Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Improve waterproof and fireproof performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

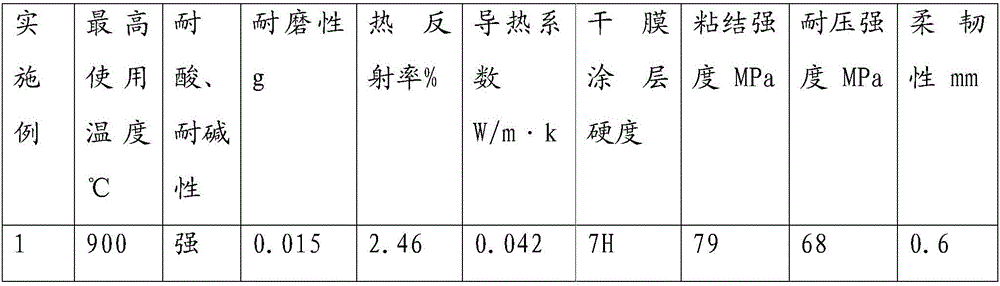

High-temperature-resistant heat-insulation paint

InactiveCN106497306AImprove insulation performanceLow thermal conductivityFireproof paintsPlastic/resin/waxes insulatorsTemperature resistanceHot Temperature

The invention relates to a high-temperature-resistant heat-insulation coating. An inorganic film-forming material and organic thermosetting resin are compounded to be main film-forming materials; heat-reflecting materials are added, so that the obtained coating has corrosion resistance, high-temperature resistance and heat insulation effects and is easy to use. The coating has advantageous effects of pressure resistance, corrosion resistance, abrasion resistance, acid and alkali resistance, an insulation property, waterproof performance, fireproof performance, high temperature resistance and a heat insulation property.

Owner:江苏龙冶节能科技有限公司

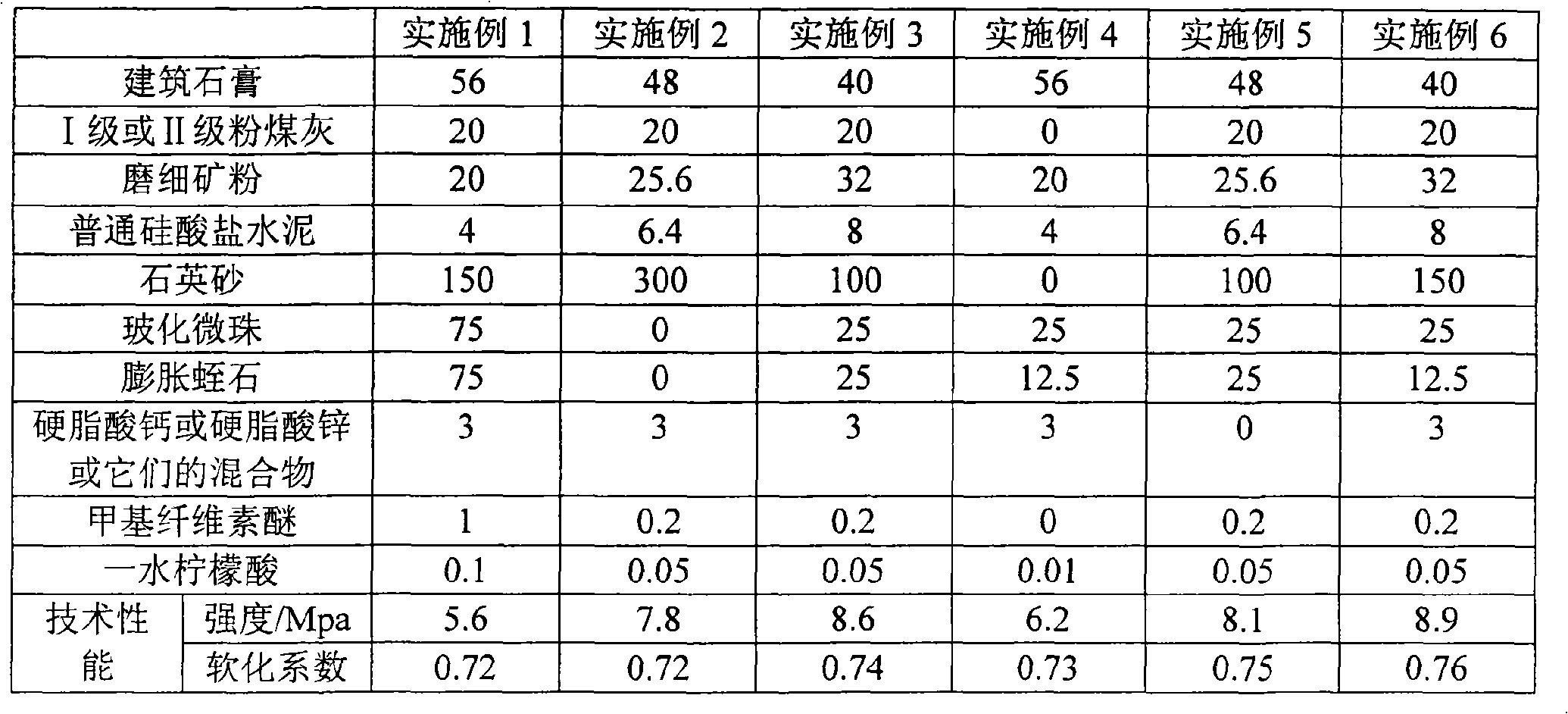

Waterproof fireproofing inorganic plugging material

InactiveCN101353261AFast hydrationHigh strengthSolid waste managementCitric Acid MonohydrateMaterials science

The invention discloses a waterproof and fireproof inorganic blocking material which is prepared by mixing the following raw materials with the parts by weight: 40-56 parts of construction gypsum, 0-20 parts of grade I fly ash or grade II fly ash, 24-40 parts of fine mineral powder and common Portland cement, 0-1 part of methyl cellulose ether, 0-3 parts of calcium stearate or zinc stearate or the mixture thereof, 0-0.1 part of citric acid monohydrate, 0-300 parts of quartz sand, 0-75 parts of vitrified micro bead and 0-75 parts of expanded vermiculite. The waterproof and fireproof inorganic blocking material of the invention has the advantages of superior waterproof and fireproof performance, fast coagulating and hardening speed, quick increase in early strength, moderate later strength, convenient disassembly, simple construction, immediate use after being mixed, free adjustment of coagulating time, convenient storage and transportation, environmental protection, etc.

Owner:NANJING EFFUL

Heat-insulating plastering gypsum for building interior wall and preparation method thereof

The invention discloses heat-insulating plastering gypsum for a building interior wall and a preparation method thereof and relates to the technical field of plastering gypsum. The heat-insulating plastering gypsum comprises 55-75 parts of desulfurized gypsum, 20-30 parts of natural gypsum, 15-20 parts of cement, 15-20 parts of heat-insulating filler, 10-15 parts of modified heavy calcium carbonate, 10-15 parts of plant source additive, 5-10 parts of rubber powder, 5-10 parts of modified expandable graphite and 7-12 parts of auxiliary. The preparation method includes: pretreating the natural gypsum. The heat-insulating plastering gypsum is used for being brushed on the building interior wall, is excellent in heat-insulating performance and has high adhesiveness, and a coating is free of shrinking and cracking and less prone to shedding.

Owner:HEFEI FENGTENG ENERGY SAVING TECH CO LTD

Waterproof fireproof reinforced binder used for straw building block and preparation method thereof

The invention discloses a waterproof fireproof reinforced binder used for a straw building block and a preparation method thereof. The binder comprises the following components: 53 to 57% of magnesium oxide, 30 to 34% of magnesium chloride, 0.05 to 0.1% of ammonium chloride, 0.02 to 0.1% of trisodium phosphate, 0.05 to 0.1% of sodium fluosilicate, 5 to 6% of 191 resin, 4 to 5% of a nanometer silicon waterproof agent and 1.5 to 2.5% of silica micro powder. A preparation method for the binder comprises the following steps: preparing an aqueous solution of magnesium chloride, sequentially adding magnesium oxide, ammonium chloride, trisodium phosphate, sodium fluosilicate and silica micro powder into the aqueous solution of magnesium chloride, carrying out stirring, then adding the 191 resin and the nanometer silicon waterproof agent and carrying out uniform stirring; The preparation method provided in the invention is simple to operate, and the binder is healthy and environment friendly, costs little, has a strong binding force and excellent waterproof and fireproof performances and enables the crop straw to be effectively utilized.

Owner:JIANGSU ZHUSHENG NEW MATERIAL TECH

Cement-imitated wood and preparation method thereof

The invention discloses cement-imitated wood which comprises a substrate, an antioxidant layer, a decorative layer and an enamel layer, wherein the substrate comprises the following raw materials in parts by weight: 300-500 parts of coarse aggregates, 100-150 parts of fine aggregates, 300-400 parts of Portland cement, 20-40 parts of alumina ore, 50-100 parts of mineral slag, 50-100 parts of furnace slag, 15-30 parts of boiled slag, 40-90 parts of municipal wastes, 5-10 parts of expanded perlite, 30-50 parts of coal gangue, 20-30 parts of plant straws, 30-50 parts of coal ash, 30-35 parts of waste rubber powder, 8-15 parts of waste wood flour, 50-70 parts of fibers, 20-40 parts of titanium oxide, 2-5 parts of a water reducing agent, 5-9 parts of an accelerator, 6-12 parts of a de-foaming agent, 5-8 parts of an anti-rusting agent, 1-5 parts of an early strength agent, 4-9 parts of polyvinyl formal or polyvinyl acetate emulsion, 5-10 parts of borax, 15-25 parts of white sludge, 45-65 parts of tourmaline powder, 20-35 parts of silica sand, 20-25 parts of gypsum and 500-1000 parts of water.

