Preparation method and product of full-color carbon dots for multi-color fluorescent printing

A technology of carbon dots and fluorescence, applied in chemical instruments and methods, applications, household appliances, etc., can solve the problems of difficulty in obtaining long-wavelength fluorescent carbon dots, low fluorescence quantum yield of carbon dots, and difficulties in product separation and purification. Achieve excellent stability and practicability, simple preparation method, and strong fluorescence emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

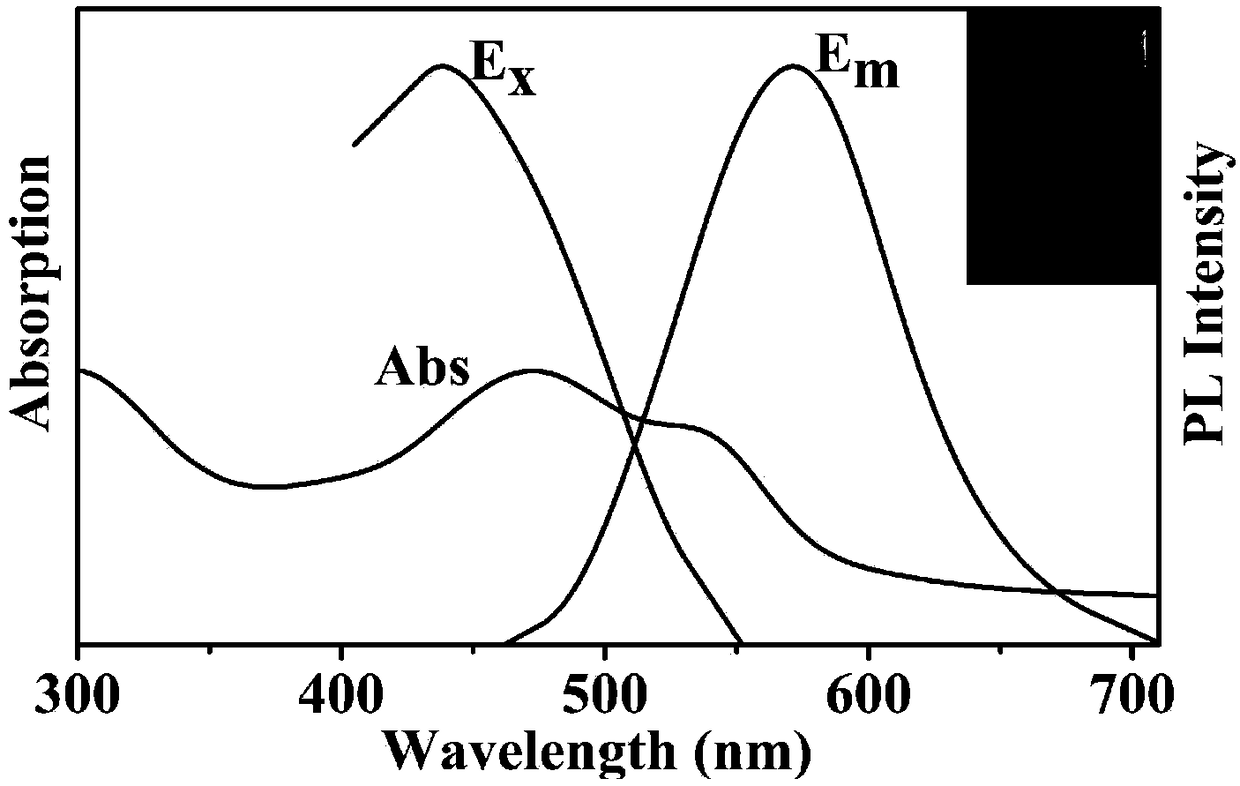

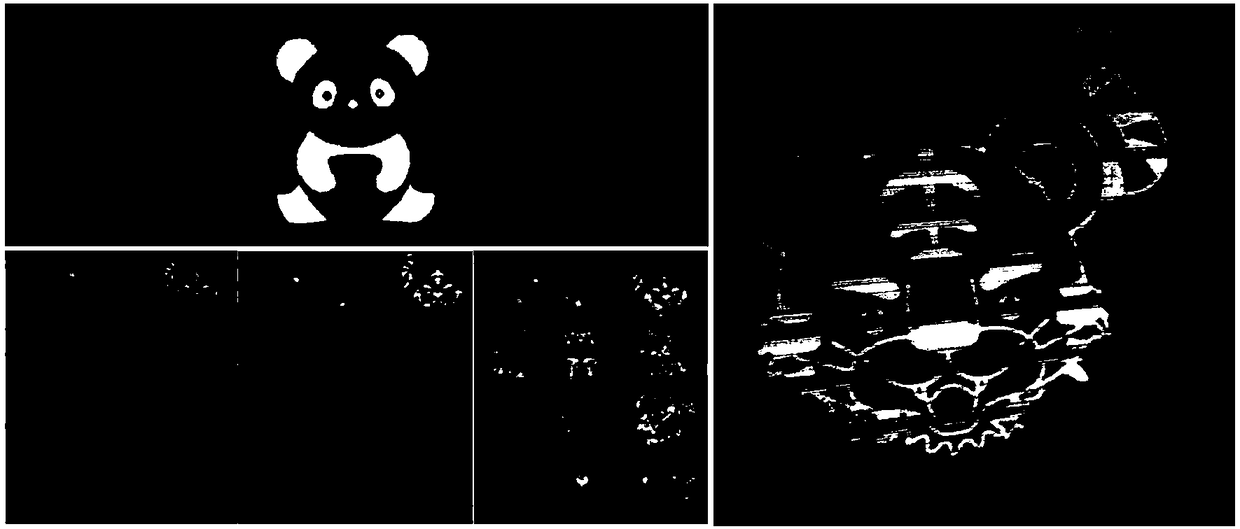

Embodiment 1

[0034] Weigh 1g of citric acid and 2g of urea and dissolve them in 10mL of DMF, stir evenly, transfer the transparent solution to a 15mL stainless steel reaction kettle, seal it, put it in an oven, and heat it at 180°C for 6h to obtain Black carbon dot mixed solution. Centrifuge the resulting mixed solution of carbon dots at 9000rpm for 20min, remove the large black precipitate, use column chromatography to finely separate the mixed solution of carbon dots in the upper layer, and use the mixed solution of methanol and dichloromethane as the eluent agent, adjust the volume ratio (1:1-15) of the two, and a single blue, green, yellow and orange-red luminescent carbon dot solution can be obtained. The specific operation process is as follows: fill the chromatographic column with ordinary silica gel, add the mixed sample, rinse the sample with 100mL 1:15 eluent, then increase the polarity of the eluent, and use 100mL 1:12,1: 10. Rinse with 1:8 eluent. At this time, blue and green ...

Embodiment 2

