Method for pretreating fresh cocoon

A pretreatment and fresh cocoon technology, which is applied in mechanical treatment, fiber treatment, silk fiber production, etc., can solve the problems of unfavorable perennial silk reeling, large cold storage, and short shelf life of fresh cocoons, so as to reduce the roughness of silk cocoons and improve The effect of relaxation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

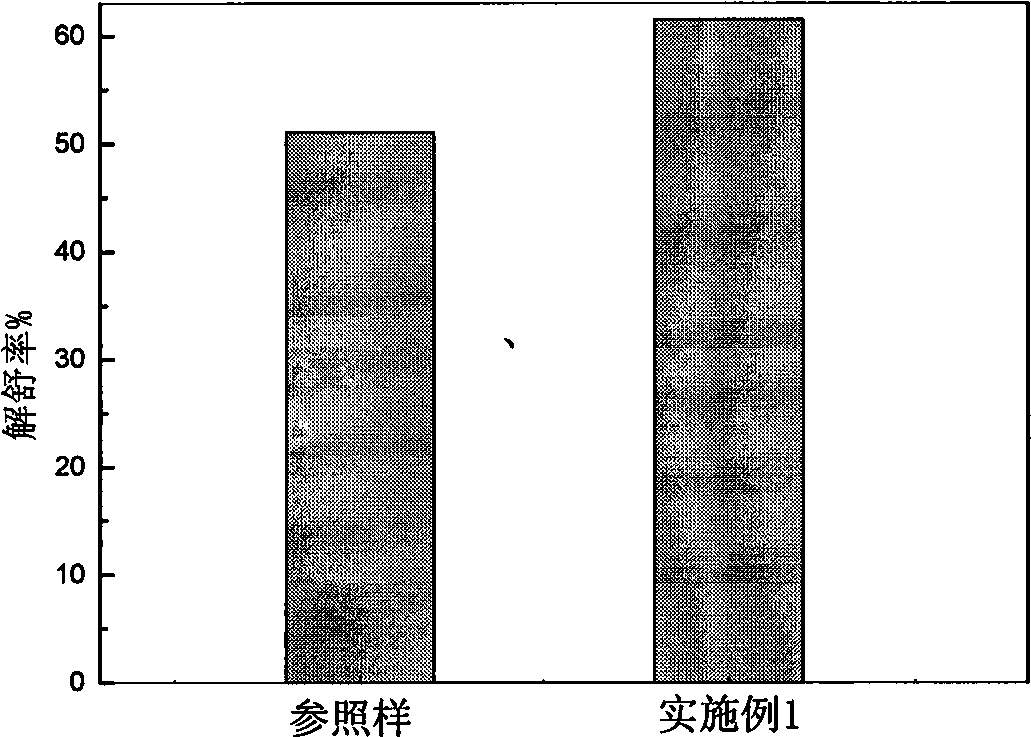

[0018] Select the spring cocoons from Jiaxing, Zhejiang, transfer them to the conveyor belt, and bring the fresh cocoons into the ambient temperature of -2°C through the conveyor belt. After 0.15 hours, enter the ambient temperature of -10°C. After 2 hours, enter the ambient temperature of 0 In the ambient temperature of ℃, after 0.15 hours, enter the normal temperature environment, and after 8 hours of natural equilibrium, carry out conventional hot air drying. As a comparison, silkworm cocoons from Tongzhuangkou were selected, and conventional hot air drying was performed directly without pretreatment. All the quality indexes of the obtained silkworm cocoons were significantly improved compared with the reference sample, especially the improvement of the unwinding rate was obvious, such as figure 1 shown.

