Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Improve the stability of mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicate-based light-weight foam concrete and preparation method thereof

ActiveCN106966670AImproved carbonation resistanceImprove the stability of mechanical propertiesCeramicwareFoam concreteFoaming agent

The invention discloses silicate-based light-weight foam concrete and a preparation method thereof. The silicate-based light-weight foam concrete is prepared from silicate cement, an inorganic admixture, water, a foaming agent and an additive, wherein the mass ratio of the inorganic admixture to the silicate cement is 0.3 to 1.3; the water accounts for 35 to 65 percent by mass; and the foaming agent accounts for 3 to 10 percent by mass. The silicate-based light-weight foam concrete has the beneficial effects that the silicate cement is used as a cementing material; and compared with a sulfoaluminate-based material, the silicate-based light-weight foam concrete has the advantages that the carbonation resistance, the mechanical performance stability, the temperature tolerance and other properties are improved. By adjustment of the contents of all functional components (a thickening time control agent, a foam stabilizer, a water reducing agent, an anti-cracking component, an expanding agent and the like), the silicate-based light-weight foam concrete can conform to various preparation conditions of the silicate cement used as a base material.

Owner:CHINA ACAD OF CIVIL AVIATION SCI & TECH

Preparation method for flexible transparent conductive thin film with high thermal stability and product thereof

ActiveCN105405492AFracture failure temperature increasedImprove thermal stabilityConductive layers on insulating-supportsCable/conductor manufactureUltravioletTransmittance

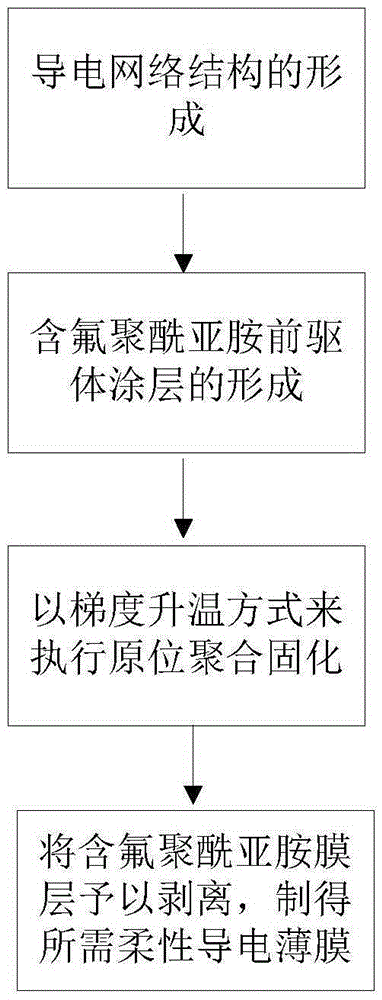

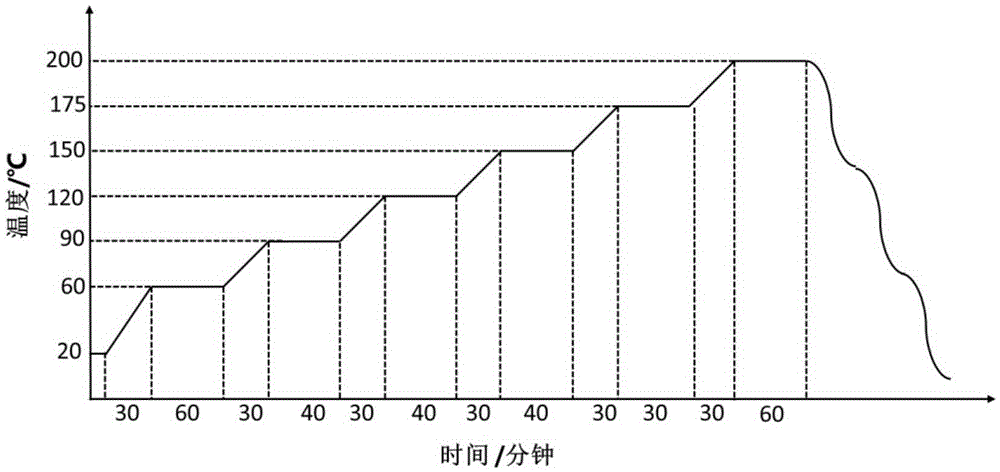

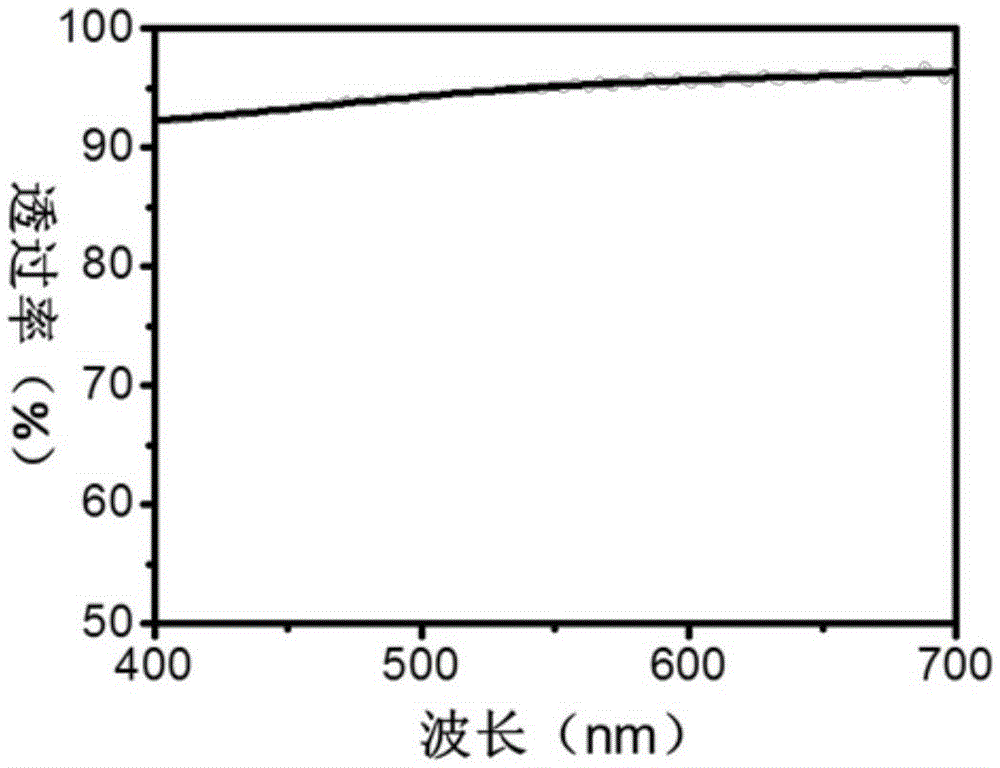

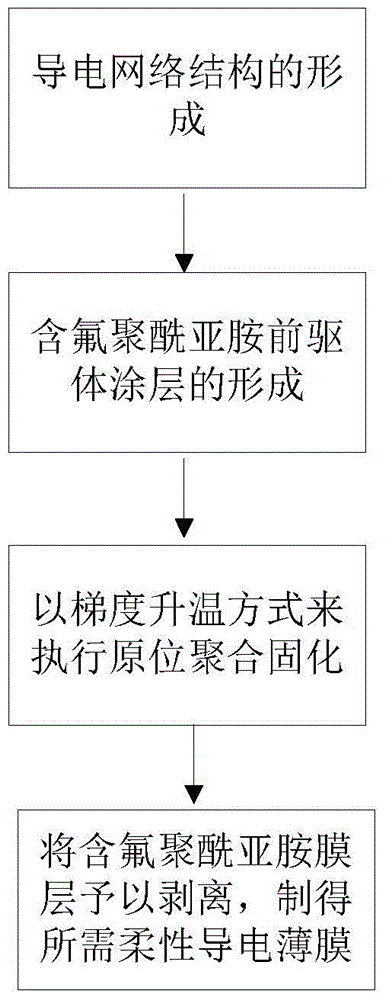

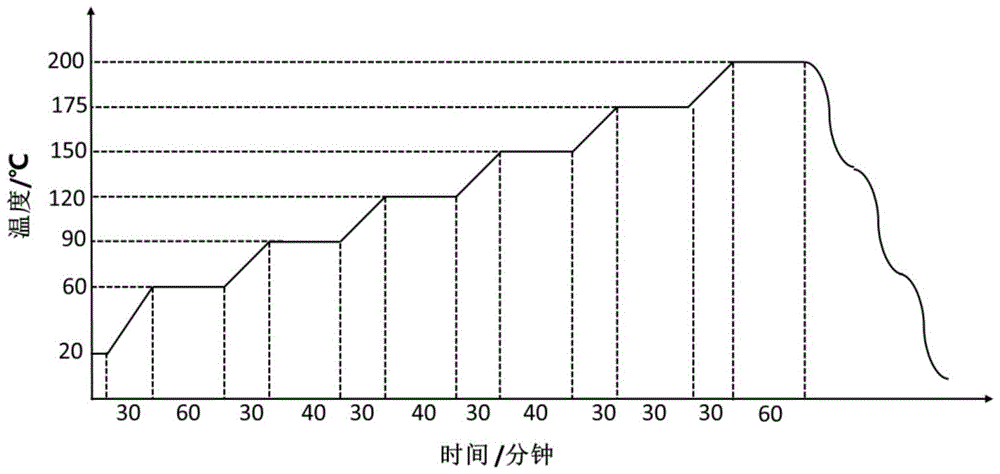

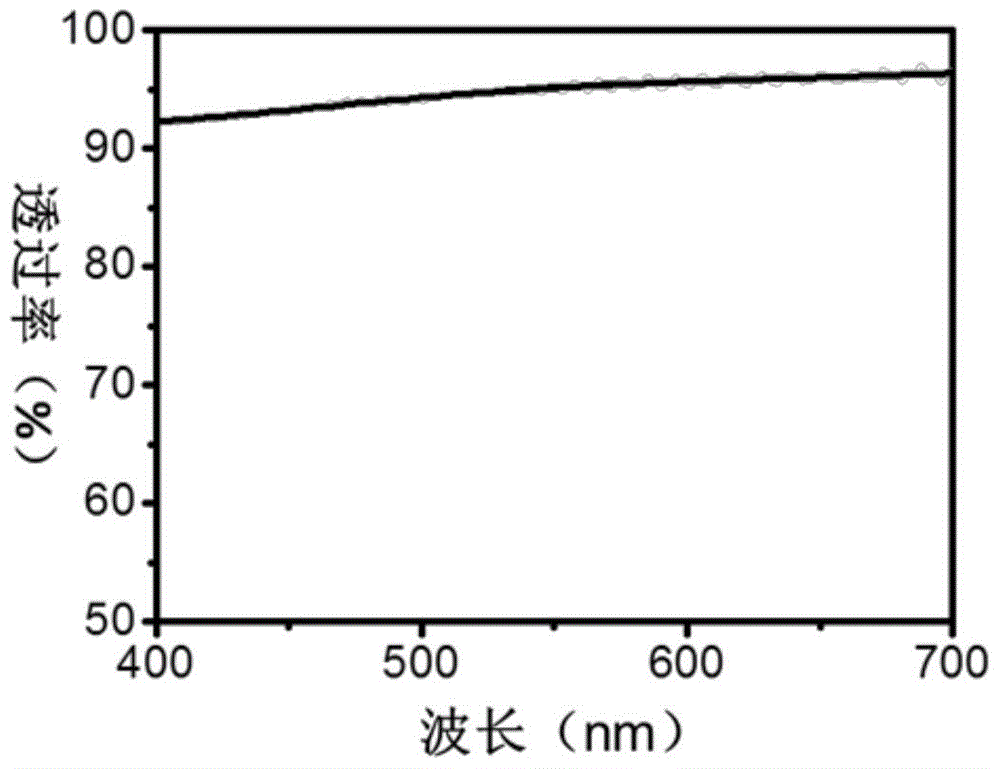

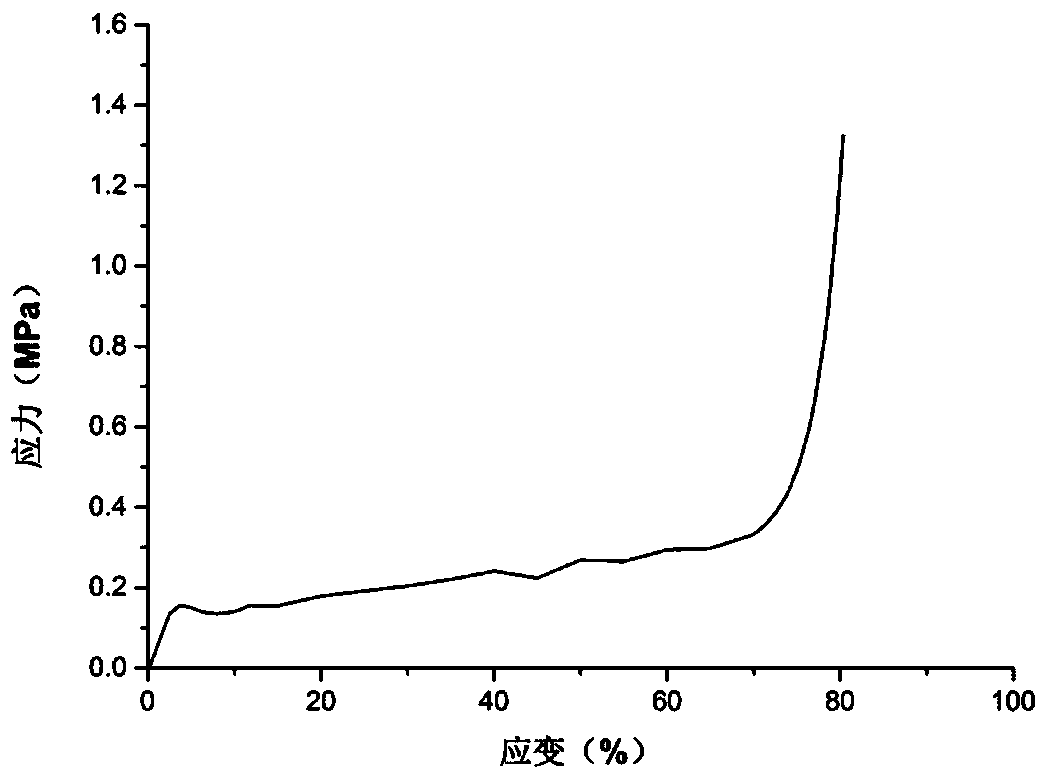

The invention discloses a preparation method for a flexible transparent conductive thin film with high thermal stability. The preparation method comprises the steps of step 1, uniformly coating the surface of a tidy and smooth target substrate with a one-dimension-structured conductive metal nanomaterial, and forming a conductive network structure; step 2, performing blade coating on the surface of the target substrate with the conductive network structure to form a precursor coating layer containing fluorinated polyimide; step 3, performing a curing process on the precursor coating layer containing fluorinated polyimide through a gradient temperature rise manner; and step 4, peeling off the cured fluorinated polyimide contained film layer from the target substrate to obtain the required finished product. The invention also discloses a corresponding flexible transparent conductive thin film product and characteristics of the product. Through the preparation method, the flexible transparent conductive thin film can be prepared in an efficient manner, and the quality control can be performed conveniently; and the prepared flexible transparent conductive thin film has the characteristics of low sheet resistance, high visible light transmittance, anti-ultraviolet property, high flexibility, low surface roughness, excellent high-temperature endurance and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

