Preparation method for flexible transparent conductive thin film with high thermal stability and product thereof

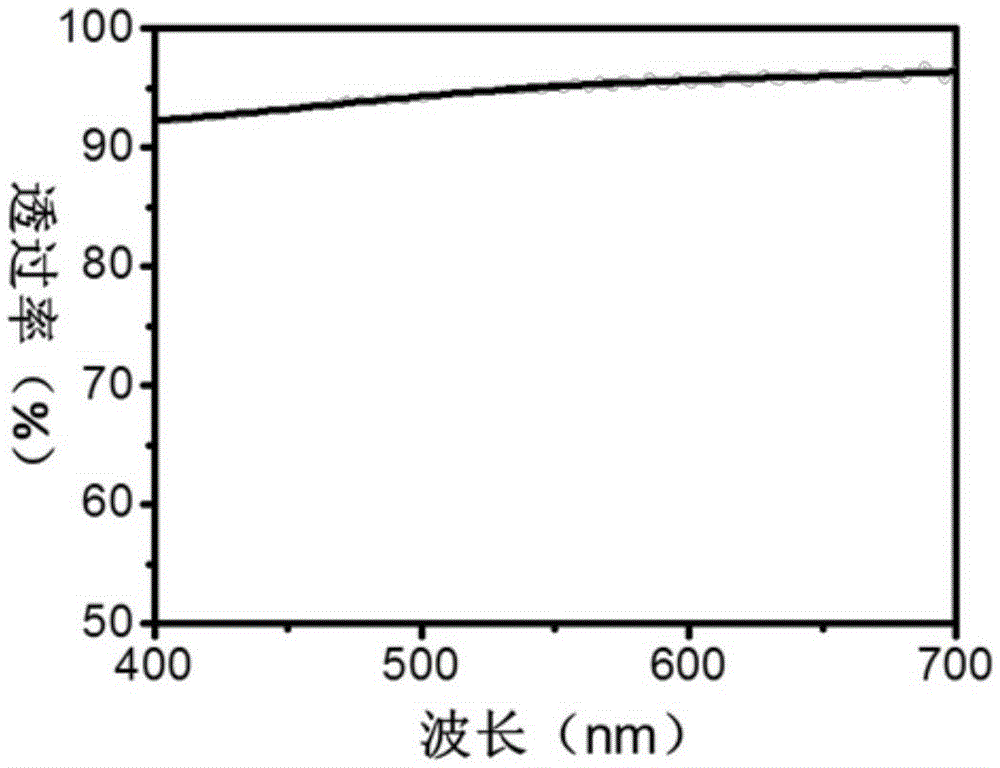

A transparent conductive film, high thermal stability technology, applied to conductive layers on insulating carriers, cable/conductor manufacturing, circuits, etc., can solve the problems of decreased thermal stability, poor thermal stability, low conductivity of conductive polymers, etc. Achieve the effect of increasing fracture failure temperature, improving thermal stability, and good ultra-high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

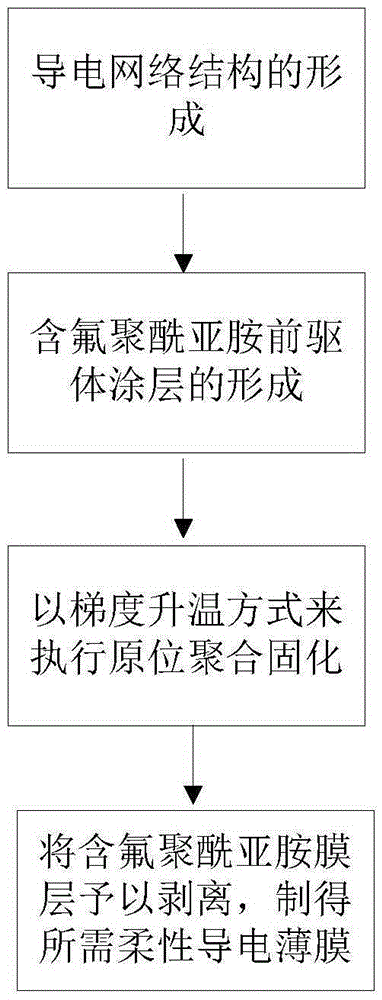

Method used

Image

Examples

Embodiment 1

[0039] Use an ethanol solution of silver nanowires with an average aspect ratio of about 1000 to evenly coat the silver nanowires on the silicon wafer with a squeegee tool. The square resistance is set to 70Ω / sq, for example; the coating method can be specifically selected as suction filtration , drop coating, spin coating, scraping film method, spraying method, nanomaterial self-assembly method and so on.

