Low-cost low alloy steel coil and manufacturing method thereof

A low-alloy steel and a manufacturing method technology, which are applied to the low-cost low-alloy steel coil and the manufacturing field thereof, can solve the problem of high production cost, and achieve the effects of reducing alloy cost, saving labor cost, and avoiding corner cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

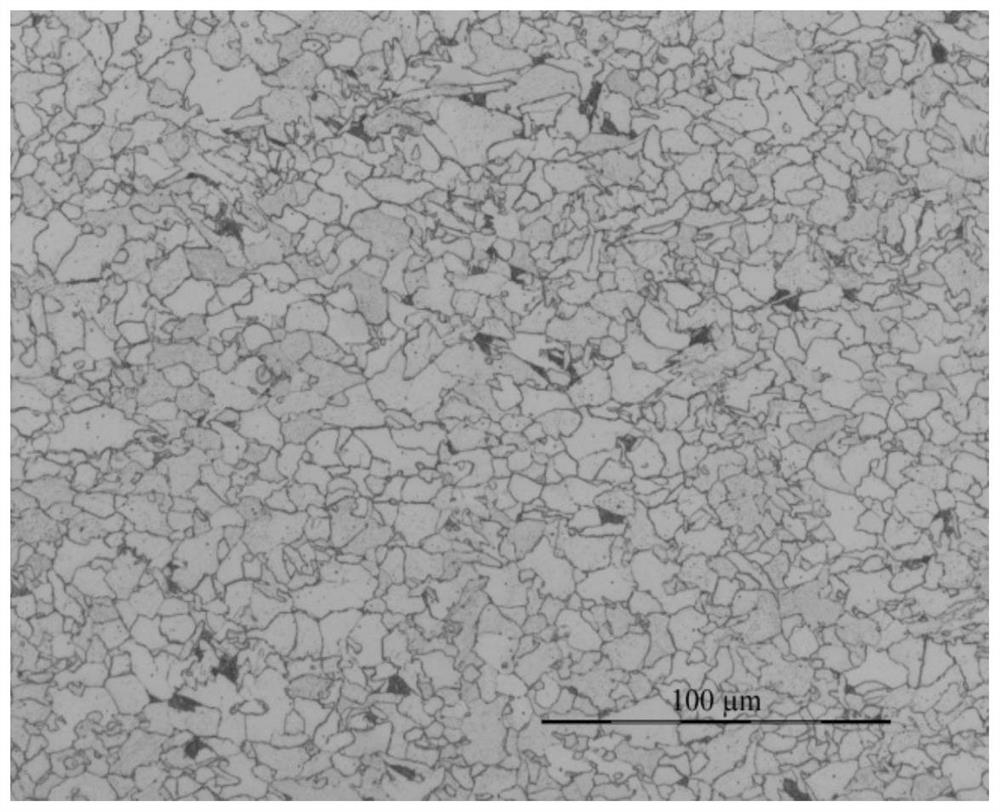

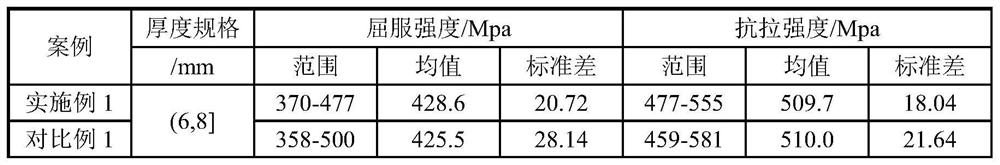

Embodiment 1

[0060] A low-cost low-alloy steel coil in this embodiment, its chemical composition and its mass percentage are: C: 0.07%; Mn: 0.60%; P: 0.005%; S: 0.004%; Ti: 0.05%; Al: 0.045%; N: 0.0040%; O: 0.0020%, the rest is Fe and unavoidable impurities. Its composition content satisfies the formula 0.024≤Ti-3.42N-1.5S≤0.034, and its thickness satisfies the formula H≤23-85.7C+1.43Mn-119Ti.

[0061] The specific manufacturing process of the low-alloy steel coil is as follows: add 38 tons of self-circulating scrap steel, and add 286 tons of molten iron. In the later stage of converter blowing, the strong bottom blowing mode is adopted to strengthen the stirring of the molten pool; the amount of slag discharged by the converter is strictly controlled. The feeding sequence in the tapping process is: pre-deoxidized carbon powder-aluminum particles-medium carbon ferromanganese-slag material; the end temperature of the converter is 1640°C.

[0062] Refining outside the RH furnace adopts the...