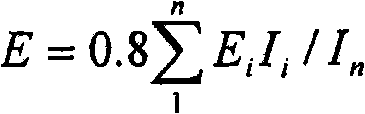

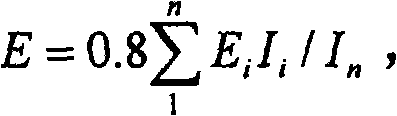

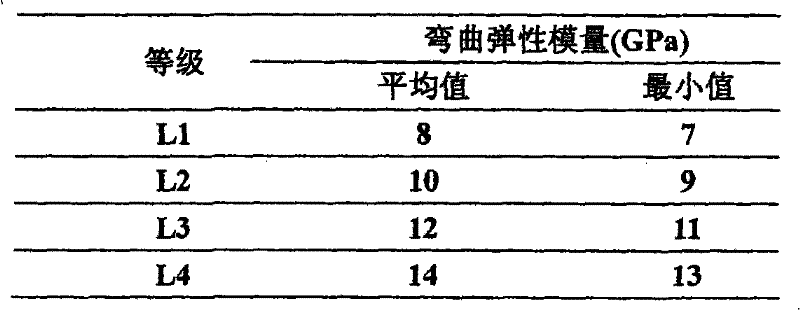

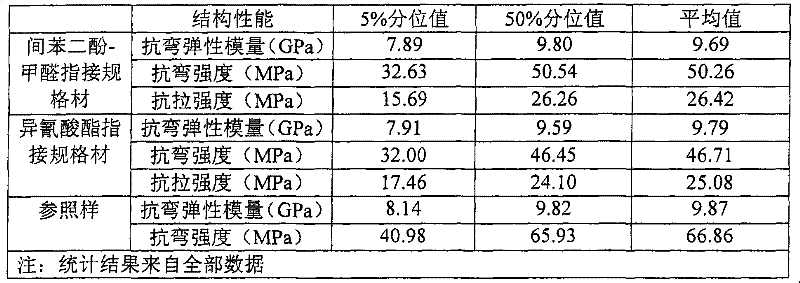

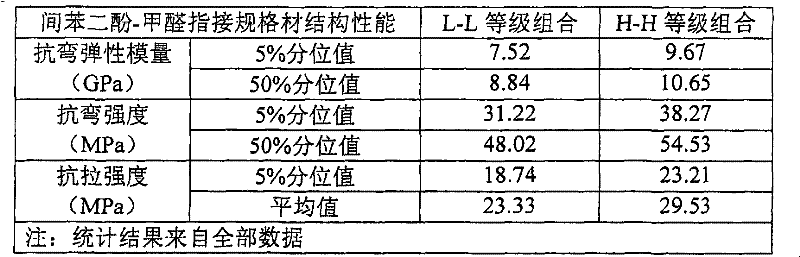

Structural laminwood and preparation method thereof

InactiveCN101564854AImprove structural performanceIncrease profitOther plywood/veneer working apparatusWood veneer joiningLower gradeEngineering

The invention provides a structural laminwood and a preparation method thereof. The laminwood is stacked and glued by 2-7 layers of veneers, wherein the grade of the external layer veneer of the laminwood is equal to the grade of the adjacent internal layer veneer or higher than the adjacent internal layer veneer by one grade; the veneer grade is determined by the average value of flexural elastic modulus of the target grades of all veneers; and compared with the veneers with lower grades, the veneers with higher grades have greater average value of the flexural elastic modulus of the target grades. The method lengthens the stock lumbers of short dimensions by mechanical stress grading and uses the lengthened stock lumbers as the veneers, then configures the veneer structures according to a grade configuration principle and coldly presses and glues the veneers to prepare the structural laminwood. The laminwood has excellent structural performance and can be used for the components such as beams, columns, and the like in wood structure buildings or other buildings.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

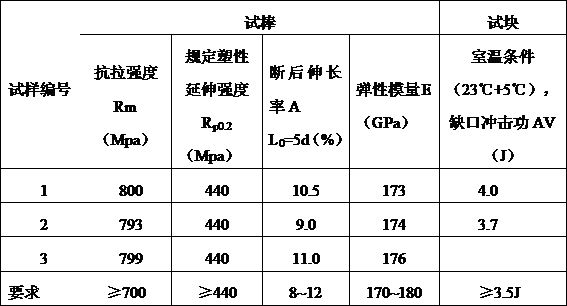

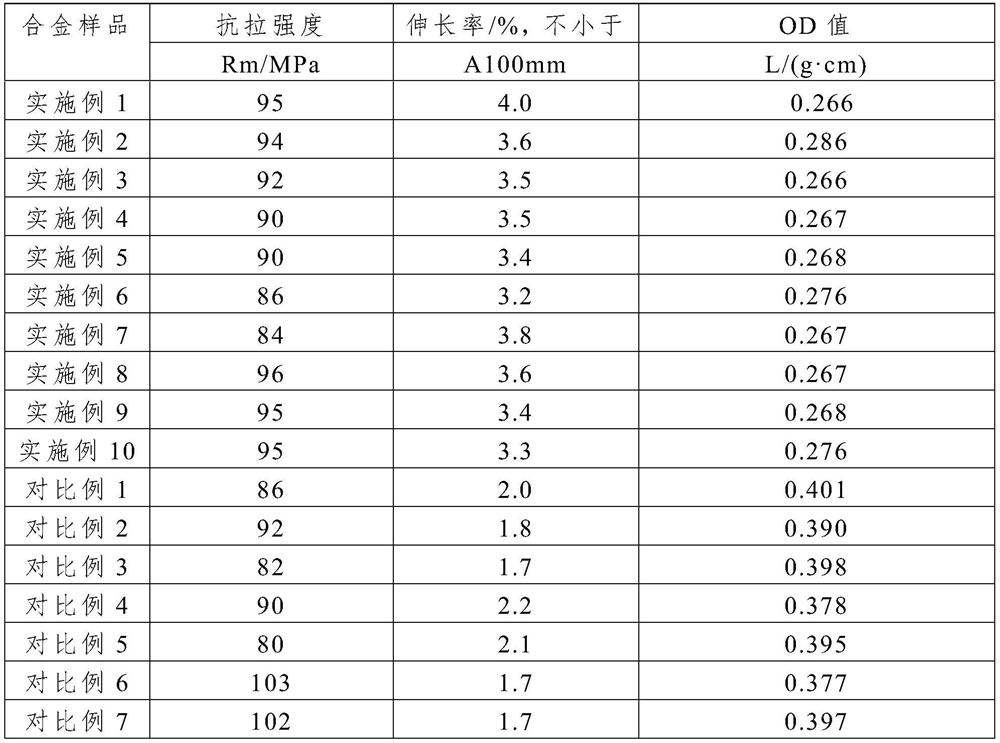

Medical high-strength Ti-6Al-4V alloy wire and preparation technique and application thereof

ActiveCN105970019AMeet performance requirementsEasy to operateFurnace typesHeat treatment furnacesStress reliefTi 6al 4v

The invention relates to a medical high-strength Ti-6Al-4V alloy wire and a preparation technique and application thereof and belongs to the technical field of metal material preparation. The medical high-strength Ti-6Al-4V alloy wire comprises, by mass, 5.9%-6.3% of Al, 4.0%-4.3% of V, 0.10%-0.16% of O, 0.14%-0.22% of Fe and the balance Ti. The preparation technique comprises the steps of smelting, forging, two times of large-deformation rolling, cold drawing, intermediate annealing, temperature-control hot drawing, stress relief annealing of a semi-finished product, one-pass cold drawing, straightening and cutting-off, stress relief annealing, polishing and obtaining of a finished product. The medical high-strength Ti-6Al-4V alloy wire and the preparation technique and application thereof have the beneficial effects that the Ti-6Al-4V alloy wire is prepared through the technical process that heat machining, cold drawing and temperature-control hot drawing are combined, and the Ti-6Al-4V alloy wire has the advantages that the mechanical performance is high, the dimensional precision is high, the surface smoothness is high, and the structure property uniformity is good.

Owner:DALIAN SUNNY TITANIUM IND

Full-automatic submerged-arc welding solid welding wire for nickel-saving high-manganese low-temperature steel

InactiveCN112171109AReduce manufacturing costImprove stabilityArc welding apparatusWelding/cutting media/materialsArc weldingWeld bead

The invention relates to a full-automatic submerged-arc welding solid welding wire for nickel-saving high-manganese low-temperature steel. According to the technical scheme, the full-automatic submerged-arc welding solid welding wire is prepared from the following chemical components in percentage by weight: 0.20-0.45% of C, 0.03-0.10% of Si, 26-31% of Mn, less than or equal to 1.2% of Ni, 2-6% ofCr, less than or equal to 1% of Mo, 0.02-0.08% of N, less than or equal to 0.002% of P, less than or equal to 0.001% of S, and the balance of Fe and inevitable impurities. The production cost is low;formed weld metal has high elongation and stable mechanical properties, and the strength and low-temperature toughness of the weld metal are matched with those of the high-manganese low-temperature steel; and a welded joint has high strength and excellent ultralow-temperature toughness mechanical properties, and can meet the technical requirements on the room-temperature and low-temperature properties of LNG storage tanks prepared by welding.

