Low viscosity UV/moisture dual-curing polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive, dual-curing technology, used in polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of volatile, easy to bring pollution, peculiar smell, etc. , Avoid pollution problems and odor problems, improve the effect of final adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

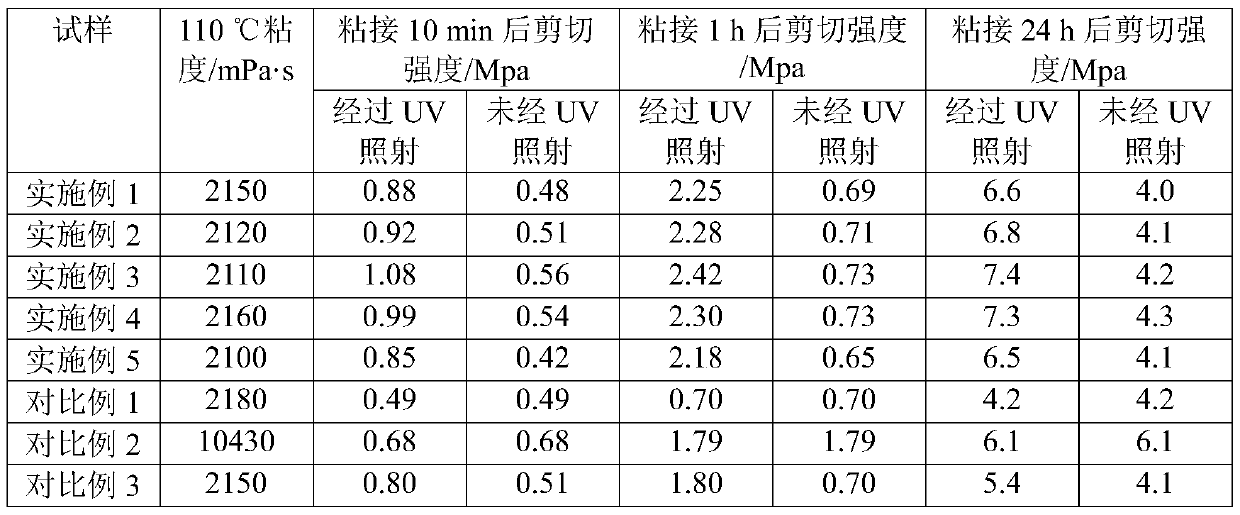

Examples

Embodiment 1

[0028] A low-viscosity UV / moisture dual-curing polyurethane hot-melt adhesive, in parts by weight, the hot-melt adhesive comprises the following components: 95.06 parts of UV / moisture dual-curing polyester polyether polyurethane, free radical photoinitiator ( 2,2-dimethoxy-2-phenylacetophenone) 2.5 parts, cationic photoinitiator (diphenyliodonium hexafluorophosphate) 1.5 parts, photosensitizer (2-isopropylthioxanthone ) 0.6 part, polyurethane catalyst (0.12 part of bismorpholine diethyl ether and 0.01 part of dibutyltin dilaurate) 0.13 part, water reducer (benzoyl chloride) 0.01 part, antioxidant (antioxidant 1010) 0.2 part . Prepare as follows:

[0029] In parts by weight, 10 parts of crystalline polyester diol (hexanediol adipate diol) with a molecular weight of 1000, 30 parts of crystalline polyester diol (succinic acid) with a molecular weight of 6000 butylene glycol ester diol), 20 parts of polyether diol (polypropylene glycol diol) with a molecular weight of 2000, 10 p...

Embodiment 2

[0033] A low-viscosity UV / moisture dual-curing polyurethane hot-melt adhesive, by weight, the hot-melt adhesive comprises the following components: 96.71 parts of UV / moisture dual-curing polyester polyether polyurethane, free radical photoinitiator ( 1-hydroxy-cyclohexyl-phenyl ketone) 2 parts, cationic photoinitiator (4-isobutylphenyl-4'-methylphenyliodonium hexafluorophosphate) 0.5 parts, photosensitizer (2, 0.5 parts of 4-diethylthioxanth-9-one), 0.175 parts of polyurethane catalyst (0.16 parts of bismorpholine diethyl ether and 0.015 parts of dibutyltin dilaurate), 0.015 parts of water reducer (heptanoyl chloride), Antioxidant (antioxidant 1076) 0.1 part. Prepare as follows:

[0034] In parts by weight, 25 parts of crystalline polyester diol (butylene adipate diol) with a molecular weight of 3000, 10 parts of polyether diol (bisphenol A polyoxyl) with a molecular weight of 400 Vinyl ether diol), 28 parts of polyether diol (polypropylene glycol diol) with a molecular weig...

Embodiment 3

[0038] A low-viscosity UV / moisture dual-curing polyurethane hot-melt adhesive, in parts by weight, the hot-melt adhesive comprises the following components: 96.16 parts of UV / moisture dual-curing polyester polyether polyurethane, free radical photoinitiator ( 2,4,6-trimethylbenzoyl-diphenylphosphine oxide) 3 parts, cationic photoinitiator (4-tert-butylphenyl-4'-tert-butylphenyliodonium hexafluorophosphate) 0.25 parts, 0.25 parts of photosensitizer (N-vinyl carbazole), 0.27 parts of polyurethane catalyst (0.24 parts of bismorpholine diethyl ether and 0.03 parts of dibutyltin dilaurate), 0.02 parts of water reducer (cyclohexyl chloride) Part, antioxidant (antioxidant 164) 0.05 part. Prepare as follows:

[0039] In parts by weight, 30 parts of crystalline polyester diol (butylene sebacate diol) with a molecular weight of 4000, 5 parts of polyether diol (bisphenol A polyoxyl) with a molecular weight of 500 Propylene ether diol), 10 parts of polyether diol (polypropylene glycol d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com