Owner:祝莉玲

Waterproof plastering gypsum and production method thereof

The invention discloses waterproof plastering gypsum and a production method thereof, which relate to the technical field of a plastering material. The waterproof plastering gypsum comprises the following raw materials by parts: 55-65 parts of desulfurized gypsum, 42-44 parts of cement, 38-40 parts of modified kaolin, 32-33 parts of fireproof particles, 26-28 parts of anhydrous magnesium chloride, 24-26 parts of a crystal growth stimulator, 21-23 parts of floating beads, 18-19 parts of an organosilicon water repellent, 15-16 parts of an auxiliary agent, and 65-70 parts of water. The waterproof plastering gypsum has excellent waterproof performance, is not easily damped and shed, and has high stability.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

Paper face waterproof board and its mfg. method

InactiveCN1833841ANo pollution in the processImprove waterproof and fireproof performanceWood working apparatusFlat articlesFiberAdhesive

Owner:乔刚

High definition print processing method for surface of cementum plate and cementum plate with prints

InactiveCN103696553AStrong textureHigh degree of simulationCovering/liningsDuplicating/marking methodsFire preventionHigh definition

The invention discloses a high definition print processing method for the surface of a cementum plate and the cementum plate with prints. The processing method comprises the following steps: sanding the cementum plate: a layer of permeable primer is painted on the front of the cementum plate; processing putty; painting a layer of seal undercoat; sanding processing; painting a layer of white primer; sanding processing; painting a layer of super-white paint. The surface of the cementum plate is subjected to special pretreatment, thus colored paint and ink can be stuck on the surface of the cementum plate, and the surface of the cementum plate is provided with a variety of colors, figures or patterns, and the patterns are not easy to fall off. Therefore the cementum plate with the prints is wear-resisting, ageing resistant, not susceptible to pollution and waterproof, and has good fire prevention performance. The cementum plate with the prints is suitable for decorating the indoor wall face. The cementum plate is provided with the fire-prevention, tough, impact resistant and environment-friendly performances of the cementum plate as well as the decoration effects of high imitation wood grain, marbling, personalized patterns, and the preparation cost is lower.

Owner:FOSHAN ARTECH PANEL

Aluminum alloy rolled plate and producing method thereof

ActiveCN101319285ALow material densityReduced corrosion resistanceTemperature control deviceMetal rolling arrangementsVolumetric Mass DensityUltimate tensile strength

Owner:河南明晟新材料科技有限公司

Waterproof and fireproof coating for aluminum charger shell

InactiveCN107641448AImprove waterproof and fireproof performanceFireproof paintsPolyurea/polyurethane coatingsSodium polyacrylateEmulsion

The invention discloses a waterproof and fireproof coating for an aluminum charger shell. The waterproof and fireproof coating is prepared from the following raw materials: polyurethane, vinyl acetatehomopolymer milk, styrene-acrylate copolymerized emulsion, nano titanium dioxide, nano magnesium hydroxide, expanded vermiculite, molybdenum disulfide, attapulgite, nano zinc borate, magnesium hydroxide, nano barium sulfate, aluminium triphosphate, meerschaum, tributyl phosphate, sodium polyacrylate, polyamide, a silane coupling agent KH-560, fluorosilicon oil, carbonized cellulose, a curing agent, a waterproof modification additive and a fireproof modified filling material. The coating for the aluminum charger shell disclosed by the invention has excellent waterproof and fireproof performance.

Owner:天长市优信电器设备有限公司

Novel building heat-preservation and anti-seismic material and preparation method thereof

The invention belongs to the field of building materials, and particularly relates to a novel building heat-preservation and anti-seismic material and a preparation method thereof. The novel buildingheat-preservation and anti-seismic material is prepared from the following components in parts by mass: 30-100 parts of straw, 20-80 parts of rubber powder, 60-250 parts of magnesium oxide, 20-80 parts of magnesium chloride, 50-215 parts of water, 7-28 parts of urea formaldehyde resin, 4-20 parts of ferrous sulfate, 2-10 parts of silicone acrylic emulsion, and 0.1-1.0 part of an additive. The preparation method comprises the following steps that raw materials are weighed, the magnesium chloride, the urea formaldehyde resin, the ferrous sulfate and the silicone acrylic emulsion are dissolved inwater and mixed, and even stirring is conducted to obtain a mixed solution; the straw and the rubber powder are mixed and evenly stirred, and a mixture is obtained; the magnesium oxide is added intothe mixed solution, sufficient and even stirring is conducted to form slurry; the mixture is added into the slurry, and even stirring is conducted to form a mixed material; and a mold is evenly filledwith the mixed material, after cold press molding, demolding is conducted, curing is conducted in air until the age is reached, and thus the novel building heat-preservation and anti-seismic materialis obtained. The novel building heat-preservation and anti-seismic material has the characteristics of low volume weight, high strength, low heat conductivity coefficient, good waterproof, fireproofand anti-corrosion performance, and the like.

Owner:YANCHENG INST OF TECH +1

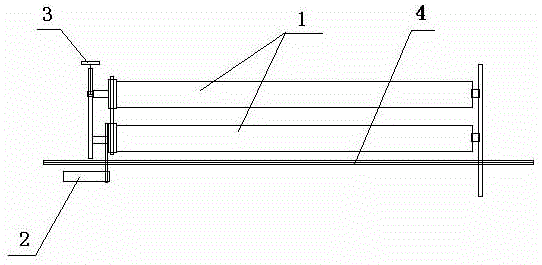

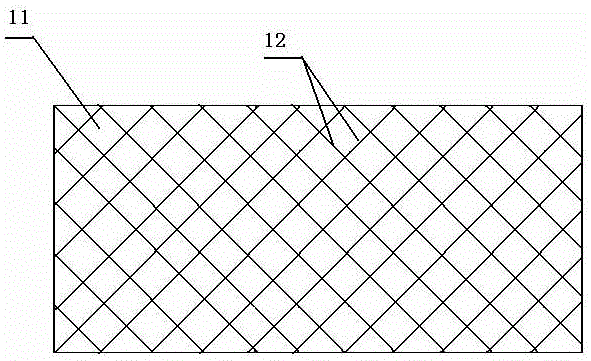

Insulation board production device

PendingCN106426901ASimple structureEasy to useHeat proofingElectrical and Electronics engineeringExtrusion

The invention discloses an insulation board production device. The insulation board production device comprises a rack. The rack is provided with a pair of compression rollers which are arranged on the rack in a top-and-bottom manner and connected in a transmission manner, one compression roller is also connected with a motor in a transmission manner, and a plurality of raised extrusion lines are arranged on the surfaces of the two compression rollers and are obliquely arranged to form a plurality of rhombic structures. The insulation board production device has the beneficial effects that the device structure is simple, using is convenient, the technological process is simplified, the working efficiency is improved, the adsorptive performance of the product is greatly improved, the waterproof and fireproof performance is good, and the product quality is high.

Owner:北鹏建材集团股份有限公司

Plastic-steel door and window unit with heat preservation and sound insulation functions and preparation process of plastic-steel door and window unit

InactiveCN113236076AExtended service lifePlay a supporting roleFireproof doorsNoise insulation doors/windowsFoaming agentWeather resistance

The invention relates to the technical field of plastic-steel doors and windows, and discloses a plastic-steel door and window unit with heat preservation and sound insulation functions and a preparation process of the plastic-steel door and window unit. The plastic-steel door and window unit comprises a plastic-steel door and window frame body, wherein laminated glass is fixedly installed in the middle of the plastic-steel door and window frame body, a PVC plate layer is arranged on the outermost layer of the plastic-steel door and window frame body, a glass wool cloth layer is arranged on the inner surface of the PVC plate layer, a composite filler layer is arranged on the inner surface of the glass wool cloth layer, a foaming agent core is arranged on the inner surface of the composite filler layer, a steel plate layer is arranged on the inner surface of the foaming agent core, a silencing cavity is formed on the inner surface of the steel plate layer, a silencing rod is arranged in the silencing cavity, a heat preservation layer is arranged on the inner surface of the silencing cavity, a waterproof layer is arranged on the inner surface of the heat preservation layer, and a fireproof layer is arranged on the inner surface of the waterproof layer. The plastic-steel door and window unit prepared with the preparation process of the plastic-steel door and window unit with heat preservation and sound insulation functions has the characteristics of light weight, good weather resistance, acid and alkali corrosion resistance, high strength, good heat preservation and sound insulation performance and long service life.

Owner:重庆品卓智能家居有限公司

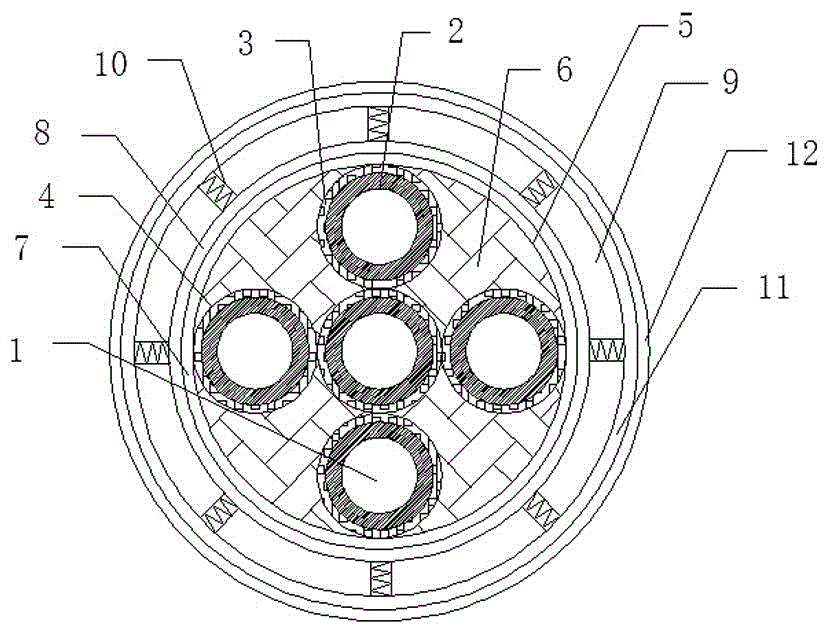

Special cable for concrete processing machinery

InactiveCN106298003AImprove pressure resistanceImprove resistance to damageInsulated cablesInsulated conductorsSurface layerUltimate tensile strength

The invention relates to a special cable for concrete processing machinery. The special cable comprises a cable core, wherein an outer wall of the cable core is provided with an insulating layer; an outer wall of the insulating layer is provided with a soft filling layer; the soft filling layer adheres to an inner wall of an embedded tube; an outer side of the embedded tube is provided with a fixed tube; a filler is arranged between the fixed tube and the embedded tube; an outer wall of the fixed tube is provided with an anti-static layer; an outer side of the anti-static layer is provided with a waterproof layer; an outer side of the waterproof layer is provided with an anti-expansion buffer layer; a plurality of buffer springs are arranged in an inner cavity of the anti-expansion buffer layer; and an outer side of the anti-expansion buffer layer is provided with a fireproof layer. Through adoption of the special cable, the overall strength of the cable is enhanced; the pressure resistant performance of the cable is enhanced; the overall structure of the cable is prevented from being broken easily by stretching; the phenomenon of circuit break is avoided; the damage resistance and corrosion resistance of a surface layer of the cable are enhanced effectively; the waterproof and fireproof performance is enhanced; damage to the cable caused by static electricity is reduced; and the service time of the cable is prolonged. The special cable is novel in structure, and has high practicability.

