Phosphogypsum-based foam-like structure building material and preparation method thereof

A technology of foam structure and building materials, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as technical solutions for imitation foam structures, and achieve sustainable development and good decorative effects , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Formula: 300kg of phosphogypsum, 150kg of electrolytic yellow phosphorus slag, 10kg of quicklime, 6kg of sepiolite, 5kg of expanded perlite, and 2kg of floating beads.

[0040] Preparation:

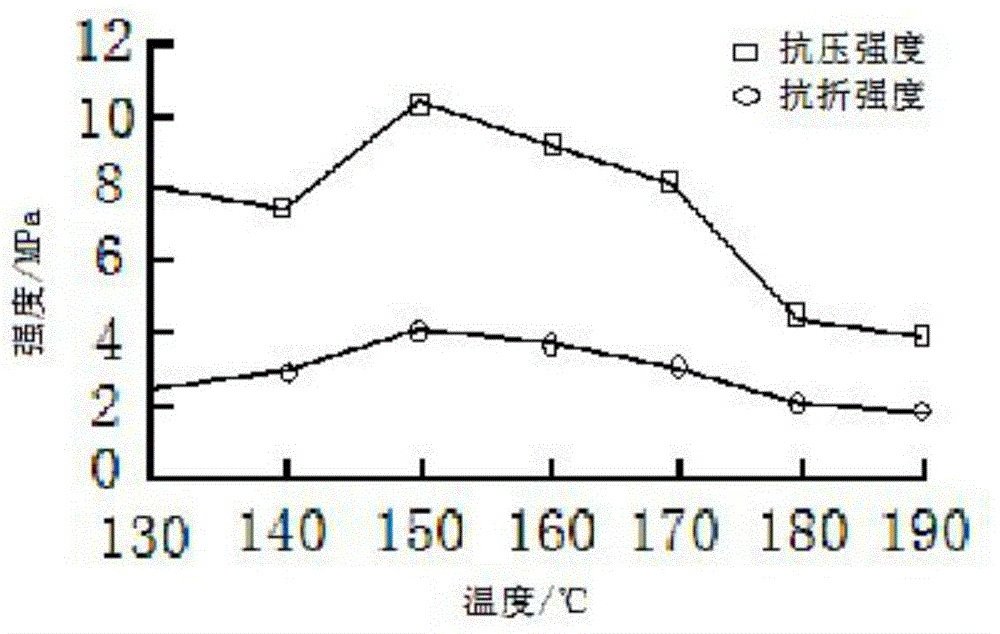

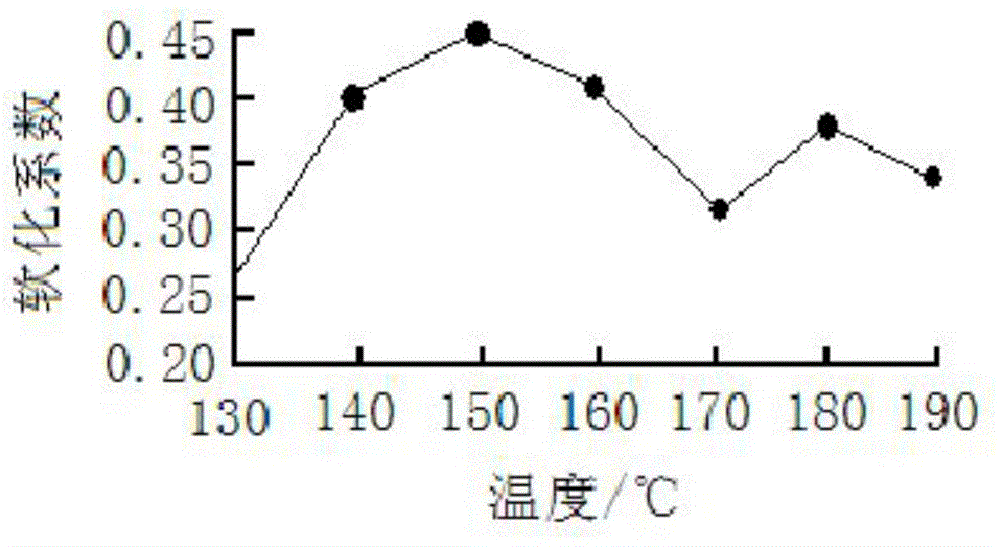

[0041] Take phosphogypsum and unslaked lime according to the mass ratio of 10:1 and neutralize them for 1min, put them in a mixer and stir for 30s, then turn on the mixer, add electrolytic yellow phosphorus slag and continue to stir for 60s to obtain a mixed material, and then dry the mixed material to After the free water is ≤1%, put it into a ball mill for grinding for 40 minutes, until the specific surface area is 275m 2 / kg; the mixed material after ball milling was calcined at 140°C for 3 hours, and then aged for 24 hours; the aged material was put into a vibration molding machine, and formed by vibration according to the required shape; After natural curing of the vibration-molded material for 7 days, autoclave curing is carried out. The heating rate is 20°C / h, the control ...

Embodiment 2

[0043] Formula: 800kg of phosphogypsum, 600kg of electrolytic yellow phosphorus slag, 100kg of quicklime, 6kg of sepiolite, 5kg of expanded perlite, and 2kg of floating beads.

[0044] Preparation:

[0045] Take phosphogypsum and unslaked lime according to the mass ratio of 10:1 and neutralize them for 1min, put them in a mixer and stir for 30s, then turn on the mixer, add electrolytic yellow phosphorus slag and continue to stir for 60s to obtain a mixed material, and then dry the mixed material to After the free water is ≤1%, put it into a ball mill and grind for 42 minutes until the specific surface area is 275m 2 / kg; the mixed material after ball milling was calcined at a temperature of 142°C for 3 hours, and then aged for 26 hours; the aged material was put into a vibration molding machine, and formed by vibration according to the required shape; After natural curing of vibration-molded materials for 7 days, autoclave curing is carried out. The heating rate is 20°C / h, th...

Embodiment 3

[0047] Formula: phosphogypsum 400kg, electrolytic yellow phosphorus slag 250kg, quicklime 30kg, sepiolite 6kg, expanded perlite 5kg, floating beads 2kg.

[0048] Preparation:

[0049] Take phosphogypsum and unslaked lime according to the mass ratio of 10:1 and neutralize them for 1min, put them in a mixer and stir for 30s, then turn on the mixer, add electrolytic yellow phosphorus slag and continue to stir for 60s to obtain a mixed material, and then dry the mixed material to After the free water is ≤1%, put it into a ball mill and grind for 44 minutes until the specific surface area is 276m 2 / kg; the mixed material after ball milling was calcined at a temperature of 144°C for 3 hours, and then aged for 28 hours; the aged material was put into a vibration molding machine, and formed by vibration according to the required shape; After natural curing of the vibration-molded material for 7 days, autoclave curing is carried out. The heating rate is 20°C / h, the control temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com