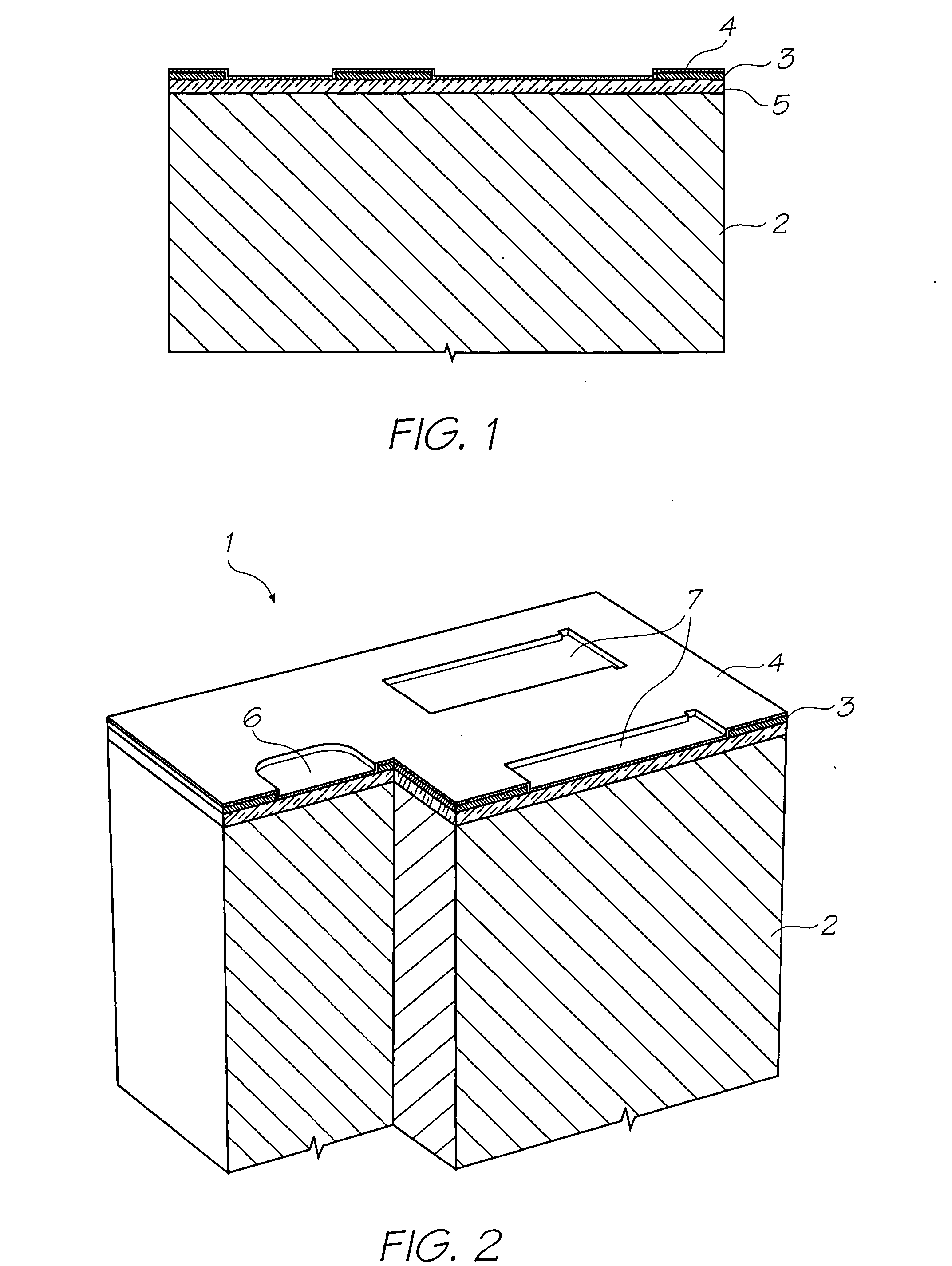

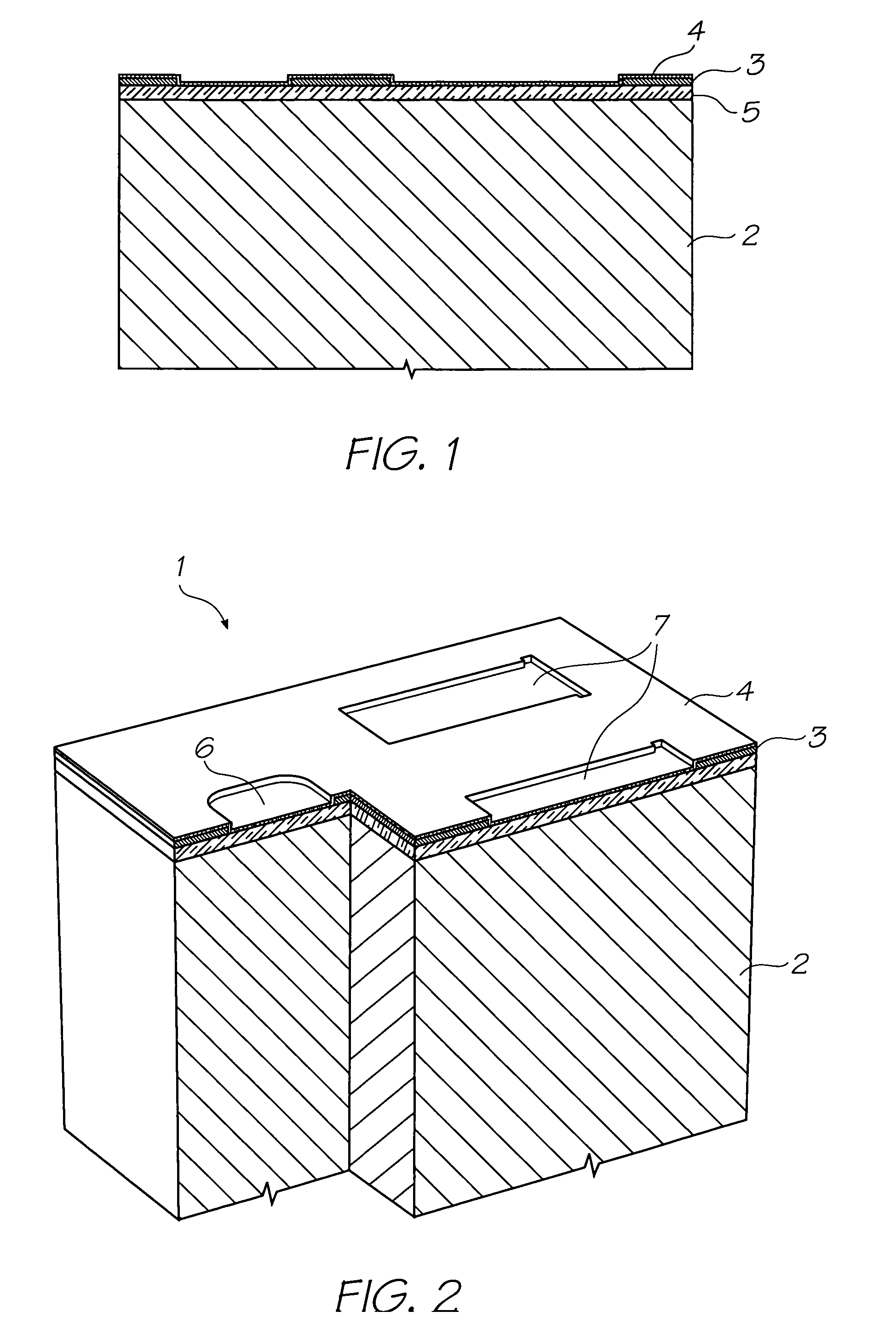

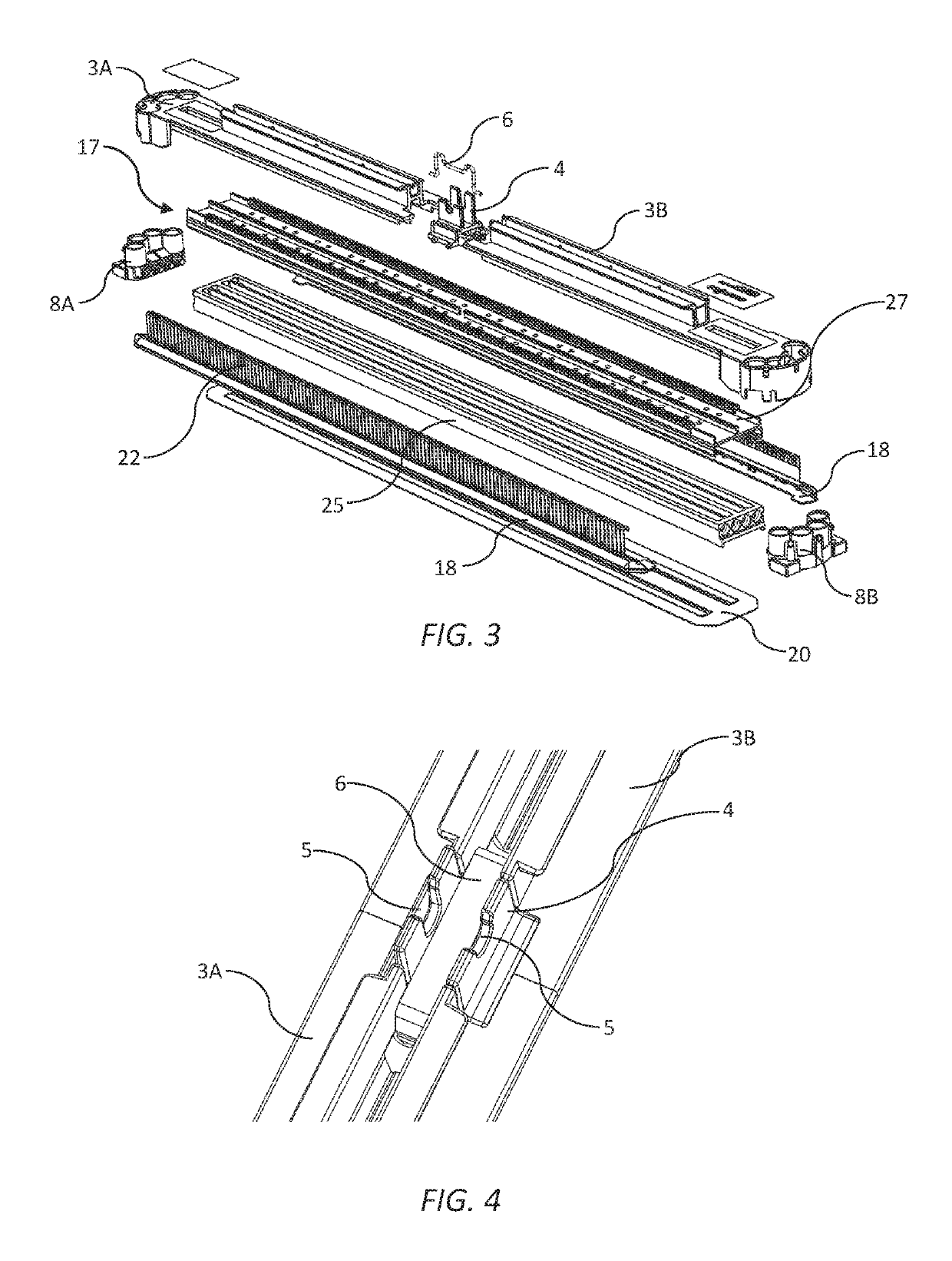

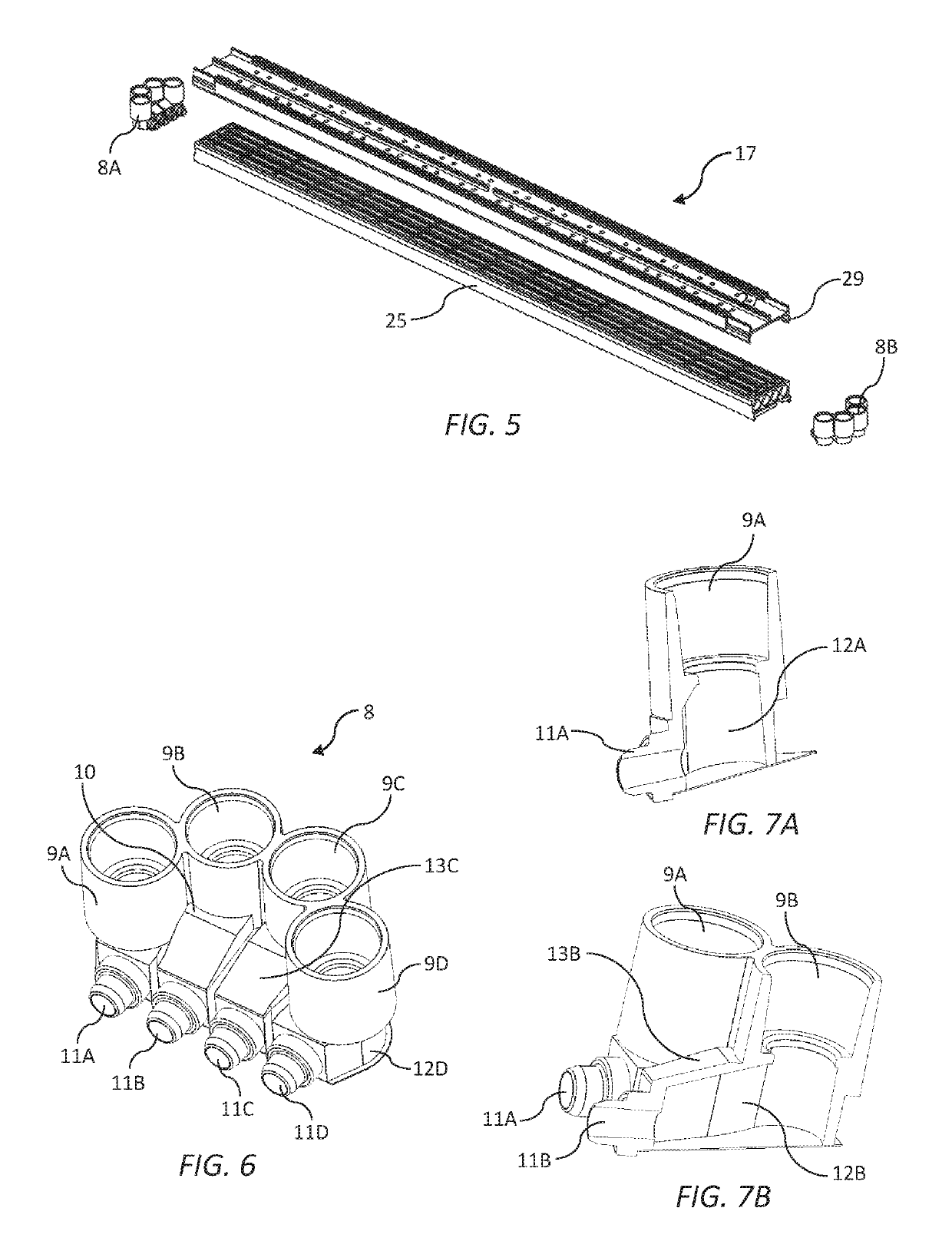

Printer with ink flow shutoff valve

InactiveUS20070206069A1Minimize color mixingMinimize detrimental impactOther printing apparatusInk printerEngineering

An inkjet printer with a printhead integrated circuit (IC) (28), an ink supply reservoir (6) for storing ink, an ink supply line (3) defining a flow path from the ink supply reservoir to the printhead IC, and a valve (22) in the ink supply line proximate the printhead IC selectively closing the flow path to the printhead IC.

Owner:SILVERBROOK RES PTY LTD +1

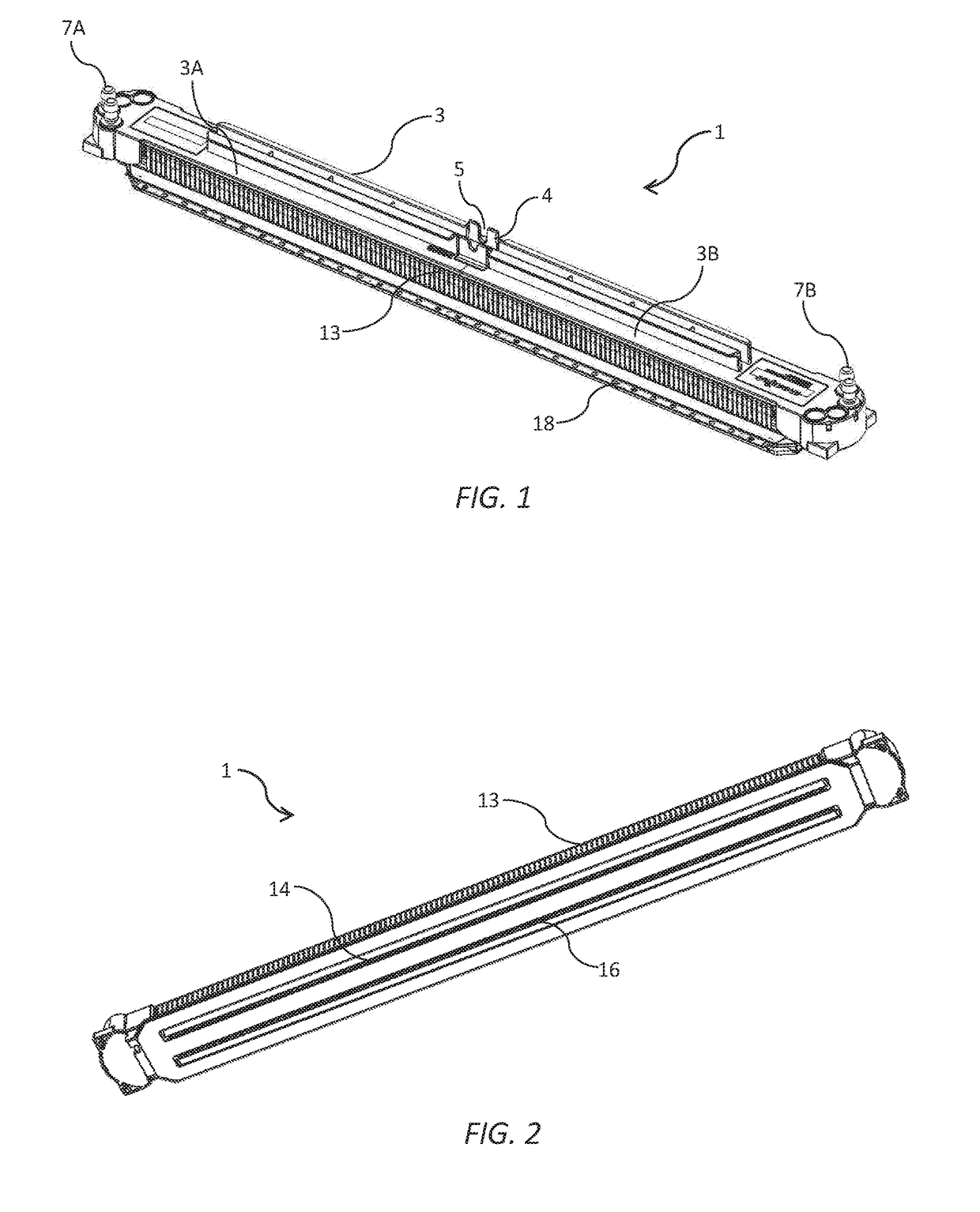

Inkjet printhead for full color pagewide printing

ActiveUS10293609B2Increase distanceMinimize color mixingInking apparatusPower drive mechanismsMechanical engineeringFull color

Owner:MEMJET TECH LTD

Method of forming low-stiction nozzle plate for an inkjet printhead

InactiveUS20070079509A1Prevent backflowMinimize color mixingPrinted circuit assemblingRecording apparatusEngineeringStiction

A method of forming a low-stiction nozzle plate for an inkjet printhead, said nozzle plate having a plurality of nozzle apertures defined therein, each nozzle aperture having a respective nozzle rim, said method comprising the steps of: (a) providing a partially-fabricated printhead comprising a plurality of inkjet nozzle assemblies sealed with roof material; (b) etching partially into said roof material to define simultaneously said nozzle rims and a plurality of stiction-reducing formations; and (c) etching through said roof material to define said nozzle apertures, thereby forming said nozzle plate.