Embodiment 2

[0020] Select fresh cocoons in late autumn from Jiaxing, Zhejiang, transfer them to the conveyor belt, and then bring the fresh cocoons into the ambient temperature of -4°C through the conveyor belt. After 0.25 hours, enter the ambient temperature of -5°C. After 15 hours, enter the 2 In the ambient temperature of ℃, after 0.5 hours, enter the normal temperature environment, and after 2 hours of natural equilibrium, dry the cocoons with superheated steam. As a comparison, the silkworm cocoons from Tongzhuangkou were selected, and the cocoons were directly dried by superheated steam without pretreatment, and the silkworm cocoons were used as a reference sample. The comparison results of the 10,000-meter roughness of the cocoons obtained are as follows: figure 2 shown.

Embodiment 3

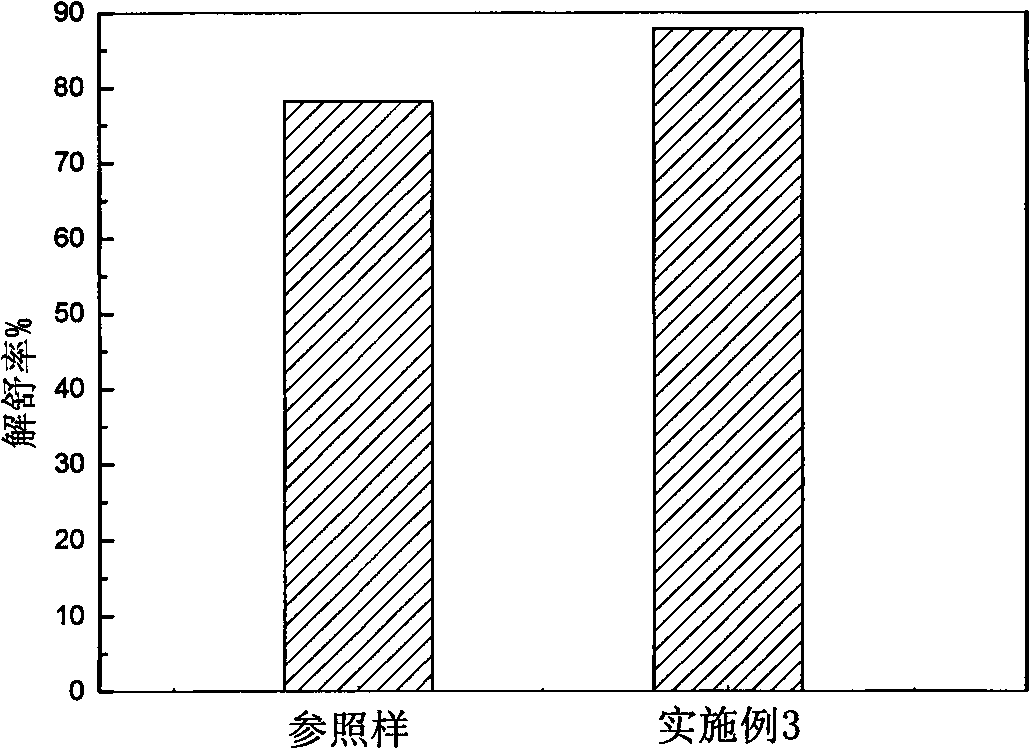

[0022] Shandong Rizhao spring cocoons are selected. After the fresh cocoons are purchased at the cocoon station, they have been transported for 1 day. After arriving at the destination, they have been balanced for 2 hours. After being transferred to the conveyor belt, the fresh cocoons are brought into the In the ambient temperature of -3°C, enter the ambient temperature of -8°C after 0.75 hours, enter the ambient temperature of 3°C after 20 hours, enter the ambient temperature environment after 0.5 hours, and overheat after 15 hours of natural equilibrium Steam drying silkworm cocoons. As a comparison, the silkworm cocoons from Tongzhuangkou were selected, and the cocoons were directly dried by superheated steam without pretreatment, and the silkworm cocoons were used as a reference sample. All the quality indexes of the obtained silk cocoon were significantly improved compared with the reference sample. In particular, the improvement of the release rate is obvious, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com