Owner:WUHAN UNIV OF SCI & TECH +1

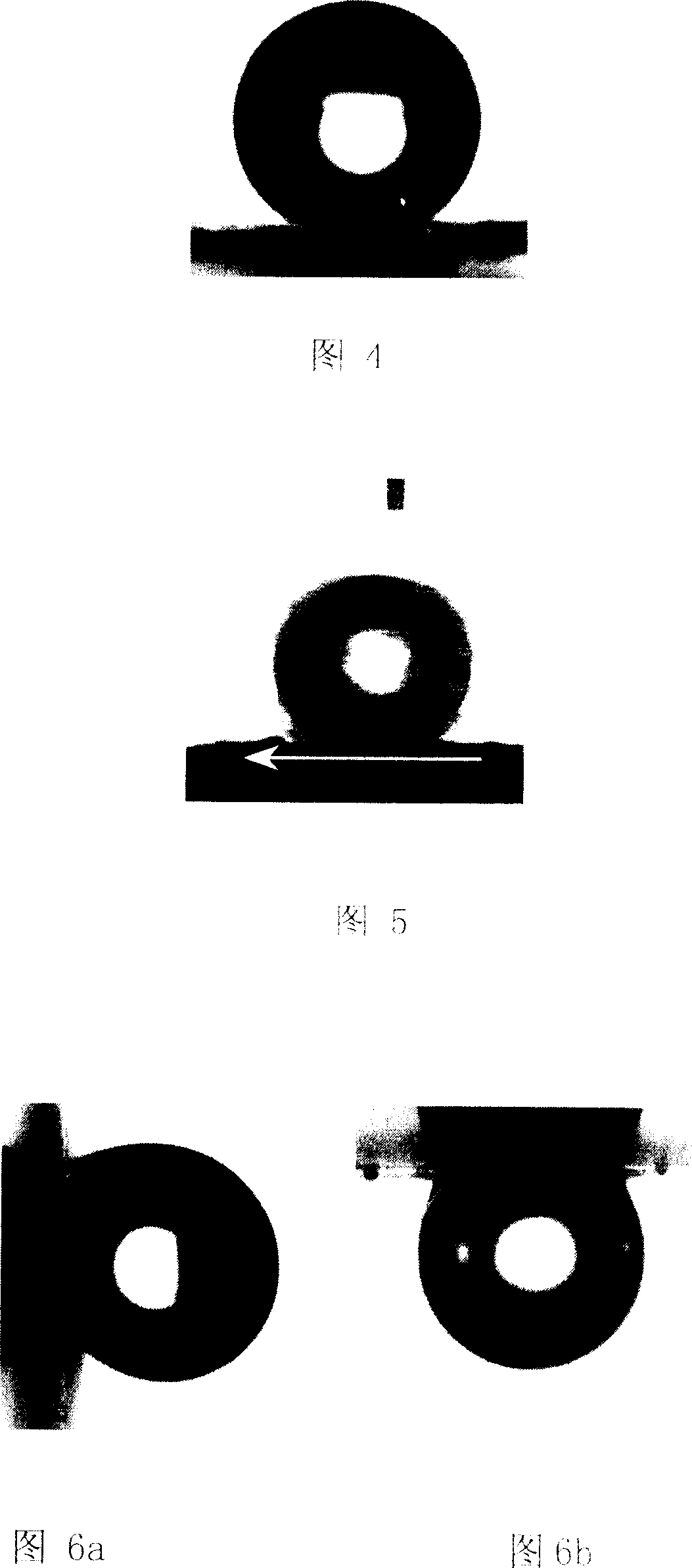

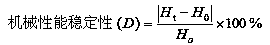

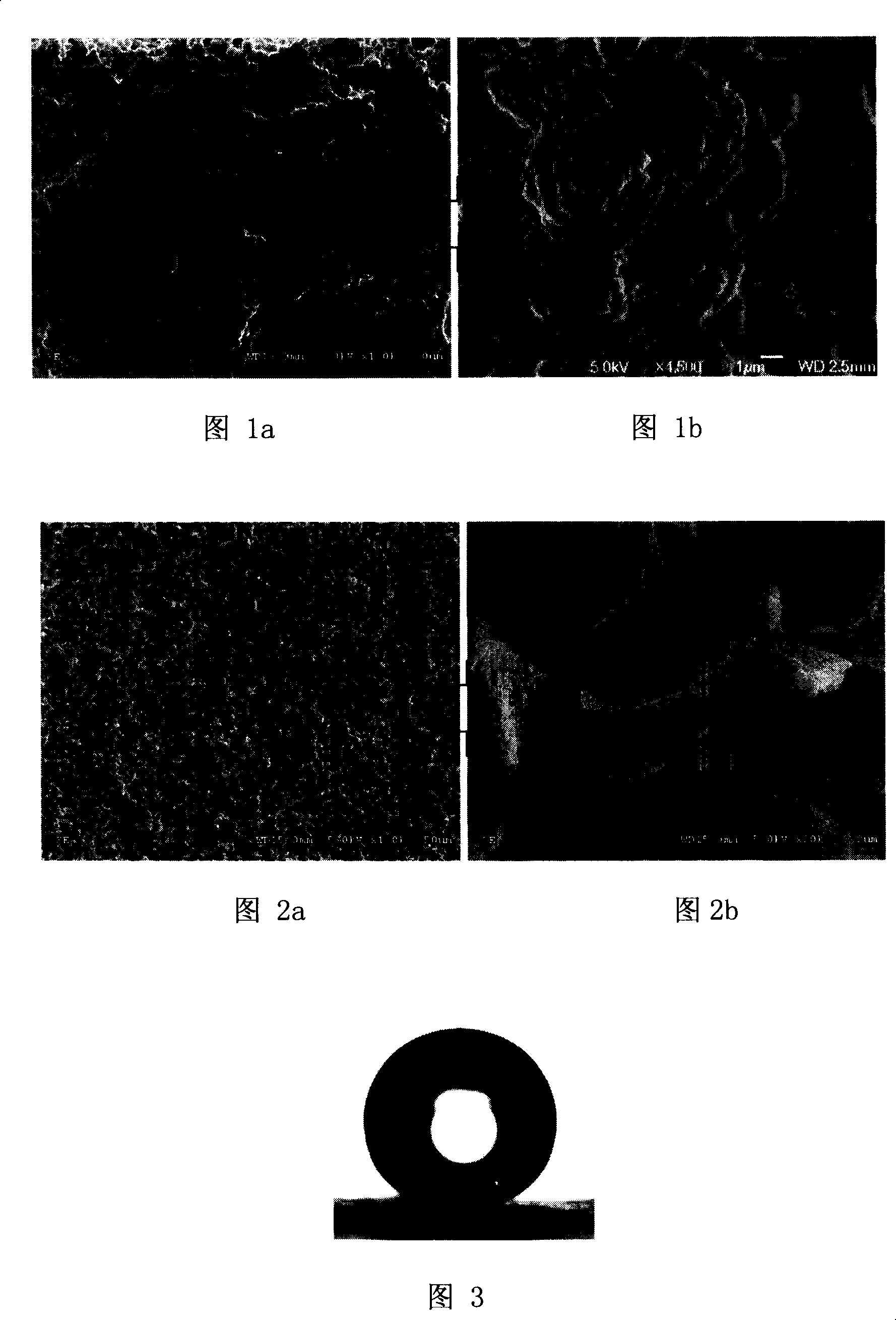

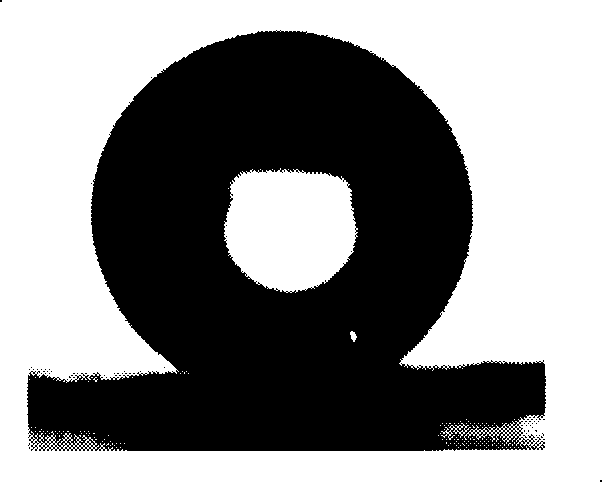

Roll-position-controllable polypropylene super hydrophobic film or block material and their preparing method

The present invention belongs to the field of polypropylene film or mass materials, especially relates to the rolling-angle controllable, super-hydrophobic, polypropylene film or mass and its preparation method. Solving polypropylene in solvent, and passing through processes of shearing, heat treatment, cooling, phase separation / crystallization, solidification, shaping, and drying at last, the films or masses with different morphological crystal networks are formed. With the minimum rolling ability on film or mass surface, water drops will roll, while the rolling angle is between 0 degree and 1 degree, and with the maximum rolling ability, the drops will not roll, while the rolling angle is 90 degree or 180 degree. The contact angle between film or mass surface and water is larger than 150 degree. The present invention achieves the control of super-hydrophobic property and rolling angle of general polyolefin resin film, without any later modification by low-surface-energy materials (containing fluoride materials or silane, etc.), and has good surface-structure stability, wind and rain resistance, and chemical corrosion resistance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

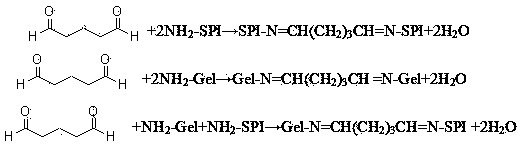

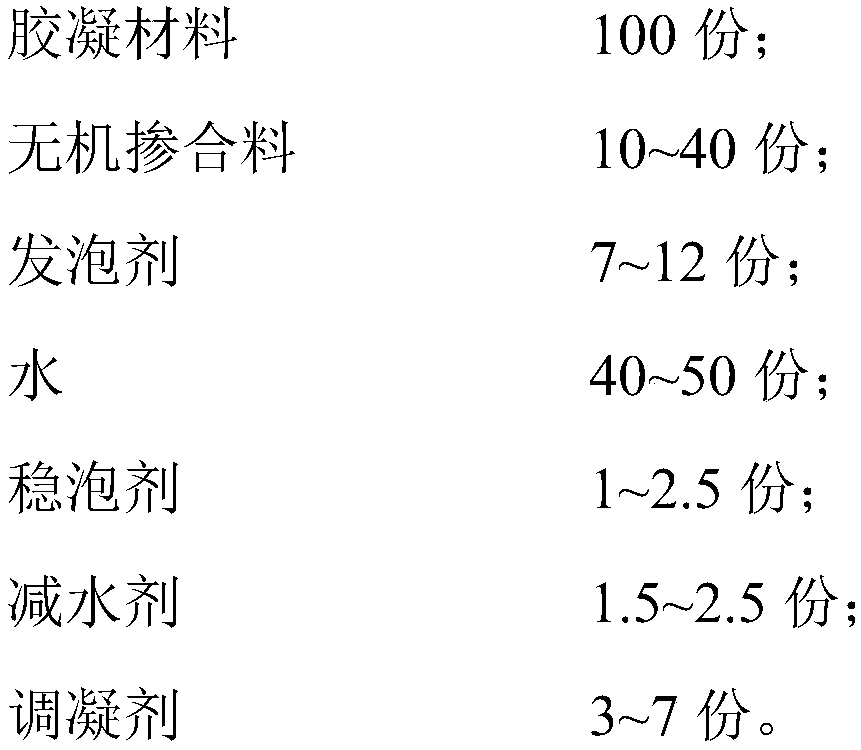

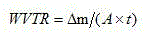

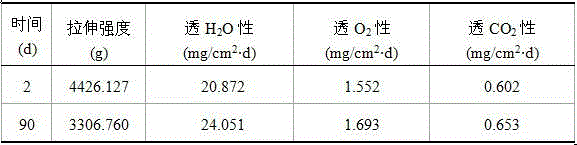

Edible composite membrane with stable mechanical properties and preparation method thereof

ActiveCN103740117AStable mechanical propertiesImprove mechanical propertiesFlexible coversWrappersCarrageenanPlasticizer

The invention discloses an edible composite membrane with stable mechanical properties and a preparation method thereof. Soybean protein isolate and gelatin are subjected to steam cross-linking processing under the participation and assistance of kappa-carrageenan and under unique reaction conditions, so that the internal structure of soybean protein isolate and gelatin protein is reconstructed; and also by further choosing specific usage amount of various compositions and specific plasticizer compositions and ratio, protein forms a relatively compact uniform three-dimension stereo net structure, so that the stability of the membrane material is effectively improved, the variation amplitude of mechanical properties is relatively small within the storage period of 3 months, the tensile strength is reduced only by 5-12%, the composition membrane is increased in water permeability only by 5-8%, increased in oxygen permeability only by 3-5.5% and increased in carbon dioxide permeability only by 2-4.5%, the color and the transparency are not influenced, and the shelf life of food is prolonged. According to the composite membrane, the operation is simple, the product quality is stable and reliable, and the composite membrane is suitable for industrial production.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

