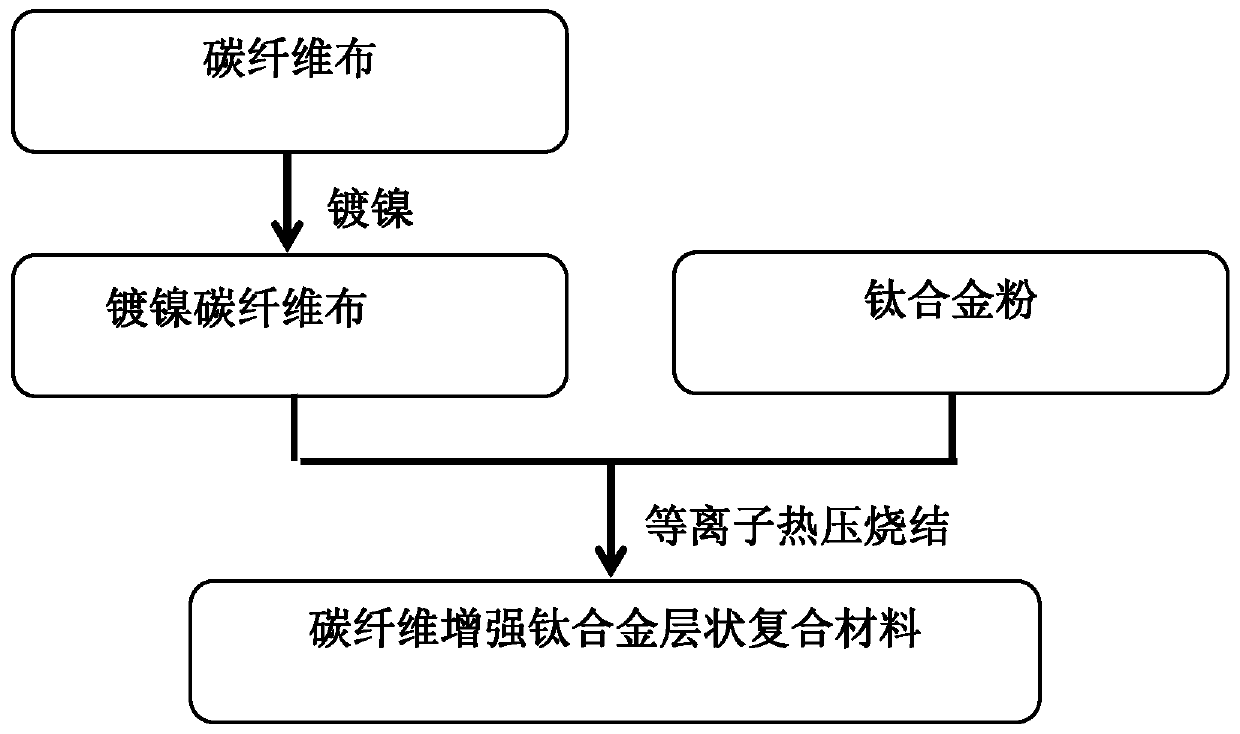

Method for rapidly preparing carbon fiber reinforced titanium alloy layered composite material

A layered composite material and titanium alloy technology, which is applied in the direction of metal material coating process, coating, liquid chemical plating, etc., can solve the problems of severe interface reaction, carbon fiber reinforced titanium and the reduction of mechanical properties of composite materials, etc. Effects of improved performance, increased preparation speed, and short holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment includes the following steps:

[0031] Step 1. Put the carbon fiber cloth in absolute ethanol and ultrasonically clean it for 10 minutes, and then dry it at 100°C for 10 hours;

[0032] Step 2: Carry out sensitization treatment with sensitization solution to the carbon fiber cloth dried in step 1, then use activation solution to perform activation treatment, then use 10g / L sodium hypophosphite aqueous solution to perform reduction treatment, wash with distilled water and then dry dry; the sensitization solution consists of SnCl 2 , hydrochloric acid solution with a mass concentration of 37% and distilled water, the SnCl in the sensitization solution 2 The concentration of the hydrochloric acid solution is 1g / L, the mass percent of the hydrochloric acid solution is 1%, and the activation solution is composed of PdCl 2 , ethanol and distilled water, PdCl in the activation solution 2 The concentration is 0.1g / L;