Owner:SILVERBROOK RES PTY LTD +1

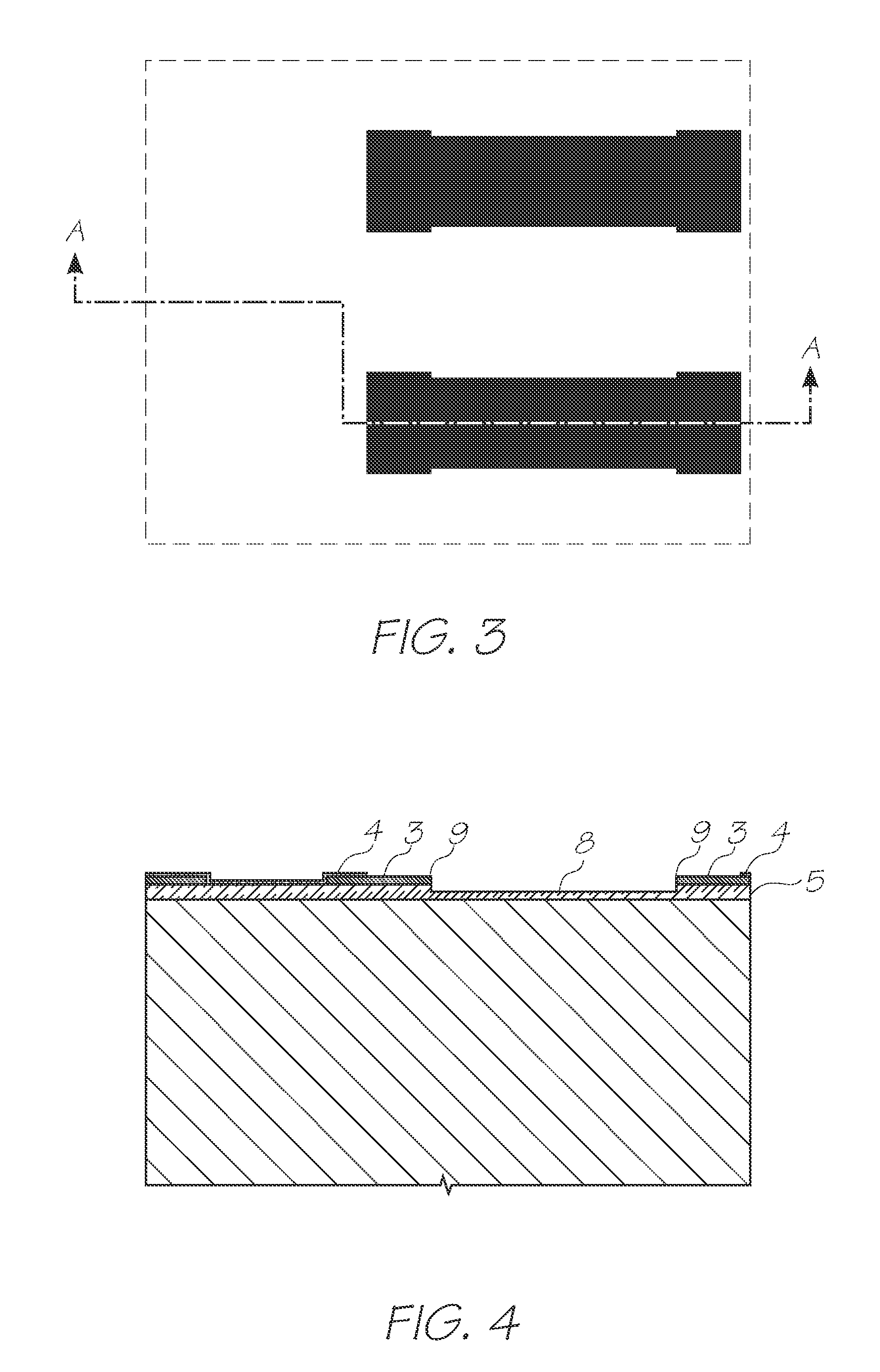

Method of fabricating inkjet nozzles having associated ink priming features

ActiveUS7401405B2Prevent backflowMinimize color mixingRecording apparatusPrinted circuit assemblingEngineeringNozzle

A method of fabricating a plurality of inkjet nozzles on a substrate, each nozzle comprising a nozzle chamber having a roof spaced apart from said substrate and sidewalls extending from said roof to said substrate, said chamber having an entrance for receiving ink from at least one ink inlet defined in said substrate, said at least one ink inlet having at least one priming feature extending from a respective rim thereof, said method comprising the steps of:(a) providing a substrate having a plurality of trenches corresponding to said ink inlets;(b) depositing sacrificial material on said substrate so as fill said trenches and form a scaffold on said substrate;(c) defining openings in said sacrificial material, said openings being positioned to form said chamber sidewalls and said at least one priming feature when filled with roof material;(d) depositing roof material over said sacrificial material to form simultaneously said nozzle chambers and said at least one priming feature;(e) etching nozzle apertures through said roof material, each nozzle chamber having at least one nozzle aperture; and(f) removing said sacrificial material.By introducing a priming feature into the plane of the inlet aperture, the surface tension in the ink meniscus can be redirected to pull the ink along the intend flow path rather than push it back into the inlet.

Owner:SILVERBROOK RES PTY LTD +1

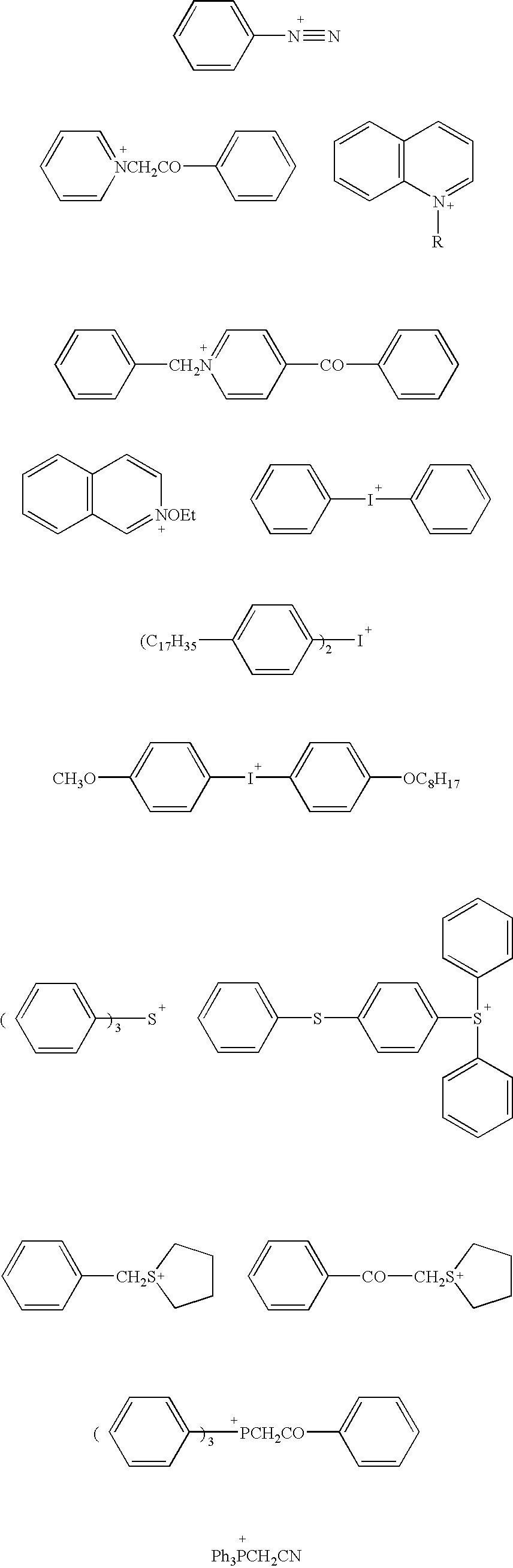

Image forming method, actinic radiation curable ink-jet ink, and inkjet recording apparatus

ActiveUS7878642B2Stable recordingQuality improvementMeasurement apparatus componentsDuplicating/marking methodsHueRadiation exposure

A method of producing an image including the steps of: (a) ejecting droplets of at least two actinic radiation curable ink-jet inks from an ink-jet recording head so as to deposit onto a recording medium; and (b) irradiating the deposited droplets of the actinic radiation curable ink-jet inks with actinic radiations, wherein the two actinic radiation curable ink-jet inks being different in hue with each other; and an absolute value of ΔS(Slow−Shigh) is 5-1,000 mPa·s, where Slow represents a viscosity of the actinic radiation curable ink-jet ink measured with a share rate of 11.7 l / s at 25° C., Shigh represents a viscosity of the actinic radiation curable ink-jet ink measured with a share rate of 1,000 l / s at 25° C., and ΔS(Slow−Shigh) represents a difference between the viscosities of Slow and Shigh.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