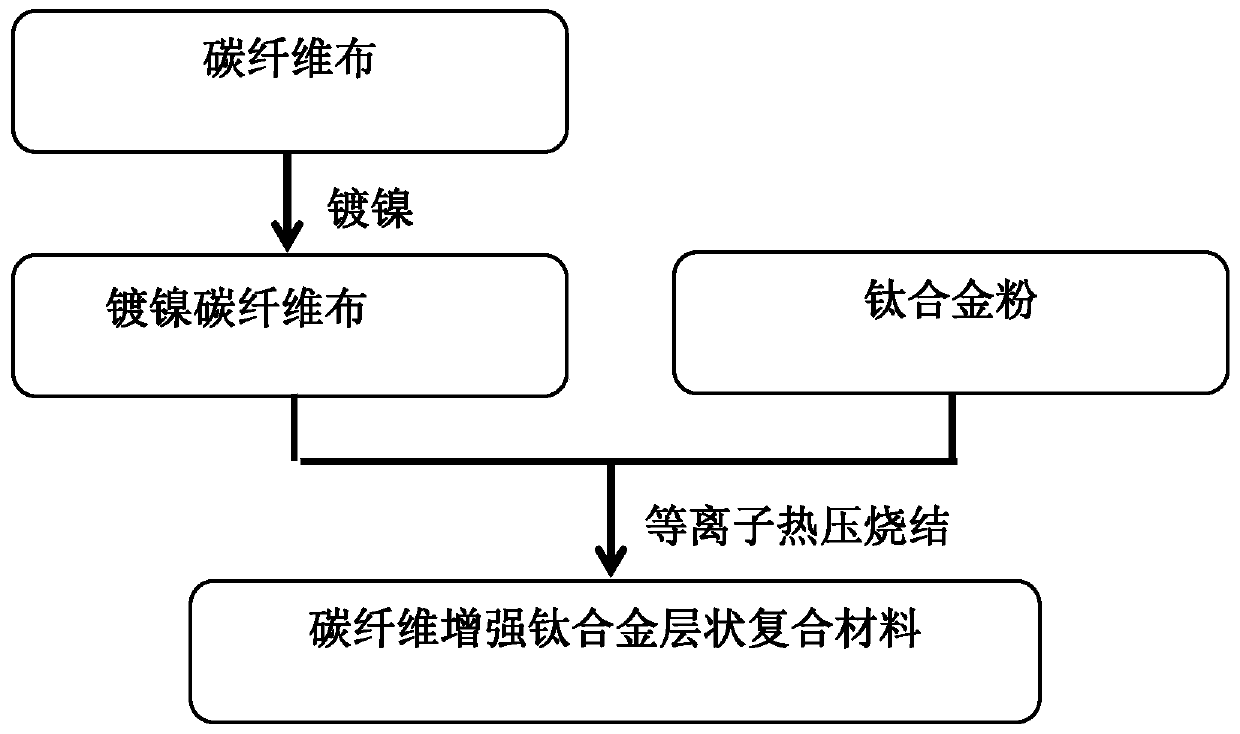

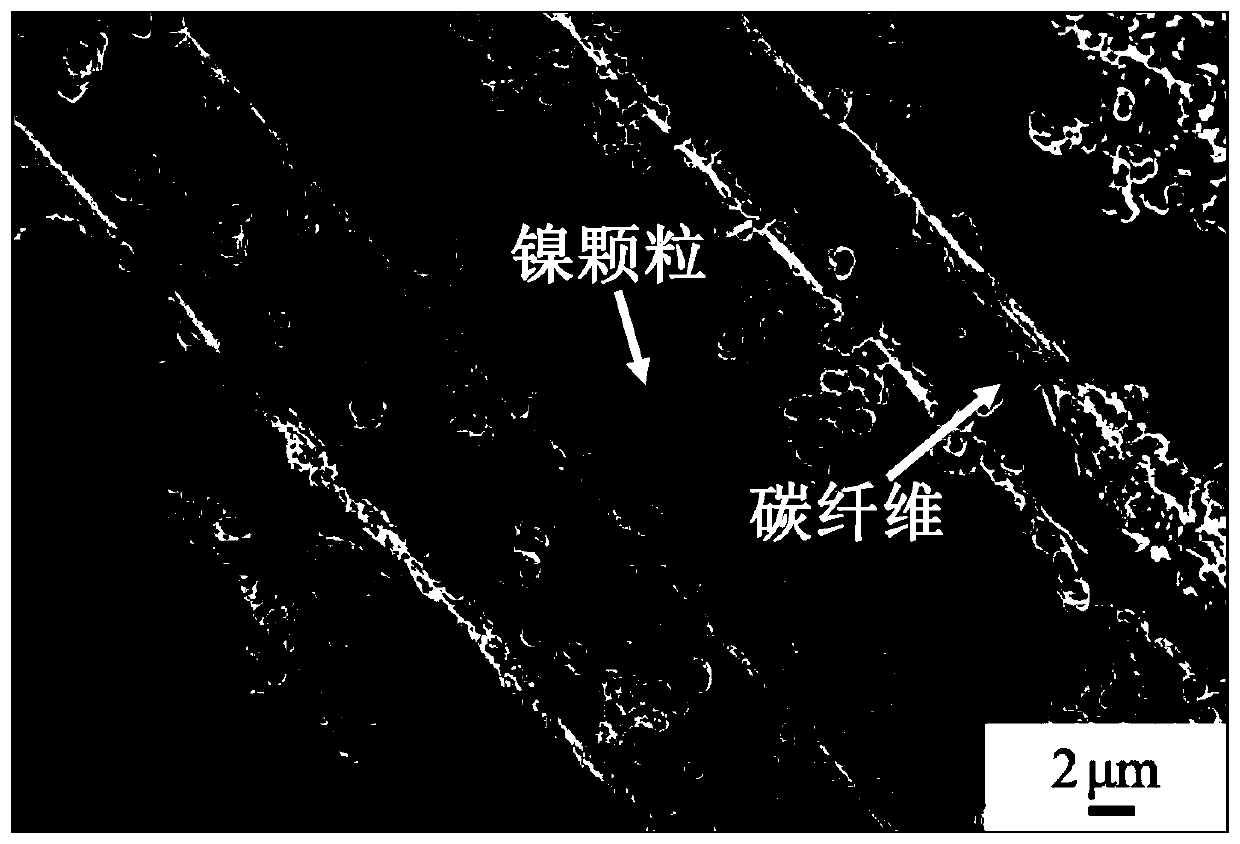

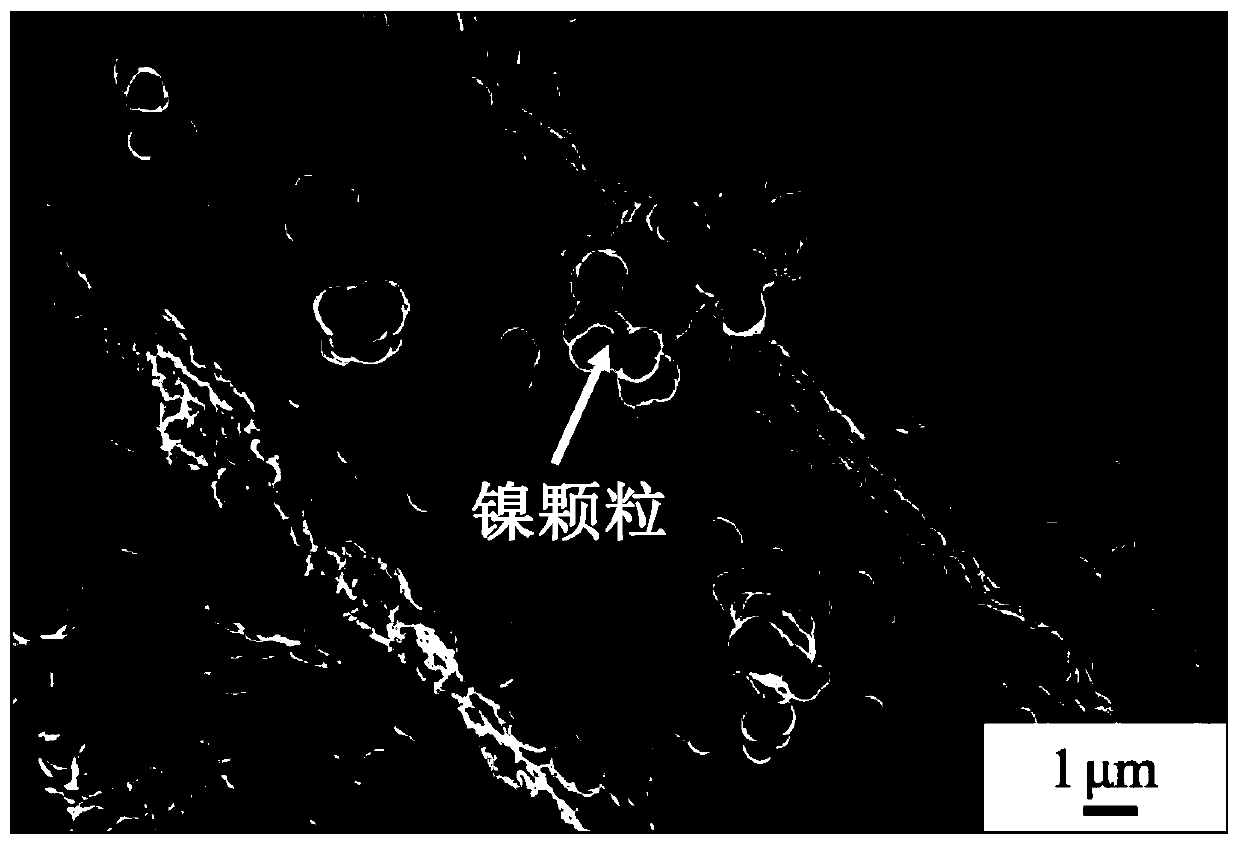

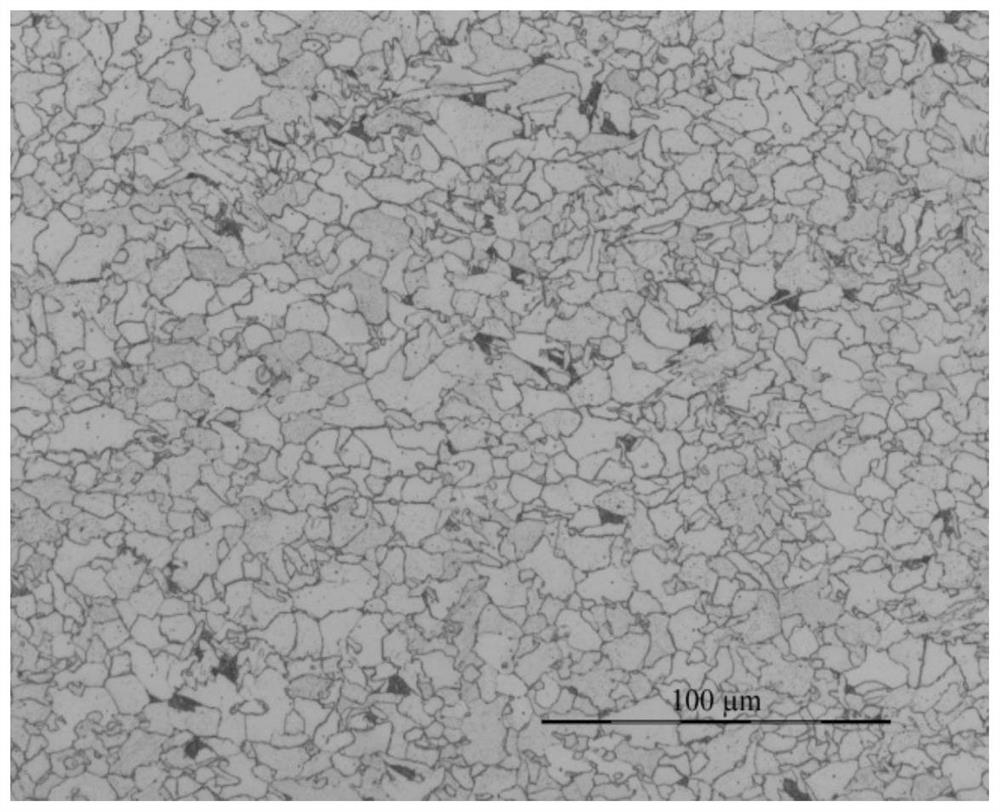

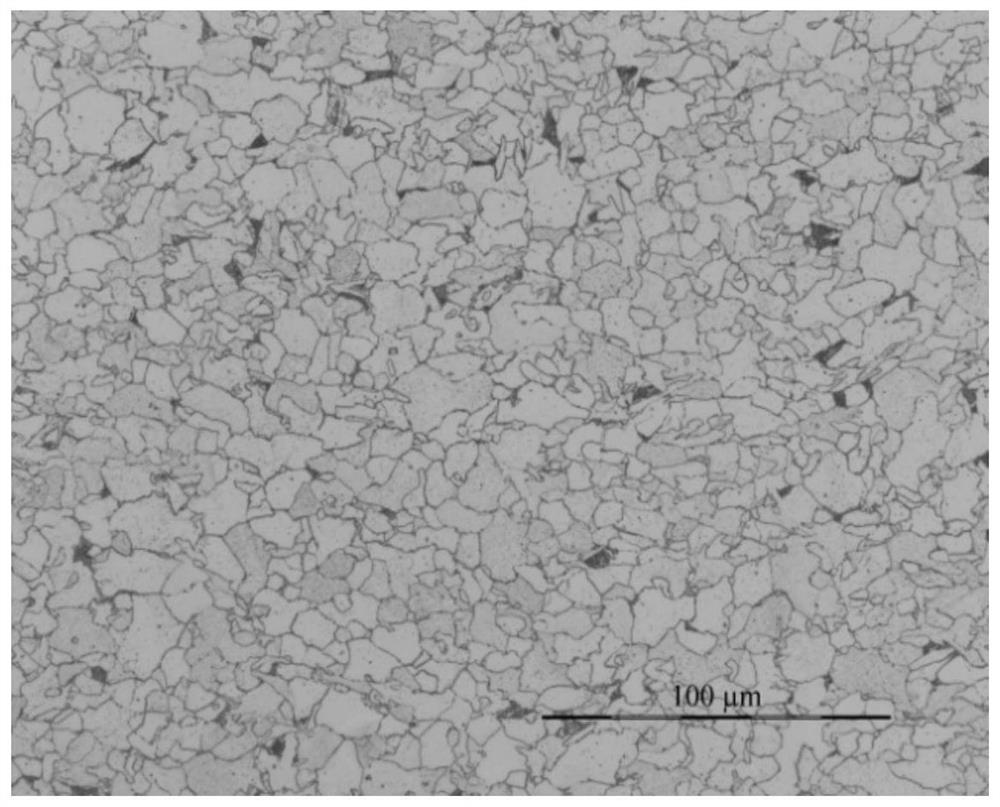

Method for rapidly preparing carbon fiber reinforced titanium alloy layered composite material

InactiveCN110315083AShort holding timeIntegrity guaranteedLiquid/solution decomposition chemical coatingMegasonic cleaningMechanical properties of carbon nanotubes

The invention discloses a method for rapidly preparing a carbon fiber reinforced titanium alloy layered composite material. The method comprises the following steps of S1, ultrasonically cleaning carbon fiber cloth and drying; S2, sequentially carrying out sensitization, activation and reduction on the dried carbon fiber cloth, and cleaning and drying; S3, plating nickel on the dried carbon fibercloth to obtain nickel-plated carbon fiber cloth; and S4, laying a nickel-plated carbon fiber cloth layer after the titanium alloy powder is laid on a plasma hot-pressing sintering mold, and then laying a titanium alloy powder layer, sequentially repeating the powder layer and the cloth layer paving process, and obtaining the carbon fiber reinforced titanium alloy layered composite material through discharge plasma hot-pressing sintering. According to the method, due to the fact that the heating rate is high, the heat preservation time is short and the pressure is high in the discharge plasmahot-pressing sintering process, and the isolation effect of the nickel-plated layer on the surface of the nickel-plated carbon fiber cloth to the the carbon fiber and the titanium alloy powder, the carbon fiber reinforced titanium alloy laminar composite material can be rapidly prepared, so that the integrity of the carbon fiber is ensured, and the mechanical property of the carbon fiber reinforced titanium alloy layered composite material is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

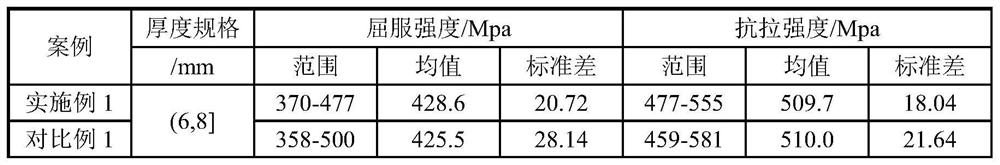

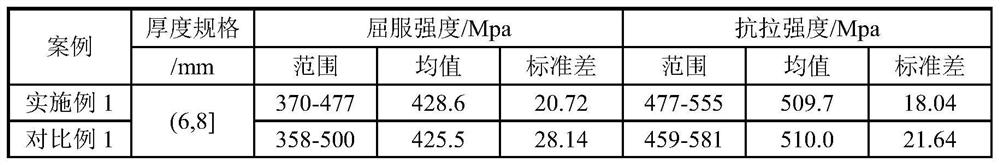

Low-cost low alloy steel coil and manufacturing method thereof

The invention discloses a low-cost low alloy steel coil and a manufacturing method thereof and belongs to the technical field of production of hot continuous rolled plates and strips. The chemical ingredients of the low-cost low alloy steel coil comprise, by mass percentage, 0.06%-0.08% of C, 0.50%-0.80% of Mn, not larger than 0.015% of P, not larger than 0.008% of S, 0.045%-0.075% of Ti, 0.04%-0.05% of Al, not larger than 0.004% of N, not larger than 0.0030% of O and the balance Fe and inevitable impurities. The manufacturing method comprises the step of converter smelting, the step of RH secondary refining, the step of continuous casting, heating and TMCP and the step of laminar cooling and coiling. By the adoption of the technical scheme, without the need for adding the expensive microalloying alloy elements such as Nb and V, the strength and toughness comprehensive performance of the obtained steel coil product can reach the same level of the existing microalloyed steel coil adopting Nb and V, and therefore the production cost is remarkably lowered. Meanwhile, the mechanical performance stability of the steel coil can be further improved, performance fluctuation is reduced, andproduction requirements can be well met.

Owner:MAANSHAN IRON & STEEL CO LTD

Steel bonded carbide, and preparation method and application thereof

The invention discloses a steel bonded carbide, and a preparation method and application thereof. The steel bonded carbide comprises the following components by mass: 35%-45% of titanium carbide, 40%-50% of reduced iron powder, 2%-5% of reduced molybdenum powder, 2%-5% of reduced nickel powder, 10%-15% of manganese powder and 0-3% of chromium powder. According to the steel bonded carbide, and thepreparation method and application thereof, through selection and proportion design of a hard phase and a binding phase, proportion design of binding components and a reasonable preparation process, the prepared steel bond carbide has high impact resistance and abrasion resistance, and meanwhile has high thermal stability; after water toughening treatment, no cracking phenomenon exists, and the mechanical property stability is high; and the steel bonded carbide is suitable for casting a roller sleeve or a roller lining plate of an integrated roller press.