Owner:张家港市华扬冶金机械有限公司

Phosphogypsum substrate simulated wood floor and preparation method thereof

InactiveCN104725017ASolving the mountain of status quoReduce manufacturing costSolid waste managementCeramic shaping apparatusFiberSlag

The invention discloses a phosphogypsum substrate simulated wood floor and a preparation method thereof. The phosphogypsum substrate simulated wood floor is prepared from the following raw materials in parts by weight: 50-70 parts of phosphogypsum, 10-18 parts of flyash, 0.5-3 parts of fiber, 20-30 parts of yellow phosphorus slag and 2-6 parts of quick lime. The phosphogypsum substrate simulated wood floor is prepared by taking the phosphogypsum as the main raw material, solves the current situation that the phosphogypsum is piled up like a mountain and has an important meaning for the environment protection and the sustainable development. Besides, the produced phosphogypsum substrate simulated wood floor has the advantages of light weight, good waterproof and fireproof performances, high compressive strength and strong weather fastness and can be widely used as an indoor and outdoor decorative material.

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION

Phosphogypsum base material marble-imitated floor tile and preparation method thereof

InactiveCN104725013ASolving the mountain of status quoWide variety of sourcesSolid waste managementCeramic shaping apparatusFiberHydration reaction

The invention discloses a phosphogypsum base material marble-imitated floor tile and a preparation method thereof. In parts by weight, the floor tile is prepared from 50-80 parts of phosphogypsum, 20-40 parts of yellow phosphorus slag, 0.1-2 parts of fiber and 1-8 parts of quicklime. Phosphorus slag powder which is good in fluidity and uniform in particle can be prepared by mixing the yellow phosphorus slag with the phosphogypsum, stirred and reacted at 90-100 DEG C, and then ground. The quicklime, the fiber and the phosphorus slag powder are mixed under a certain temperature and a stirring speed and are subjected to aging treatment, so as to significantly shorten aging time; through a hydration reaction, the phosphorus slag powder can generate a main product, namely ettringite crystal; the intensity and the water resistance of the phosphogypsum base material marble-imitated floor tile are significantly improved; and the content of soluble impurities in the phosphogypsum is reduced and the coagulation property of the phosphogypsum base material marble-imitated floor tile is greatly improved.