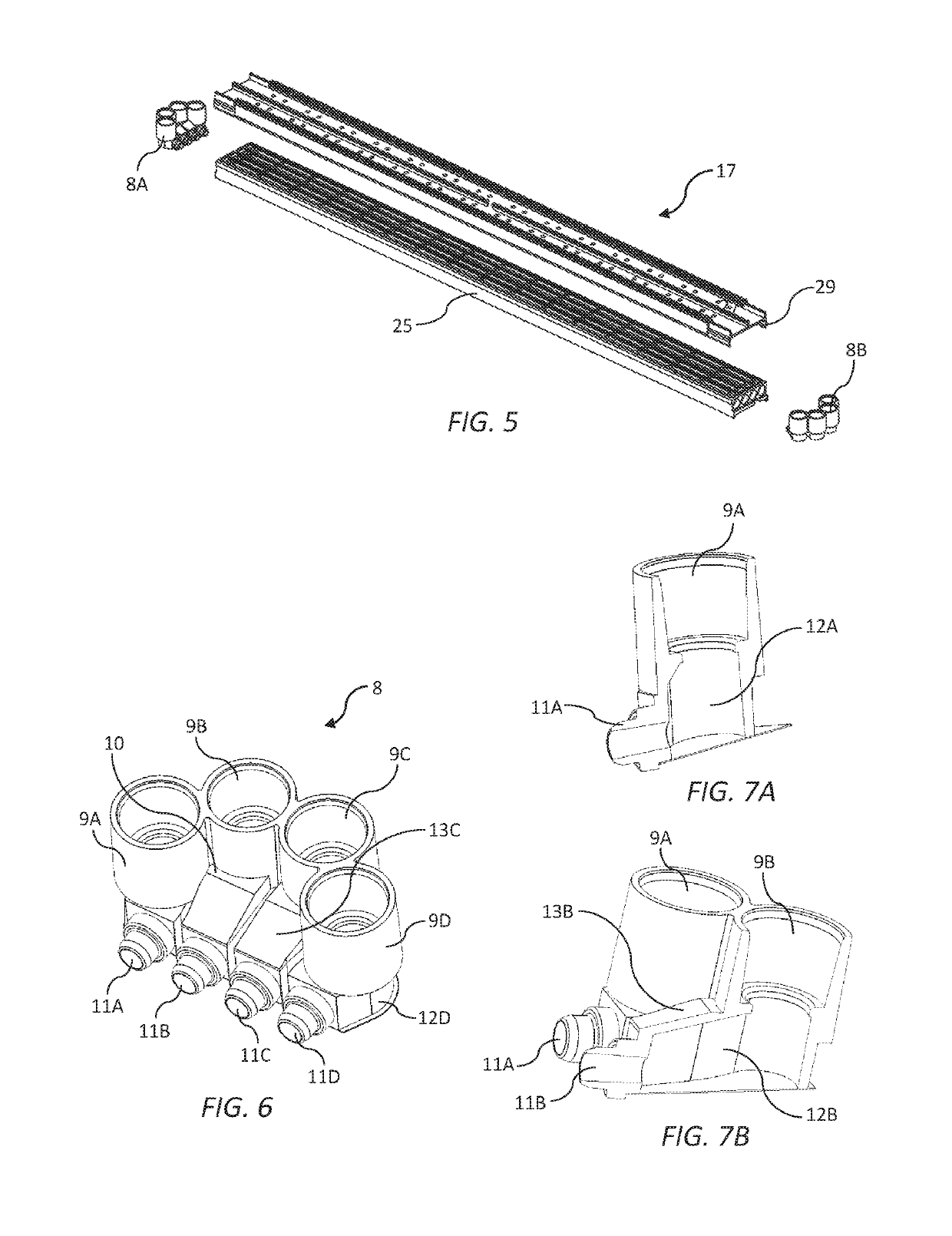

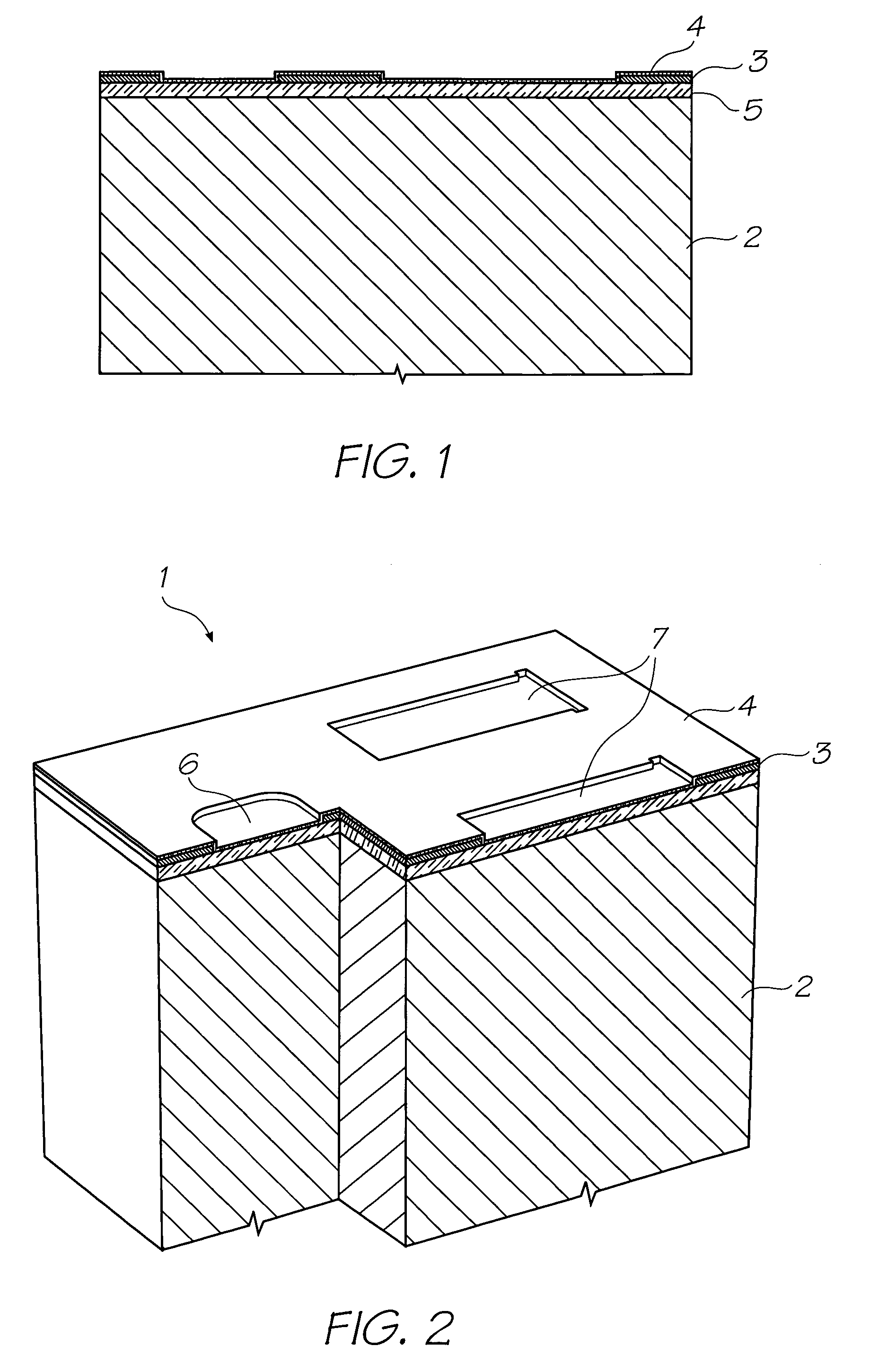

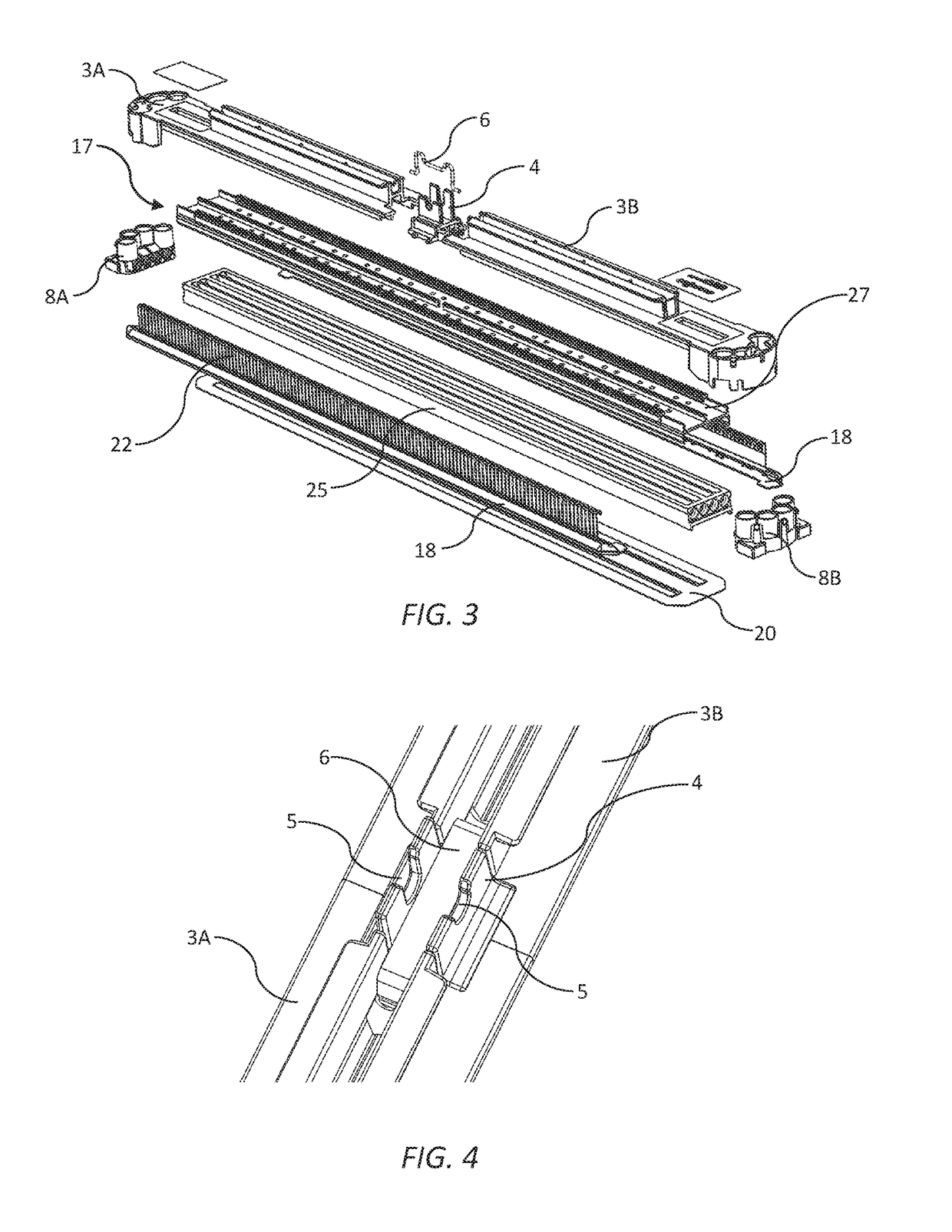

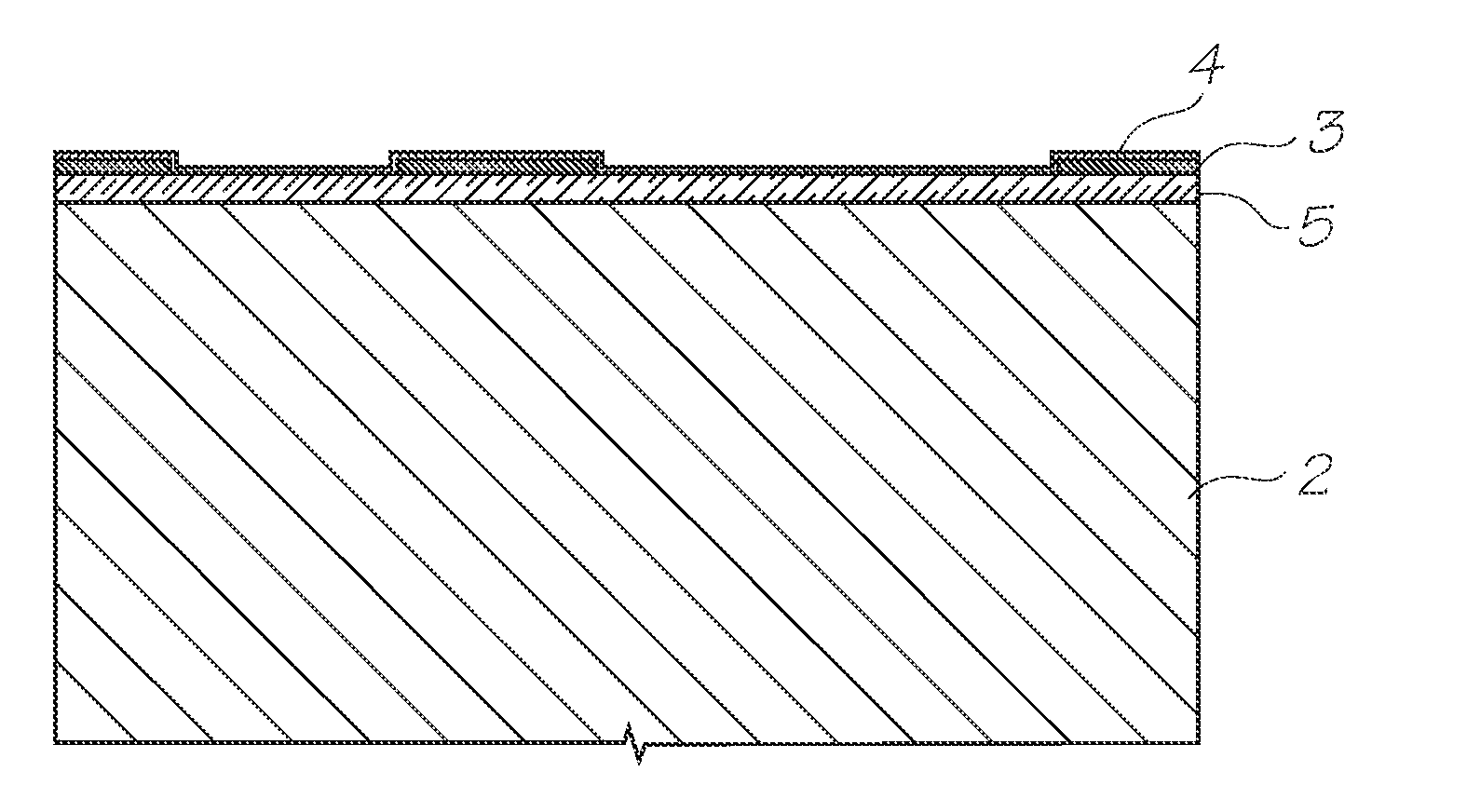

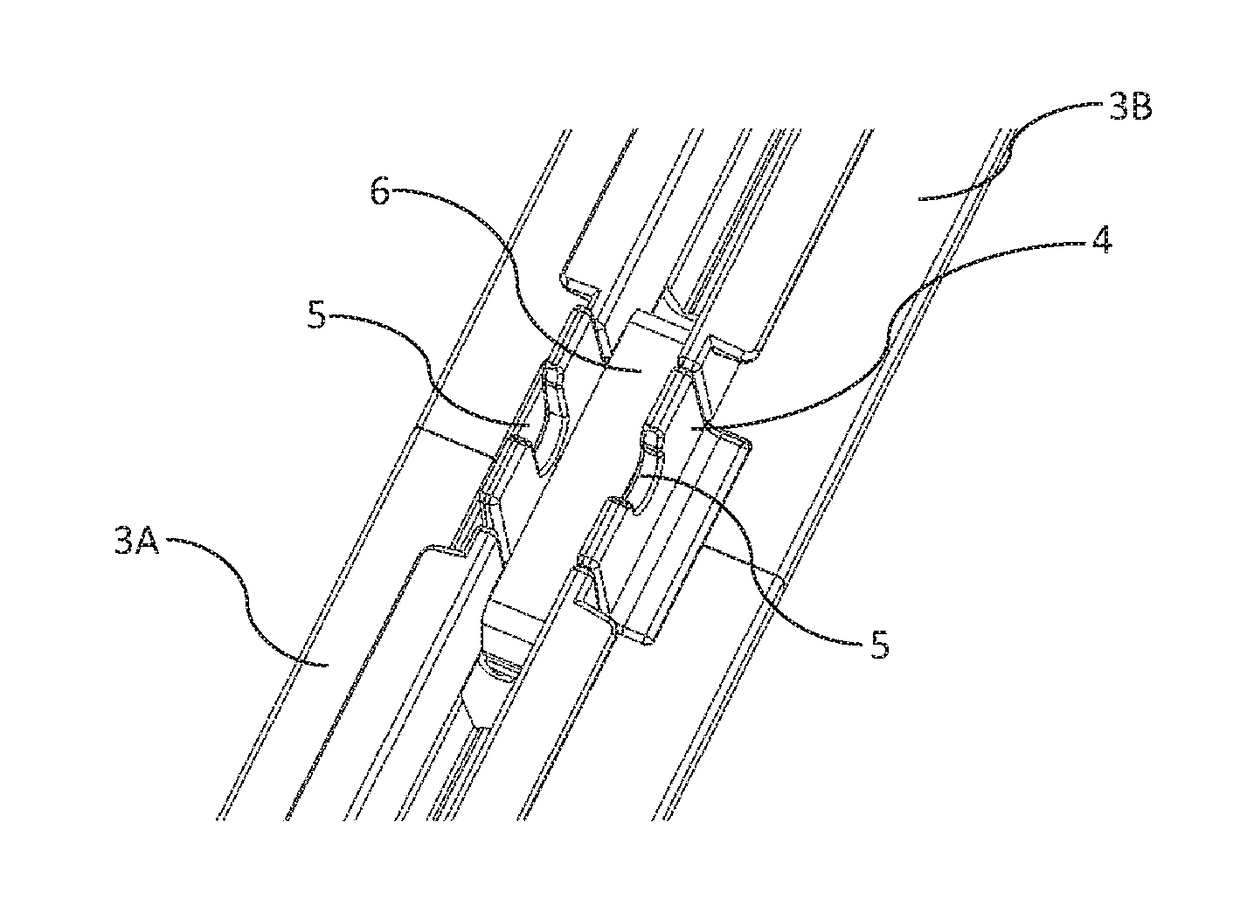

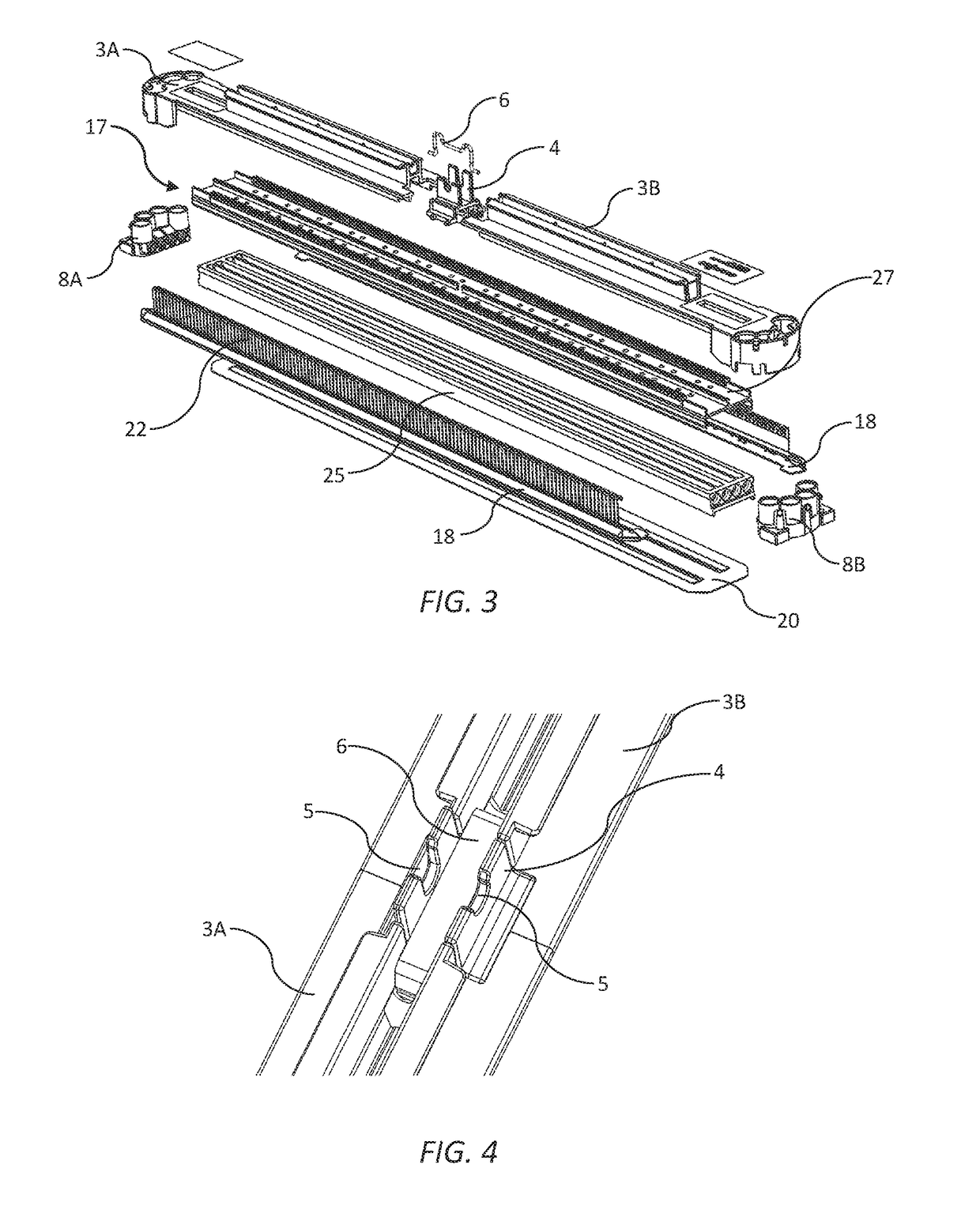

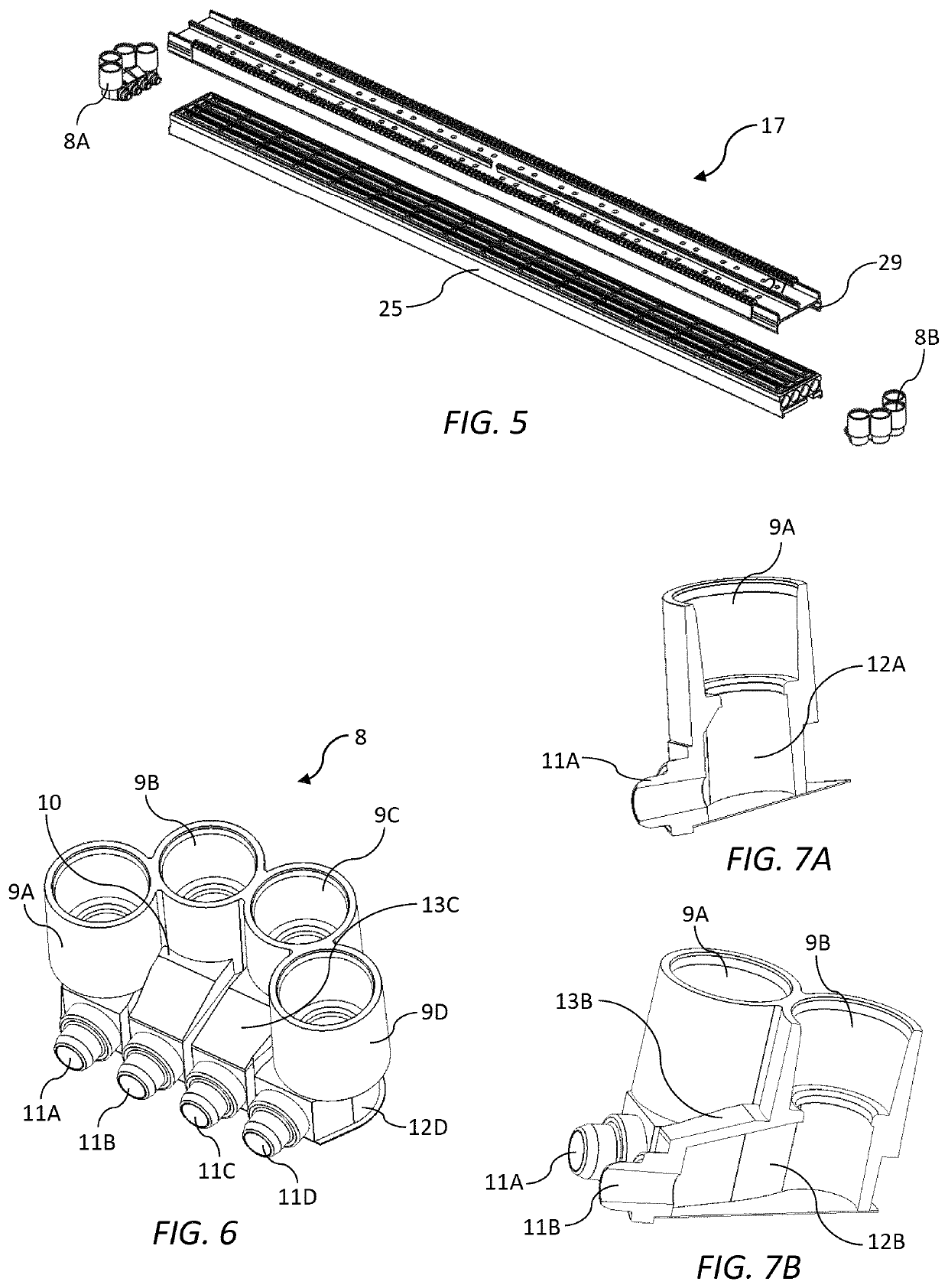

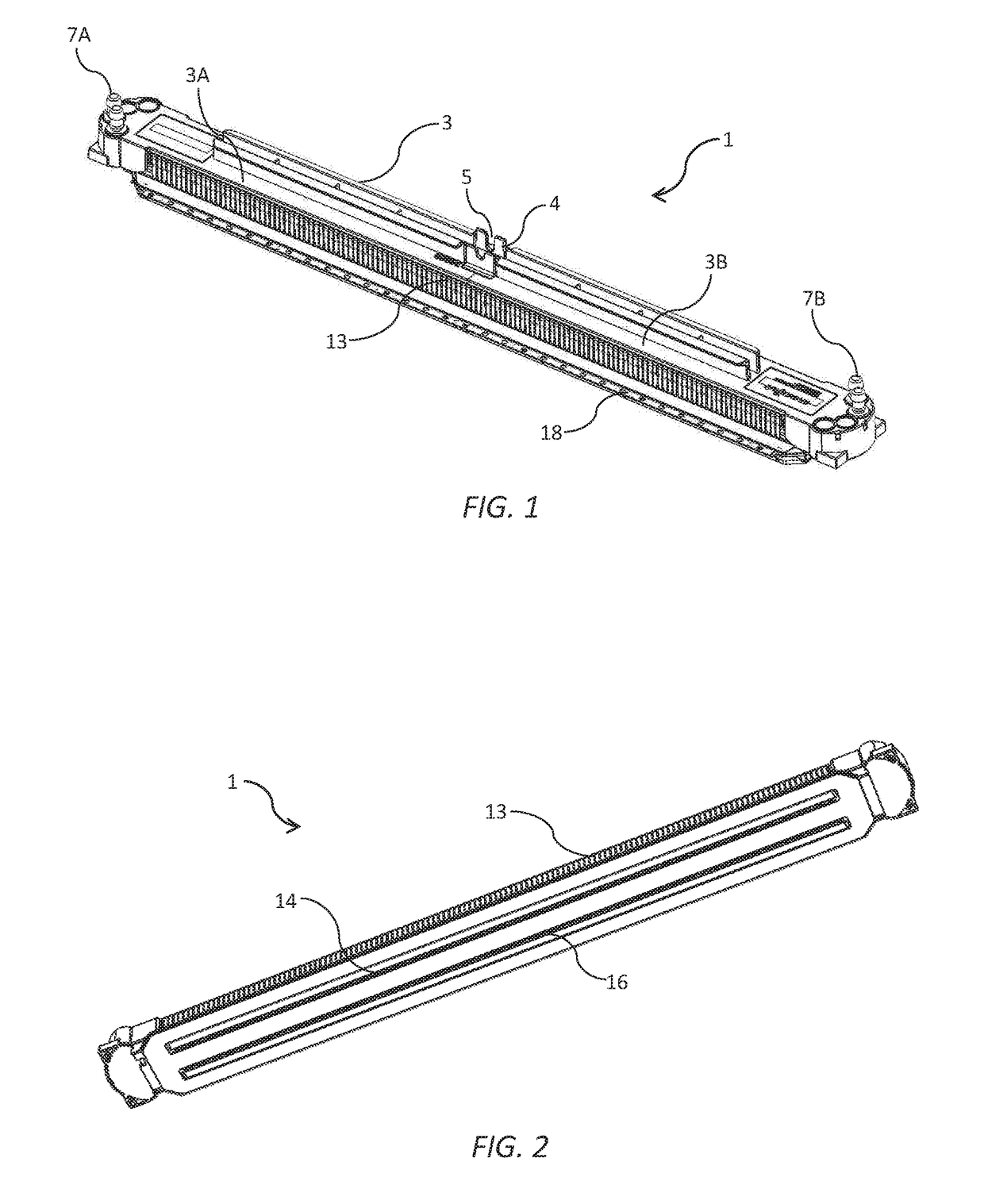

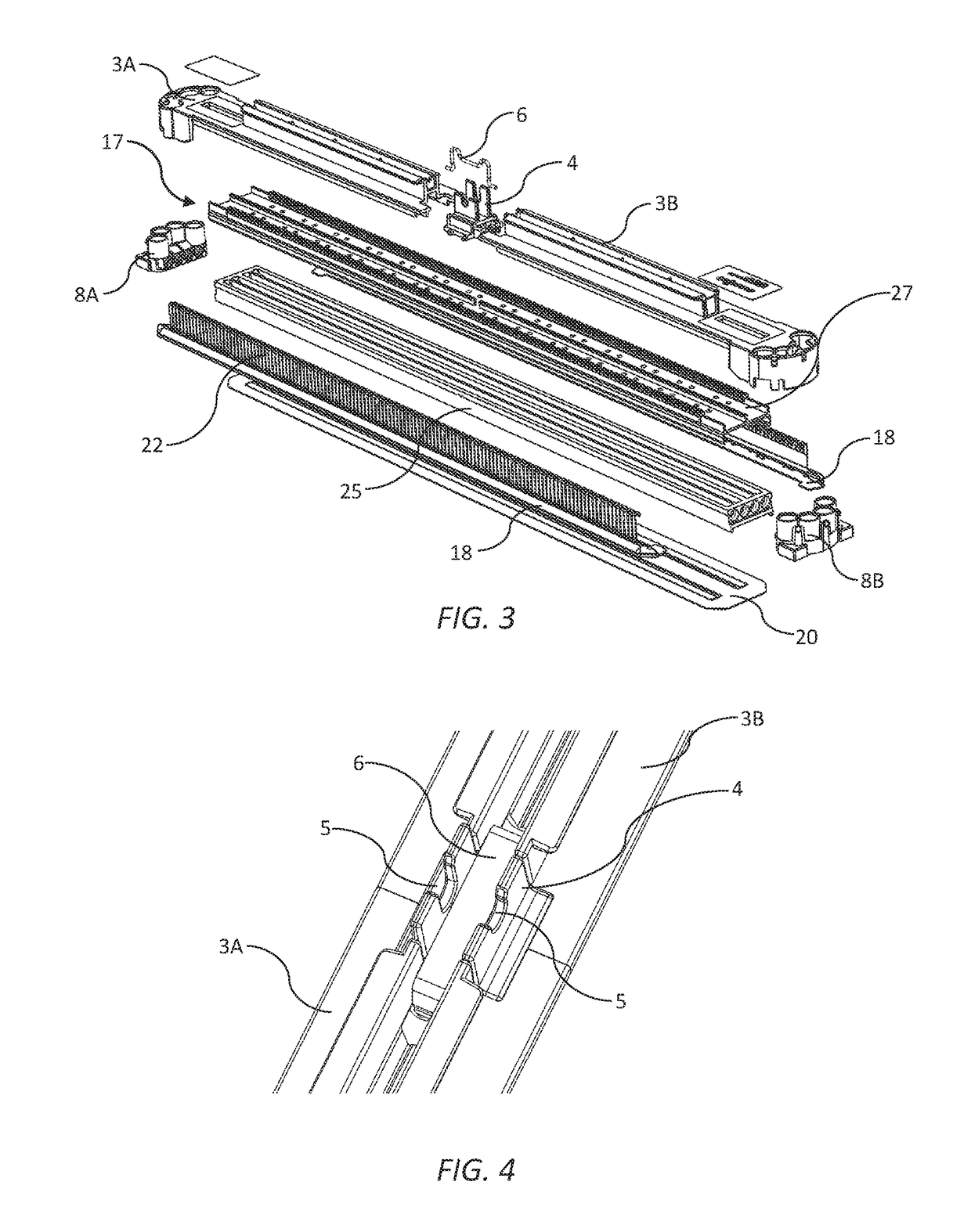

Robust printhead chip mounting suitable for long inkjet printheads

ActiveUS20180222199A1Easy temperature adjustmentIncrease distanceInking apparatusPower drive mechanismsMetal alloyEngineering