Owner:常熟市电力耐磨合金铸造有限公司

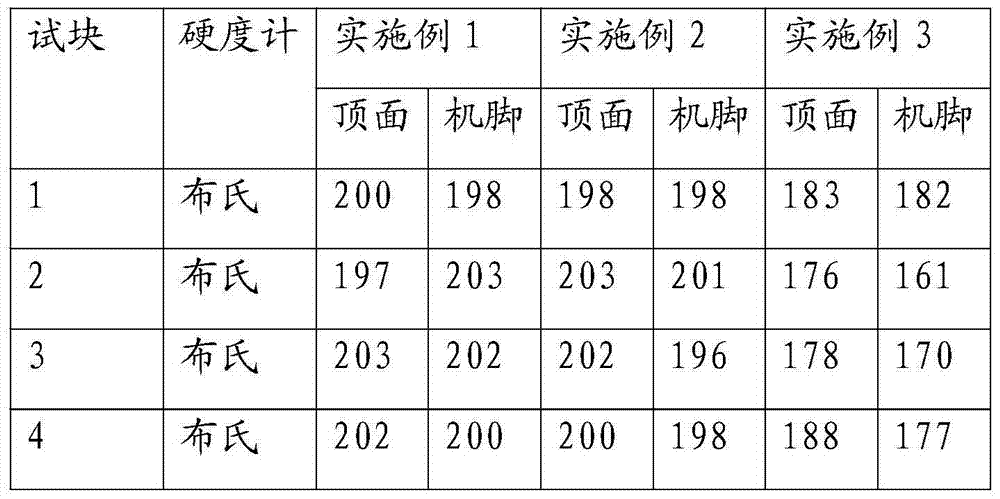

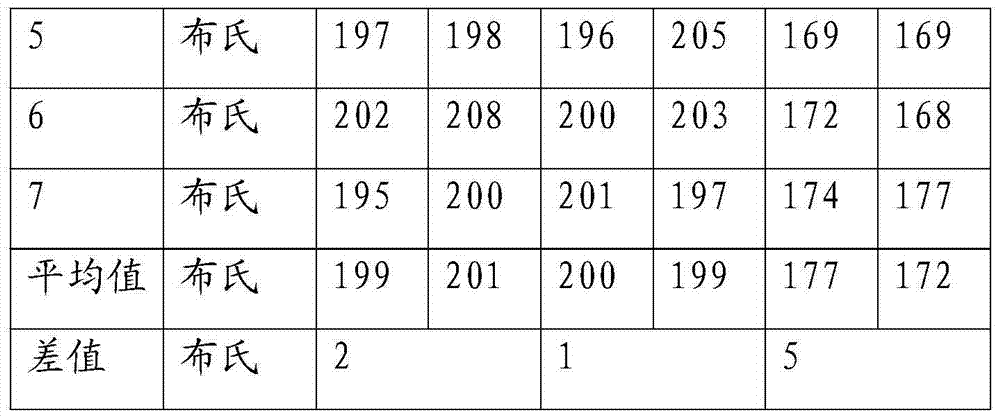

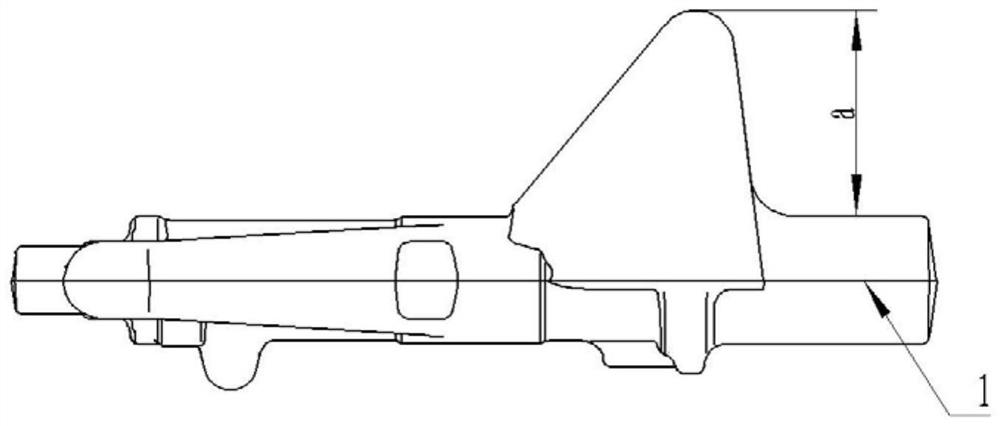

Engine cylinder block cast casting method

InactiveCN103586425AReduced wall thickness sensitivityMinimize Microstructural DifferencesCylinder blockHardness

The invention provides an engine cylinder block cast casting method. The engine cylinder block cast casting method is characterized in that metal-stream inoculation is carried out twice, and the time when a nucleating agent is added, the usage amount of the nucleating agent, the particle size and temperature of the nucleating agent, constituents of the nucleating agent and the mass percents of the constituents are controlled in each time of metal-stream inoculation. By means of the method, the problem that an existing cast is poor in tensile strength and uniformity of hardness can be solved, the metallographic phase, hardness, mechanical performance and other properties of the cast are greatly improved, and the mechanical property stability of the cast is greatly improved.

Owner:WUJIANG HYDRAULIC COMPONENTS FOUNDRY

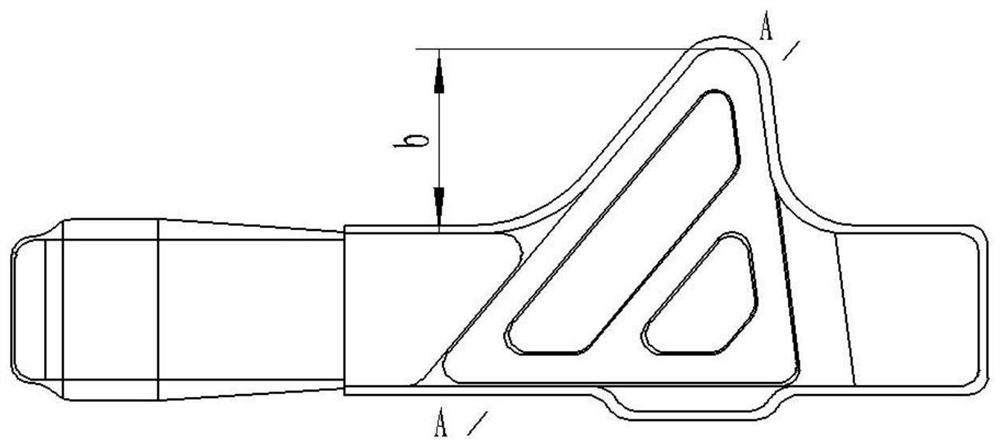

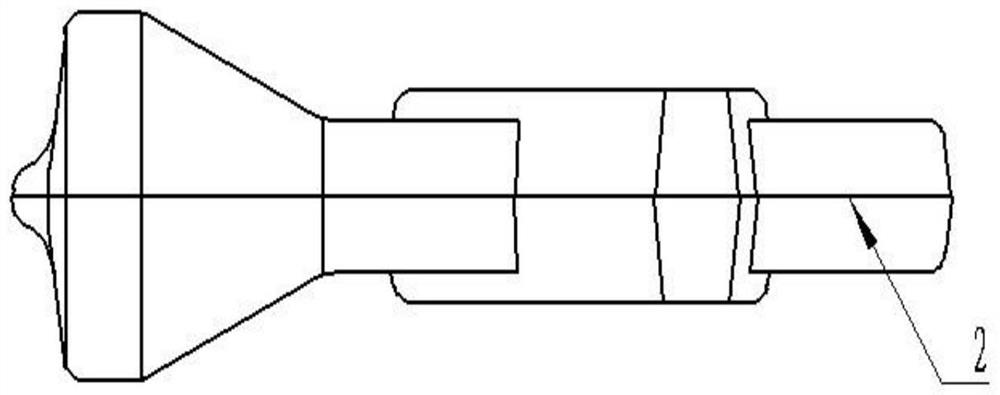

Forging method of high-boss TC18 titanium alloy die forging

The invention belongs to the field of forging hot working, and relates to a forging method of a high-boss TC18 titanium alloy die forging. The method comprises the following steps: designing a final forging according to the shape of a part; taking the maximum projection plane of the final forging projected to the horizontal plane as the parting surface of the final forging; taking the maximum projection surface of the final forge piece which is overturned by 90 degrees and projected to the horizontal plane as a pre-forge piece parting surface; and pre-forging and finish-forging the blank with the boss according to the parting surface of the pre-forged piece and the parting surface of the finish-forged piece by adopting a cross-shaped cross die forging method.

Owner:SHAANXI HONGYUAN AVIATION FORGING

Roll-position-controllable polypropylene super hydrophobic film or block material and their preparing method

InactiveCN101070408BImprove structural stabilityImprove the stability of mechanical propertiesPolyolefinPolymer science

The present invention belongs to the field of polypropylene film or mass materials, especially relates to the rolling-angle controllable, super-hydrophobic, polypropylene film or mass and its preparation method. Solving polypropylene in solvent, and passing through processes of shearing, heat treatment, cooling, phase separation / crystallization, solidification, shaping, and drying at last, the films or masses with different morphological crystal networks are formed. With the minimum rolling ability on film or mass surface, water drops will roll, while the rolling angle is between 0 degree and1 degree, and with the maximum rolling ability, the drops will not roll, while the rolling angle is 90 degree or 180 degree. The contact angle between film or mass surface and water is larger than 150 degree. The present invention achieves the control of super-hydrophobic property and rolling angle of general polyolefin resin film, without any later modification by low-surface-energy materials (containing fluoride materials or silane, etc.), and has good surface-structure stability, wind and rain resistance, and chemical corrosion resistance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

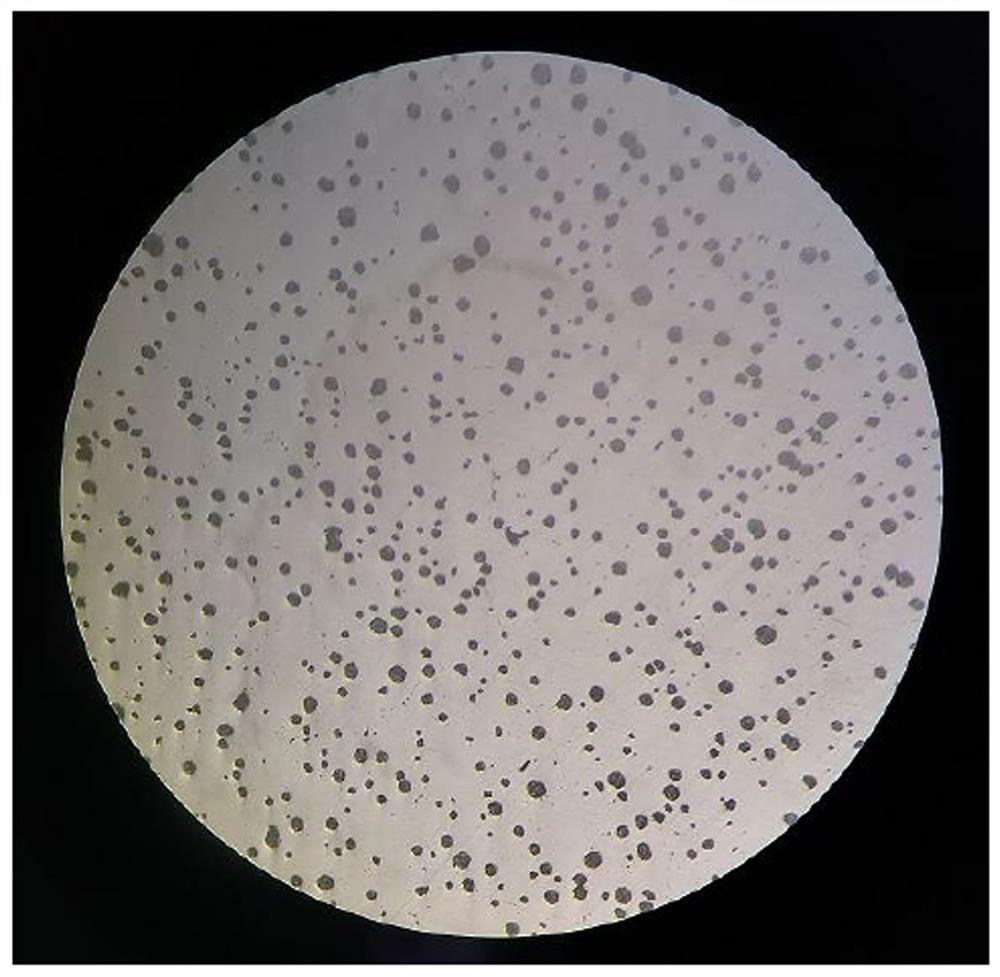

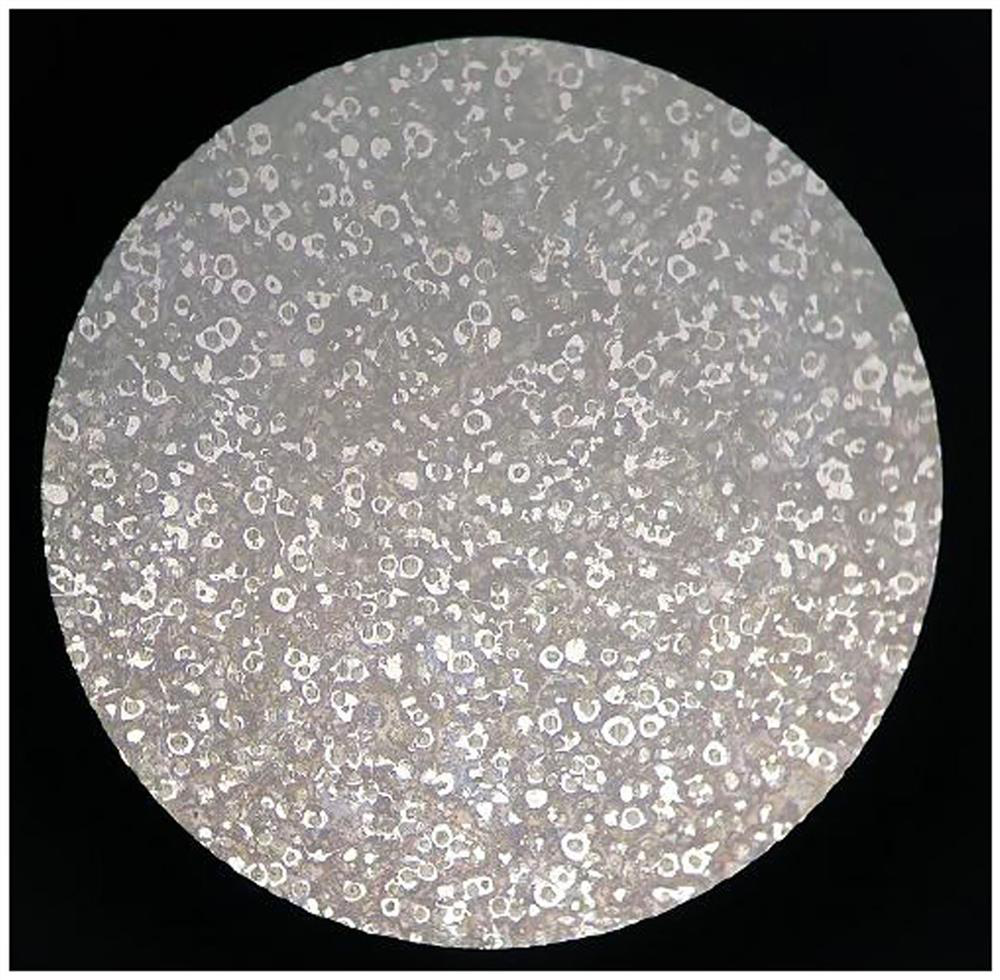

Preparation method of high-strength and high-elongation clay sand as-cast QT700-10 ductile iron casting

ActiveCN114457280AReduce manufacturing costImprove economic efficiencyProcess efficiency improvementBriquetteScrap

The invention relates to the technical field of casting technologies and new materials, in particular to a preparation method of a high-strength and high-elongation clay sand as-cast QT700-10 ductile iron casting, which comprises the following steps: step 1, weighing a carburant, a scrap steel briquette, foundry returns and a pretreating agent in batches according to a batching list, adding the weighed materials into an electric furnace for smelting, sampling, analyzing the components of molten iron, adjusting the components to be qualified, and taking out the molten iron; keeping the temperature at 1520-1550 DEG C for 5-8 minutes, and slagging off; 2, molten iron is weighed and transferred to a spheroidizing bag, Cu and Sn micro-alloy is added for discharging and flushing, meanwhile, a spheroidizing line and an inoculation line are inserted for wire feeding spheroidizing inoculation, and scum is removed after completion of wire feeding spheroidizing inoculation; 3, the molten iron is transferred to a casting machine, a silicon-barium inoculant is added for ladle-to-ladle inoculation, and slag removal and temperature measurement are conducted after ladle-to-ladle inoculation is completed; 4, the automatic casting machine is started, an efficient inoculant is added, and stream inoculation is carried out; and 5, after pouring is finished, heat preservation is conducted for 2-4 h, box pushing and shakeout are conducted, the metallographic phase and performance of a casting are detected to be qualified, and a qualified casting is obtained. The requirements of mechanical parts for high-strength and high-toughness ductile iron castings and the requirement for light weight of automobile parts can be met.

