Phosphogypsum-based simulative heat-preservation building material and preparation method of same

A technology of building materials and phosphogypsum, which is applied in the manufacture of tools, ceramic molding machines, etc., can solve problems such as not being seen, and achieve the effects of avoiding water pollution, improving toughness, and high flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Formula: phosphogypsum 35kg, electrolytic yellow phosphorus slag 20kg, quicklime 1.75kg, silica sand 10kg, glass fiber 7kg, pulp 6kg.

[0037] Preparation:

[0038] (1) Ingredients: Take phosphogypsum and quicklime according to the mass ratio of 20:1 and neutralize them for 1 minute, put them into a mixer, add silica sand, glass fiber, and pulp and stir for 30 seconds, then turn on the mixer, add electrolytic yellow phosphorus slag to continue Stir for 60s to obtain the mixed material, then dry the mixed material until the free water ≤ 1%, put it into a ball mill and grind for 40 minutes;

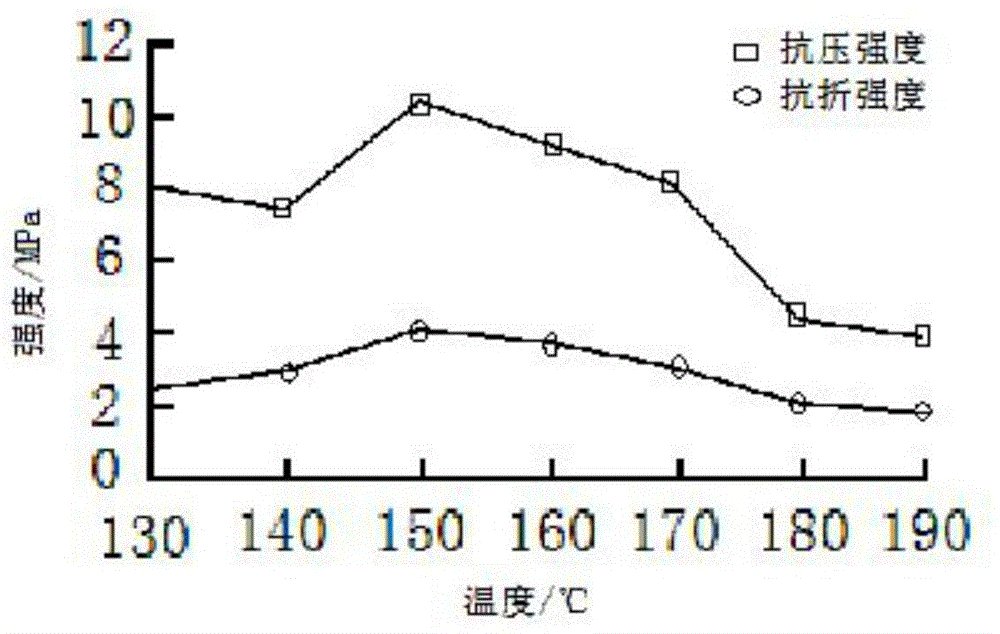

[0039] (2) Aging: aging the mixed material after ball milling in step (1) after calcining at a temperature of 140° C. for 3 hours, and the aging time is 24 hours;

[0040] (3) Forming: put the aged material into the vibration forming machine, and vibrate and form according to the required shape;

[0041] (4) Autoclave curing: after the vibratory forming material is naturally cured ...

Embodiment 2

[0046] Formula: phosphogypsum 85kg, electrolytic yellow phosphorus slag 65kg, quicklime 4.25kg, silica sand 10kg, glass fiber 7kg, pulp 6kg.

[0047] Preparation:

[0048] (1) Ingredients: Take phosphogypsum and quicklime according to the mass ratio of 20:1 and neutralize them for 1 minute, put them into a mixer, add silica sand, glass fiber, and pulp and stir for 30 seconds, then turn on the mixer, add electrolytic yellow phosphorus slag to continue Stir for 60s to obtain the mixed material, then dry the mixed material until the free water ≤ 1%, put it into a ball mill and grind for 42 minutes;

[0049] (2) Aging: aging the mixed material after ball milling in step (1) after calcining at a temperature of 145° C. for 3 hours, and the aging time is 24 hours;

[0050] (3) Forming: put the aged material into the vibration forming machine, and vibrate and form according to the required shape;

[0051](4) Autoclave curing: After the vibration-formed material is naturally cured fo...

Embodiment 3

[0056] Formula: 55kg of phosphogypsum, 30kg of electrolytic yellow phosphorus slag, 2.75kg of quicklime, 10kg of silica sand, 7kg of glass fiber, and 6kg of pulp.

[0057] Preparation:

[0058] (1) Ingredients: Take phosphogypsum and quicklime according to the mass ratio of 20:1 and neutralize them for 1 minute, put them into a mixer, add silica sand, glass fiber, and pulp and stir for 30 seconds, then turn on the mixer, add electrolytic yellow phosphorus slag to continue Stir for 60s to obtain the mixed material, then dry the mixed material until the free water ≤ 1%, put it into a ball mill and grind for 46 minutes;

[0059] (2) Aging: aging the mixed material after ball milling in step (1) after calcining at a temperature of 152° C. for 4 hours, and the aging time is 34 hours;

[0060] (3) Forming: put the aged material into the vibration forming machine, and vibrate and form according to the required shape;

[0061] (4) Autoclave curing: After the vibratory forming materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com