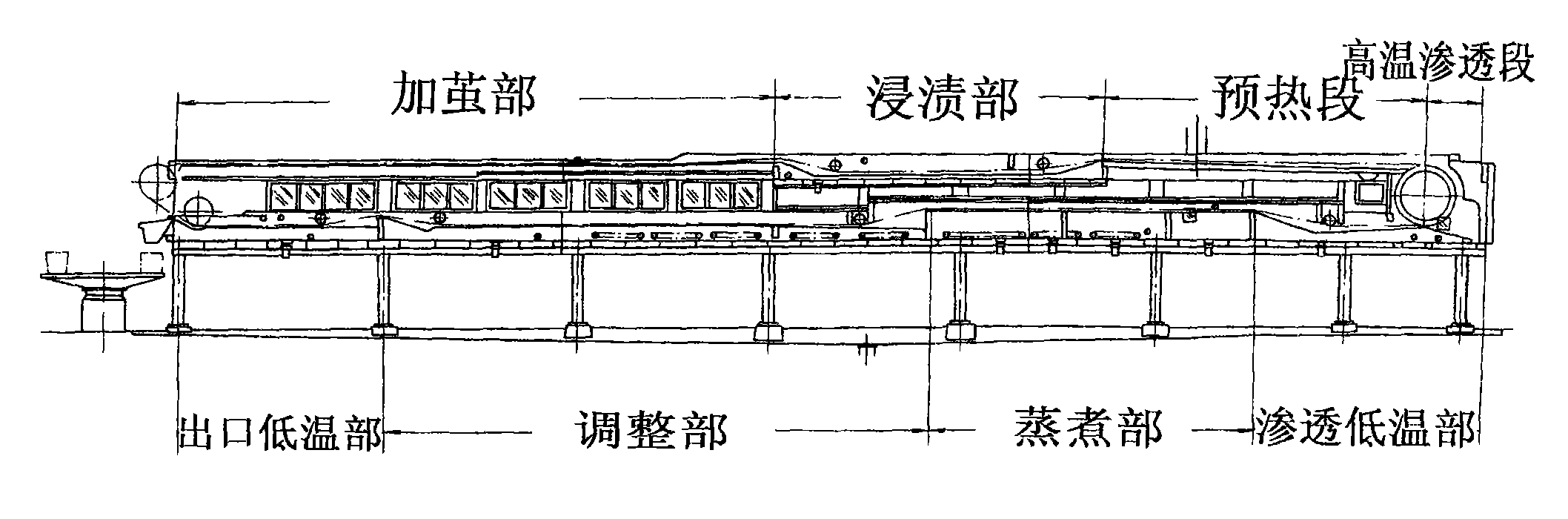

Steam cooking process for cocoon cooking and device thereof

A process and cocoon cooking technology, applied in silk fiber production, textile and papermaking, mechanical processing and other directions, can solve the problems of complex structure of cocoon cooking machine, unfavorable popularization and application, occupying a high space, etc. The effect of uniform cooking and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