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION

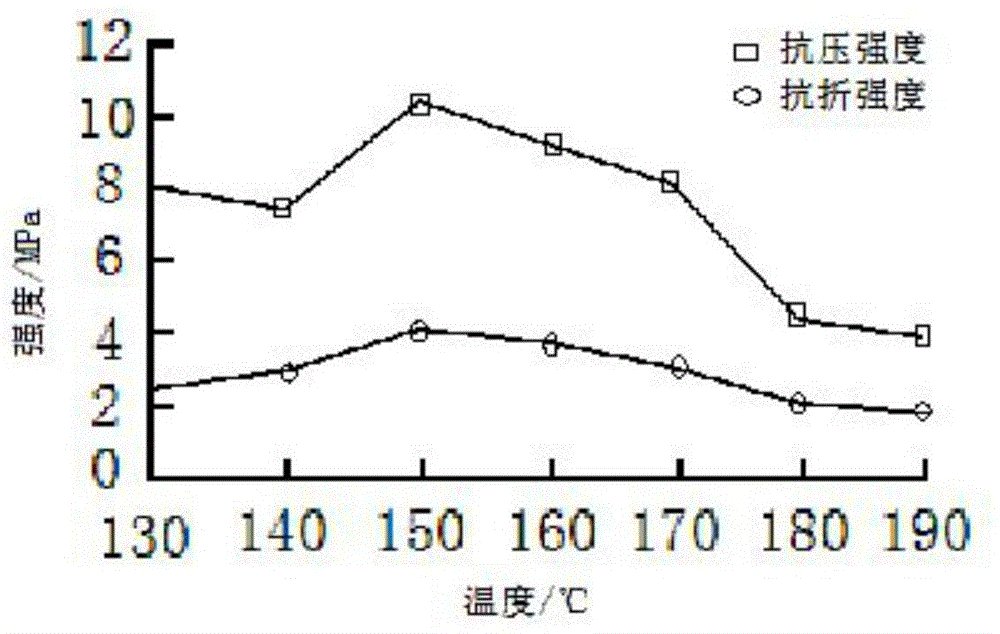

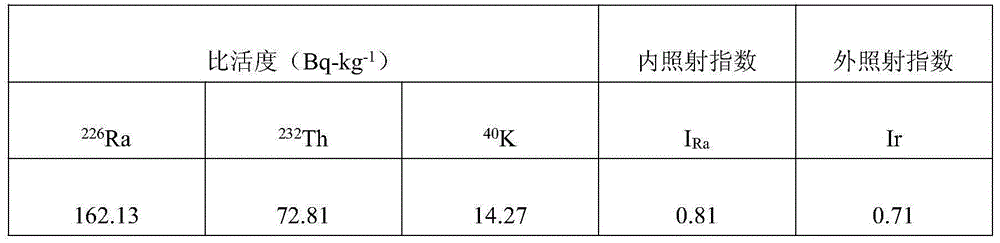

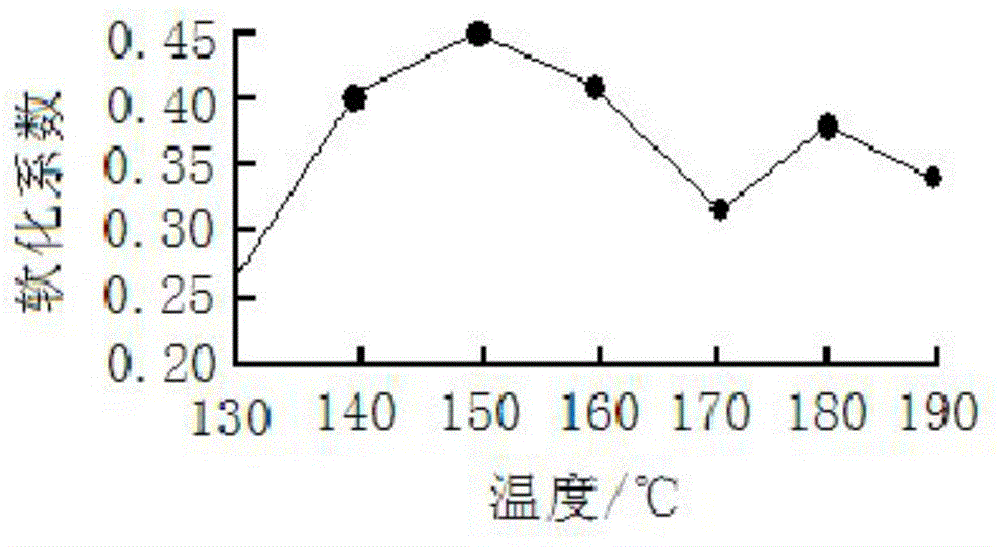

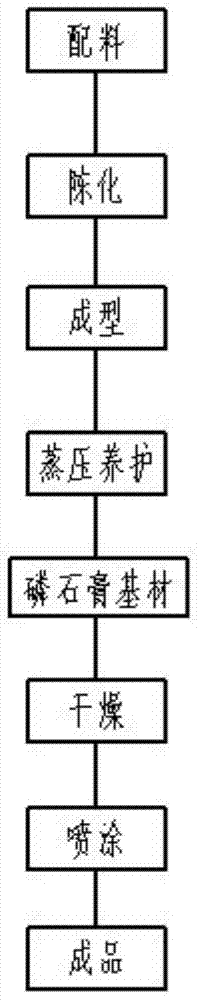

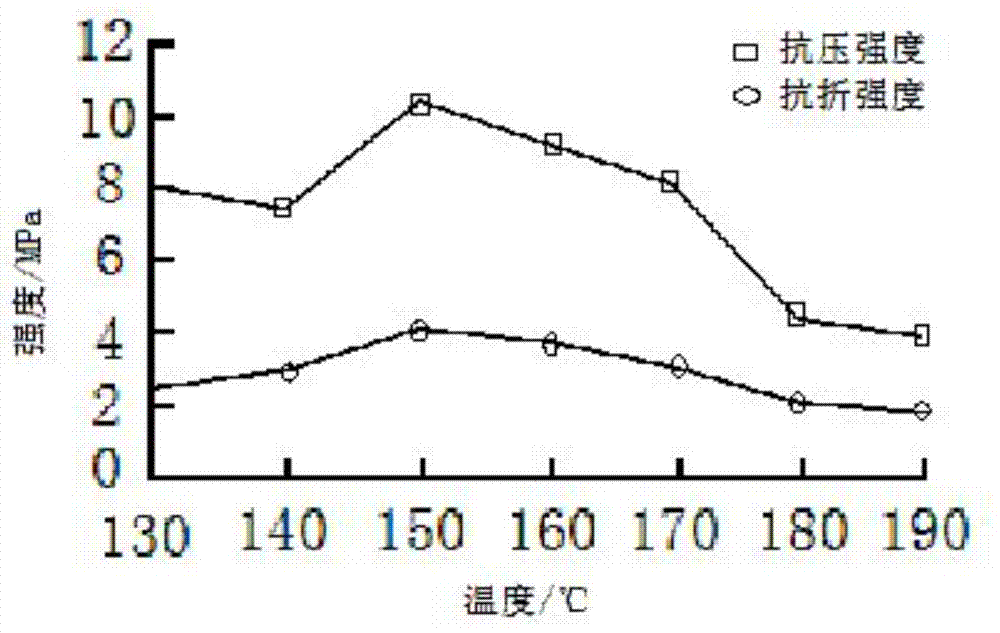

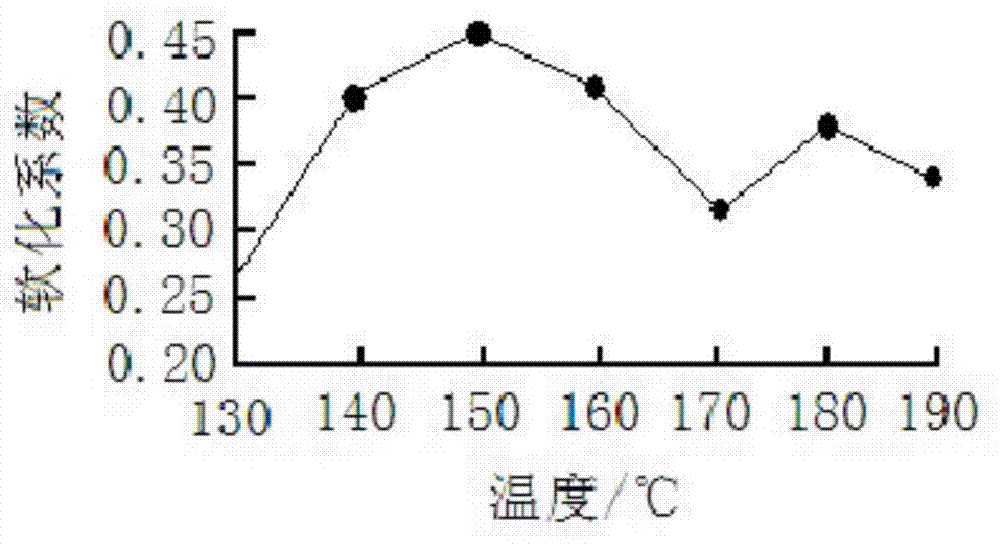

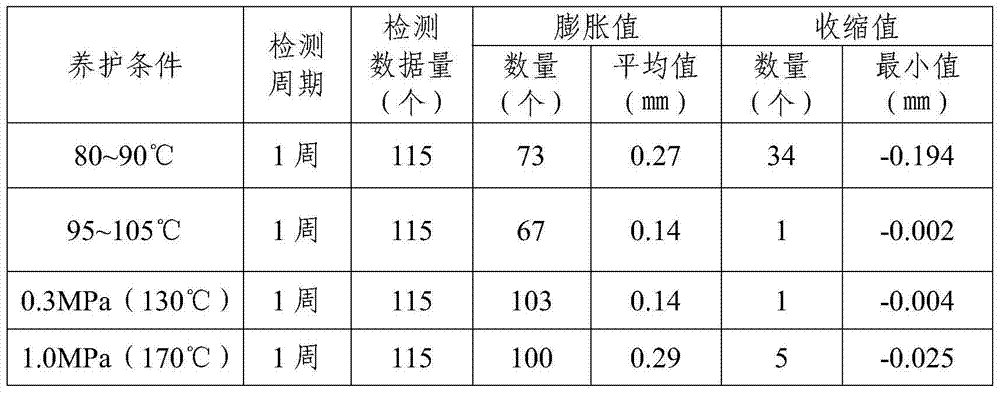

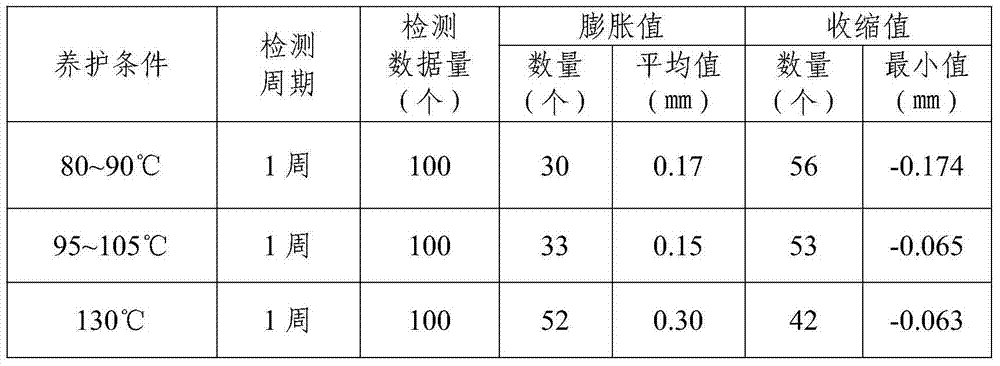

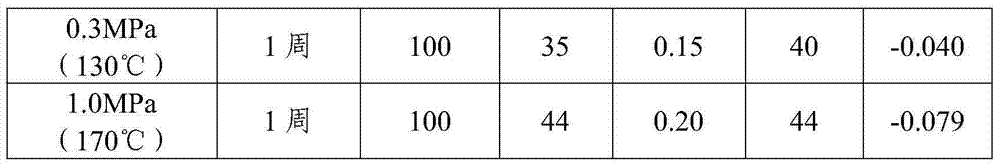

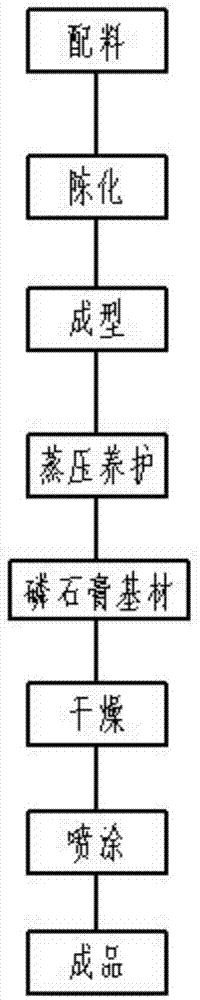

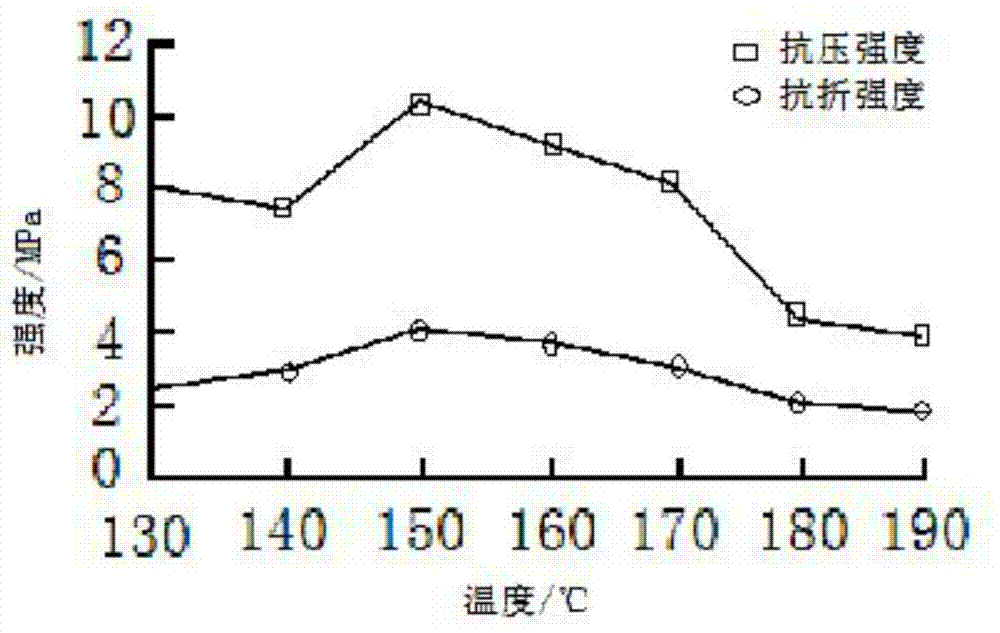

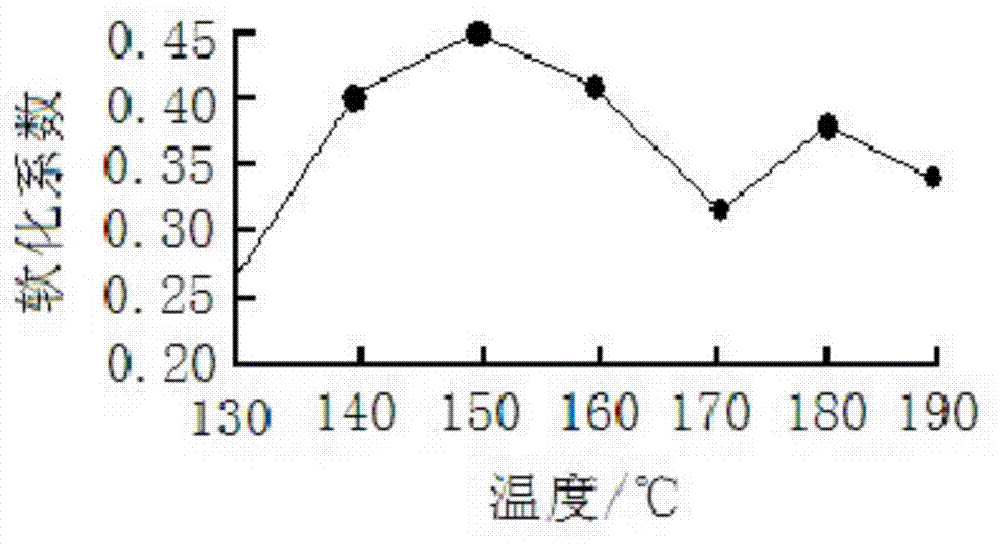

Phosphogypsum-based simulative heat-preservation building material and preparation method of same

InactiveCN105036675AImprove particle gradation to show normal distributionReduce contentCeramic shaping apparatusWeather resistanceSlag

The invention discloses a phosphogypsum-based simulative heat-preservation building material and a preparation method of same. The material includes the following raw materials, by weight, 35-85 parts of phosphogypsum, 20-65 parts of electrolytic yellow phosphorus slag and 1.75-4.25 parts of quick lime. The preparation method includes the following steps: material preparing, aging, moulding, autoclaved curing, preparation of a phosphogypsum base material, and drying to obtain the finish product. The phosphogypsum-based simulative heat-preservation building material is simple in construction technology, is light in weight, is good in waterproof and fireproof performance, is high in compressive strength and flexural strength, is strong in weather resistance and has excellent decorative effects as an indoor decorative building material. The method has quite important significance in protection of environment and achievement of sustainable development since large quantity of the phosphogypsum is consumed.

Owner:GUIZHOU KAILIN GRP CO LTD

Phosphogypsum-based imitated granite structure building material and preparation method thereof

InactiveCN104891918AImprove particle gradation to show normal distributionReduce contentSolid waste managementCompressive resistanceArchitectural engineering

The invention discloses a phosphogypsum-based imitated granite structure building material and a preparation method thereof. The phosphogypsum-based imitated granite structure building material comprises the following raw materials in parts by weight: 400-800 parts of phosphogypsum, 300-500 parts of electrolyzed yellow phosphorus slag and 20-40 parts of quick lime. The preparation method comprises the steps of material preparing, ageing, forming, autoclave curing, phosphogypsum base material preparing, drying, spraying and finished product forming. The phosphogypsum-based imitated granite structure building material has the characteristics of simple construction process, light weight, good waterproofness and fire resistance, high compressive strength, high bending strength and good weatherability; furthermore, the phosphogypsum-based imitated granite structure building material as an indoor decorative building material has the excellent decoration effect; besides, a large amount of phosphogypsum is consumed, the exploitation of natural stones is reduced, and very important significance is provided for environmental protection and achievement of sustainable development.

Owner:GUIZHOU KAILIN GRP CO LTD

Formaldehyde-zero ecological plate and preparation method thereof

The invention discloses a formaldehyde-zero ecological plate. The formaldehyde-zero ecological plate is prepared from the following raw materials in parts by weight: 1 to 95 parts of wood flour or wood shavings, 1 to 95 parts of cellosilk, 1 to 50 parts of an organic adhesive, 0.1 to 50 parts of an inorganic adhesive, 0 to 20 parts of aluminum powder, 0.01 to 5 parts of a fire-proofing agent and 0.01 to 2 parts of a water-proofing agent. The invention also discloses a preparation method of the formaldehyde-zero ecological plate. According to the formaldehyde-zero ecological plate disclosed bythe invention, recycled abandoned plates can be reasonably utilized, and the prepared formaldehyde-zero ecological plate has the characteristics of light weight, high compression strength, good fireproofness and waterproofness, zero formaldehyde emission and the like.