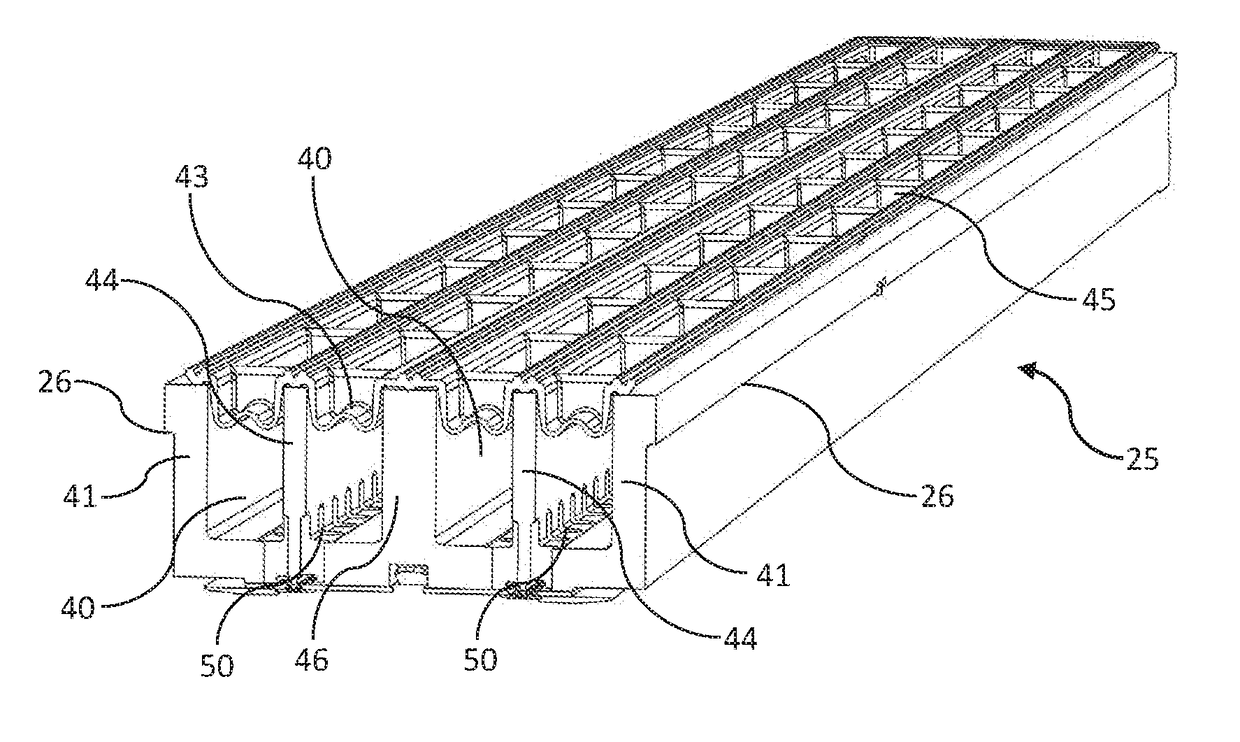

An inkjet printhead includes: a rigid elongate manifold having ink supply channels extending along its length and a plurality of ink outlets defined therein; a shim attached to the manifold, the shim having a plurality of shim apertures for receiving ink from the ink outlets; and a plurality of printhead chips adhesively bonded directly to the shim, each printhead chip receiving ink from one or more of the ink outlets. The the shim is formed of a metal alloy having a CTE of 5 ppm / ° C. or less.