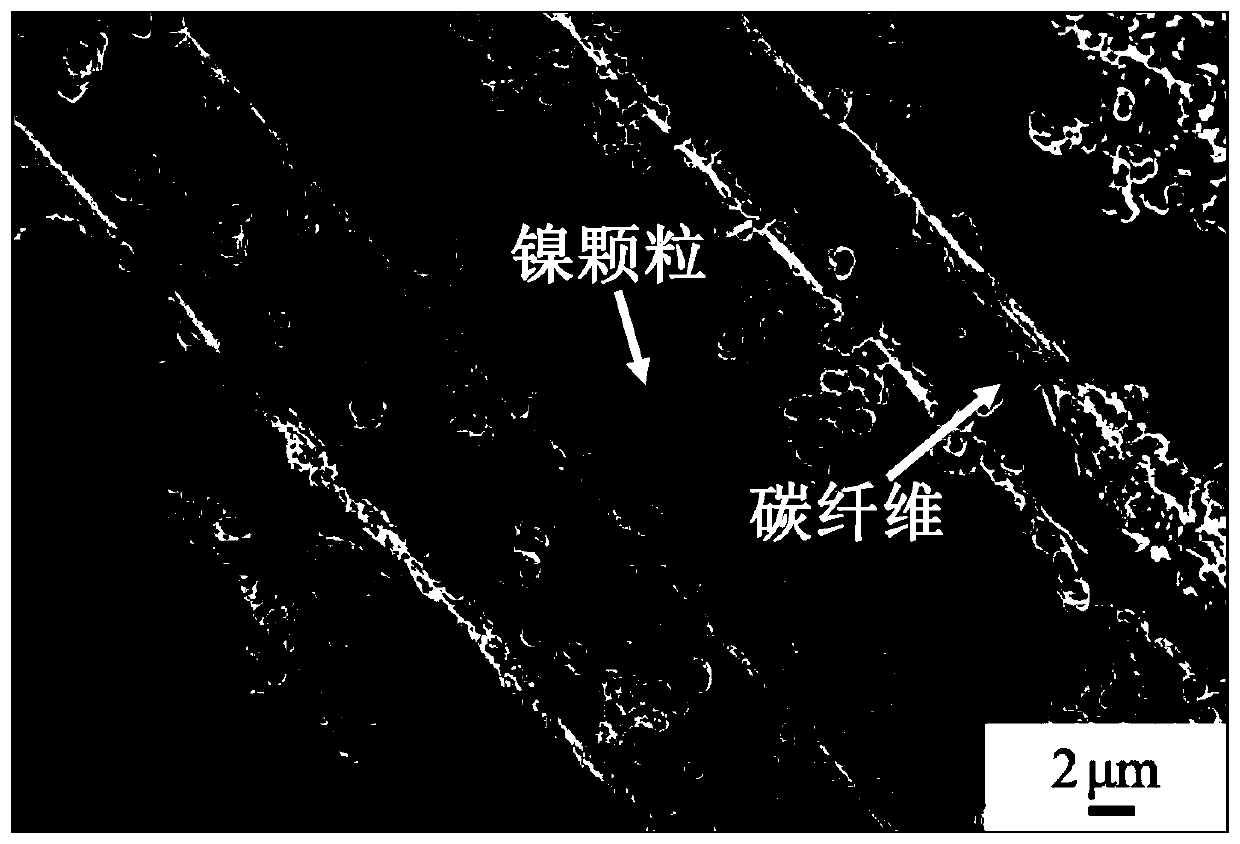

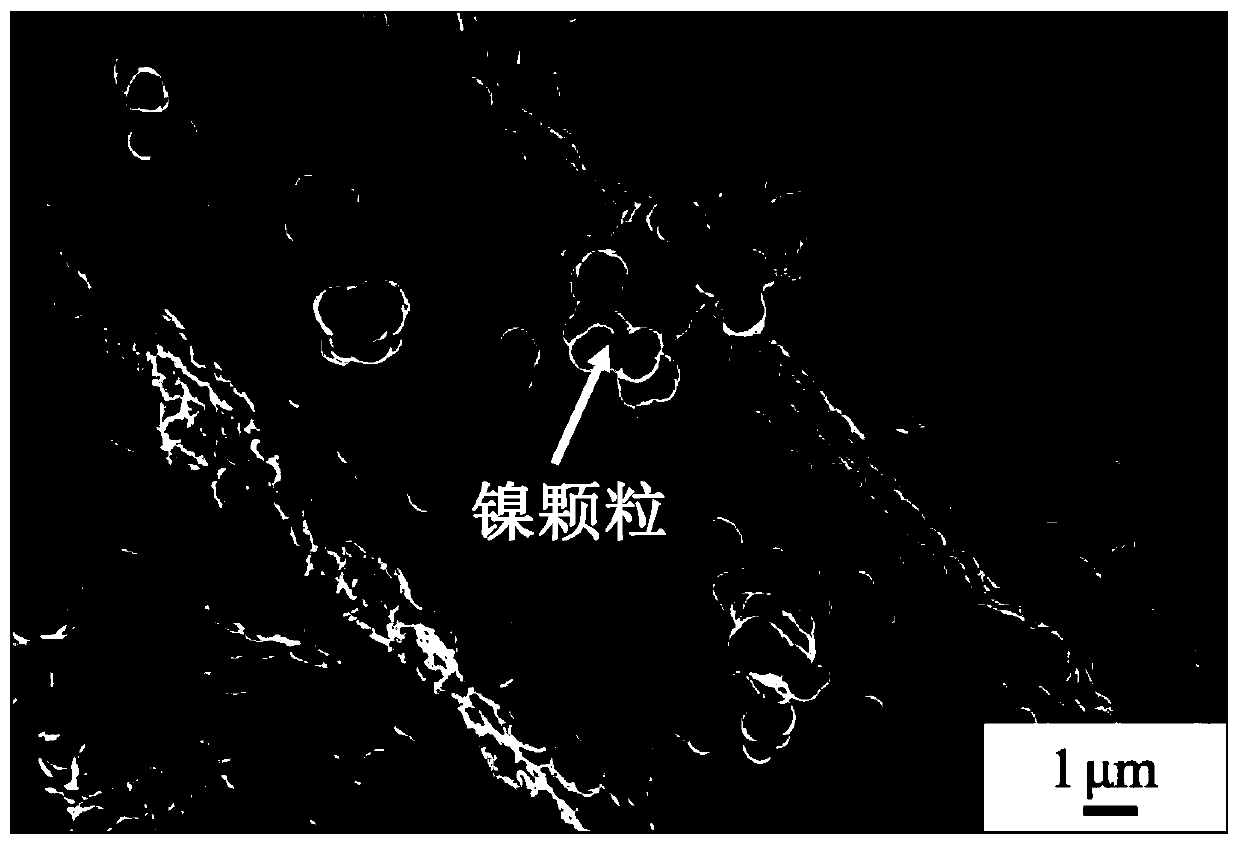

[0033]Step 3, put the dried carbon fibe...

Embodiment 2

[0052] This embodiment includes the following steps:

[0053] Step 1. Put the carbon fiber cloth into absolute ethanol and ultrasonically clean it for 30 minutes, and then dry it at 100°C for 20 hours;

[0054] Step 2: Carry out sensitization treatment with sensitization solution to the carbon fiber cloth dried in step 1, then use activation solution to perform activation treatment, then use 10g / L sodium hypophosphite aqueous solution to perform reduction treatment, wash with distilled water and then dry dry; the sensitization solution consists of SnCl 2 , hydrochloric acid solution with a mass concentration of 37% and distilled water, the SnCl in the sensitization solution 2 The concentration is 20g / L, the mass percent of hydrochloric acid solution is 5%, and described activation solution is made of PdCl 2 , ethanol and distilled water, PdCl in the activation solution 2 The concentration is 0.6g / L;

[0055] Step 3, put the dried carbon fiber cloth in step 2 into the nicke...

Embodiment 3

[0058] This embodiment includes the following steps:

[0059] Step 1. Put the carbon fiber cloth in absolute ethanol and ultrasonically clean it for 20 minutes, and then dry it at 100°C for 15 hours;

[0060] Step 2: Carry out sensitization treatment with sensitization solution to the carbon fiber cloth dried in step 1, then use activation solution to perform activation treatment, then use 10g / L sodium hypophosphite aqueous solution to perform reduction treatment, wash with distilled water and then dry dry; the sensitization solution consists of SnCl 2 , hydrochloric acid solution with a mass concentration of 37% and distilled water, the SnCl in the sensitization solution 2 The concentration is 10g / L, and the mass percent of hydrochloric acid solution is 3%, and described activation solution is made of PdCl 2 , ethanol and distilled water, PdCl in the activation solution 2 The concentration is 0.3g / L;

[0061]Step 3, put the dried carbon fiber cloth in step 2 into the nick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com