Owner:黎长才

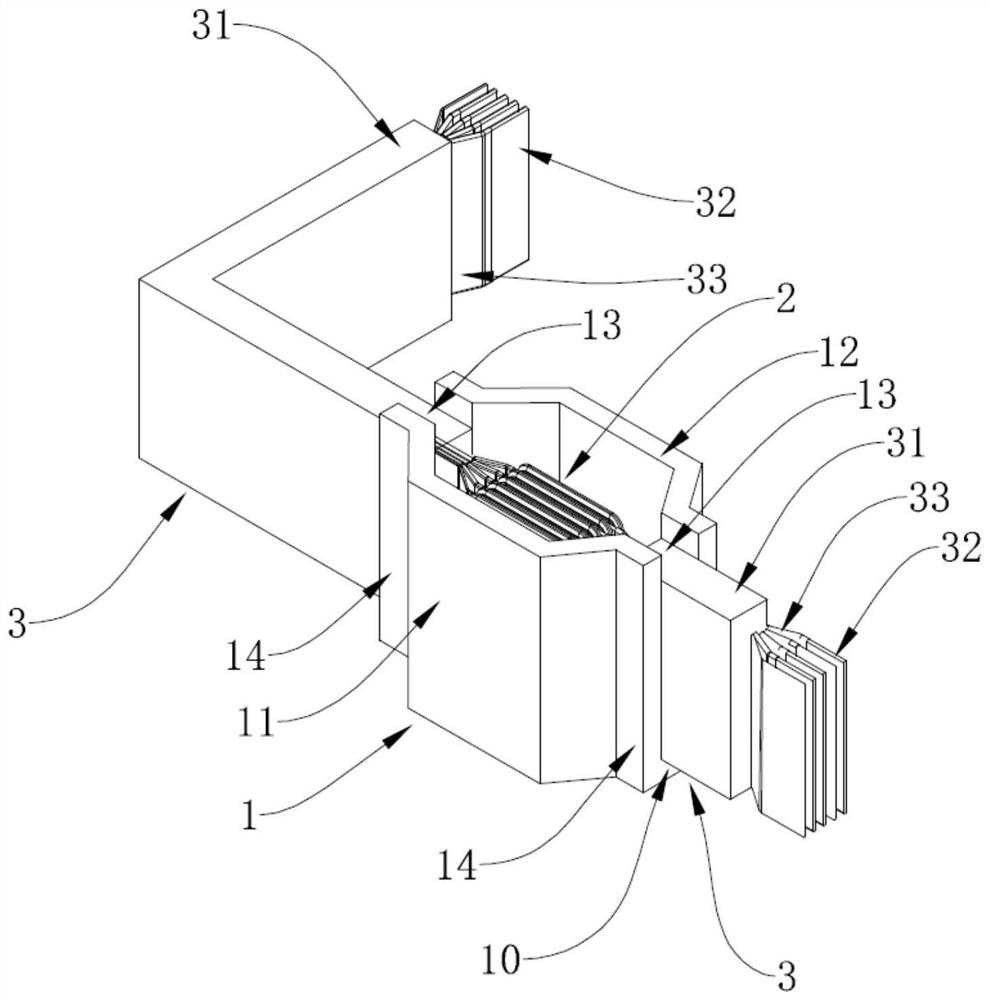

Intensive pouring bus duct assembly

PendingCN112821319ASmall footprintSimple structureTotally enclosed bus-bar installationsStructural engineeringMechanical engineering

An intensive pouring bus duct assembly provided by the present invention comprises a connecting outer box, a splicing unit and a plurality of bus duct units, each bus duct unit comprises a shell and a plurality of copper bars, the surface of each copper bar is provided with a film-coated insulating layer, the plurality of copper bars are stacked and arranged in the inner cavity of the shell in a penetrating manner, and the two ends of each copper bar extend out of the inner cavity of the shell. The copper bars of two adjacent bus duct units are connected through the splicing unit, the connecting outer box is arranged outside the exposed connecting part of the two copper bars, an accommodating space is defined by the outer box, and a fireproof pouring material is poured in the accommodating space. Insulation between the copper bars is achieved through the film-coated insulating layers on the surfaces of the copper bars, the multiple copper bars are stacked and fixed in the shell made of the fireproof pouring material, the copper bars extend out of the front end and the rear end of the shell, the adjacent bus duct units are connected through the splicing units, the occupied space is small, energy is saved, environment friendliness is achieved, the structure is simple, and the waterproof and fireproof performance is excellent; the device is suitable for indoor places with high fire-fighting requirements, and is safe and reliable.

Owner:珠海顺鑫电气设备有限公司

Ardealite-based wood-like floor, and preparation method thereof

InactiveCN106630887ASolving the mountain of status quoReduce manufacturing costSolid waste managementFiberWeather resistance

The invention discloses an ardealite-based wood-like floor, and a preparation method thereof. The ardealite-based wood-like floor is prepared from, by weight, 50 to 70 parts of ardealite, 10 to 18 parts of fly ash, 0.5 to 3 parts of fiber, 20 to 30 parts of yellow phosphorus slag, and 2 to 6 parts of quick lime. The ardealite-based wood-like floor is prepared taking ardealite as a main raw material, is capable of solving problems caused by excess ardealite, and possesses important significance on environment protection and sustainable development. The obtained ardealite-based wood-like floor is light, possesses excellent water resistance, flame resistant, and weather resistance, is high in compressive strength, and can be widely taken as indoor and outdoor decorative materials.