Owner:MEMJET TECH LTD

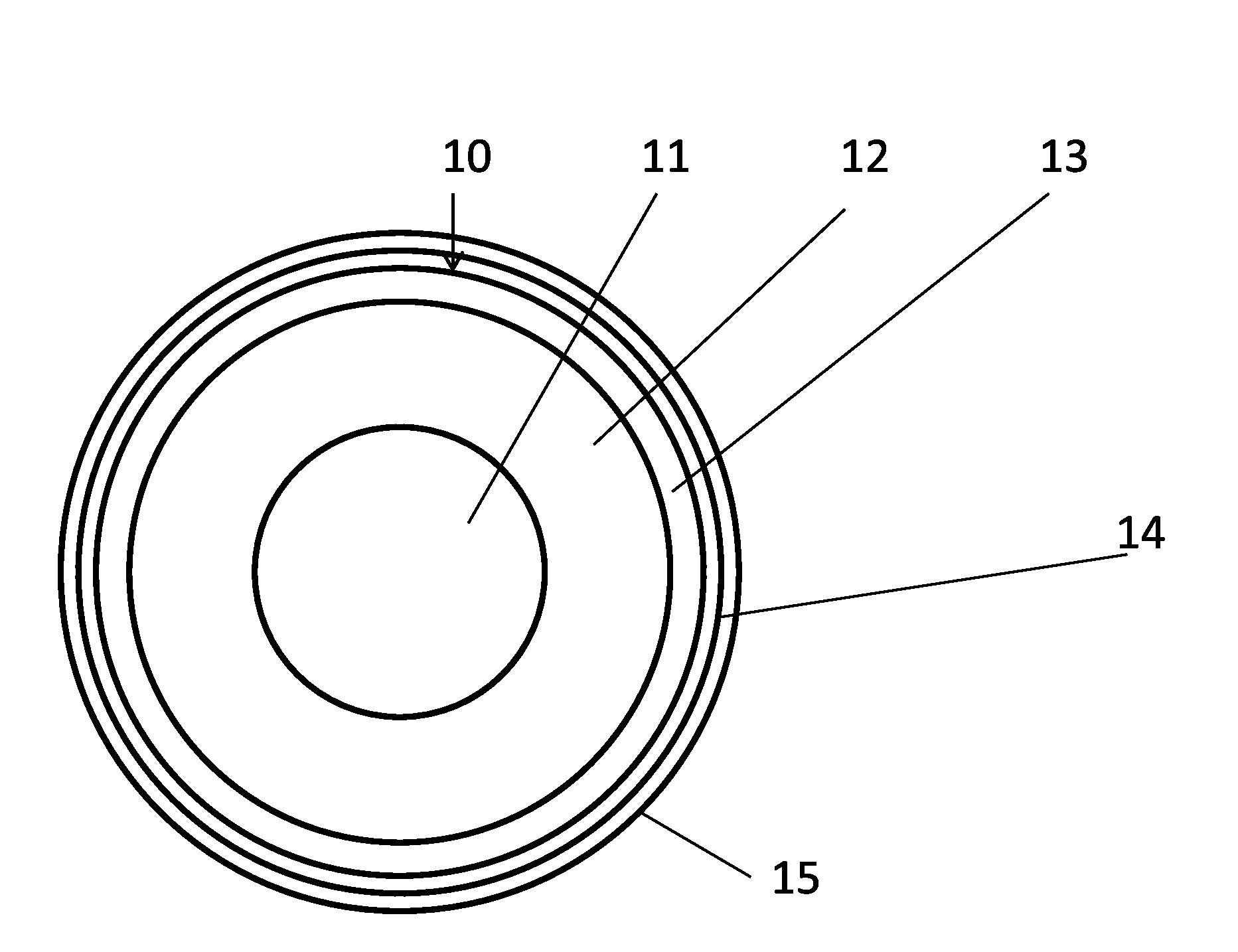

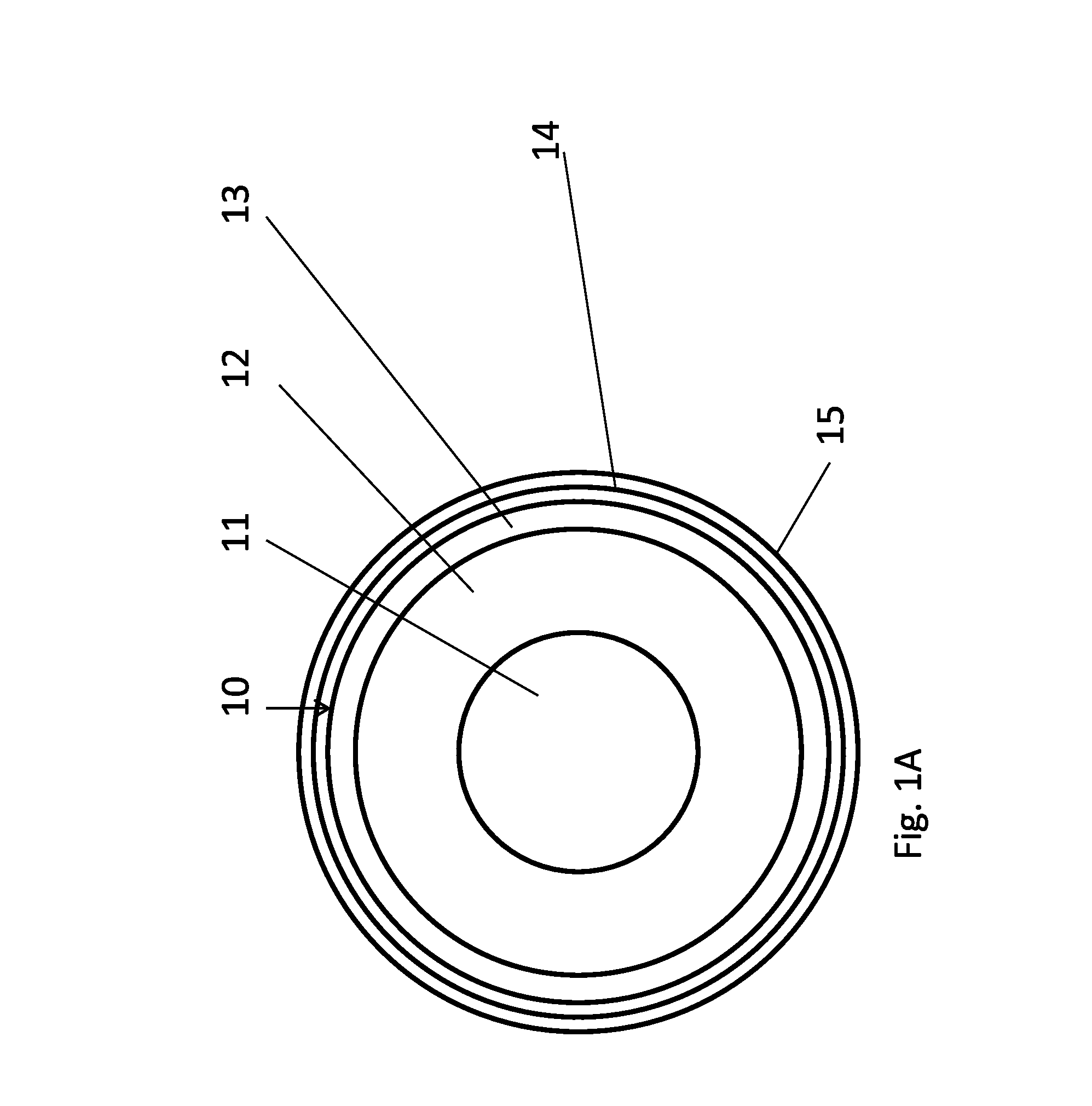

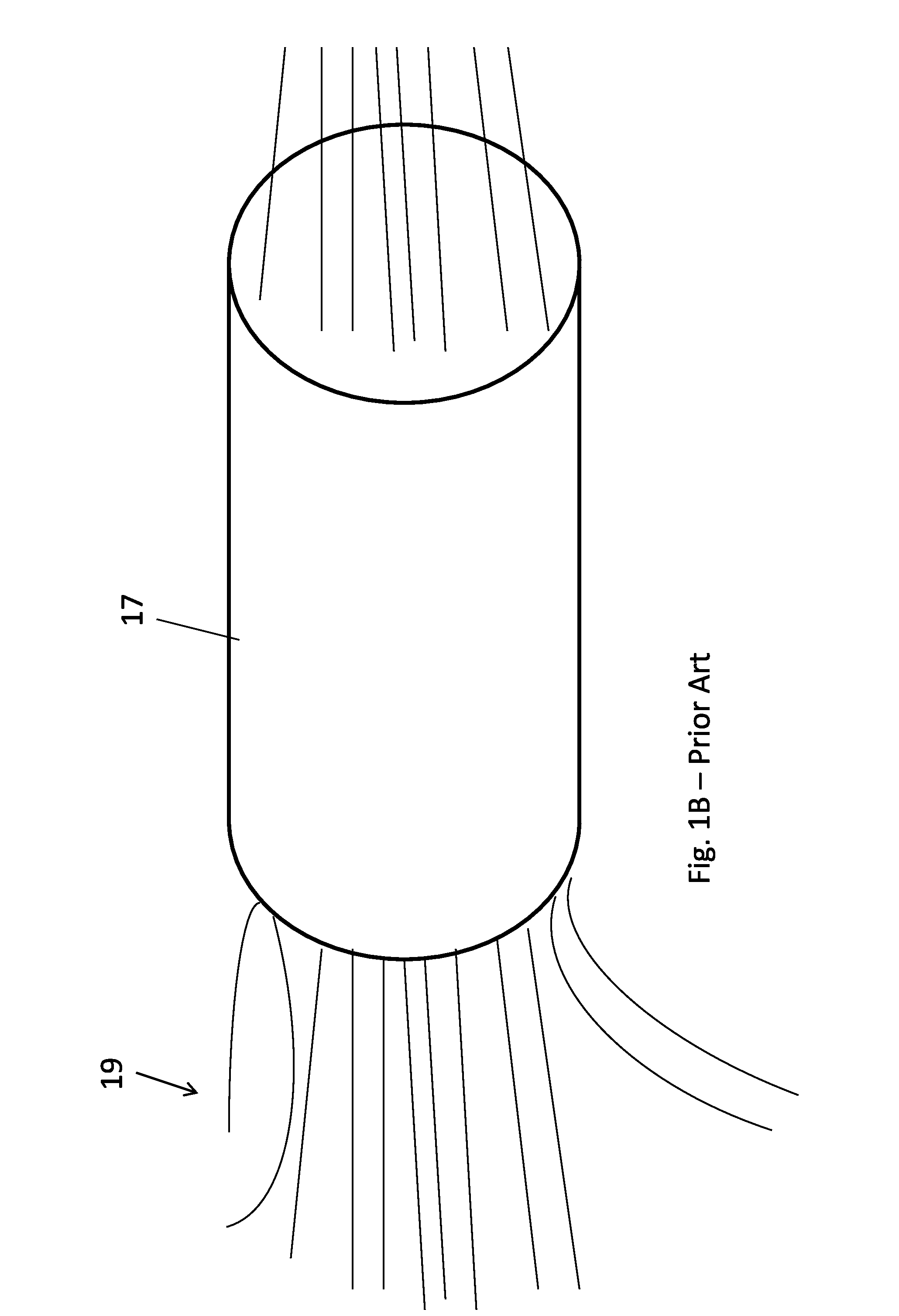

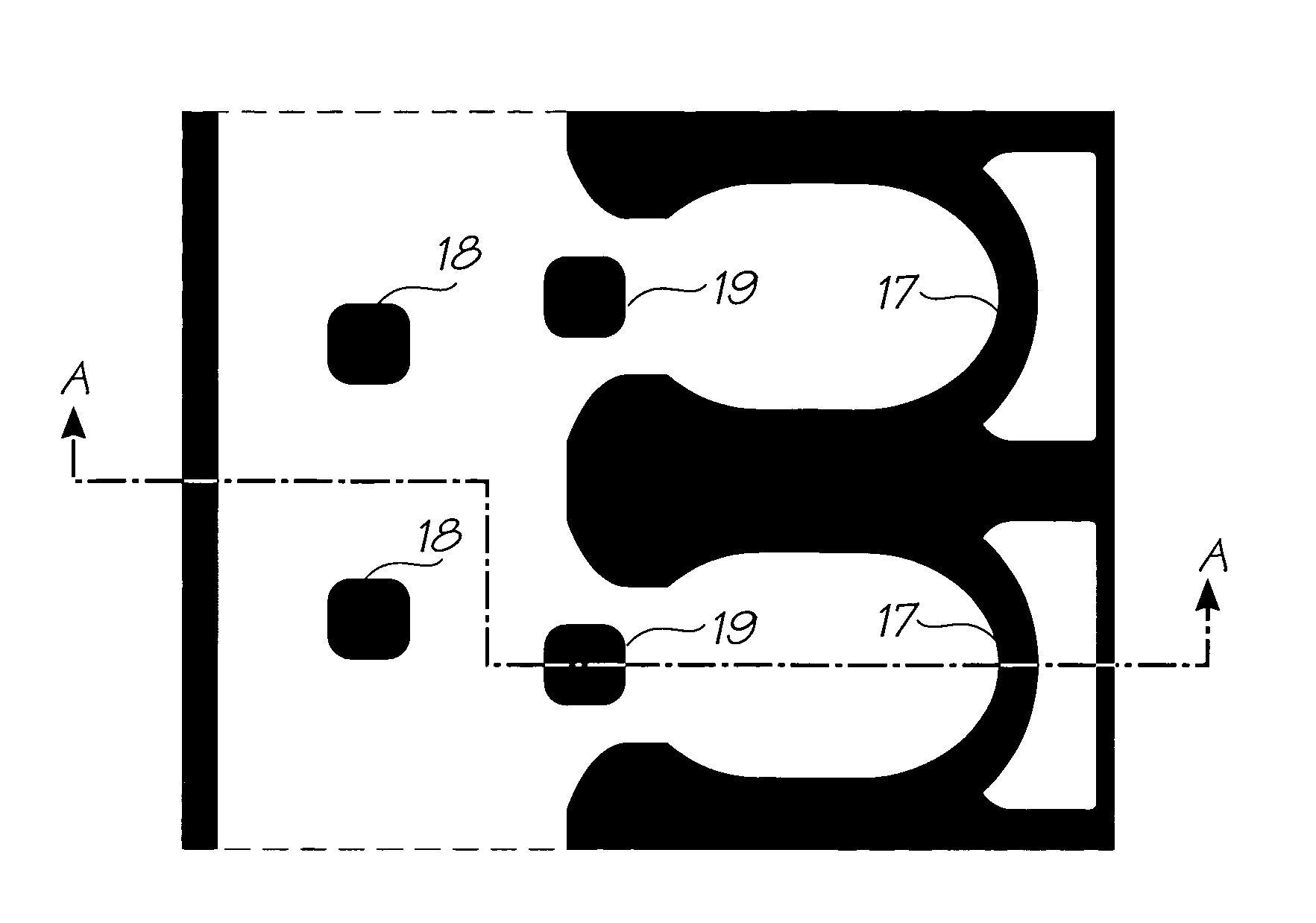

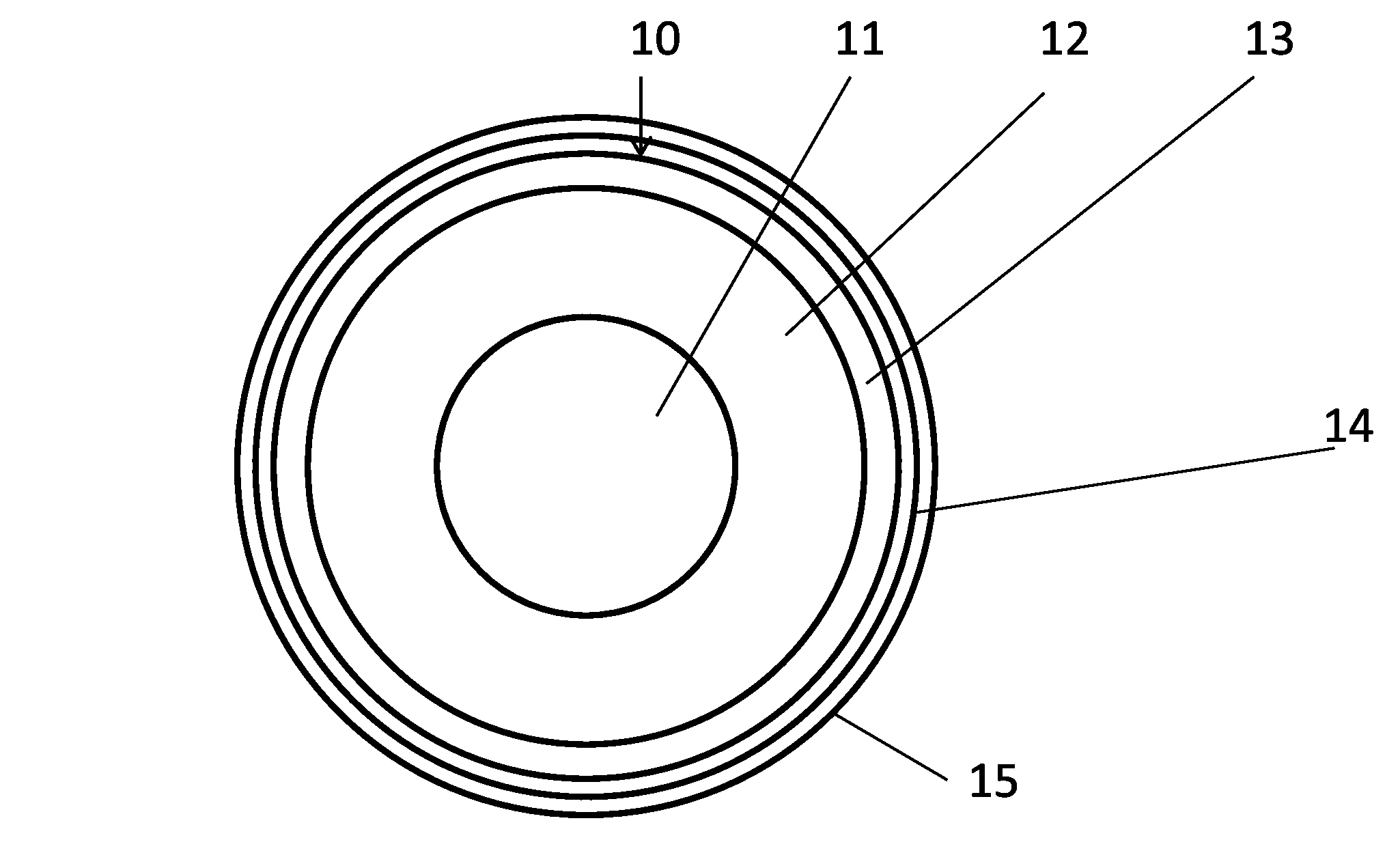

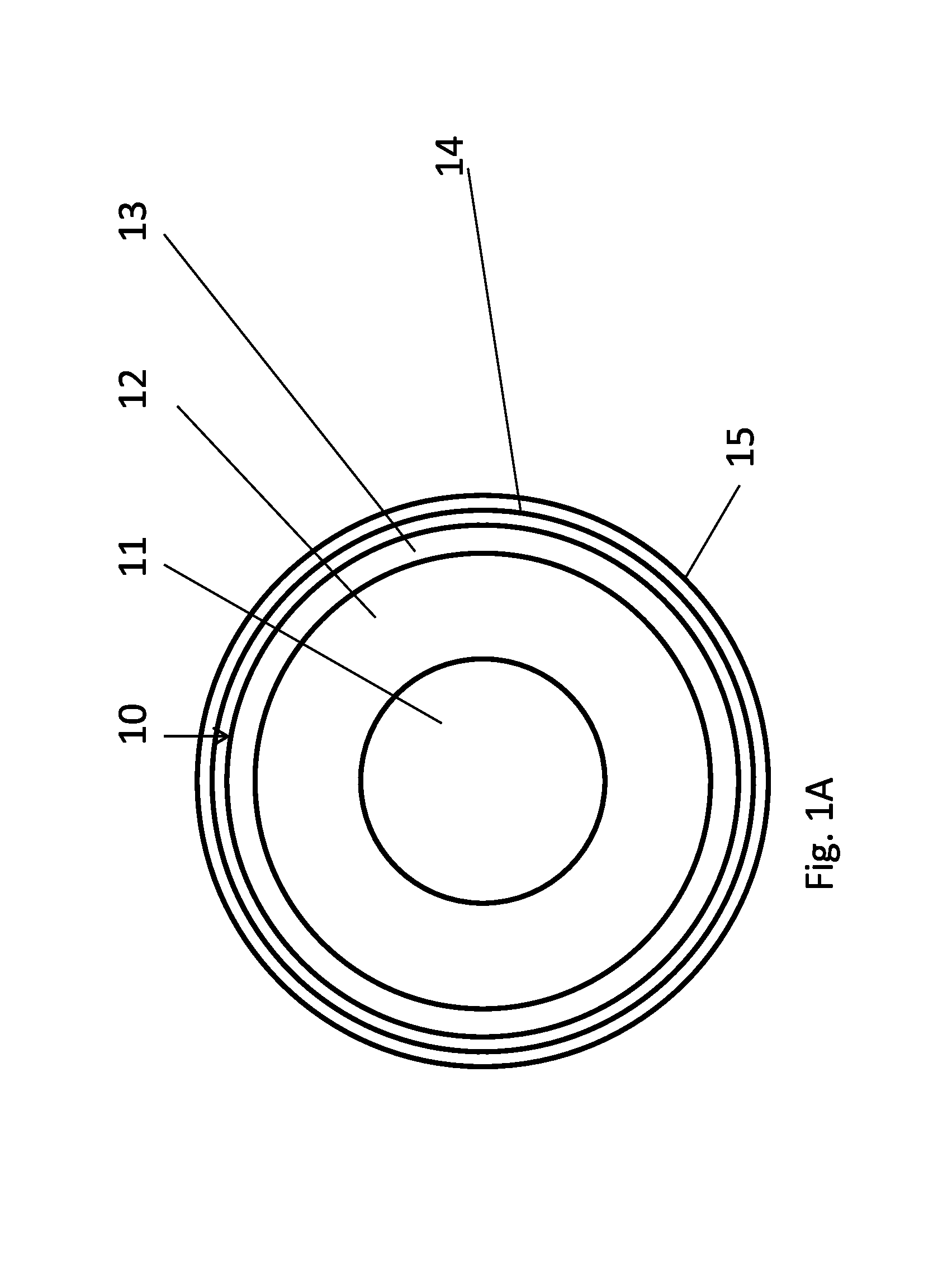

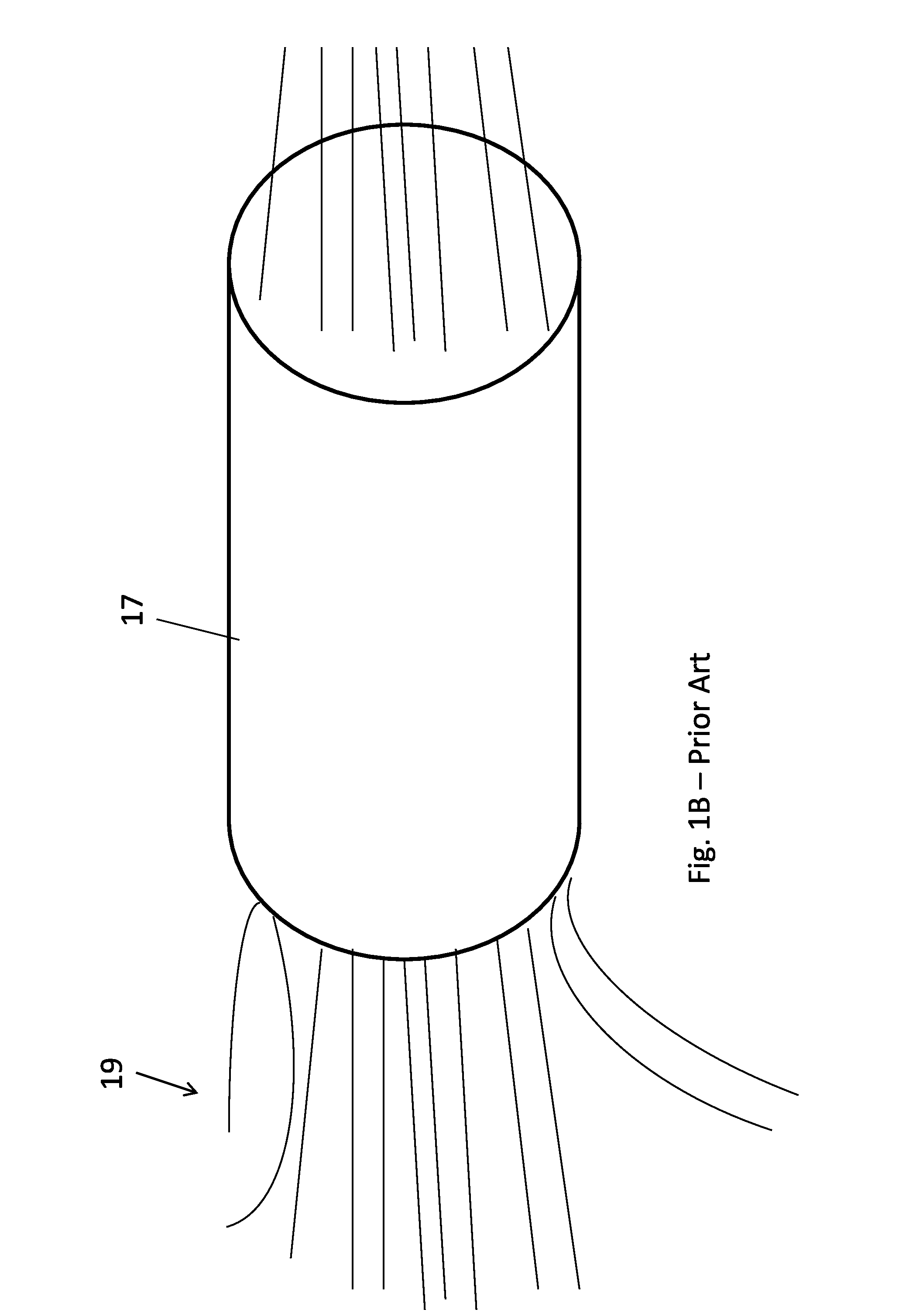

Dual-color coating of optical fibers with UV curable inks

ActiveUS20150259246A1Minimize color mixingCladded optical fibreRadiation applicationsFiberSilicon dioxide

A method of coating a silica-silica optical fiber, comprising, in a single pass on a fiber coating machine: applying a primary layer of UV curable acrylate carrying a first color, on said fiber; and applying a second layer of UV curable acrylate carrying a second color different from the first color, on top of the primary layer, the second layer being applied in patterns over the primary layer. The method is used to identify fibers in bundles or loose tubes where there are more fibers than there are basic colors.

Owner:TELDOR CABLES & SYST

Method of fabricating inkjet nozzle chambers having filter structures

InactiveUS7464466B2Induce turbulencePrevent backflowRecording apparatusPrinted circuit assemblingEngineeringNozzle

A method of fabricating a plurality of inkjet nozzles on a substrate. The method comprises the steps of: (a) providing a substrate having a plurality of trenches corresponding to ink inlets; (b) depositing sacrificial material so as fill the trenches and form a scaffold on the substrate; (c) defining openings in the sacrificial material; (d) depositing roof material over the sacrificial material to form nozzle chambers and filter structures simultaneously; (e) etching nozzle apertures through the roof material; and (f) removing the sacrificial material.

