Active compound activator of phosphorous slag powder and using method thereof

A composite excitation, phosphorus slag powder technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. Condensation, improving the late structure, the effect of dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

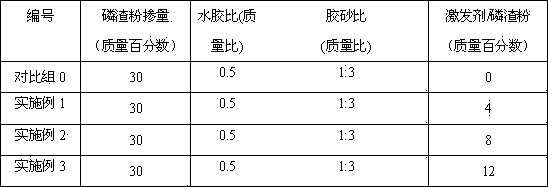

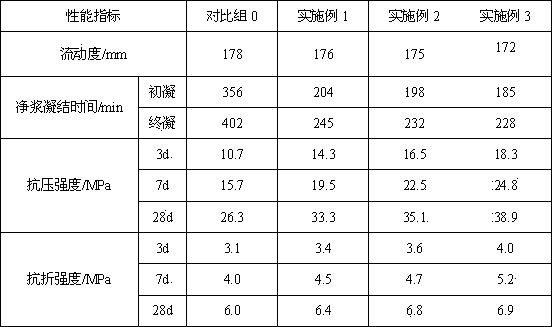

[0034]Example 1, an active composite activator of phosphorus slag powder, according to the quality of 100 carbide slag, 20 desulfurized gypsum, 20 sodium silicate (chemical reagent), 20 aluminum sulfate (chemical reagent), and 20 sodium hydroxide (chemical reagent) The ratio is matched. According to the dosage of phosphorus slag powder is 30% of the mass of cement, and the dosage of composite activator is 4% of the mass of phosphorus slag powder, the proportion of the prepared mortar is shown in Table 1, and the test results of mortar performance are shown in Table 2.

Embodiment 2

[0035] Example 2, an active compound activator of phosphorus slag powder, according to the quality of 100 calcium carbide slag, 60 desulfurized gypsum, 40 sodium silicate (chemical raw material), 40 aluminum sulfate (chemical raw material), and 35 sodium hydroxide (chemical raw material) The ratio is matched. According to the dosage of phosphorus slag powder is 30% of the mass of cement, and the dosage of composite activator is 8% of the mass of phosphorus slag powder, the proportion of the prepared mortar is shown in Table 1, and the test results of mortar performance are shown in Table 2.

Embodiment 3

[0036] Example 3, an active composite activator of phosphorus slag powder, according to the quality of 100 carbide slag, 80 desulfurized gypsum, 60 sodium silicate (chemical reagent), 60 aluminum sulfate (chemical reagent), and 60 sodium hydroxide (chemical raw material) The ratio is matched. According to the dosage of phosphorus slag powder is 30% of the mass of cement, and the dosage of composite activator is 12% of the mass of phosphorus slag powder, the proportion of the prepared mortar is shown in Table 1, and the test results of mortar performance are shown in Table 2.

[0037]

[0038] Table 1 Example Test Proportion

[0039]

[0040] Table 2 Example performance test results

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com