Owner:GUIZHOU KAILIN GRP CO LTD

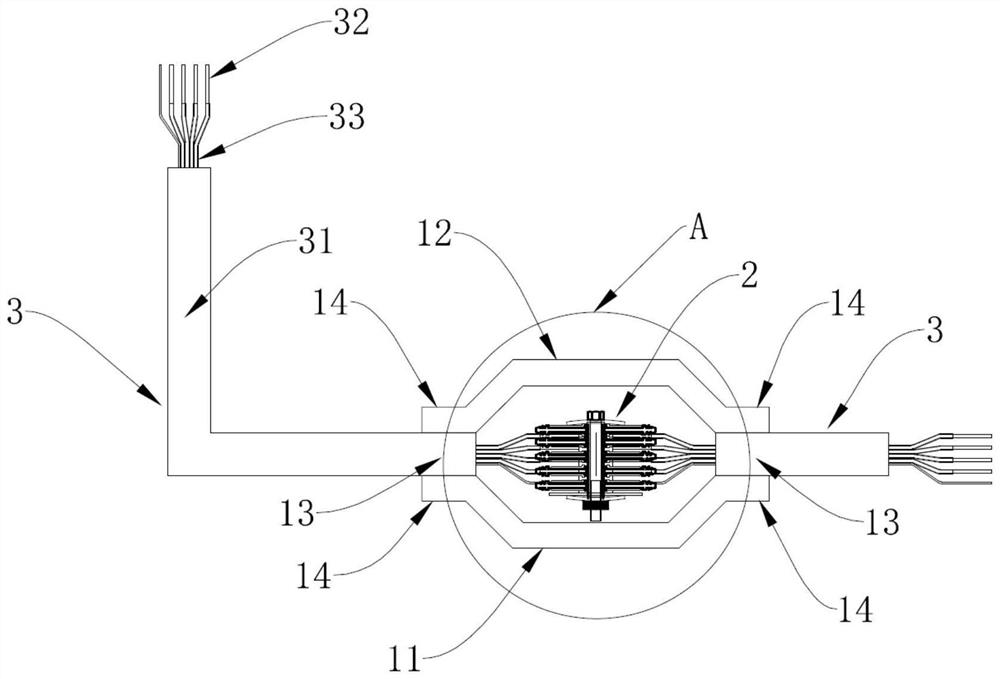

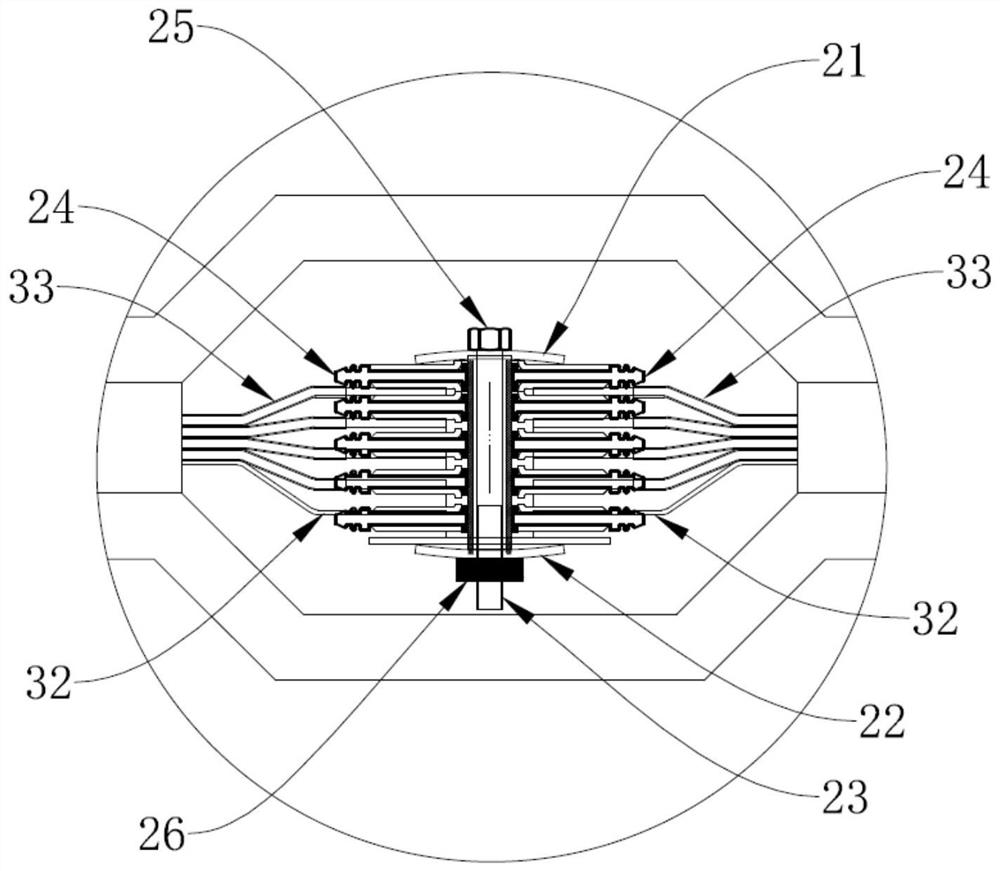

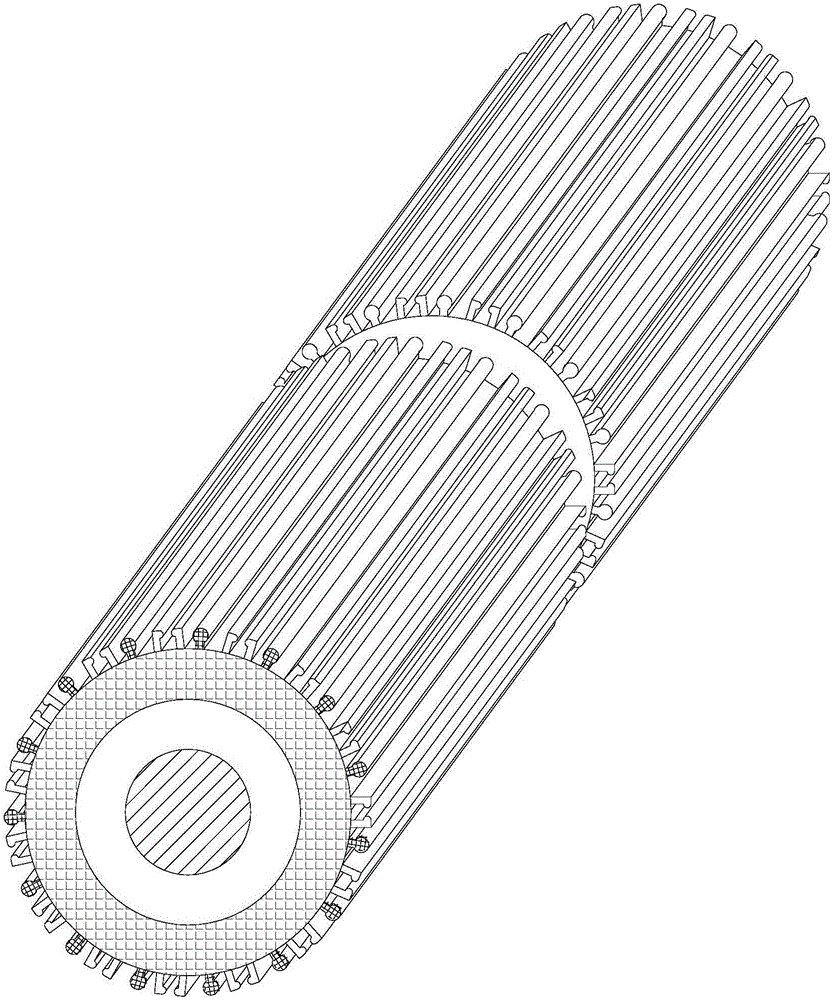

Processing technology for embedded type glass-fiber-woven flame-retardant cotton-covered wire

InactiveCN105976942AImprove waterproof and fireproof performanceReduced fire areaInsulated cablesCable/conductor manufactureLow smoke zero halogenGlass fiber

The invention proposes an embedded glass fiber braided flame-retardant cloth electric wire processing technology, comprising the following steps: A), extruding an insulating layer outside the conductor; B), weaving a glass fiber layer outside the insulation layer; C), wrapping the glass fiber Low-smoke, halogen-free and flame-retardant polyolefin is extruded on the layer to form a glass fiber embedded layer. The invention is convenient to manufacture, and effectively improves the waterproof and fireproof effect of the cable.

Owner:高桥防火科技股份有限公司

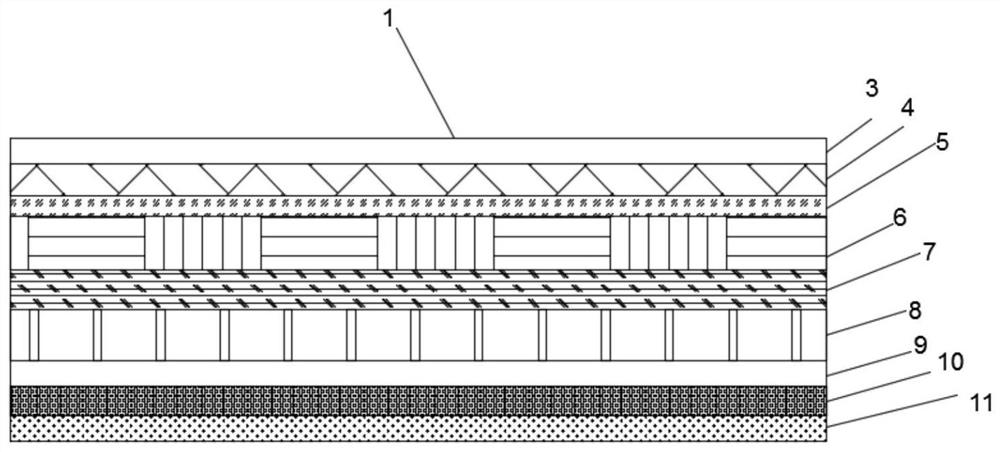

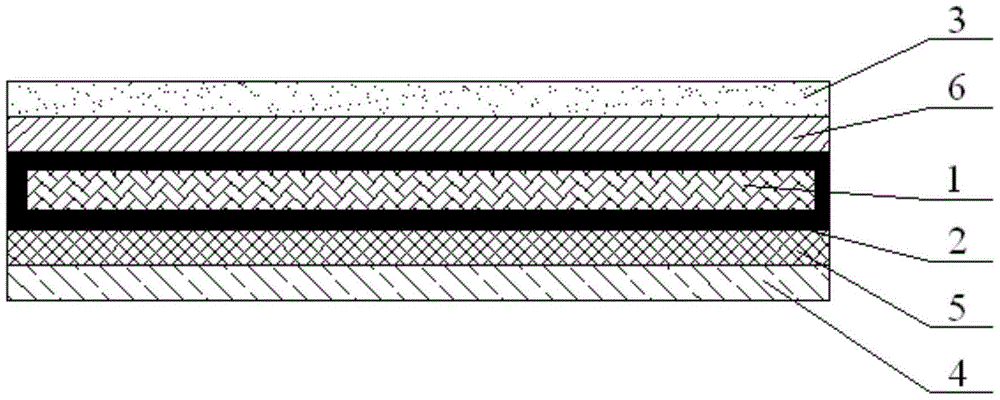

Glass fiber based asphalt shingle

InactiveCN106592875AImprove flexibilityLight weightRoof covering using tiles/slatesSynthetic resin layered productsGlass fiberAsphalt shingle

The invention provides a glass fiber based asphalt shingle which comprises a base layer, a modified petroleum asphalt layer, a coating layer, a waterproof layer, a fireproof layer and a reinforcing layer, wherein the modified petroleum asphalt layer wraps the outer side of the base layer so as to form a modified petroleum asphalt wrapped part; the coating layer and the fireproof layer are both arranged at the outer side of the modified petroleum asphalt wrapped part; the coating layer is arranged above the modified petroleum asphalt wrapped part; the fireproof layer is arranged under the modified petroleum asphalt wrapped part; the waterproof layer is arranged under the fireproof layer; the reinforcing layer is arranged between the coating layer and the modified petroleum asphalt wrapped part. The glass fiber based asphalt shingle has the advantages of different styles, heat insulation, low heat conductivity coefficient of products, sound absorption and sound insulation, colorful effect, corrosion resistance, excellent waterproof effect, dust prevention and self-cleaning effect as well as simple and convenient paving.