Owner:SILVERBROOK RES PTY LTD +1

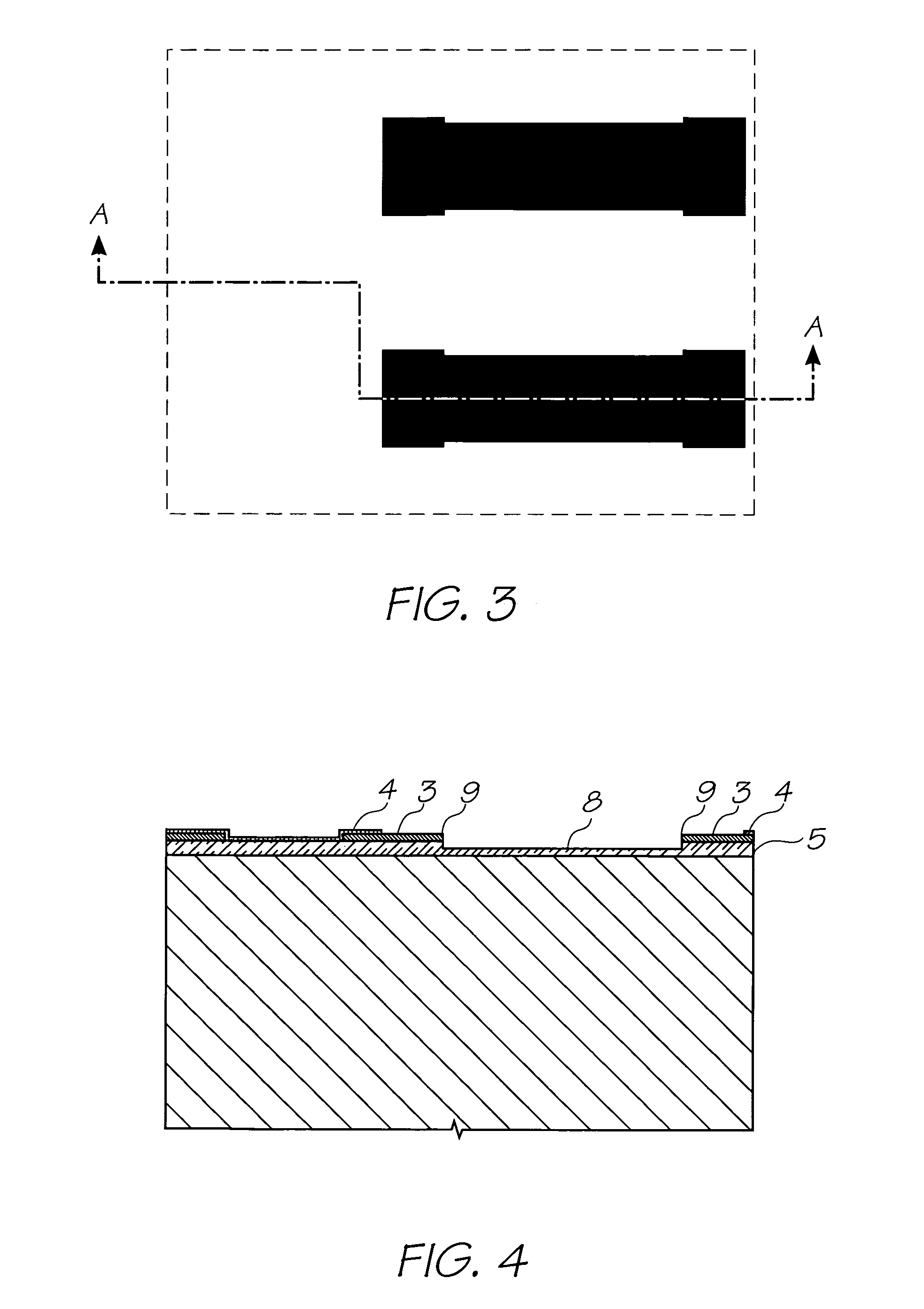

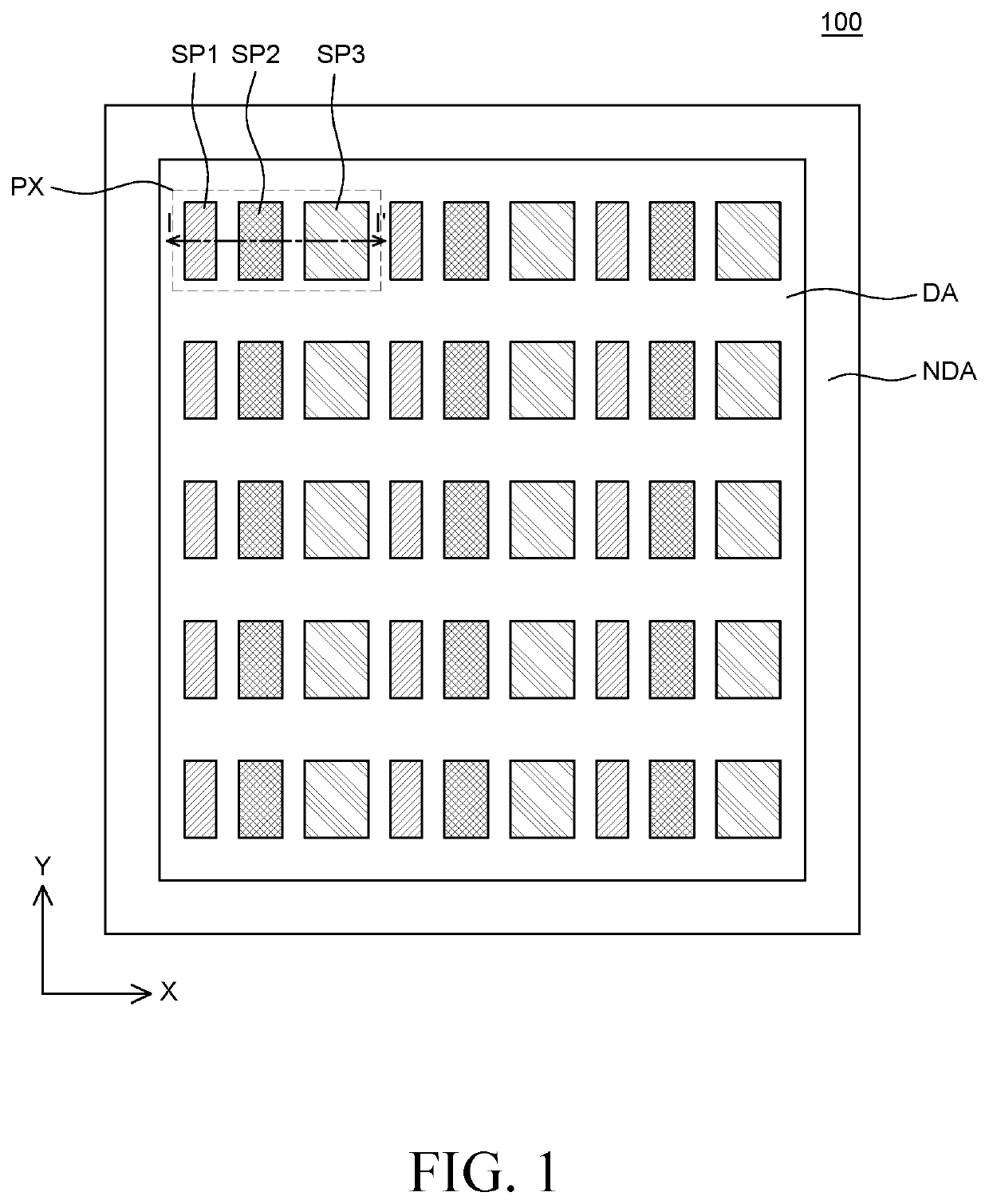

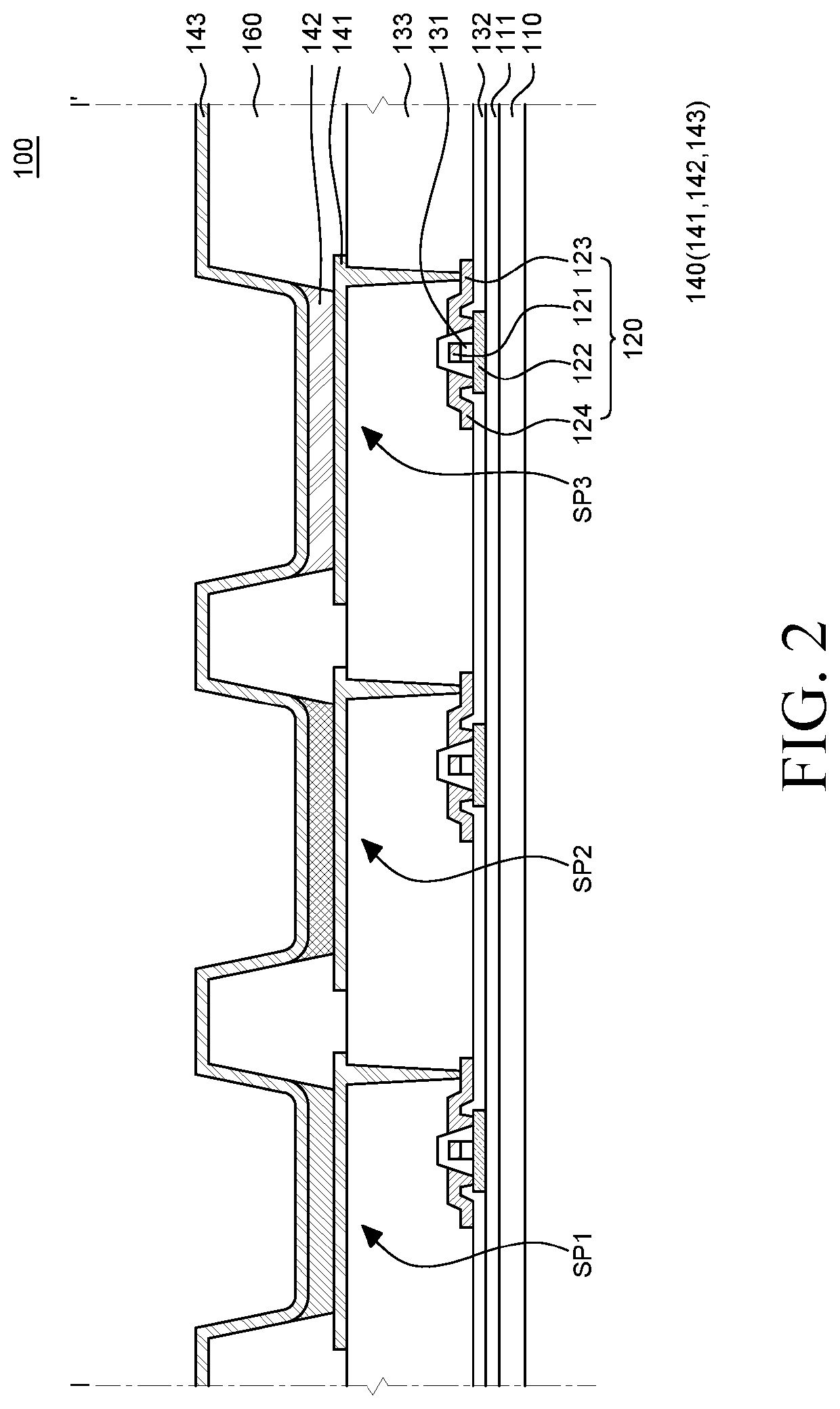

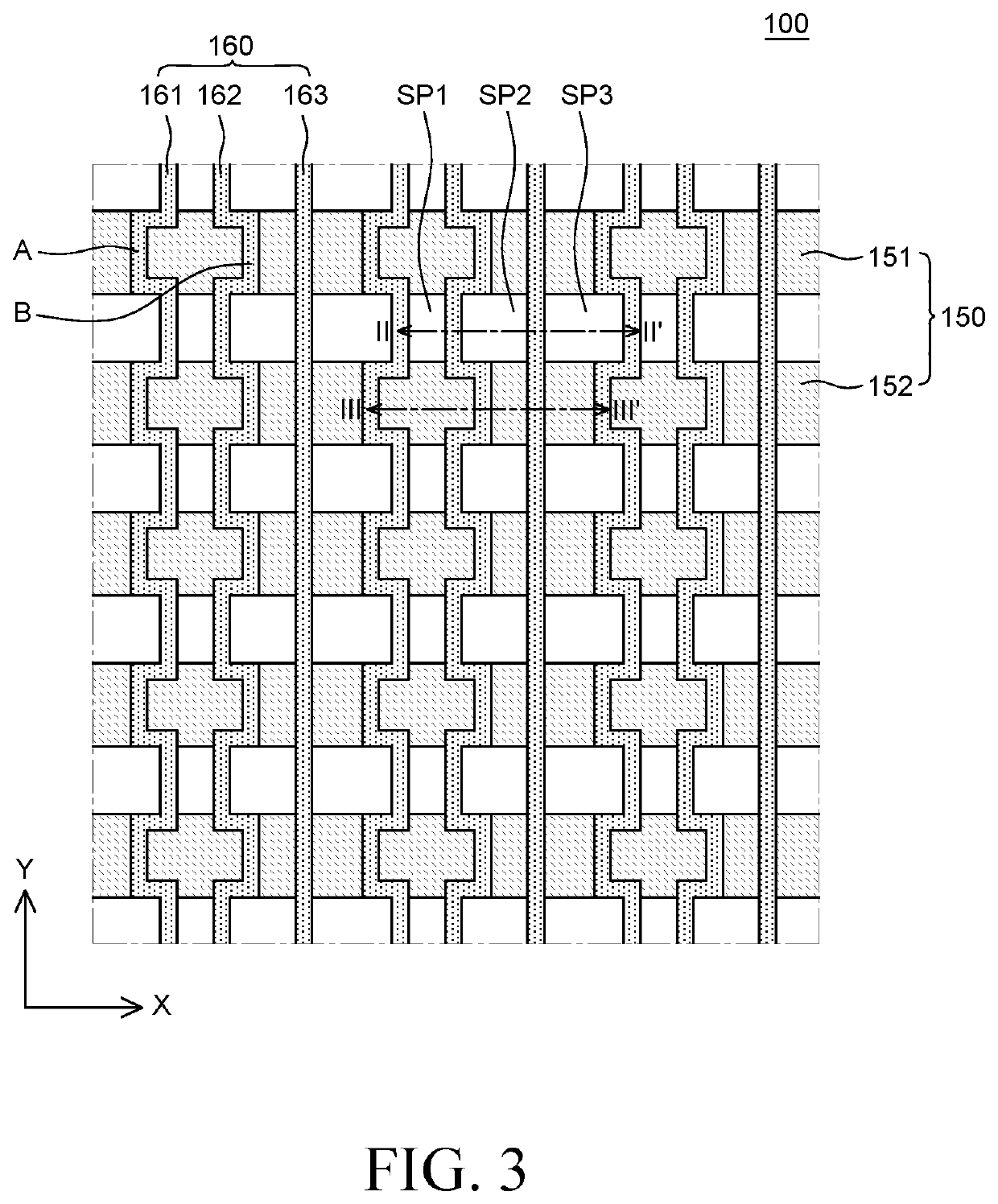

Organic Light Emitting Display Device

ActiveUS20210202609A1Solve problemsImprove display qualitySolid-state devicesSemiconductor devicesImage resolutionDisplay device

The present disclosure relates to an organic light emitting display device. According to an aspect of the present disclosure, an organic light emitting display device includes a plurality of sub-pixels including a first sub-pixel, a second sub-pixel and a third sub-pixel, a first electrode, a horizontal bank including a first horizontal bank and a second horizontal bank that are alternately arranged in a first direction to cover edges of the first electrodes, a vertical bank including a first vertical bank, a second vertical bank, and a third vertical bank that are alternately arranged in a second direction to cover edges of the first electrode and disposed on the horizontal bank, an organic light emitting layer and a second electrode. Wherein an area wider than the first sub-pixel is formed on the first horizontal bank or the second horizontal bank adjacent to the first sub-pixel, and ink is injected on the area, whereby color mixing of the ink can be minimized. And, a high-resolution organic light emitting display device can be implemented, simultaneously with improving display quality of the organic light emitting display device.

Owner:LG DISPLAY CO LTD

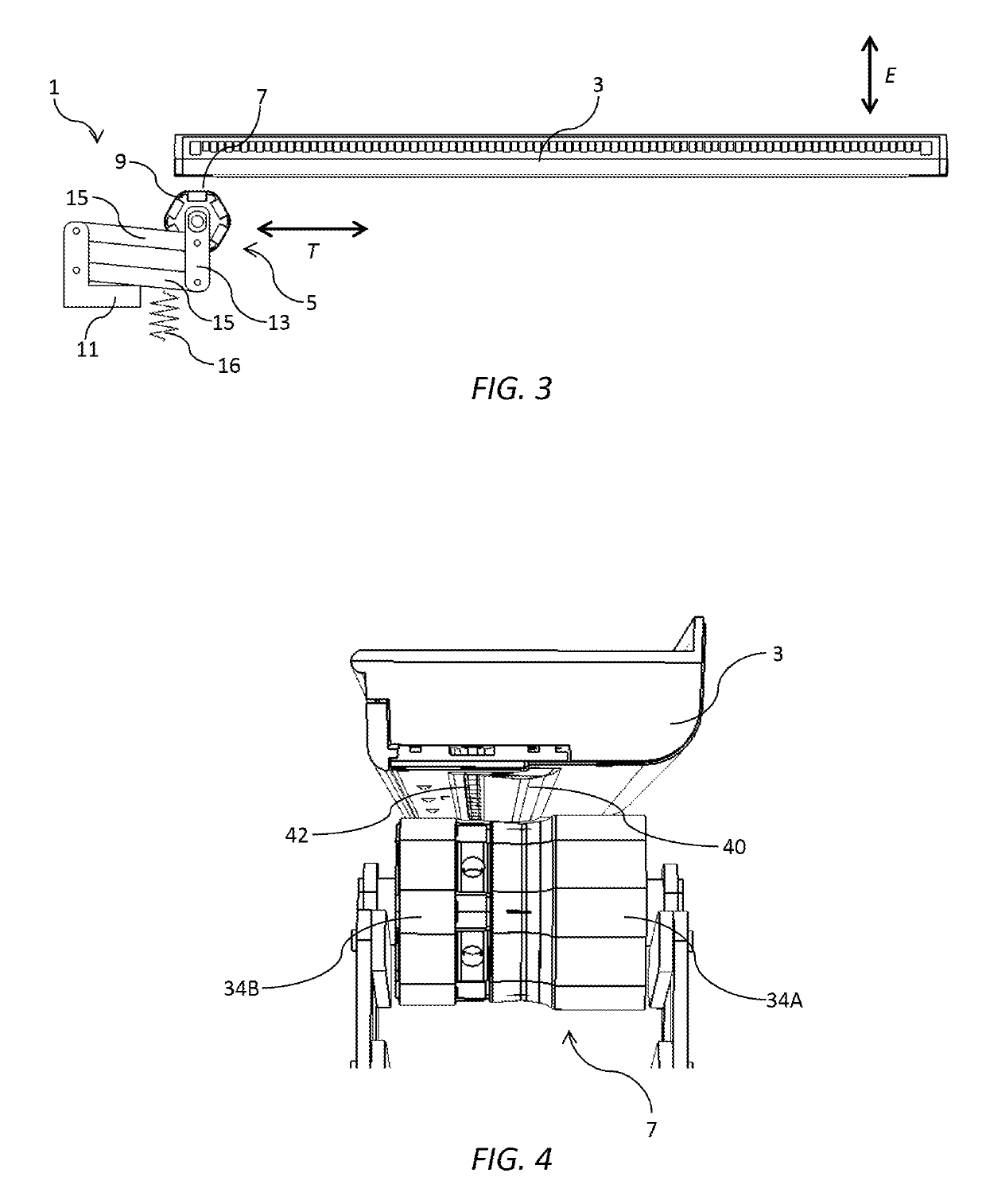

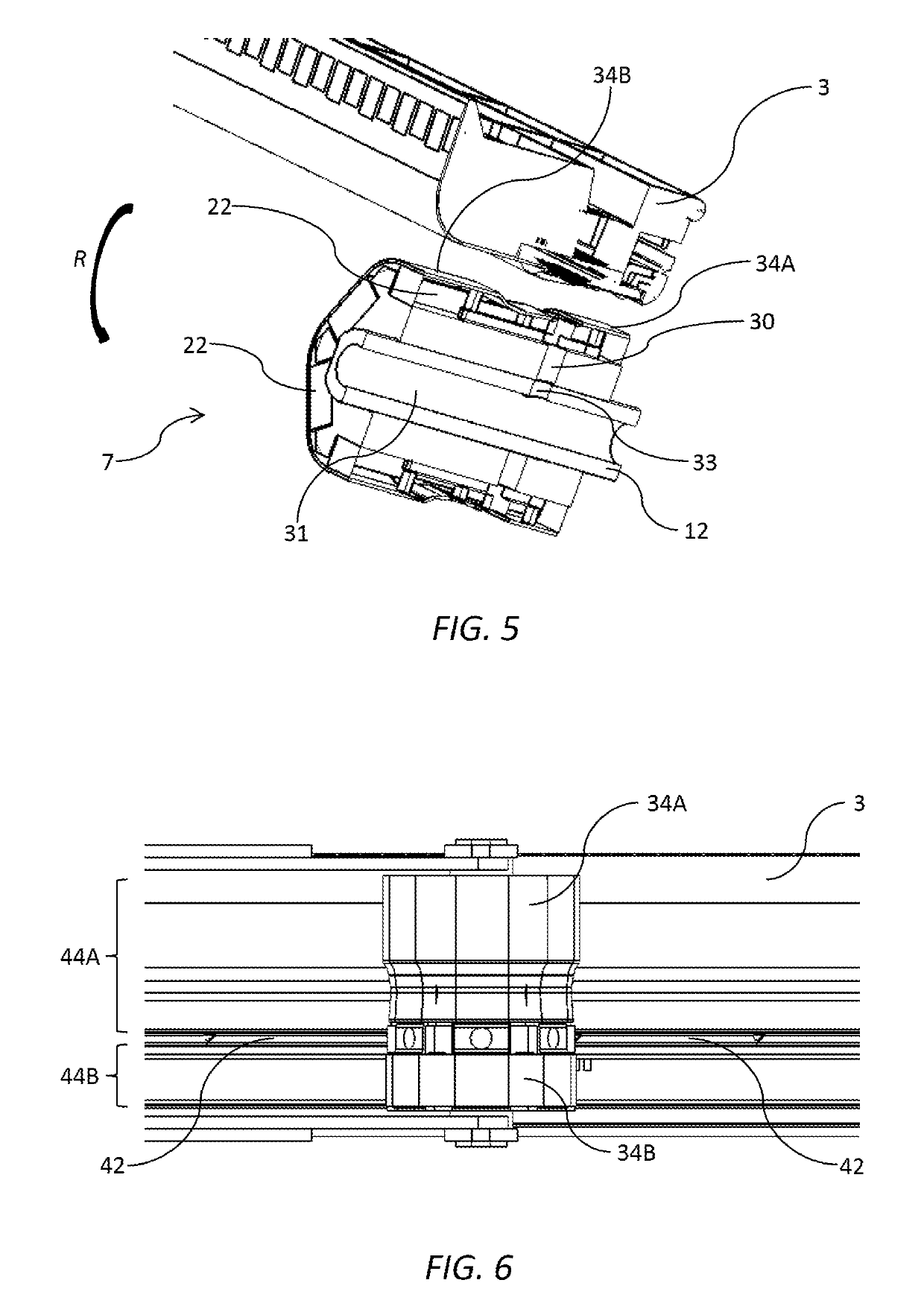

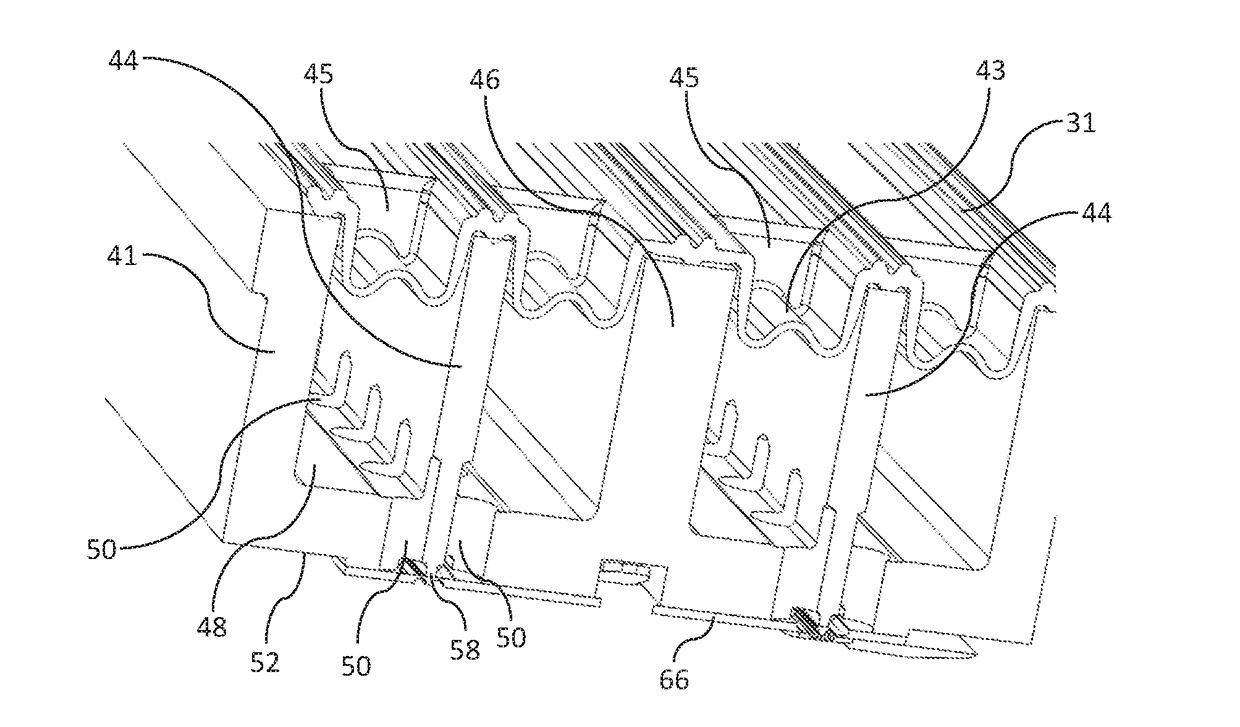

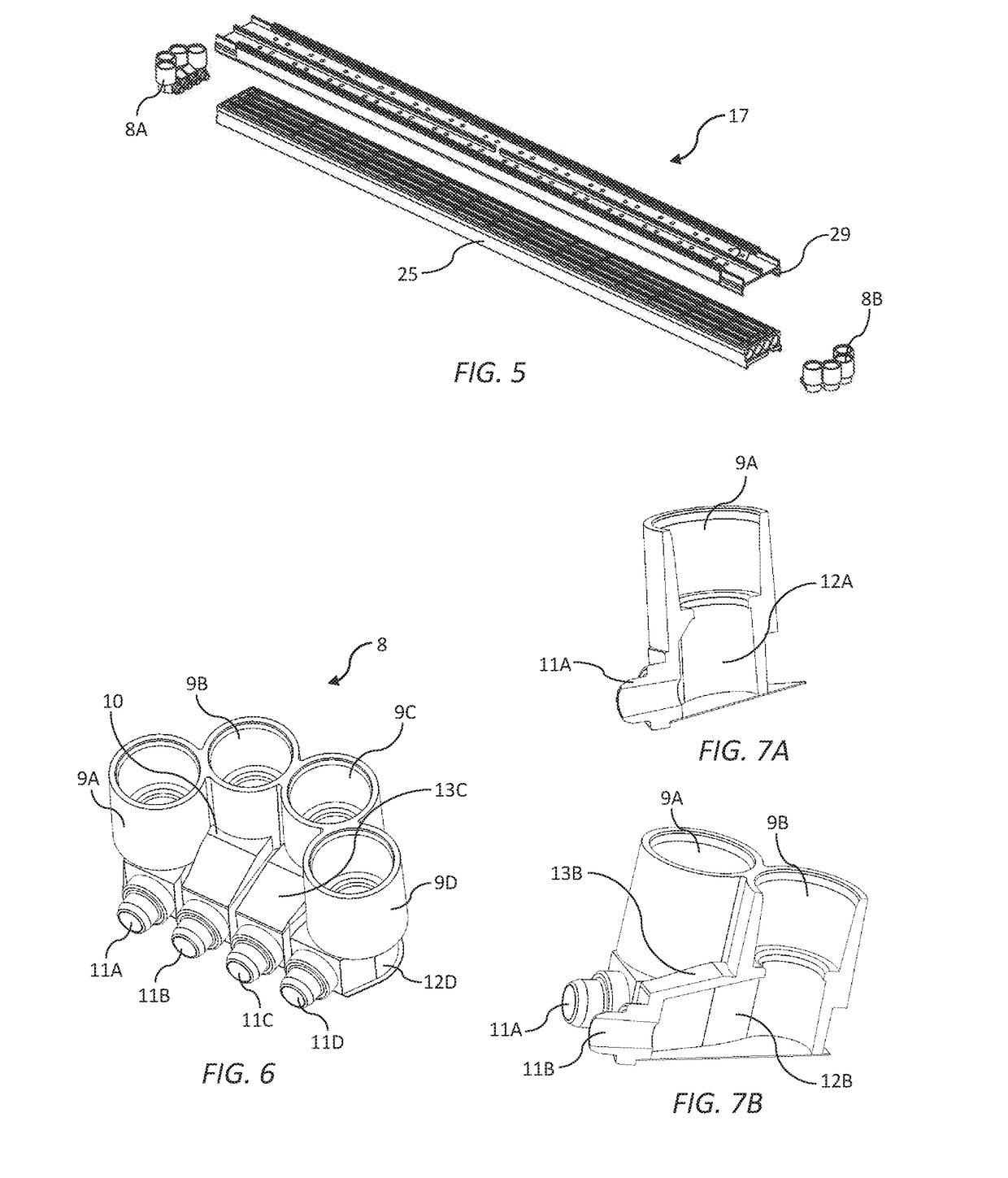

Hybrid printhead maintenance system for wiping and priming

A maintenance system for maintaining an elongate inkjet printhead. The maintenance system includes: a carriage movable longitudinally along the printhead, the carriage including a maintenance member having a primary suction nozzle facing inkjet nozzles of the printhead and a wiper adjacent the primary suction nozzle; a traversing mechanism for traversing the carriage longitudinally along the printhead; and an engagement mechanism for urging the wiper and the printhead into engagement with each other. During use, the wiper contacts a non-printing part of the printhead and the primary suction nozzle is spaced apart from the printhead.