Owner:山东宇信铸业有限公司

Medical high-strength ti-6al-4v alloy wire and its preparation process and application

ActiveCN105970019BMeet performance requirementsEasy to operateFurnace typesHeat treatment furnacesOne passMetallic materials

The invention relates to a medical high-strength Ti-6Al-4V alloy wire and a preparation technique and application thereof and belongs to the technical field of metal material preparation. The medical high-strength Ti-6Al-4V alloy wire comprises, by mass, 5.9%-6.3% of Al, 4.0%-4.3% of V, 0.10%-0.16% of O, 0.14%-0.22% of Fe and the balance Ti. The preparation technique comprises the steps of smelting, forging, two times of large-deformation rolling, cold drawing, intermediate annealing, temperature-control hot drawing, stress relief annealing of a semi-finished product, one-pass cold drawing, straightening and cutting-off, stress relief annealing, polishing and obtaining of a finished product. The medical high-strength Ti-6Al-4V alloy wire and the preparation technique and application thereof have the beneficial effects that the Ti-6Al-4V alloy wire is prepared through the technical process that heat machining, cold drawing and temperature-control hot drawing are combined, and the Ti-6Al-4V alloy wire has the advantages that the mechanical performance is high, the dimensional precision is high, the surface smoothness is high, and the structure property uniformity is good.

Owner:DALIAN SUNNY TITANIUM IND

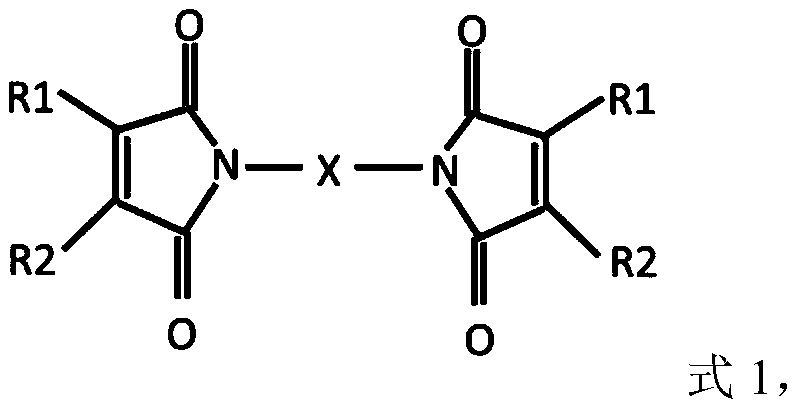

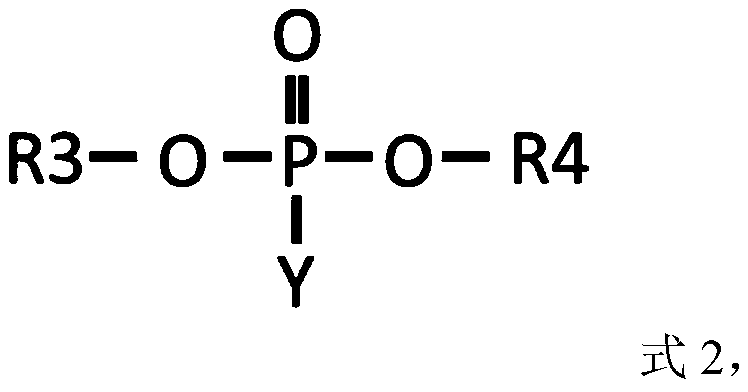

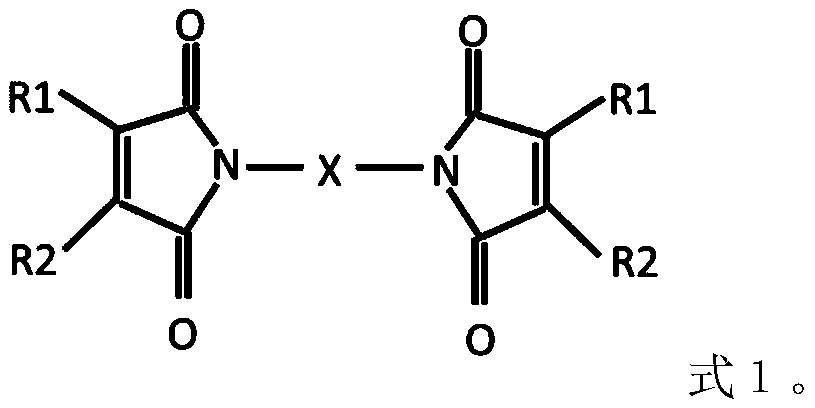

Bismaleimide resin composition and solidified matter thereof as well as composite material

The invention provides a bismaleimide resin composition. The bismaleimide resin composition is prepared from the following components in parts by weight: 100 parts of phosphorus-containing bismaleimide resin and 1 to 60 parts of epoxy resin, wherein the phosphorus-containing bismaleimide resin has a structure shown as a formula 1 and the formula 1 is shown in the description, wherein X is a phosphorus-containing group; R1 and R2 are hydrogen or alkyl; the R1 and the R2 can be the same or not. The bismaleimide resin composition provided by the invention has good interface cohesiveness with carbon fibers; a solidified matter of the bismaleimide resin composition and a composite material of the bismaleimide resin composition and the carbon fibers have high tensile strength and good toughnessand have the advantages of excellent mechanical property stability and good heat resistance, flame retarding performance and water resistance and the like, and are especially suitable for applicationwith large-size and durability requirements, such as airplanes, trains, automobiles and wind power generation blades.

Owner:JIANGSU AOSHENG COMPOSITE MATERIALS HI TECH

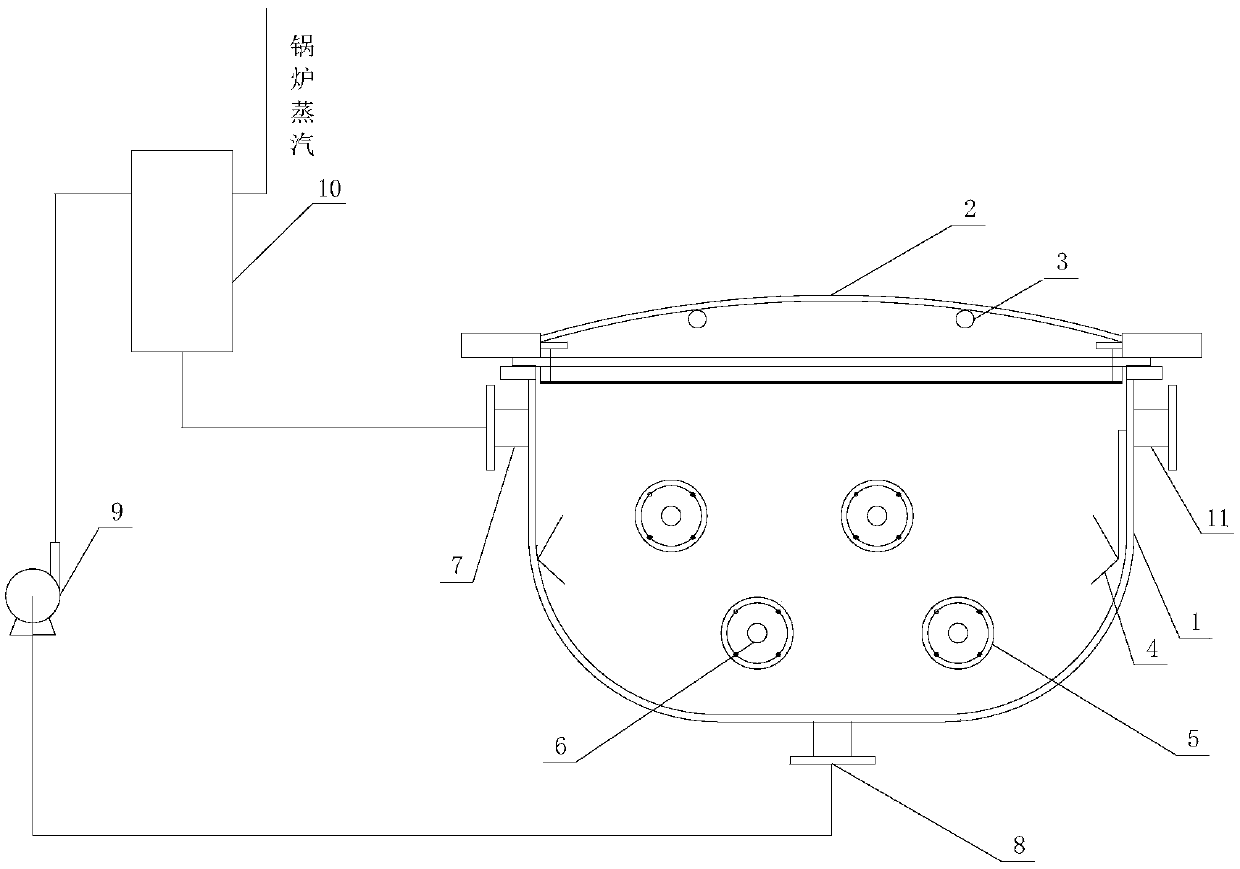

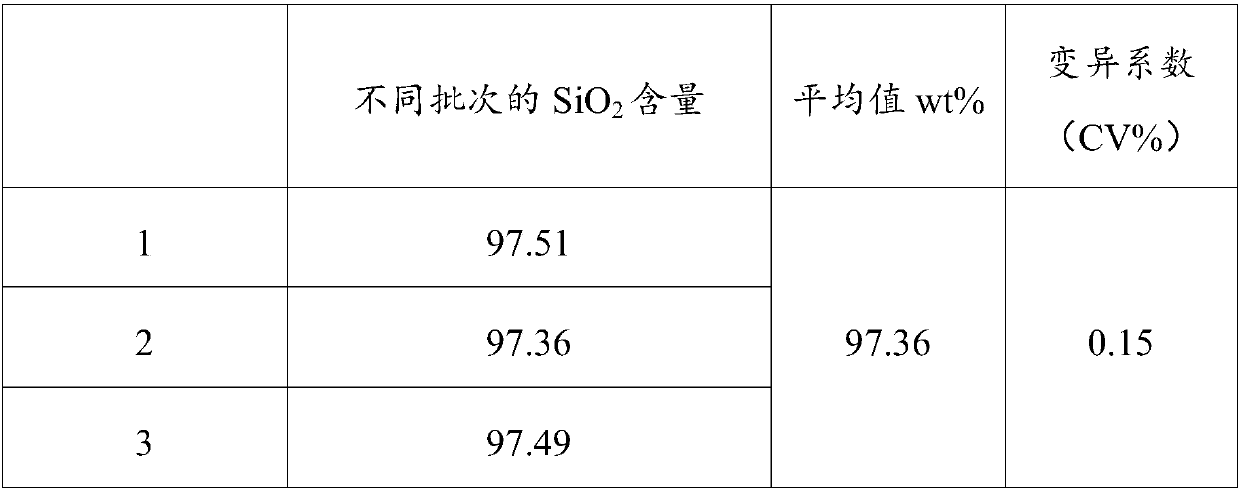

Acid leaching device for fiber yarn rope

The invention relates to equipment for acid leaching technological treatment, in particular to an acid leaching device for a fiber yarn rope. The acid leaching device comprises an acid leaching tank,a yarn carrying assembly, a driving motor and a heat exchange assembly, wherein the acid leaching tank is provided with an acid inlet and an acid outlet; the yarn carrying assembly is positioned inside the acid leaching tank and comprises a rotating shaft and a yarn reeling structure sleeving the rotating shaft; the driving motor is arranged outside the acid leaching tank and is used for driving the rotating shaft to rotate so as to drive the yarn reeling structure to rotate; the heat exchange assembly is arranged outside the acid leaching tank, communicates with the acid inlet and the acid outlet respectively, and is used for heating acid liquid at the acid outlet and then inputting the acid liquid into the acid inlet so as to complete heating of the acid liquid. The acid leaching devicecan increase the content of silicon oxide in a prepared high-silica glass fiber rope, improve the uniformity of a strength variation coefficient and improve the product quality and the production efficiency.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

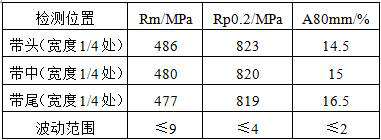

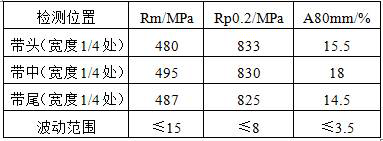

Method for improving performance uniformity of 780MPa-grade galvanized dual-phase steel

PendingCN113106208AImprove the stability of mechanical propertiesImprove mechanical propertiesFurnace typesHeat treatment process controlTemperature controlStrip steel

The invention discloses a method for improving performance uniformity of 780MPa-grade galvanized dual-phase steel, which comprises the following steps: (1) heating second-stage temperature control: controlling the temperature of strip steel at the heating second-stage to be 750-780 DEG C, and staying for 1-2 minutes; (2) controlling the temperature of a soaking section: controlling the temperature of the strip steel in the soaking section to be 750-780 DEG C, and keeping the standing time for 1-2 minutes; (3) controlling the temperature of an outlet of a slow cooling section: controlling the temperature of the outlet of the slow cooling section at 660-700 DEG C, and controlling the cooling speed of the slow cooling section at 10-20 DEG C / s; and (4) controlling the speed of the strip steel in the continuous annealing furnace: controlling the speed of the strip steel in the continuous annealing furnace to be 80-120m / min. By adjusting the phase change degree of the microscopic structure, the mechanical property uniformity is improved, the local performance fluctuation range is narrowed, and the mechanical property stability in the length direction of the strip steel can be effectively improved.

