Waterproof fireproofing inorganic plugging material

A plugging material and inorganic technology, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of slow early strength growth, slow condensation and hardening, poor fire performance, etc., and achieve rapid early strength, The effect of fast setting and hardening and moderate strength in the later stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

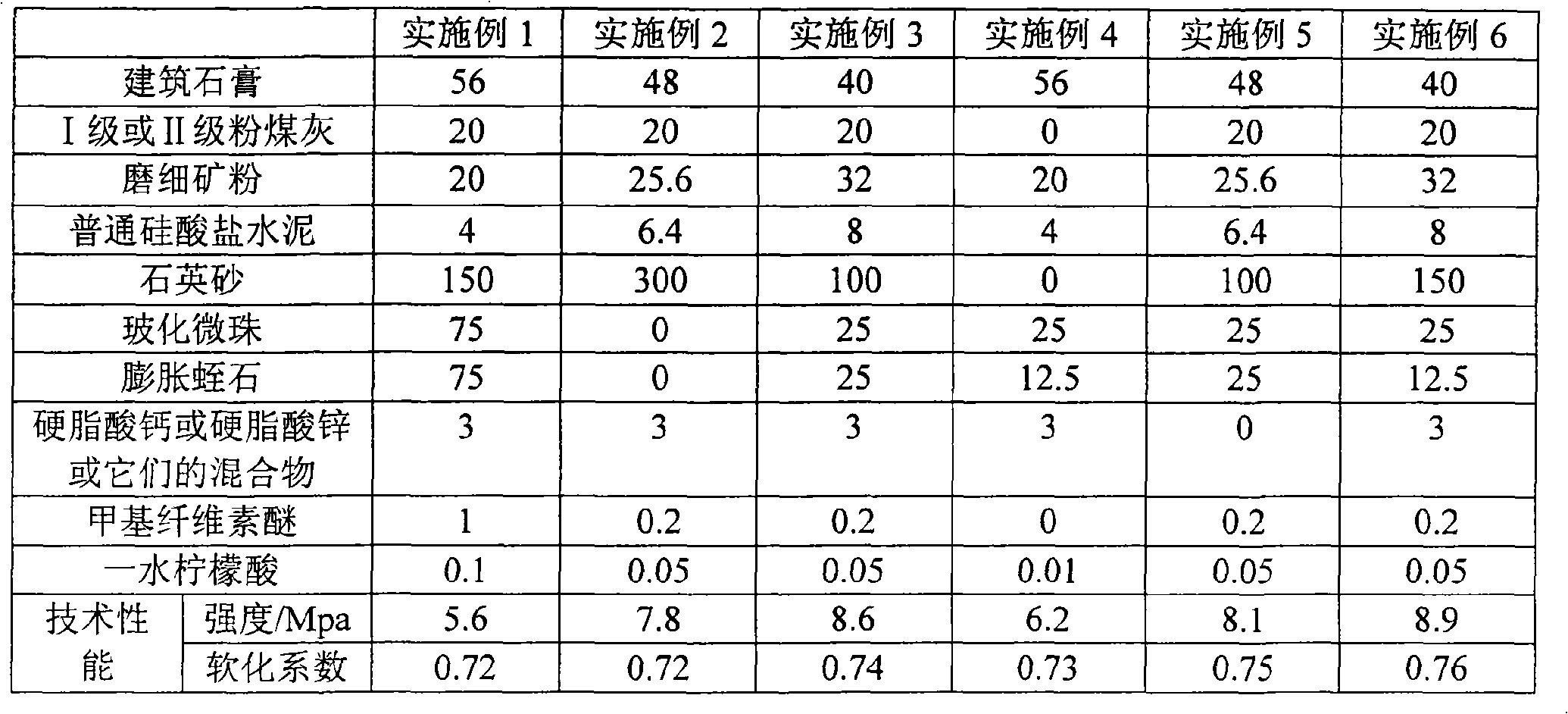

[0016] The inorganic fire-proof and waterproof sealing material of the present invention is measured in parts by weight, and is dosed according to Table 1. Each component of the inorganic waterproof and fire-proof sealing material is accurately weighed, fully mixed evenly in a mixer, and then bagged and sealed to make each component. The waterproof and fireproof inorganic sealing material of the embodiment.

[0017] Table 1 Raw materials and proportioning, technical performance table (unit: parts by weight)

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com