Owner:MEMJET TECH LTD

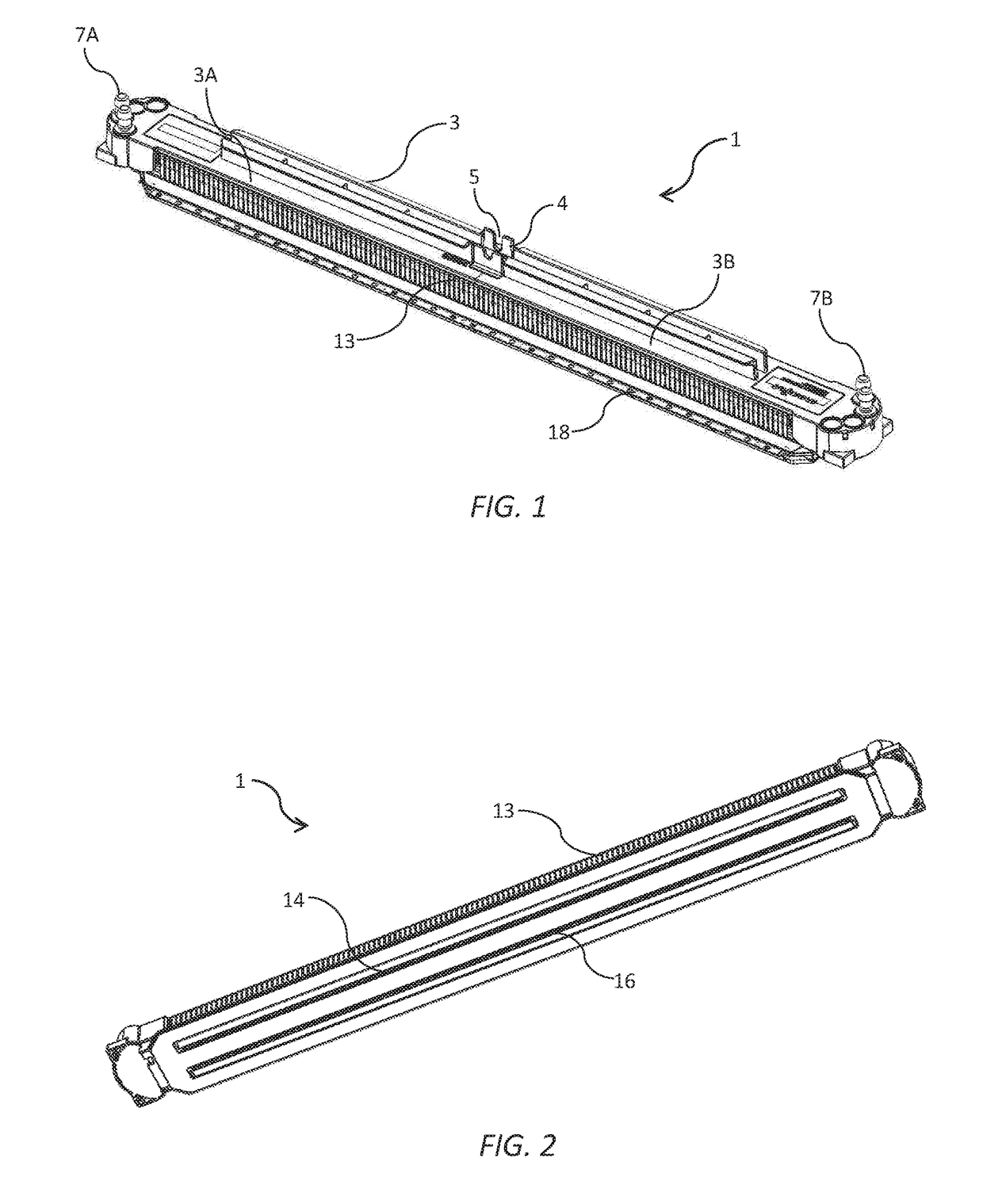

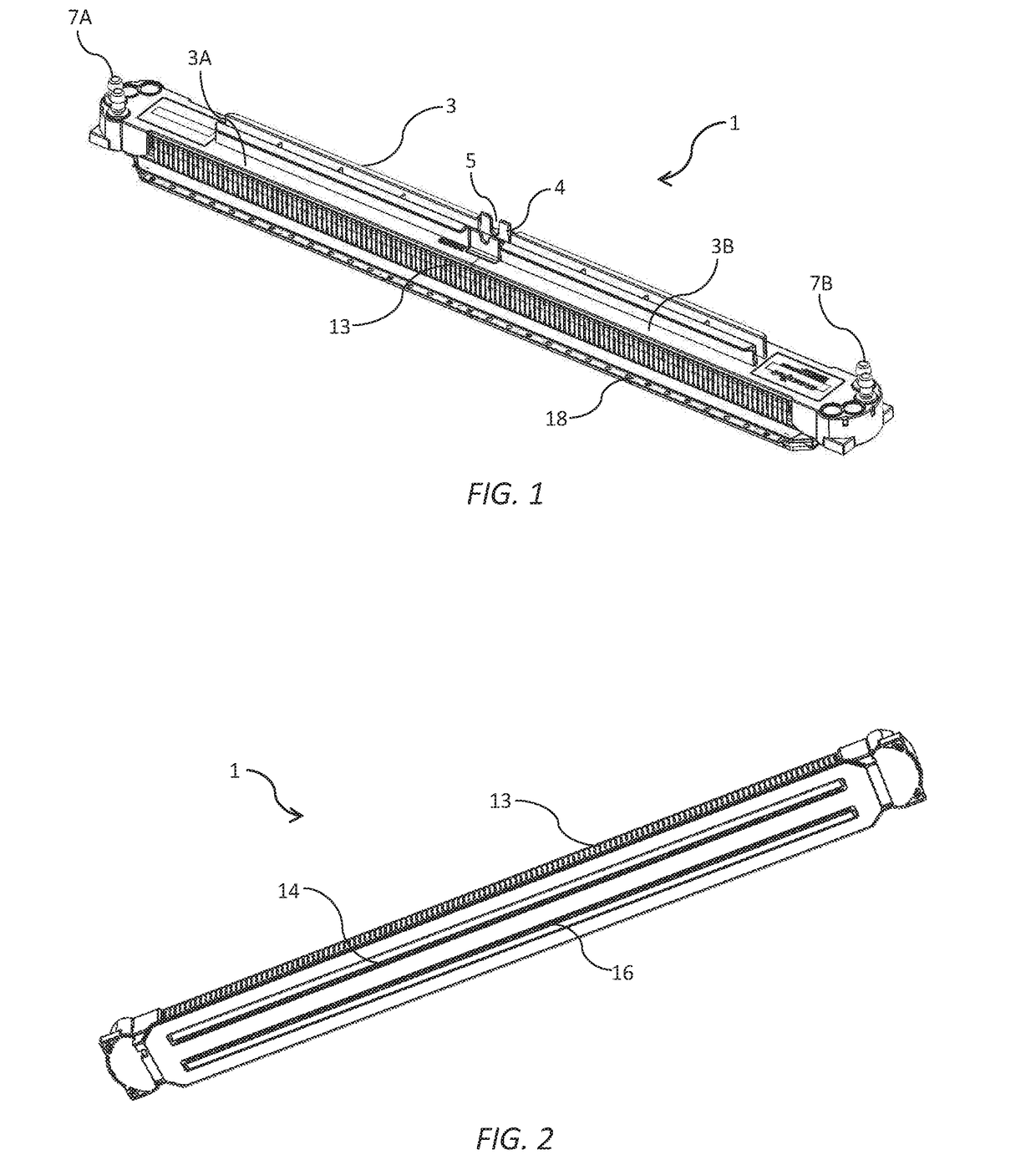

Elongate printhead having robust electrical assembly

ActiveUS20180222190A1Increase distanceMinimize color mixingInking apparatusPower drive mechanismsContact padElectrical connection

An inkjet printhead includes: a rigid elongate carrier having an ink supply channel and a lower surface having a plurality of printhead chips mounted thereon; a rigid PCB attached to the lower surface of the carrier, the PCB extending a length of the carrier and projecting laterally beyond a sidewall of the carrier; a lead retainer attached to the sidewall of the carrier; and a plurality of leads extending upwardly from contact pads positioned along a longitudinal edge portion of the PCB, each lead being secured to the sidewall of the carrier via the lead retainer. The PCB supplies power and data to the printhead chips via electrical connections between the PCB and the printhead chips.

Owner:MEMJET TECH LTD

Inkjet printhead with sealed shield plate

An inkjet printhead includes: a support structure having a plurality of printhead chips mounted thereto; and a shield plate bonded to the support structure, the shield plate having a slot aligned with the printhead chips, the slot having a perimeter edge. A sealant is disposed on all exposed portions of the support structure adjacent the perimeter edge of each slot.

Owner:MEMJET TECH LTD

Printhead having heated shield plate

ActiveUS10239316B2Increase distanceMinimize color mixingInking apparatusPower drive mechanismsThermal contactMechanical engineering

Owner:MEMJET TECH LTD

Printhead chip array having dummy color channel

ActiveUS20180222193A1Easy temperature adjustmentIncrease distanceInking apparatusPower drive mechanismsSpray nozzleEngineering

An inkjet printhead includes: a manifold having a plurality of ink outlets defined in a manifold surface; a plurality of printhead chips mounted to the manifold surface, each printhead chip having an odd number of color channels and each color channel having one or more respective rows of inkjet nozzle devices. A central color channel of each printhead chip is a dummy color channel that does not receive ink from the manifold.

Owner:MEMJET TECH LTD

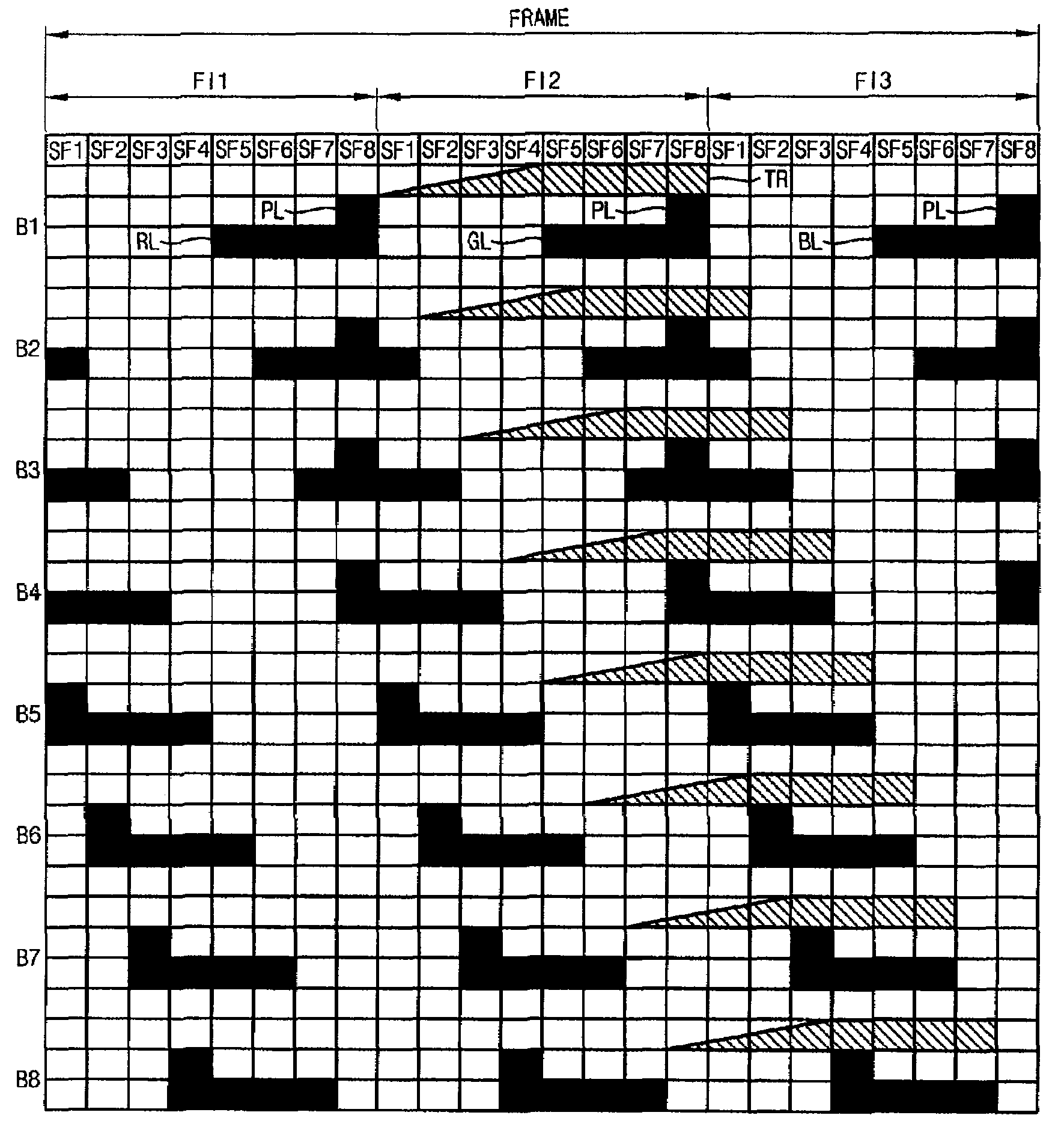

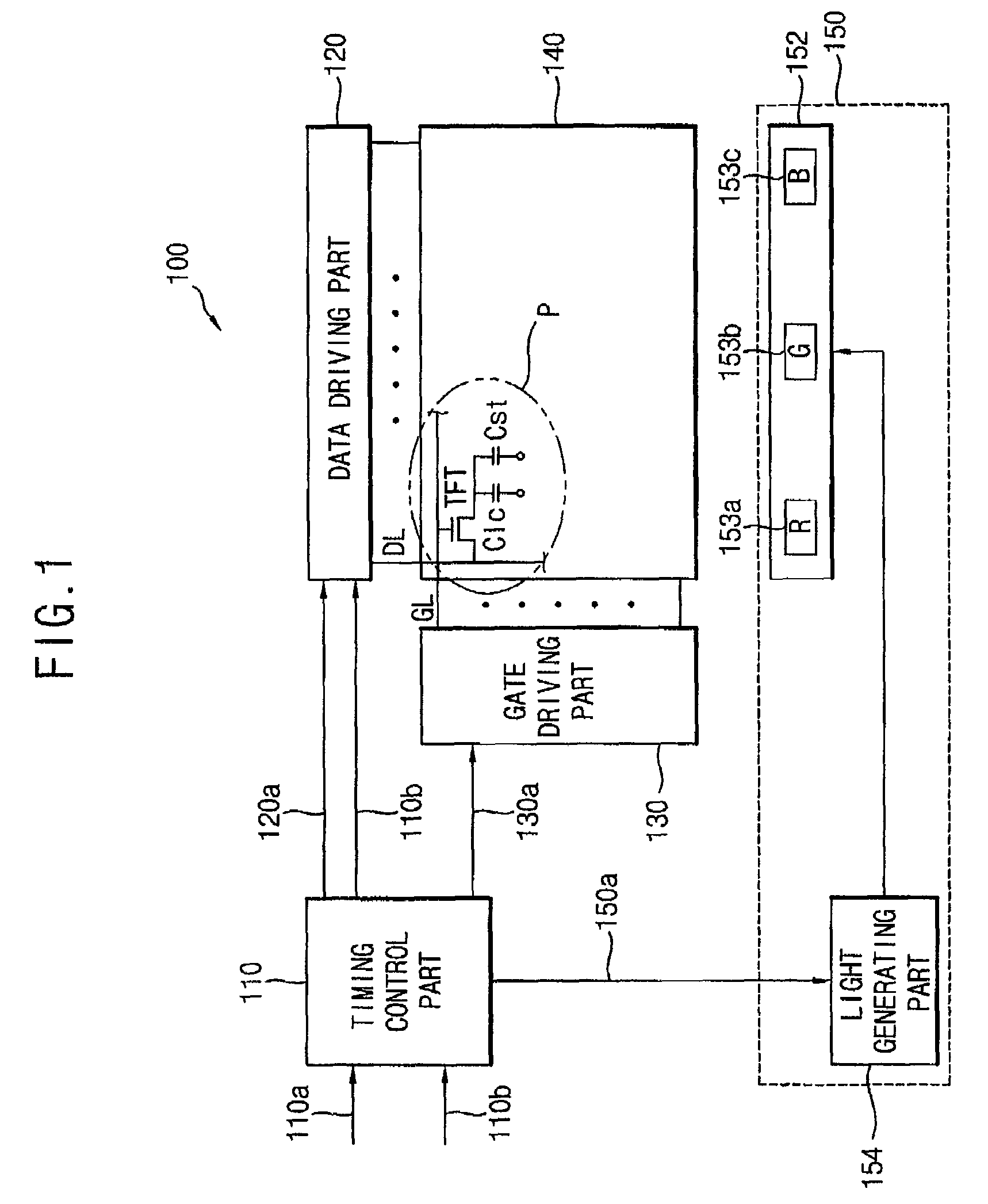

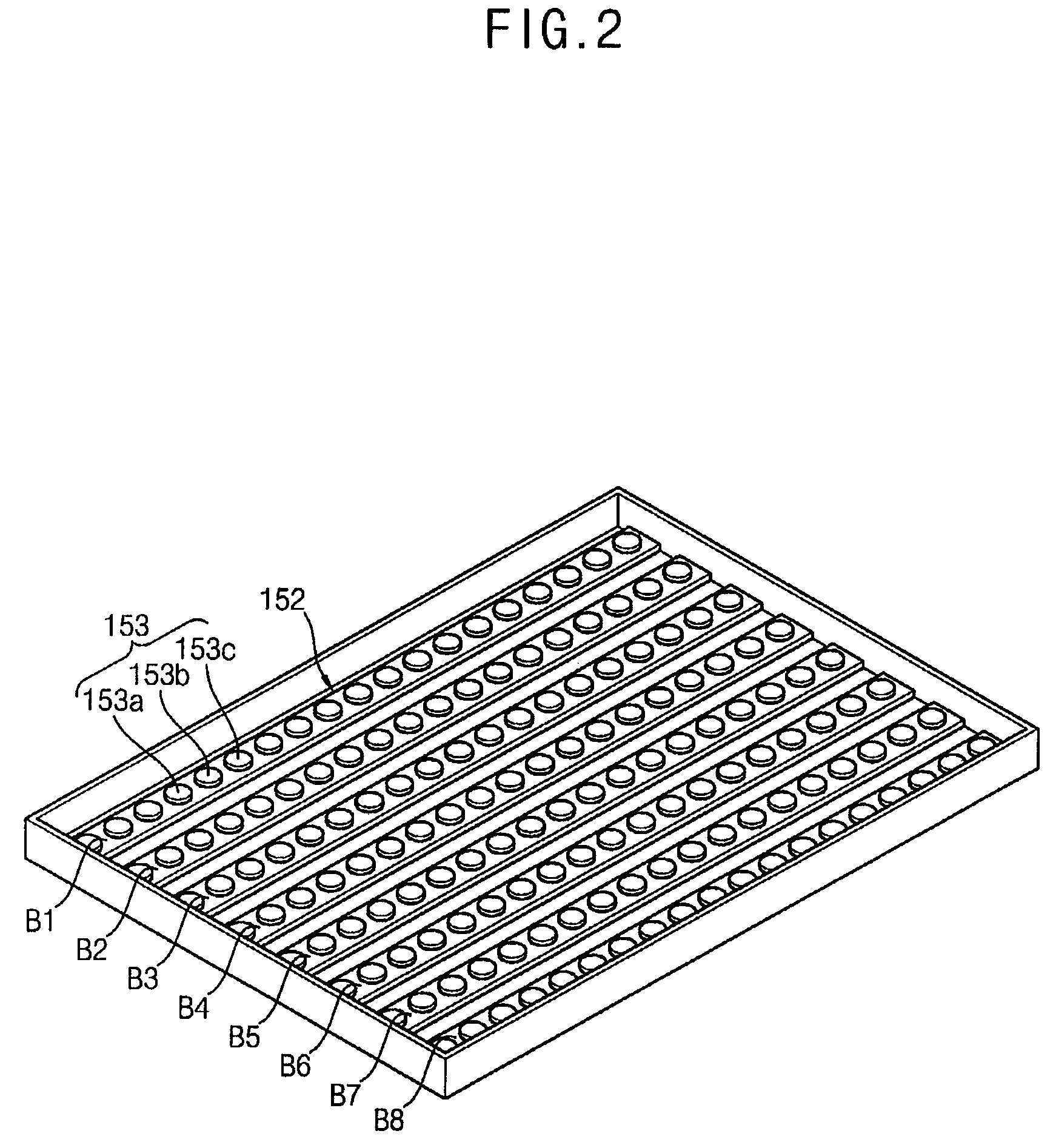

Liquid crystal display apparatus and method of driving the same

ActiveUS7764267B2Minimize color mixingHigh color purityShow cabinetsImpedence networksLiquid-crystal displayEngineering

A liquid crystal display (LCD) apparatus time-divides a frame into a plurality of fields, in which lights having a color different from each other, are generated. The LCD apparatus includes a backlight unit. The backlight unit includes n of light-generating units sequentially generating the lights in the fields. An initial light-generating time of an nth light-generating unit being delayed by a predetermined time gap relative to the (n−1)th light-generating unit so that each of the fields includes a first period, in which one of the lights is generated, and a second period, in which at least two of the lights are generated. The light-generating units generate a peak light having a peak intensity in the first period. Thus, the intensity of light or the time period for which the light is generated, is controlled so that color mixing is minimized and color purity is improved.