Owner:唐山科技职业技术学院 +1

A kind of steel-bonded hard alloy and its preparation method and application

Owner:常熟市电力耐磨合金铸造有限公司

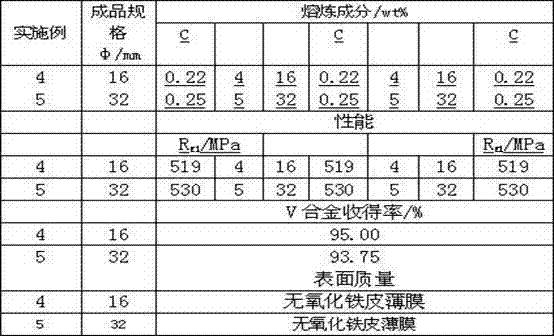

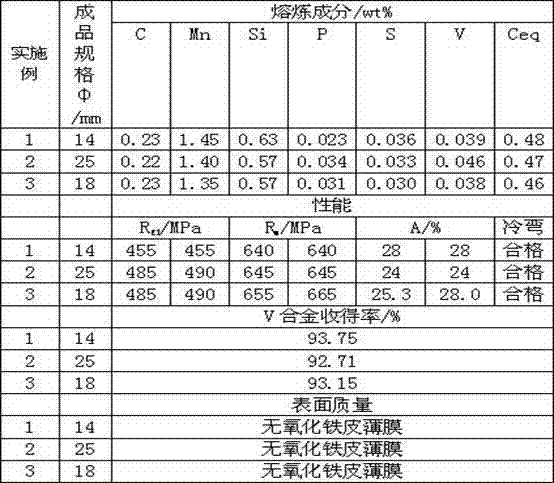

Production method for VN reinforcement bar with yield strength not less than 400MPa

ActiveCN102220449BImprove the stability of mechanical propertiesGuaranteed performanceTemperature control deviceManufacturing convertersAlloyRebar

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

A low-cost low-alloy steel coil and its manufacturing method

The invention discloses a low-cost low-alloy steel coil and a manufacturing method thereof, and belongs to the technical field of hot continuous rolling strip production. The chemical composition and mass percentage of the steel coil of the present invention are: C: 0.06-0.08%; Mn: 0.50-0.80%; P≤0.015%; S≤0.008%; Ti: 0.045-0.075%; Al: 0.04-0.05% %; N≤0.0040%; O≤0.0030%, the rest are Fe and unavoidable impurities. The manufacturing steps are: converter smelting-RH external refining-continuous casting, heating, TMCP-laminar cooling and coiling. By adopting the technical scheme of the present invention, without adding expensive microalloying alloying elements such as Nb and V, the overall strength and toughness of the obtained steel coil product can reach the same level as that of existing Nb and V microalloyed steel coils, Significantly reduced production costs. At the same time, it can further improve the stability of the mechanical properties of the steel coil and reduce performance fluctuations, thereby better meeting production requirements.

Owner:MAANSHAN IRON & STEEL CO LTD

Structural laminwood and preparation method thereof

InactiveCN101564854BIncrease profitImprove structural performanceOther plywood/veneer working apparatusWood veneer joiningLower gradeEngineering

The invention provides a structural laminwood and a preparation method thereof. The laminwood is stacked and glued by 2-7 layers of veneers, wherein the grade of the external layer veneer of the laminwood is equal to the grade of the adjacent internal layer veneer or higher than the adjacent internal layer veneer by one grade; the veneer grade is determined by the average value of flexural elasticmodulus of the target grades of all veneers; and compared with the veneers with lower grades, the veneers with higher grades have greater average value of the flexural elastic modulus of the target grades. The method lengthens the stock lumbers of short dimensions by mechanical stress grading and uses the lengthened stock lumbers as the veneers, then configures the veneer structures according toa grade configuration principle and coldly presses and glues the veneers to prepare the structural laminwood. The laminwood has excellent structural performance and can be used for the components suchas beams, columns, and the like in wood structure buildings or other buildings.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Preparation method and product of flexible transparent conductive film with high thermal stability

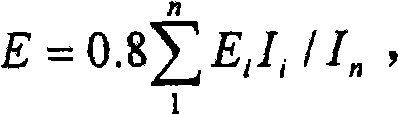

ActiveCN105405492BReduce surface roughnessImprove the stability of mechanical propertiesConductive layers on insulating-supportsCable/conductor manufactureHeat stabilityMaterials science

The invention discloses a preparation method for a flexible transparent conductive thin film with high thermal stability. The preparation method comprises the steps of step 1, uniformly coating the surface of a tidy and smooth target substrate with a one-dimension-structured conductive metal nanomaterial, and forming a conductive network structure; step 2, performing blade coating on the surface of the target substrate with the conductive network structure to form a precursor coating layer containing fluorinated polyimide; step 3, performing a curing process on the precursor coating layer containing fluorinated polyimide through a gradient temperature rise manner; and step 4, peeling off the cured fluorinated polyimide contained film layer from the target substrate to obtain the required finished product. The invention also discloses a corresponding flexible transparent conductive thin film product and characteristics of the product. Through the preparation method, the flexible transparent conductive thin film can be prepared in an efficient manner, and the quality control can be performed conveniently; and the prepared flexible transparent conductive thin film has the characteristics of low sheet resistance, high visible light transmittance, anti-ultraviolet property, high flexibility, low surface roughness, excellent high-temperature endurance and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