[0040] Next, dissolve the fluorine-containing polyimide powder in N,N-dimethylacetamide to prepare a 5% fluorine-containing polyimide precursor solution by mass ratio; then the fluorine-containing polyimide precursor The liquid is covered on the silicon wafer by the casting and scraping method, and the thickness of the precursor solution is controlled to be about 300 microns; the scraping in this step can also be, for example, adopt the spin coating method in addition to the casting and scraping film forming method;

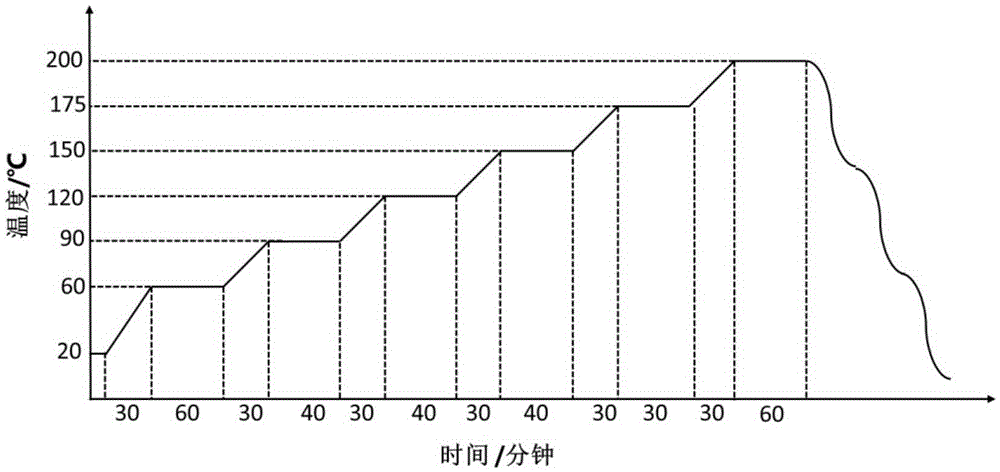

[0041] Then, for example, the whole is placed in a blas...

Embodiment 2

[0044] Use an ethanol solution of copper nanowires with an average aspect ratio of about 300 to uniformly coat the silver nanowires on the silicon wafer with a squeegee tool, and the square resistance is set to 30Ω / sq, for example;

[0045] Next, dissolve the fluorine-containing polyimide powder in N,N-dimethylacetamide to prepare a fluorine-containing polyimide precursor solution with a mass ratio of 15%; then the fluorine-containing polyimide precursor The liquid is covered on the silicon wafer by casting and scraping film, and the thickness of the precursor liquid is controlled to be about 500 microns;

[0046] Then, for example, the whole is placed in a blast drying oven to heat and solidify. First, keep it warm at 60°C for 40 minutes, and then use steps to raise the temperature to 90°C, 120°C, 150°C, 175°C, and 200°C. Each step is maintained for 40 minutes, so that The fluorine-containing polyimide precursor is cured, and the organic solvent is completely removed at the s...

Embodiment 3

[0049] Use an ethanol solution of gold nanowires with an average aspect ratio of about 800 to uniformly coat the silver nanowires on the silicon wafer with a squeegee tool, and the square resistance is set to 10Ω / sq, for example;

[0050] Next, dissolve the fluorine-containing polyimide powder in N,N-dimethyl sulfoxide to prepare a 6% fluorine-containing polyimide precursor solution by mass ratio; then the fluorine-containing polyimide precursor The liquid is covered on the silicon wafer by casting and scraping film, and the thickness of the precursor liquid is controlled to be about 700 microns;

[0051] Then, for example, the whole is placed in a blast drying oven to heat and solidify. First, heat it at 70°C for 40 minutes, and then use steps to raise the temperature to 90°C, 120°C, 150°C, 175°C, and 200°C. Each step is maintained for 40 minutes. Thus forming a fluorine-containing polyimide transparent film;

[0052] Finally, the film is peeled off from the silicon wafer to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com