Owner:TIANJIN YUSHEN BUILDING WATERPROOF MATERIAL

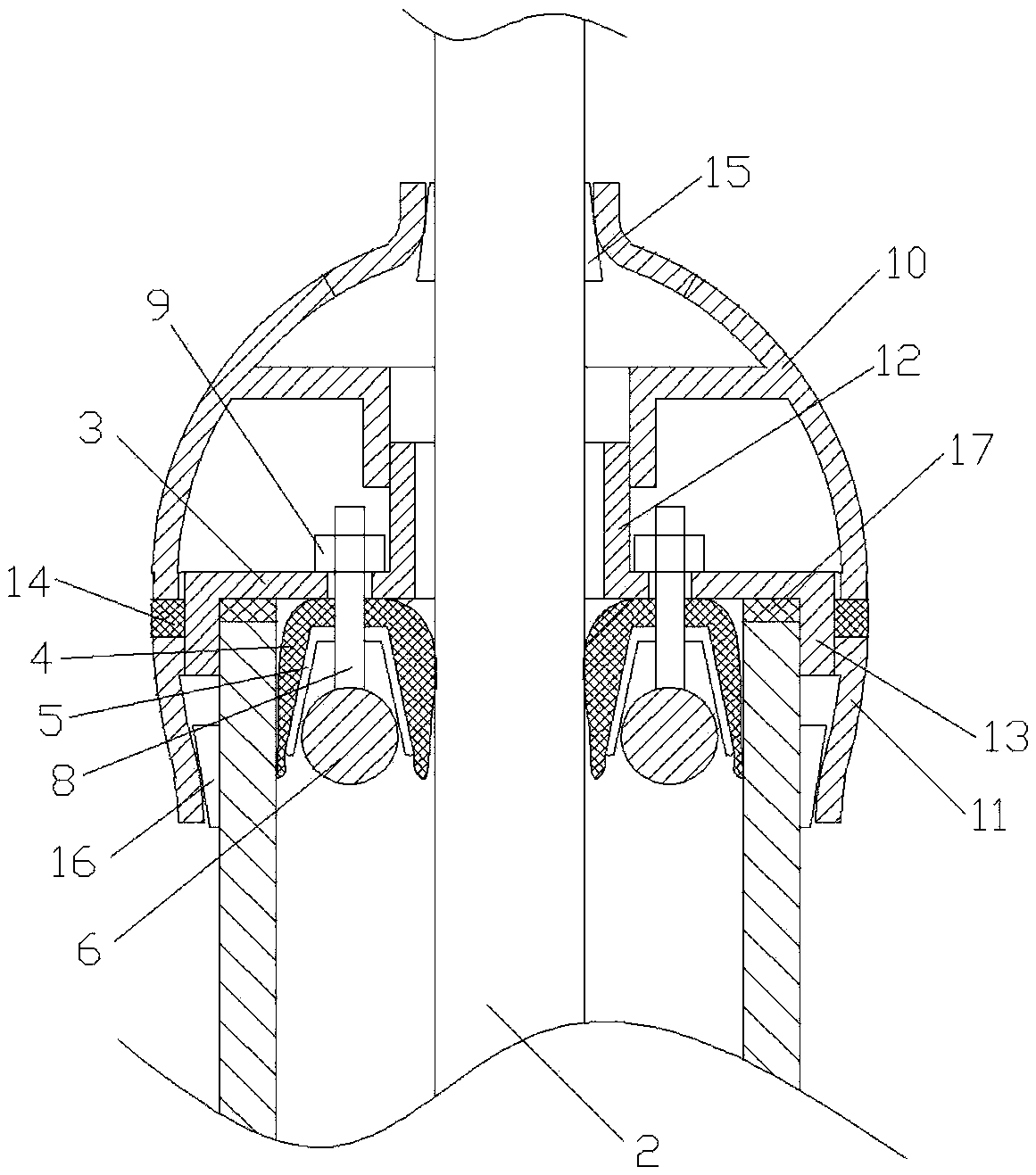

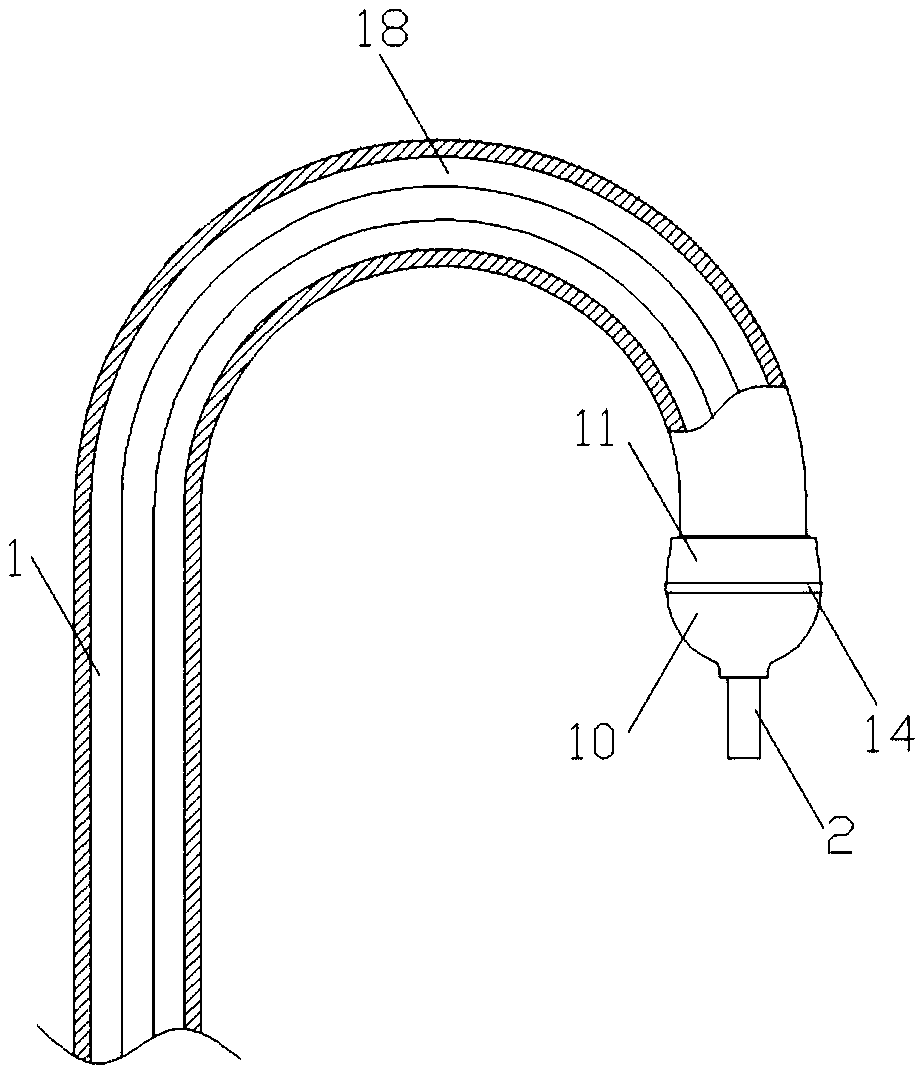

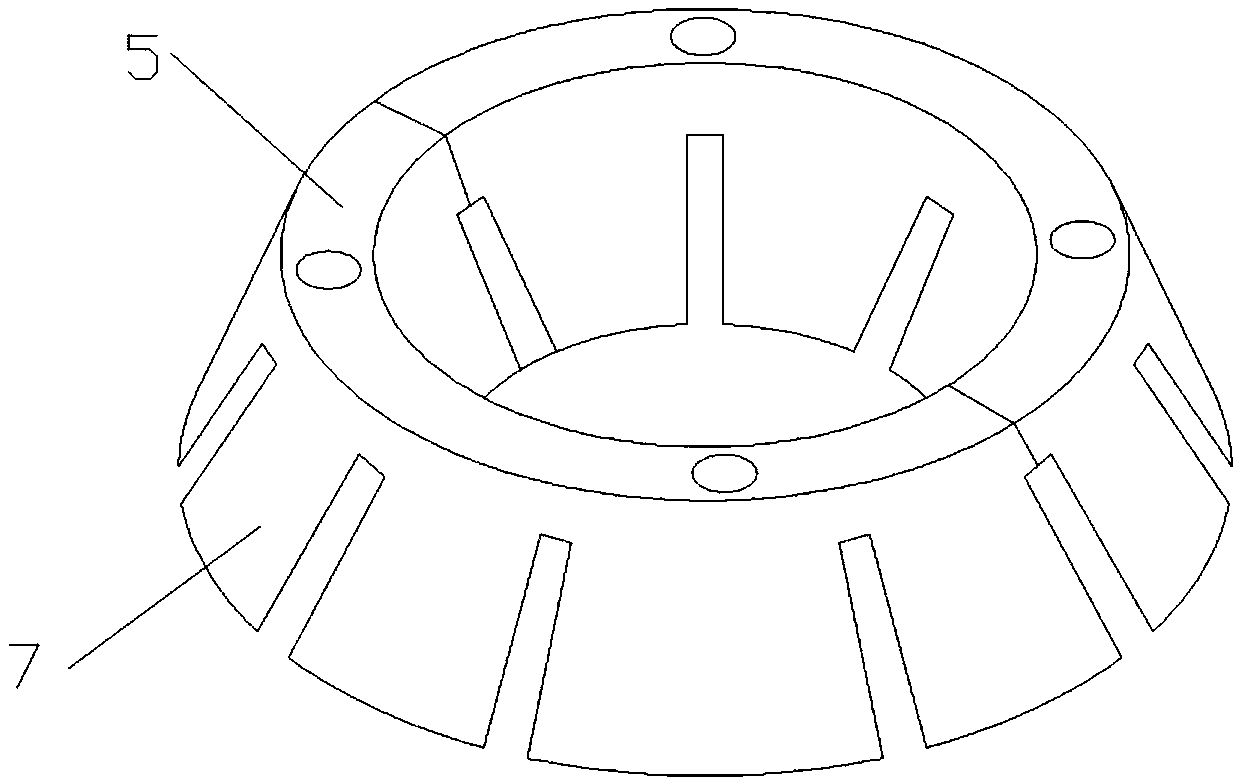

Thermal-shrinkage waterproof sealing cap for high-voltage cable

The invention belongs to the field of waterproof sealing caps for sealing cable pipe orifices, and specifically relates to a thermal-shrinkage waterproof sealing cap for a high-voltage cable. The sealing cap is low in dependence on the diameter of the cable and the diameter of a casing pipe, and can achieve the better sealing of guide cables and casing pipes in various sizes. The sealing cap employs an insulating material, and a fire retardant is added for preparation, so the waterproof performance is excellent. The sealing cape is suitable for the protection and sealing of various types of cable pipe orifices, such as a cable protection tube and a cable incoming and outgoing mouths of a transformer substation. The sealing cab can achieve the waterproof, fireproof and insulating functionsat the same time, facilitates the early construction operation and the later maintenance management, and no metal part is exposed outside. The sealing cap is good in aging resistance, insulating performance, waterproof and fireproof performances, is good in corrosion resistance, and is good in application prospect.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +2

Phosphogypsum-based stone-like structure building material and preparation method thereof

InactiveCN104725007AImprove particle gradation to show normal distributionReduce contentSolid waste managementCeramic shaping apparatusCompressive resistanceWeather resistance

The invention discloses a phosphogypsum-based stone-like structure building material and a preparation method thereof. The phosphogypsum-based stone-like structure building material is prepared from the following raw materials in parts by weight: 30-80 parts of phosphogypsum, 15-60 parts of electrolytic yellow phosphorus slag and 2-10 parts of quicklime. The preparation method comprises the following steps: burdening, ageing, molding, carrying out autoclaved curing, drying phosphorus gypsum base material, spraying and forming a finished product. The phosphogypsum-based stone-like structure building material has the characteristics of simple construction process, light weight, good waterproof and fireproof properties, high compressive strength, high breaking strength and high weather resistance, and has a good decoration effect as an indoor decoration building material; meanwhile, a lot of phosphogypsum is consumed; exploitation of natural stones is reduced; and the phosphogypsum-based stone-like structure building material has important significance on environment protection and realization of sustainable development.