[0039]Weigh 1g of citric acid and 2g of urea and dissolve them in 10mL of DMSO. After stirring evenly, transfer the transparent solution to a 15mL stainless steel reaction kettle. Black carbon dot mixed solution. The obtained mixed solution of carbon dots was centrifuged at 9000rpm for 20min, and after removing the large black precipitate, the mixed solution of carbon dots in the upper layer was finely separated by column chromatography. At this time, the mixed solution of methanol and dichloromethane is used as the eluent, and the volume ratio (1:1-15) of the two is regulated. The separation process is the same as in Example 1, and a single blue, green, yellow and orange-red can be obtained. Luminescent carbon dot solution. Finally, the eluent was removed by rotary evaporation to obtain a solid product.

[0040] The orange-red luminescent carbon dots were redispersed in water to prepare a solution with a carbon dot concentration of 1 mg / mL, and the quantum yield of the oran...

Embodiment 3

[0042] Weigh 1g of citric acid and 2g of urea and dissolve them in 10mL of acetone. After stirring evenly, transfer the transparent solution to a 15mL stainless steel reaction kettle. Dark brown carbon dot mixed solution. The obtained mixed solution of carbon dots was centrifuged at 9000rpm for 20min, and after removing the large black precipitate, the mixed solution of carbon dots in the upper layer was finely separated by column chromatography. At this time, the mixed solution of methanol and dichloromethane was used as the eluent, and the volume ratio of the two was adjusted (1:1-15). The separation process was the same as in Example 1, and a single blue and green luminescent carbon dot solution could be obtained. Finally, the eluent was removed by rotary evaporation to obtain a solid product.

[0043] Redisperse the blue and green luminescent carbon dots in water to prepare a solution with a carbon dot concentration of 1 mg / mL. The measured quantum yield of green lumines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com