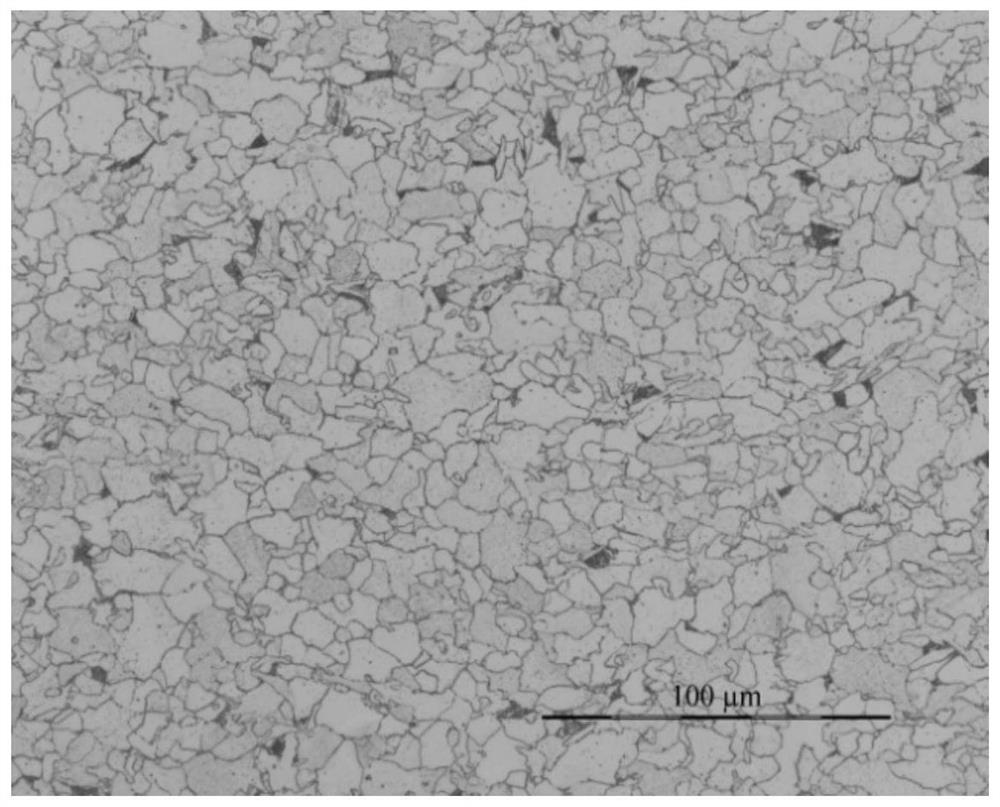

Embodiment 2

[0068] A low-cost low-alloy steel coil in this embodiment, its chemical composition and its mass percentage are: C: 0.08%; Mn: 0.80%; P: 0.015%; S: 0.008%; Ti: 0.045%; Al: 0.04%; N: 0.0010%; O: 0.0030%, and the rest are Fe and unavoidable impurities. Its component content satisfies the formula 0.024≤Ti-3.42N-1.5S≤0.034, and its thickness H≤23-85.7C+1.43Mn-119Ti.

[0069] The specific manufacturing process of the low-alloy steel coil is: add 39 tons of self-circulating scrap steel, and add 280 tons of molten iron. In the later stage of converter blowing, the strong bottom blowing mode is adopted to strengthen the stirring of the molten pool; the amount of slag discharged by the converter is strictly controlled. The feeding sequence in the tapping process is: pre-deoxidized carbon powder-aluminum particles-medium carbon ferromanganese-slag material; the end temperature of the converter is 1650°C.

[0070] Refining outside the RH furnace adopts the deep treatment mode, the vacu...

Embodiment 3

[0074] A low-cost low-alloy steel coil in this embodiment, its chemical composition and its mass percentage are: C: 0.07%; Mn: 0.50%; P: 0.009%; S: 0.007%; Ti: 0.06%; Al: 0.05%; N: 0.0020%; O: 0.0020%, and the rest are Fe and unavoidable impurities. Its composition content satisfies the formula 0.035≤Ti-3.42N-1.5S≤0.045, and its thickness satisfies the formula H≤23-85.7C+1.43Mn-119Ti.

[0075] The specific manufacturing process of the low-alloy steel coil is as follows: add 40 tons of self-circulating scrap steel, and add 290 tons of molten iron. In the later stage of converter blowing, the strong bottom blowing mode is adopted to strengthen the stirring of the molten pool; the amount of slag discharged by the converter is strictly controlled. The feeding sequence in the tapping process is: pre-deoxidized carbon powder-aluminum particles-medium carbon ferromanganese-slag material; the end temperature of the converter is 1660°C.

[0076] Refining outside the RH furnace adopts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com