Owner:SAMSUNG DISPLAY CO LTD

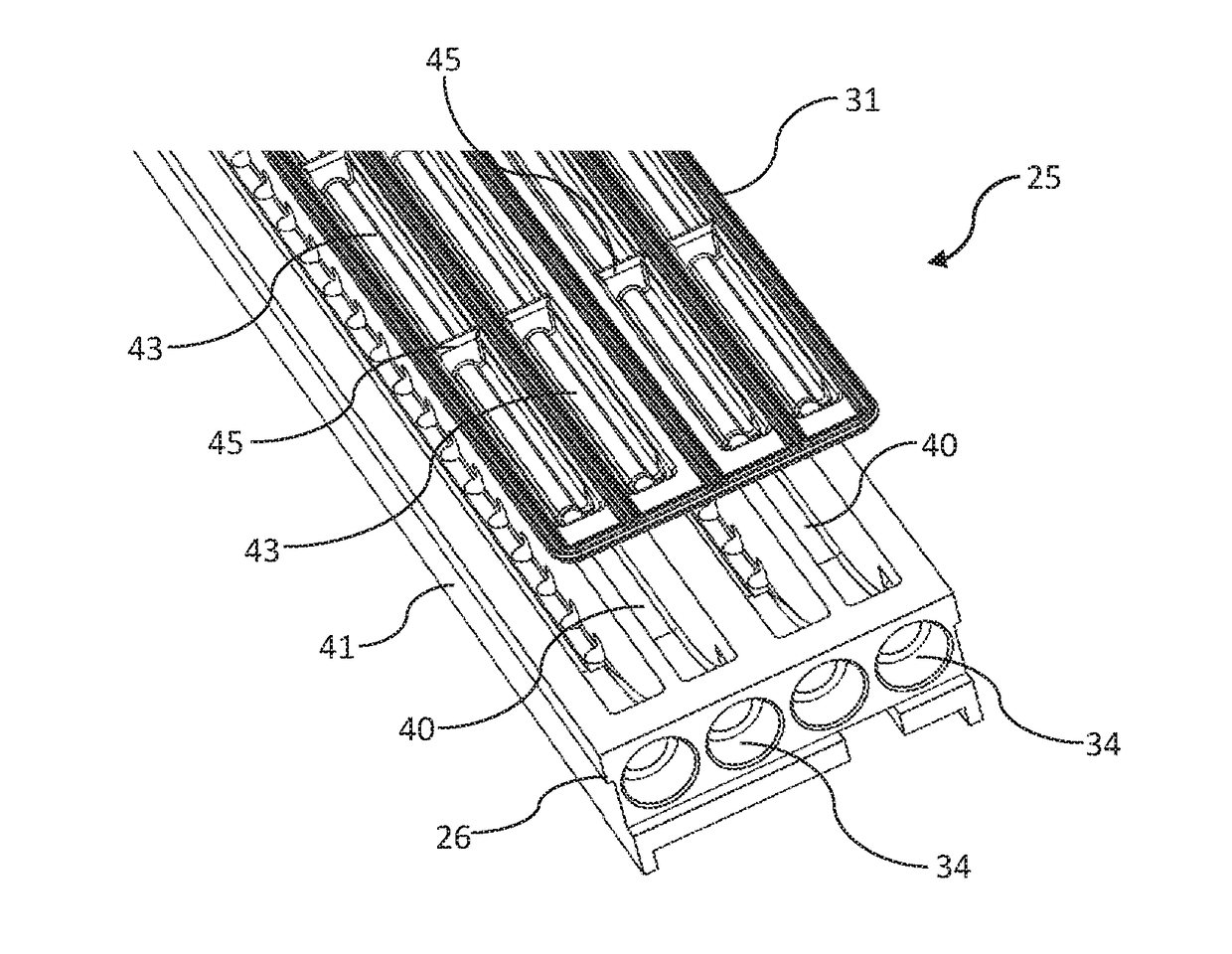

Bubble-tolerant high flow printhead architecture

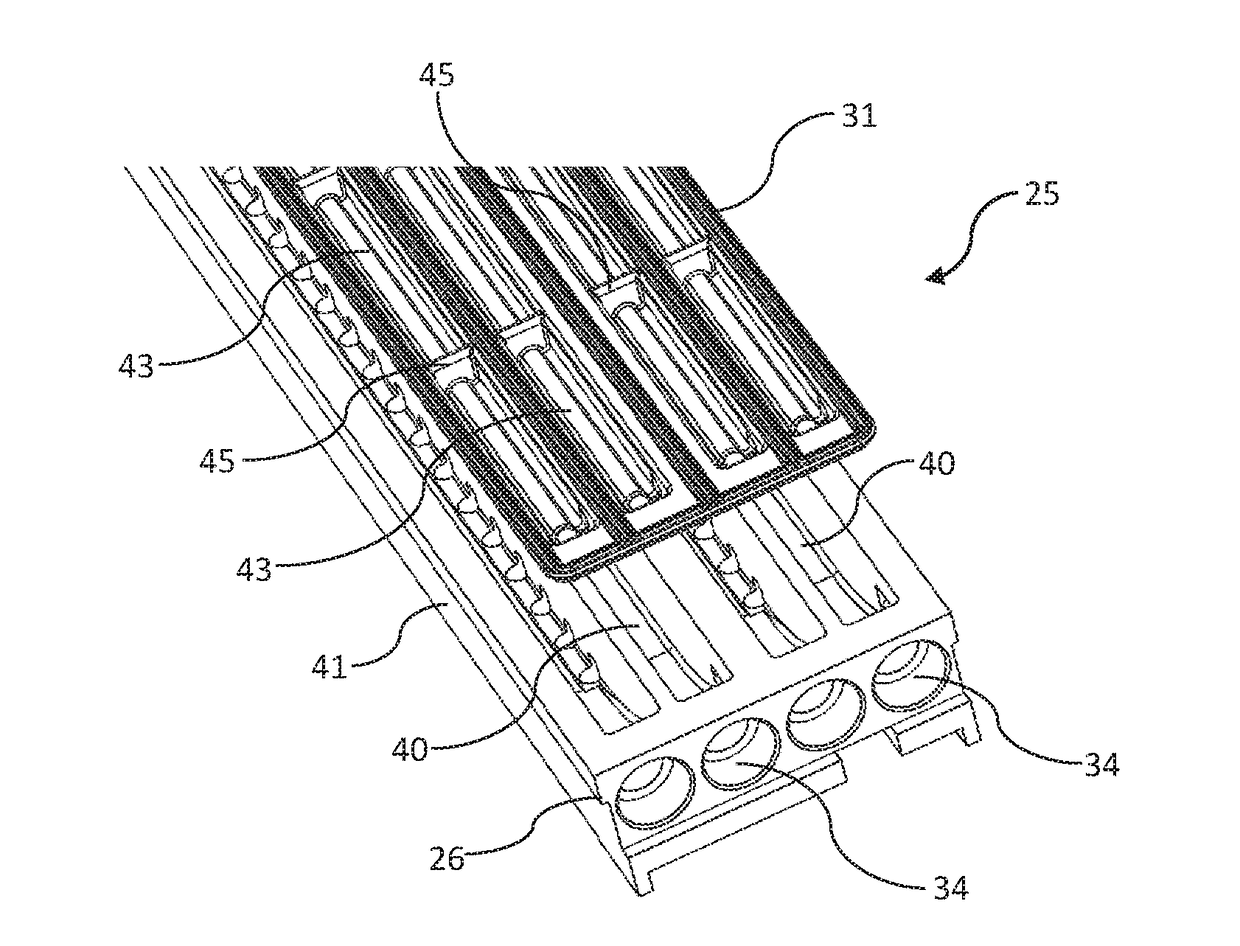

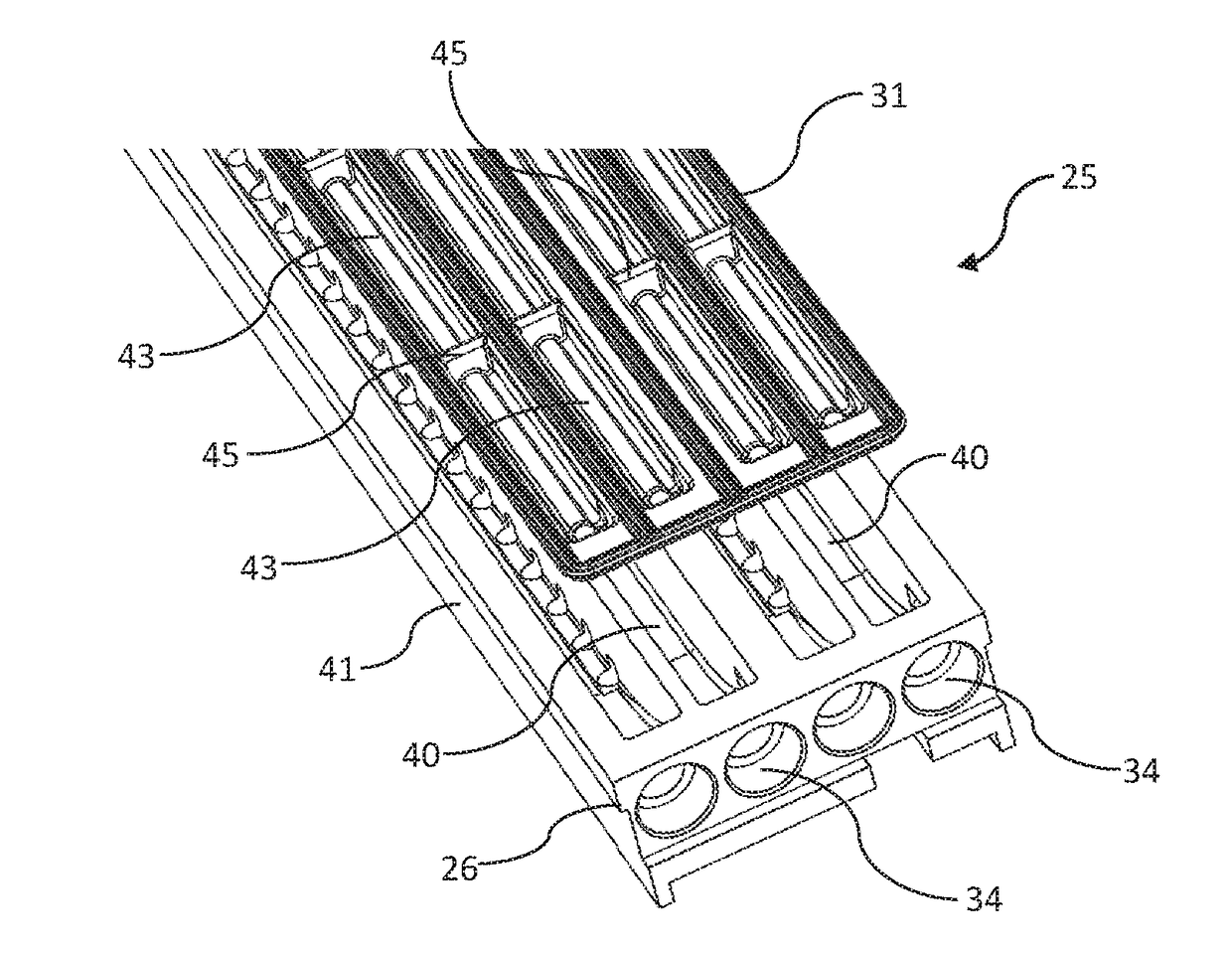

ActiveUS20180222227A1Facilitates temperature regulationIncrease distanceInking apparatusPower drive mechanismsEngineeringGasket

Owner:MEMJET TECH LTD

Dual-color coating of optical fibers with UV curable inks

ActiveUS9517971B2Minimize color mixingCladded optical fibreOptical waveguide light guideFiberChemistry

A method of coating a silica-silica optical fiber, comprising, in a single pass on a fiber coating machine: applying a primary layer of UV curable acrylate carrying a first color, on said fiber; and applying a second layer of UV curable acrylate carrying a second color different from the first color, on top of the primary layer, the second layer being applied in patterns over the primary layer. The method is used to identify fibers in bundles or loose tubes where there are more fibers than there are basic colors.

Owner:TELDOR CABLES & SYST

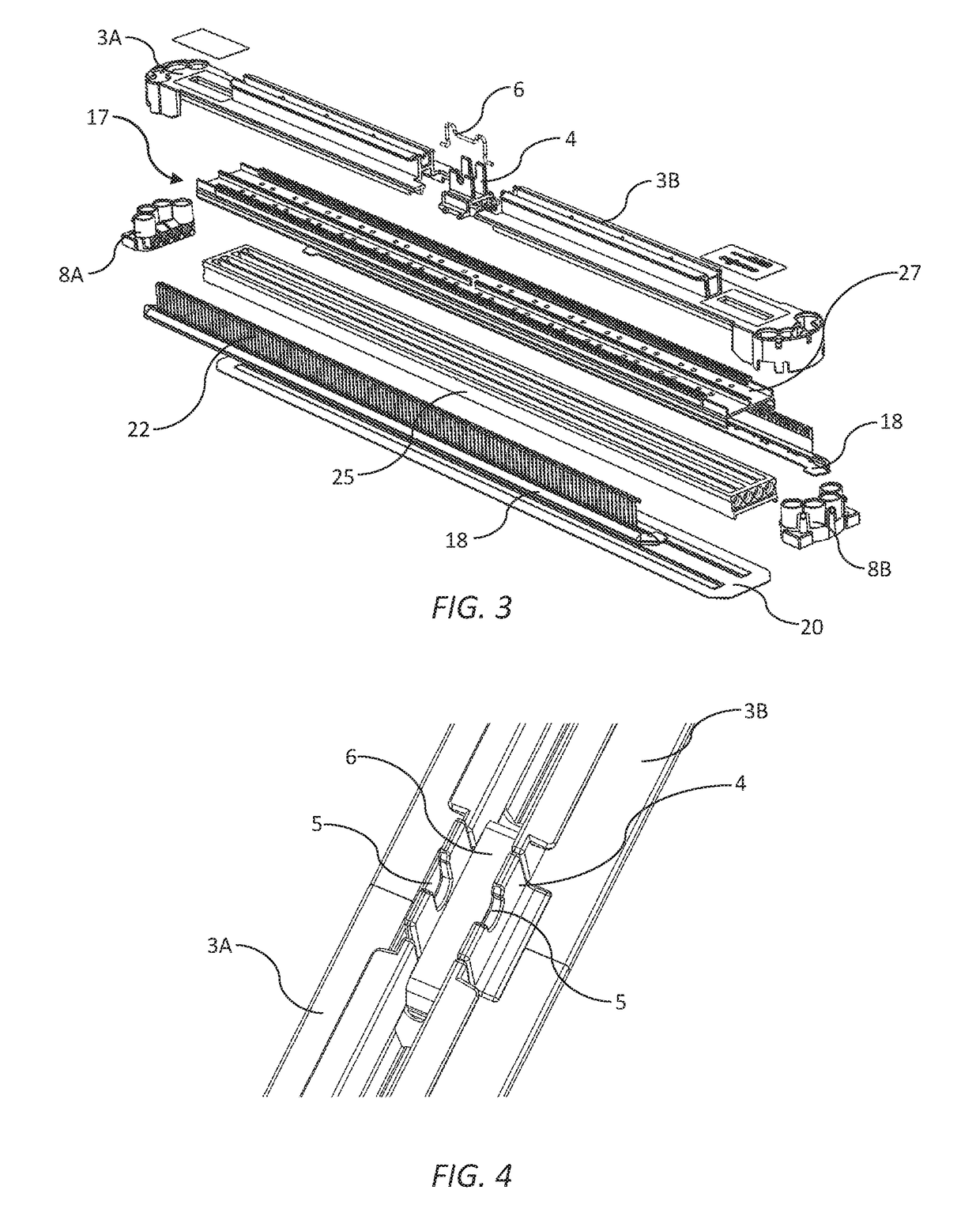

Printhead having heated shield plate

ActiveUS20180222226A1Easy temperature adjustmentIncrease distanceInking apparatusPower drive mechanismsEngineeringMechanical engineering

An inkjet printhead includes: a manifold having a plurality of ink outlets defined in a manifold surface; a plurality of printhead chips mounted to the manifold surface and aligned with the ink outlets; a PCB mounted to the manifold surface and offset from the ink outlets, the PCB being electrically connected to the printhead chips; and a shield plate covering the PCB. The shield plate has one face in thermal contact with the PCB and an exposed opposite face defining a lower surface of the printhead.

Owner:MEMJET TECH LTD

Method of fabricating inkjet printhead with projections patterned across nozzle plate

InactiveUS20090065475A1Prevent backflowMinimize color mixingPrinted circuit assemblingRecording apparatusParticulatesEngineering

A method of fabricating an inkjet printhead. The method includes the steps of: (a) forming a plurality of MEMS ink ejection assemblies on an ink-ejection surface of a silicon substrate, each ink ejection assembly being sealed with roof material spanning across the ink ejection assemblies to define a nozzle plate; (b) etching partially into the roof material to form simultaneously a respective nozzle rim for each ink ejection assembly and a plurality of projections patterned across the nozzle plate between nozzle rims; and (c) etching through the roof material to form a respective nozzle aperture for each ink ejection assembly. The projections patterned across the nozzle plate between nozzle rims are useful for reducing stiction between particulates and the nozzle plate.

Owner:SILVERBROOK RES PTY LTD +1

Strain-relieved printhead casing

ActiveUS20180222192A1Increase distanceMinimize color mixingInking apparatusPower drive mechanismsEngineering

A printhead cartridge includes: an elongate manifold; a plurality of printhead chips mounted to a lower part of the manifold; and a casing mounted to an upper part of the manifold. The casing includes a first casing part and a second casing part, the first and second parts being longitudinally biased towards each such that the casing is expandable along a longitudinal axis of the manifold.

Owner:MEMJET TECH LTD

Metal alloy shim for mounting printhead chips with high bonding strength

ActiveUS20180370223A1Stable structureGood flexibilityInking apparatusPower drive mechanismsMetal alloyEngineering

An inkjet printhead includes: a rigid elongate manifold having ink supply channels extending along its length and a plurality of ink outlets defined therein; a shim attached to the manifold, the shim having a plurality of shim apertures for receiving ink from the ink outlets; and a plurality of printhead chips adhesively bonded directly to the shim, each printhead chip receiving ink from one or more of the ink outlets. The shim is formed of a metal alloy having a CTE of 5 ppm / ° C. or less and includes an adhesion-promoting surface film layer.

Owner:MEMJET TECH LTD

Inkjet printhead with sealed shield plate

ActiveUS10870278B2Increase distanceMinimize color mixingInking apparatusStructural engineeringMechanical engineering

Owner:MEMJET TECH LTD

Metal alloy shim for mounting printhead chips with high bonding strength

ActiveUS10363736B2Increase distanceMinimize color mixingInking apparatusPower drive mechanismsMetal alloyEngineering

An inkjet printhead includes: a rigid elongate manifold having ink supply channels extending along its length and a plurality of ink outlets defined therein; a shim attached to the manifold, the shim having a plurality of shim apertures for receiving ink from the ink outlets; and a plurality of printhead chips adhesively bonded directly to the shim, each printhead chip receiving ink from one or more of the ink outlets. The shim is formed of a metal alloy having a CTE of 5 ppm / ° C. or less and includes an adhesion-promoting surface film layer.

Owner:MEMJET TECH LTD

Printer for minimizing adverse mixing of high and low luminance inks at nozzle face of inkjet printhead

ActiveUS8702206B2Suitable for MEMS fabricationMinimize color mixingInking apparatusInksInk printerEngineering

An inkjet printer includes an inkjet printhead having a plurality of color planes for ejecting a plurality of different inks. Each color plane has a nozzle row defined in a nozzle face of the printhead and each nozzle in a respective color plane is supplied with a same ink. The printhead is plumbed such that a first color plane ejecting a first ink having a relatively low luminance is sandwiched between second and third color planes ejecting respective second and third inks having a relatively high luminance. A plurality of ink reservoirs are in fluid communication with the printhead, the ink reservoirs containing the first, second and third inks. An amount of surfactant in the first ink is at least 0.4 wt % greater than an amount of surfactant in the second and third inks.

Owner:MEMJET TECH LTD

Inkjet printhead having dynamic response to pressure changes

ActiveUS20180222200A1Easy temperature adjustmentIncrease distanceInking apparatusPower drive mechanismsEngineeringBellows

An inkjet printhead includes: a rigid elongate manifold having one or more ink supply channels extending along its length, each ink supply channel having a base defining a plurality of ink outlets and a roof comprising an elongate flexible film; and a plurality of printhead chips mounted to the manifold, each printhead chip receiving ink from one or more of the ink outlets The flexible film includes a plurality of operatively independent bellows positioned along a length of one or more ink supply channels.

Owner:MEMJET TECH LTD

Method of manufacturing inkjet printhead

ActiveUS10525701B2Increase distanceMinimize color mixingInking apparatusPower drive mechanismsMetal alloyStructural engineering

A method of forming an inkjet printhead. The method includes the steps of: providing a metal alloy shim having a plurality of shim apertures; nitriding a surface of the shim; bonding the shim to a rigid elongate manifold having ink supply channels, such that each shim aperture is in fluid communication with a respective ink supply channel; and bonding printhead chips to the shim, thereby forming the inkjet printhead.

Owner:MEMJET TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com