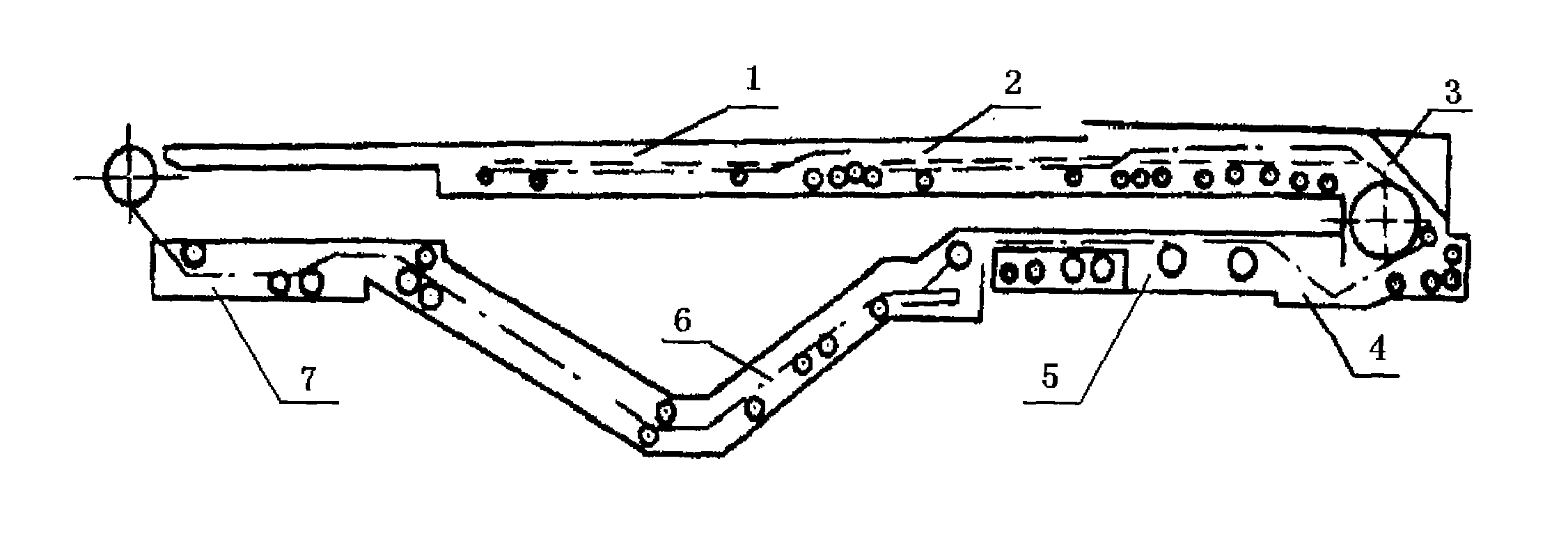

Method used

Image

Examples

Embodiment

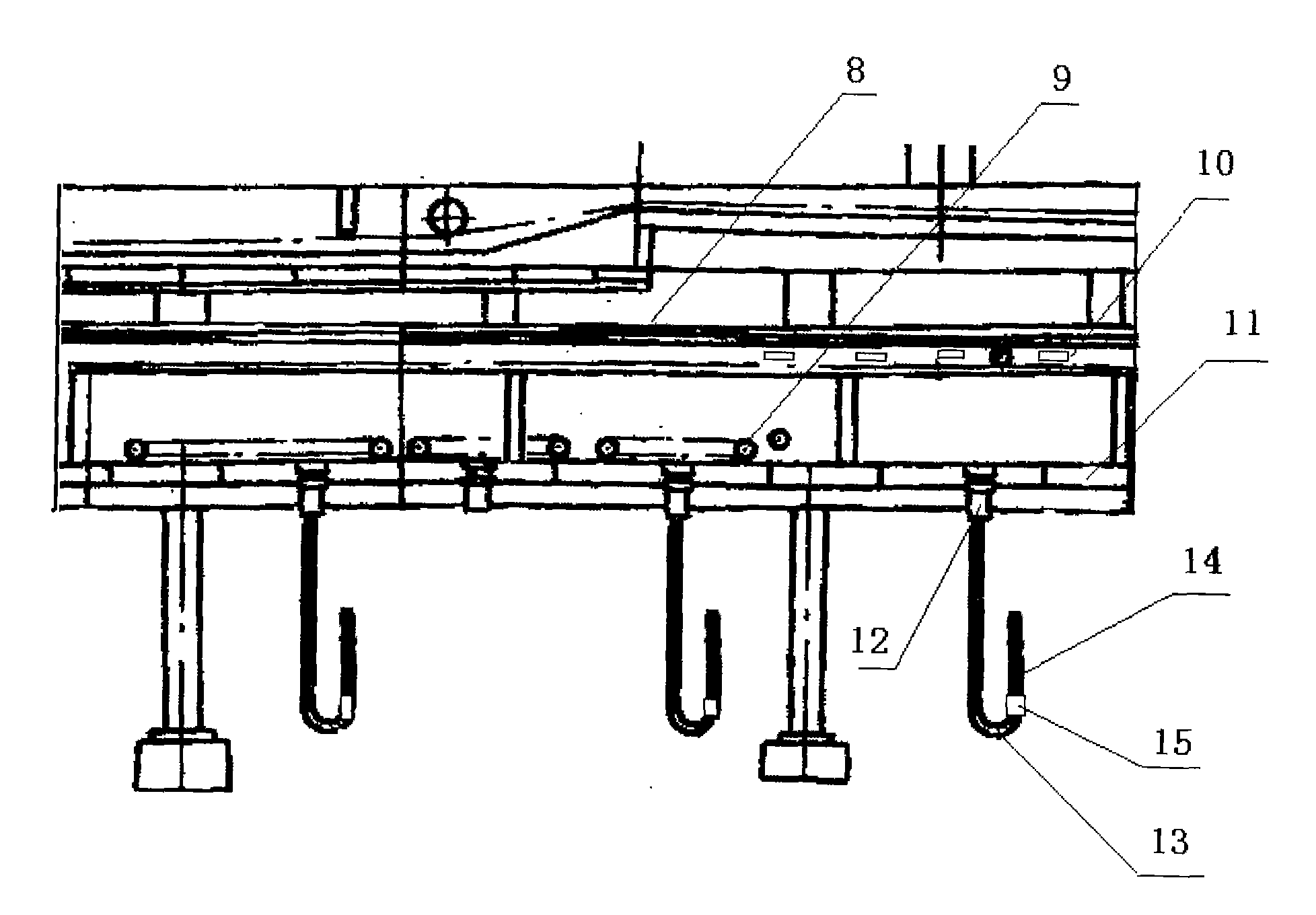

[0019] See attached image 3 , which is a schematic structural view of the cooking section of the cocoon cooking machine in this embodiment, the length of the cooking section is increased from 11.5 cages (cocoon cooking cage) in the prior art to 15.5 cages, and the elongation rate is 34.8%. Its cooking section includes a cooking section upper cover plate 8, a heater 9, a cooking section bottom 11, a drain pipe 12 and a booster. The pressurization device includes a U-shaped pipe 13 , a straight pipe 14 and a joint 15 . The cocoon cooking temperature in the cooking section of this embodiment is divided into 3 sections. The temperature of each section in the cooking section of the cocoon cooking machine, the heater composed of installed hole pipes and blind pipes, is controlled according to the requirements of the process. Adjacent sections The temperature difference is 2 ~ 10 ℃. There is a drain port at the bottom of each temperature section. After connecting the drain pipe, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com