Owner:GUIZHOU KAILIN GRP CO LTD

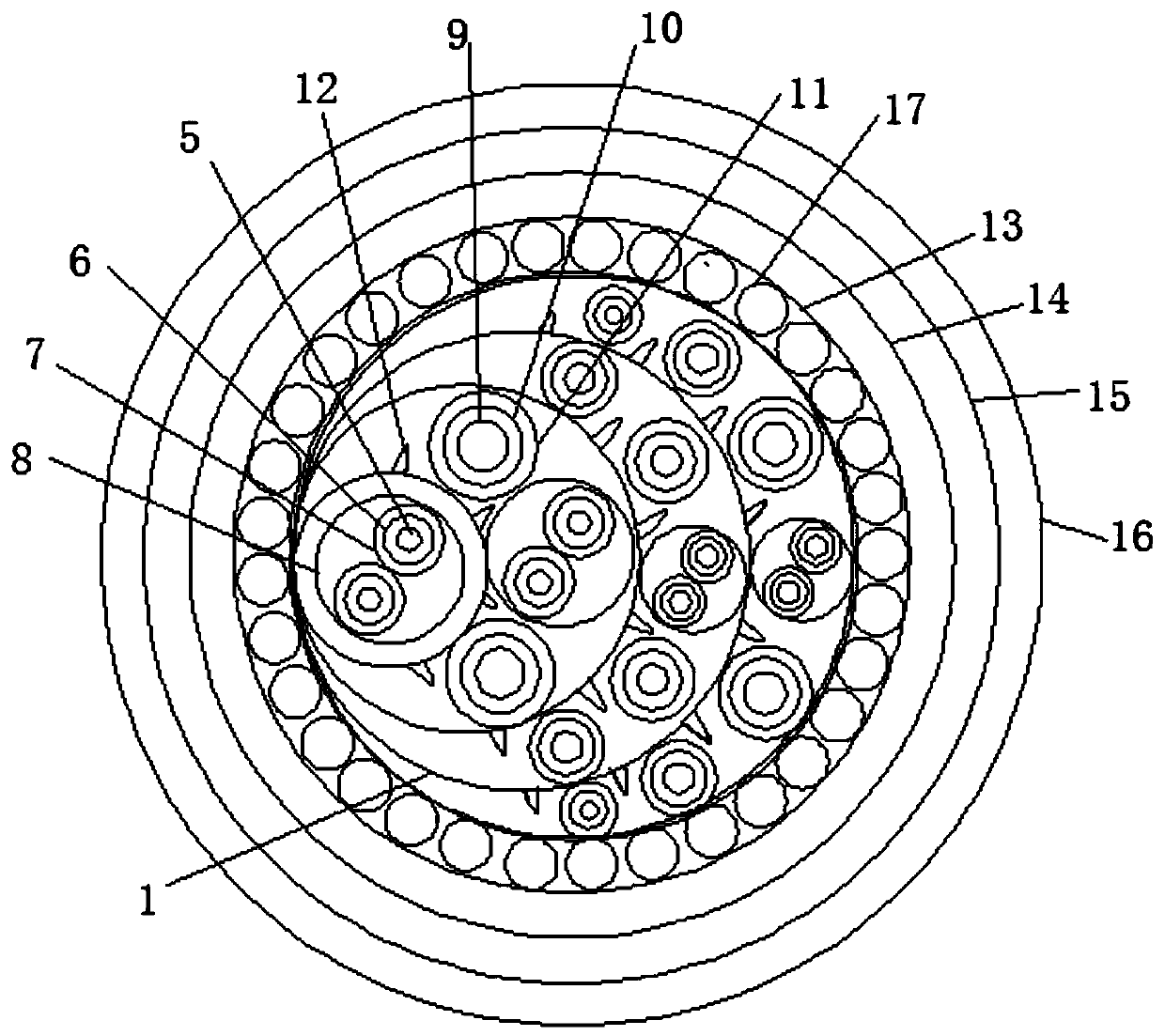

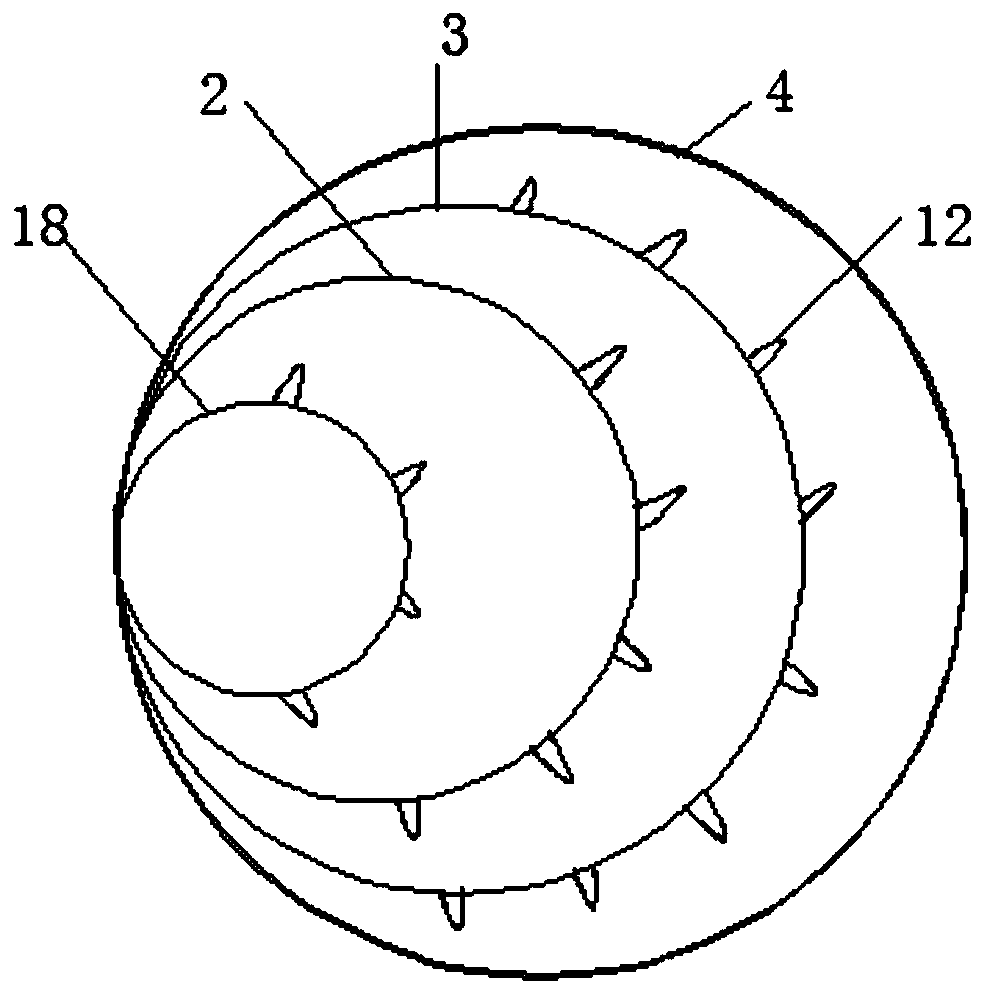

Waterproof fireproof control cable

ActiveCN109830336AThe internal structure of the cable is compact and stableGood wire core protectionInsulated cablesInsulated conductorsEngineeringEthylene propylene rubber

The invention discloses a waterproof fireproof control cable comprising a rubber skeleton, wherein the rubber skeleton comprises four circular skeletons with different radiuses; the left side surfacesof the four circular skeletons are fixedly connected together and then the four circular skeletons are successively stacked according to the radiuses; first wire cores are disposed in the four circular skeletons; a plurality of second wire cores are disposed in each of the second circular skeleton, the third circular skeleton and the fourth circular skeleton; each first wire core includes a firstconductor; and the outer side of the first conductor is successively coated with a thermoplastic vulcanized rubber insulating layer and a halogen-free glass fiber wrapping layer. The outer side of the rubber skeleton is successively coated with a glass fiber belt and ceramic silicone rubber belt wrapping layer, a lead alloy inner sheath layer, a waterproof expansion filling layer and an outer sheath. Thus, the cable is good in waterproof and fireproof effect, simple in structure, good in insulation effect, long in service life, stable in operation and low in production cost. An ethylene propylene rubber elastic rod enhances the softness of the cable.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

Granite-imitation wall body material and preparation method thereof

InactiveCN104761227AProtect environmentAchieve sustainable developmentCeramic shaping apparatusGypsumSlag

The invention discloses a granite-imitation wall body material and a preparation method thereof. The granite-imitation wall body material is prepared from following raw materials, by weight: 50-80 parts of phosphogypsum, 6-16 parts of cement, 1-2 parts of fibers, 20-30 parts of yellow phosphorus furnace slag and 2-10 parts of quick lime. In the invention, by means of the phosphogypsum, the yellow phosphorus furnace slag and the quick lime as raw materials for preparing the granite-imitation wall body material, a problem that the waste phosphogypsum is stacked just like mountains can be solved. The invention has an important significance on environment protection and sustainable development. The wall body material is light in weight, is good in water and fire resistance, is high in compressive strength and is strong in weather resistance, and can be widely used as an indoor / outdoor decorative material.

Owner:GUIZHOU KAILIN GRP CO LTD

Waterproof, anticorrosive and deformation-proof wood new material plate

PendingCN110091399ASmall molecular weightAvoid deformationWood treatment detailsPressure impregnationEngineeringPulp and paper industry

The invention belongs to the technical field of wood treatment, and discloses a waterproof, anticorrosive and deformation-proof wood new material plate, which is prepared according to the following steps: a single-layer log plate with a thickness of 8-18 mm is obtained by rotary cutting by a rotary cutting machine, the single-layer log plate and glue are placed in a pressure vessel, the pressure vessel is closed, pressurization is carried out, then the pressure vessel is opened, the plate is taken out, and natural air drying is carried out to obtain the waterproof, anticorrosive and deformation-proof wood new material plate. The glue permeates into log wood through pressure so as to improve the comprehensive performance of the wood.

Owner:王新惠 +1

A kind of phosphogypsum base material imitation marble floor tile and preparation method thereof

InactiveCN104725013BSolving the mountain of status quoWide variety of sourcesSolid waste managementCeramic shaping apparatusHydration reactionFiber

The invention discloses a phosphogypsum base material marble-imitated floor tile and a preparation method thereof. In parts by weight, the floor tile is prepared from 50-80 parts of phosphogypsum, 20-40 parts of yellow phosphorus slag, 0.1-2 parts of fiber and 1-8 parts of quicklime. Phosphorus slag powder which is good in fluidity and uniform in particle can be prepared by mixing the yellow phosphorus slag with the phosphogypsum, stirred and reacted at 90-100 DEG C, and then ground. The quicklime, the fiber and the phosphorus slag powder are mixed under a certain temperature and a stirring speed and are subjected to aging treatment, so as to significantly shorten aging time; through a hydration reaction, the phosphorus slag powder can generate a main product, namely ettringite crystal; the intensity and the water resistance of the phosphogypsum base material marble-imitated floor tile are significantly improved; and the content of soluble impurities in the phosphogypsum is reduced and the coagulation property of the phosphogypsum base material marble-imitated floor tile is greatly improved.

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION

Phosphogypsum-based stone-like structure building material and preparation method thereof

InactiveCN104725006ASimple construction processImprove waterproof and fireproof performanceSolid waste managementCeramic shaping apparatusSlagPhosphogypsum

The invention discloses a phosphogypsum-based stone-like structure building material and a preparation method thereof. The phosphogypsum-based stone-like structure building material is prepared from the following raw materials in parts by weight: 160-240 parts of phosphogypsum, 140-180 parts of electrolytic yellow phosphorus slag and 10-15 parts of quicklime. The preparation method comprises the following steps: burdening, ageing, molding, carrying out autoclaved curing, drying a phosphorus gypsum base material, spraying and forming a finished product. The phosphogypsum-based stone-like structure building material has the characteristics of simple construction process, light weight, good waterproof and fireproof properties, high compressive strength, high breaking strength and high weather resistance, and has a good decoration effect as an indoor decoration building material; meanwhile, a lot of phosphogypsum is consumed; exploitation of natural stones is reduced; and the phosphogypsum-based stone-like structure building material has important significance on environment protection and realization of sustainable development.

Owner:GUIZHOU KAILIN GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com