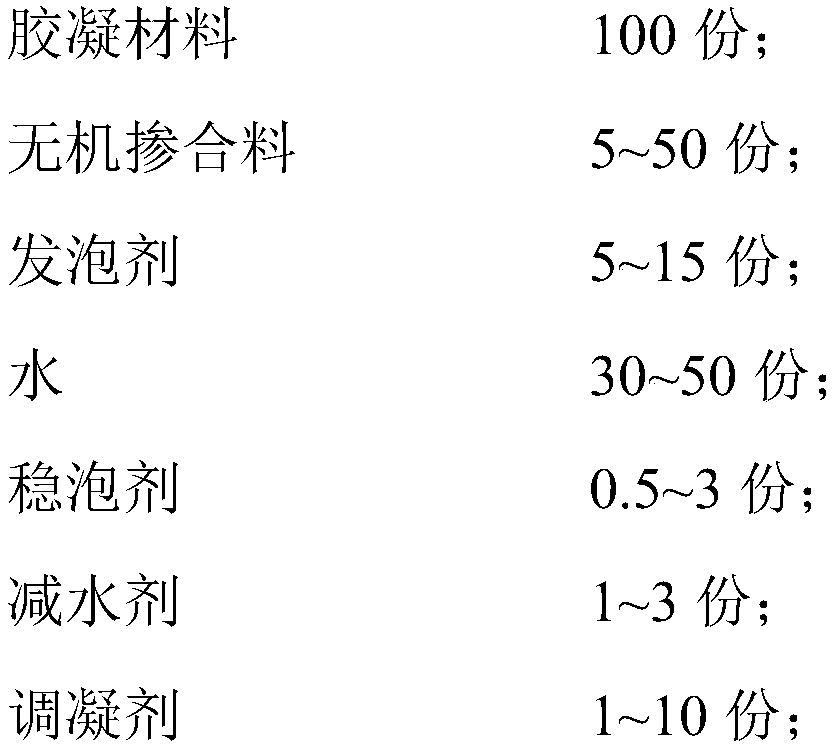

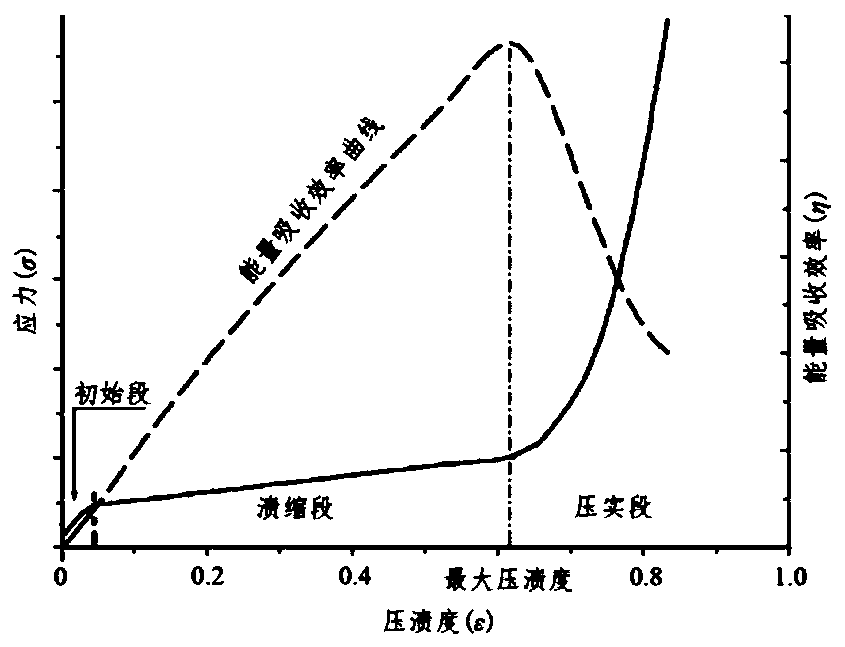

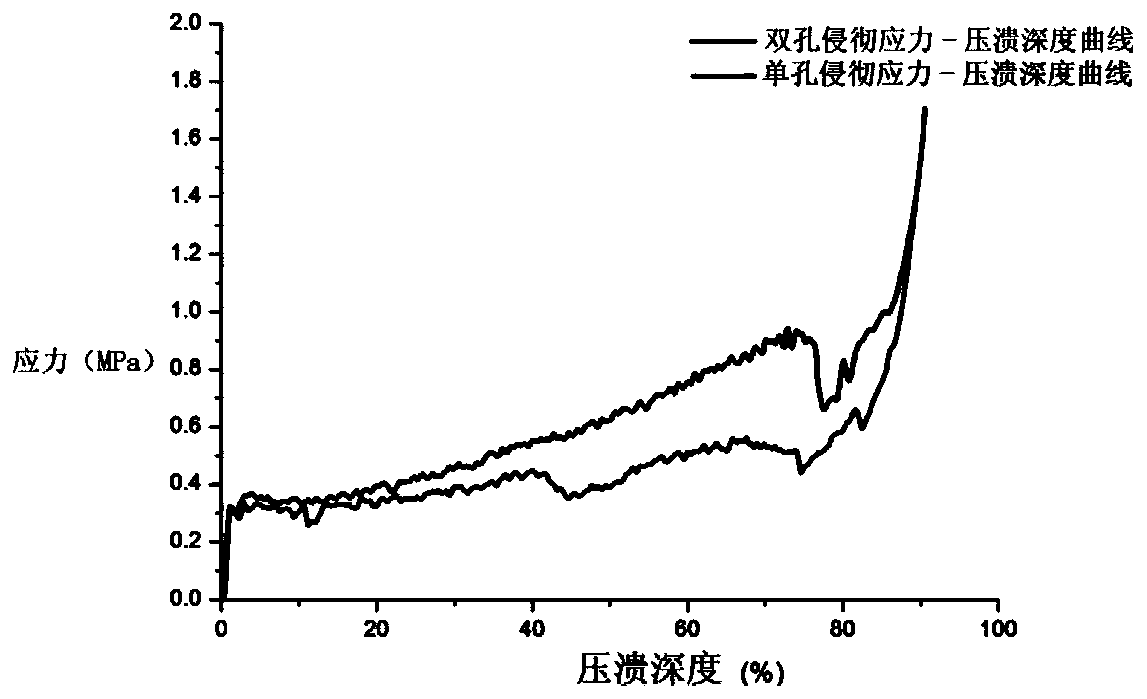

Light porous calcium carbonate material and preparation method thereof

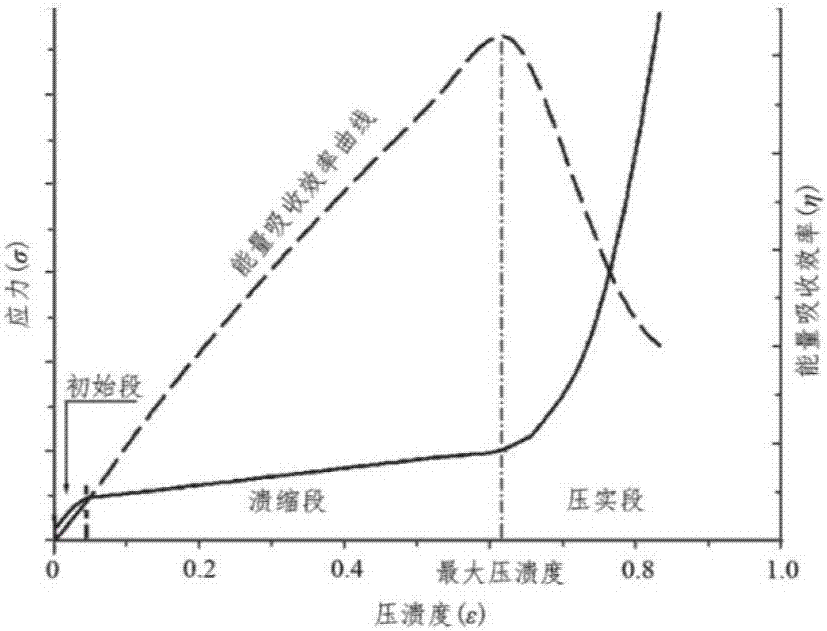

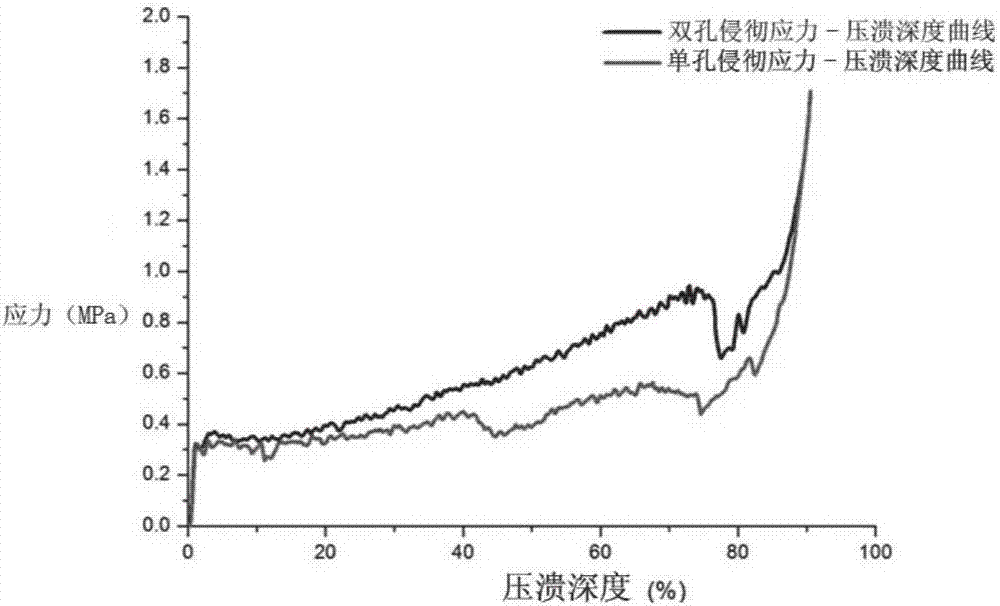

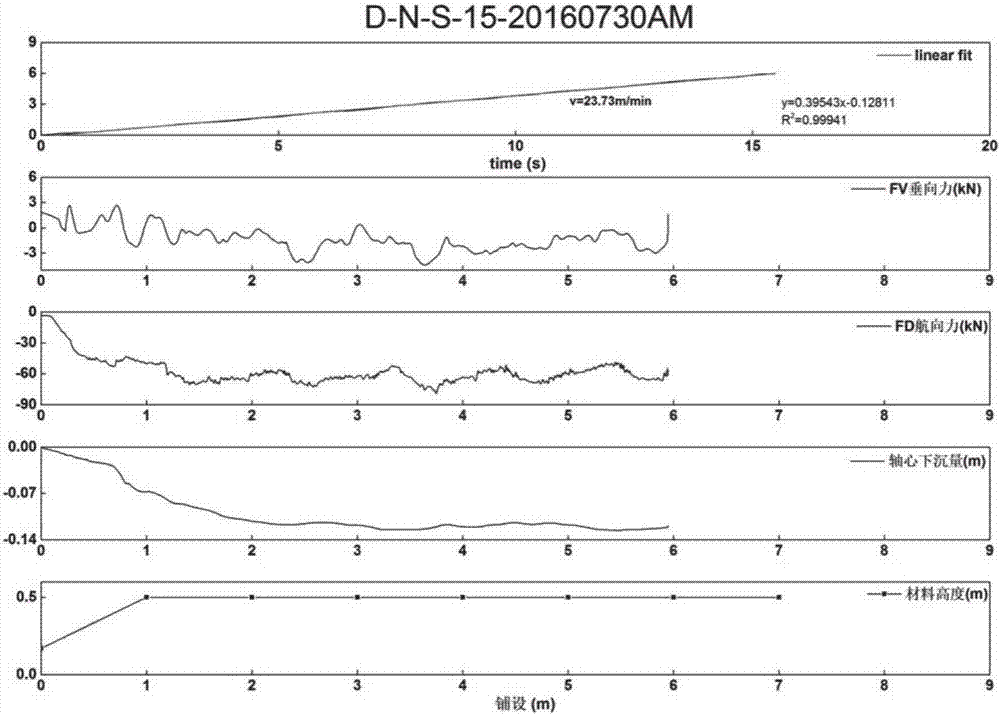

InactiveCN110698155AIncrease responsivenessImproved carbonation resistanceCeramicwarePorous carbonEnergy absorption

The invention discloses a light porous calcium carbonate material and a preparation method thereof. The light porous calcium carbonate material is prepared by combining a cementing material and an inorganic admixture, and a main component of the material after an air hardening reaction is calcium carbonate. Compared with common cement-based light porous concrete materials, the light porous calciumcarbonate material provided by the invention has the following advantage that the mineral component of raw materials of the light porous calcium carbonate material is single, and the reaction degreeof the material is high in a curing stage, so that properties such as carbonization resistance, mechanical property stability during the service life, temperature tolerance and the like are improved.Through adjustment of the content of functional components (a foam stabilizer, a water reducing agent, a setting regulator, a waterproof agent, an anti-cracking component, etc.), performance of the material and process stability can be adjusted. The material has low penetration strength and density, has a specific mechanical characteristic of energy absorption during crushing, and can be used in an engineered material arresting system at the end of airport runways.

Owner:CHINA ACAD OF CIVIL AVIATION SCI & TECH +1

A mechanically stable edible composite film and its preparation method

ActiveCN103740117BStable mechanical propertiesImprove mechanical propertiesFlexible coversWrappersCarrageenanPlasticizer

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Aluminum-titanium foil

The invention relates to an aluminum-titanium foil, in particular to an aluminum-titanium foil with good antibacterial performance. The aluminum titanium foil comprises the following chemical components in percentage by weight: 0.7 to 1.1 percent of Fe, 0.2 to 0.3 percent of Si, 0.01 to 0.03 percent of Cu, 0.05 to 0.10 percent of Ti and the balance of Al and impurities. According to the aluminum-titanium foil provided by the embodiment of the invention, the weight percentage control range of Fe, Si and Cu is reduced, and the weight percentage of Ti is increased, so that the antibacterial performance of the aluminum-titanium foil can be improved, and the aluminum-titanium foil can play a good antibacterial role when being used for packaging foods or medicines.

Owner:SNTO TECH GRP

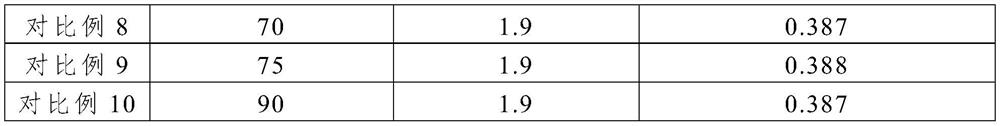

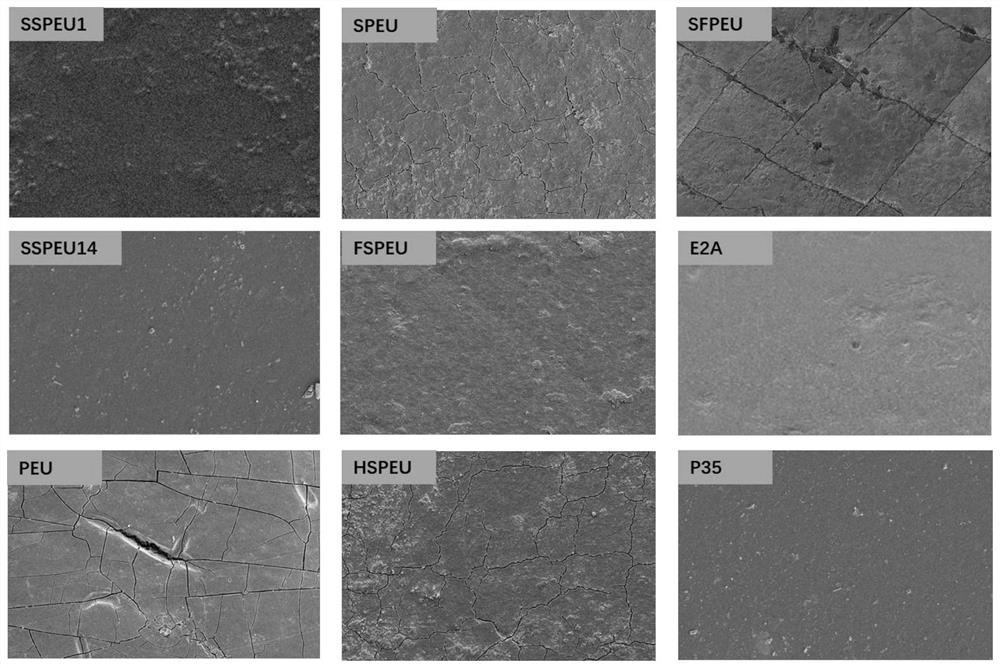

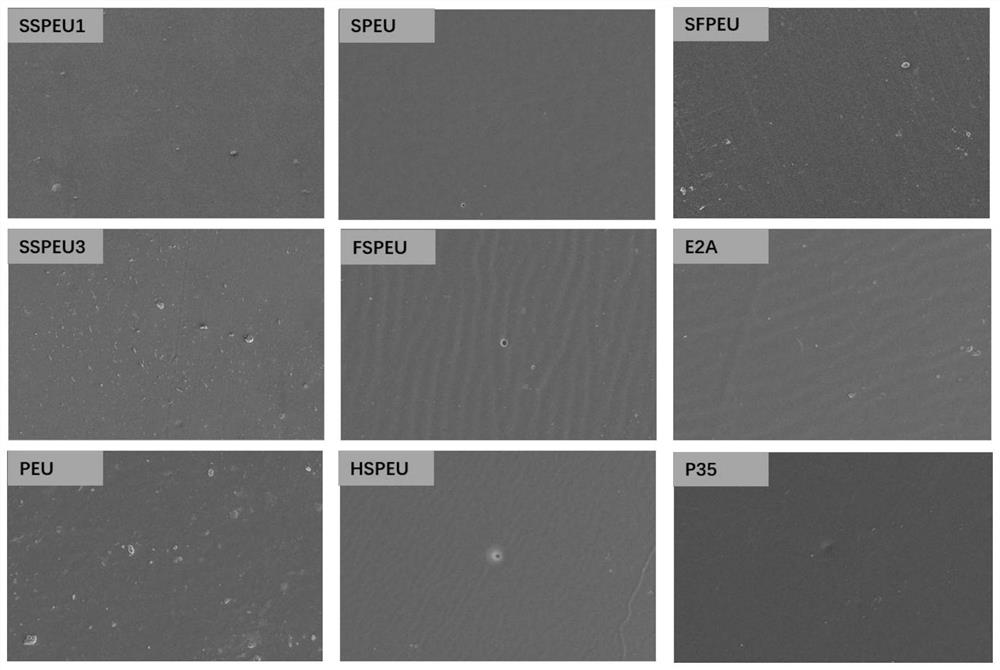

Polyurethane with biological stability and mechanical stability as well as preparation method and application thereof

ActiveCN114456346AImprove hydrolytic stabilityImprove oxidation stabilitySurgeryPolymer sciencePolyol

The invention provides polyurethane with biological stability and mechanical stability, a preparation method and application thereof, and a related medical implant material containing the polyurethane. The polyurethane with biological stability and mechanical stability is prepared by the following steps: (1) carrying out vacuum dehydration reaction on polyether glycol and polydimethylsiloxane glycol under a heating condition, cooling, adding diisocyanate and siloxane modified polyol at normal pressure, and carrying out prepolymerization reaction; and (2) adding a chain extender, uniformly stirring and mixing, carrying out a curing reaction at high temperature, and carrying out melt processing molding on a cured product to obtain the product. The polyurethane provided by the invention has the advantages of good biological stability, good hydrolysis resistance and oxidation resistance, good mechanical stability, high initial mechanical strength, small reduction amplitude of mechanical properties in a long-term use process, and basically no loss, and can be well used as a long-term implant material. The structural formula of the siloxane modified polyol is shown in the specification.

Owner:眉山尤博瑞新材料有限公司

A kind of silicate-based lightweight foam concrete and its preparation method

ActiveCN106966670BImproved carbonation resistanceImprove the stability of mechanical propertiesCeramicwareFoam concreteFoaming agent

The invention discloses silicate-based light-weight foam concrete and a preparation method thereof. The silicate-based light-weight foam concrete is prepared from silicate cement, an inorganic admixture, water, a foaming agent and an additive, wherein the mass ratio of the inorganic admixture to the silicate cement is 0.3 to 1.3; the water accounts for 35 to 65 percent by mass; and the foaming agent accounts for 3 to 10 percent by mass. The silicate-based light-weight foam concrete has the beneficial effects that the silicate cement is used as a cementing material; and compared with a sulfoaluminate-based material, the silicate-based light-weight foam concrete has the advantages that the carbonation resistance, the mechanical performance stability, the temperature tolerance and other properties are improved. By adjustment of the contents of all functional components (a thickening time control agent, a foam stabilizer, a water reducing agent, an anti-cracking component, an expanding agent and the like), the silicate-based light-weight foam concrete can conform to various preparation conditions of the silicate cement used as a base material.

Owner:CHINA ACAD OF CIVIL AVIATION SCI & TECH

I-shaped integrated material for structure and manufacturing method thereof

InactiveCN103128824BIncrease profitImprove structural performanceWood working apparatusGirdersJoistLower grade

The invention provides an I-shaped integrated material for a structure and a manufacturing method thereof. The manufacturing method comprises the steps of dividing sawn timber into high-grade sawn timber, intermediate-grade sawn timber and low-grade sawn timber according to the size of elastic modulus of the sawn timber; respectively making the same-grade sawn timber into finger joint laminates in a finger joint mode, making more than two finger joint laminates into laminated wood in a glued mode; enabling intermediate-grade laminated wood to serve as a top flange, enabling low-grade laminated wood to serve as a web plate, enabling high-grade laminated wood to serve as a bottom flange, enabling the intermediate-grade laminated wood and the high-grade laminated wood to be horizontally parallelly placed, enabling the low-grade laminated wood to be vertically placed, and manufacturing the I-shaped integrated material for the structure in a finger joint mode. The I-shaped integrated material for the structure is high in strength and stiffness and can be applied to main body beam members and joist beam members and the like in timber structure engineering.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Finger joint stock lumber for construction and manufacturing method thereof

ActiveCN101570996BImprove structural performanceIncrease profitPolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesFinger jointArchitectural engineering

Owner:FUJIAN LONTAI BAMBOO HOUSEHOLD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com