Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Thickness reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sugar-free bread and method for producing the same

The invention relates to a sugar-free bread, characterized by comprising the materials with the following components: high-gluten flour 150-900 parts, low-gluten flour 200-800 200-800 parts, water-free ghee 50-200 parts, sugar-free modifier 50-200 parts, sugar-free milk 10-150 parts, egg 50-10 parts, bread modifier 1-20 parts, yeast 10-20 parts, ghee 200-800 parts. The inventive technology avoids coldness or heat in fed materials contacted with yeast, causing the yeast to exert optimal fermentation ability. The prepared sugar-free nutritious bread is deeply favored by wide consumers.

Owner:天津金世制药有限公司

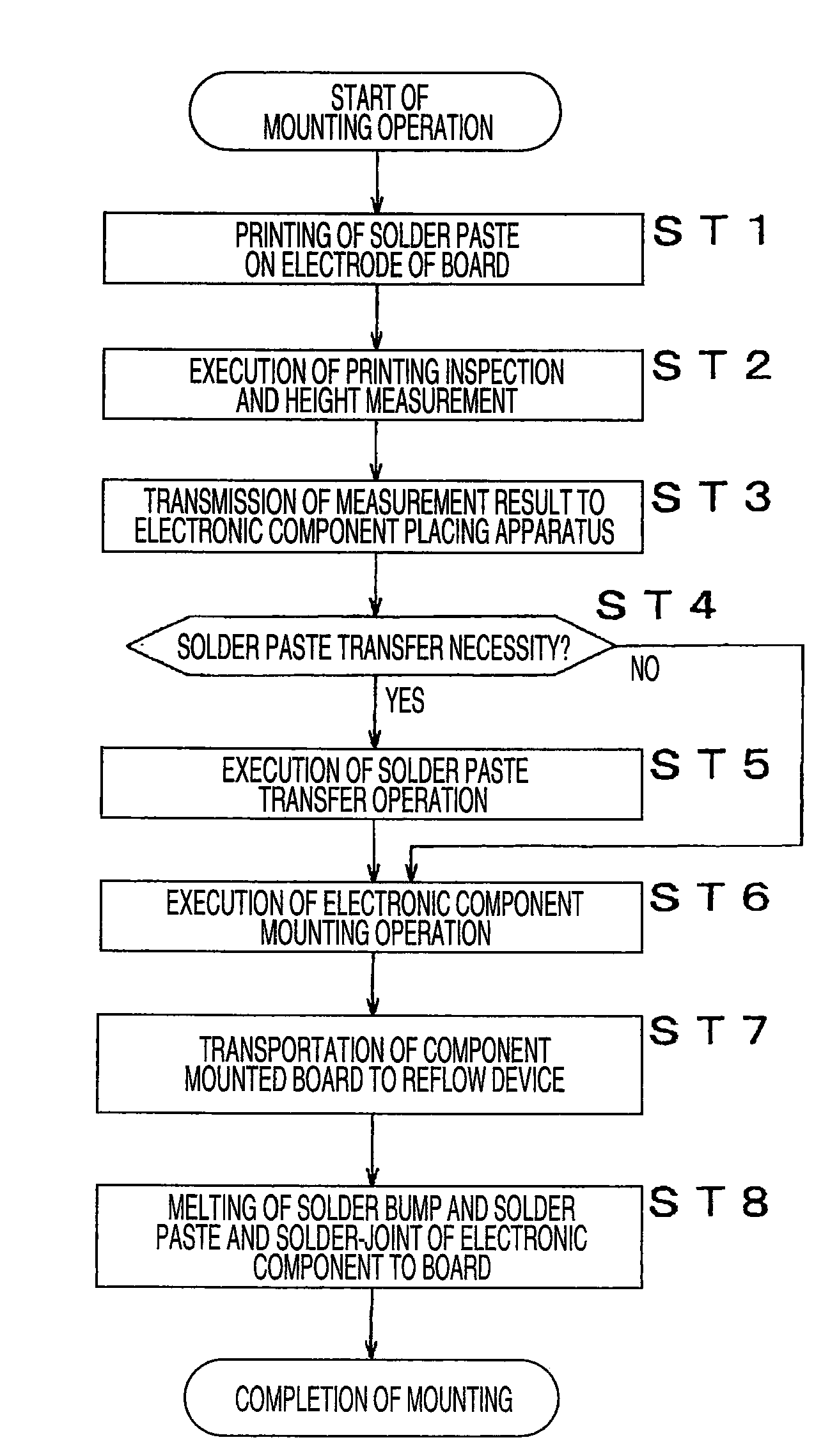

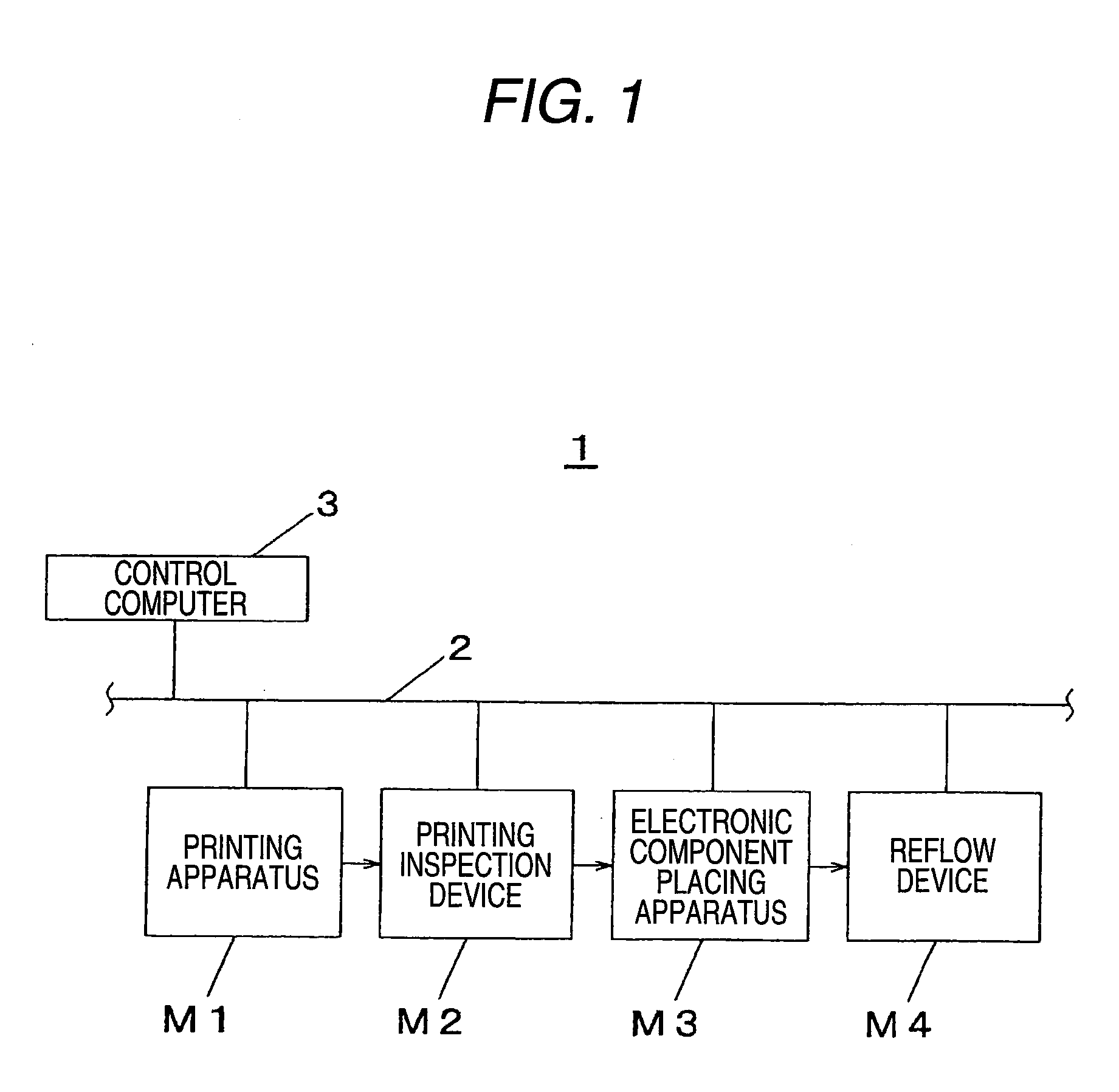

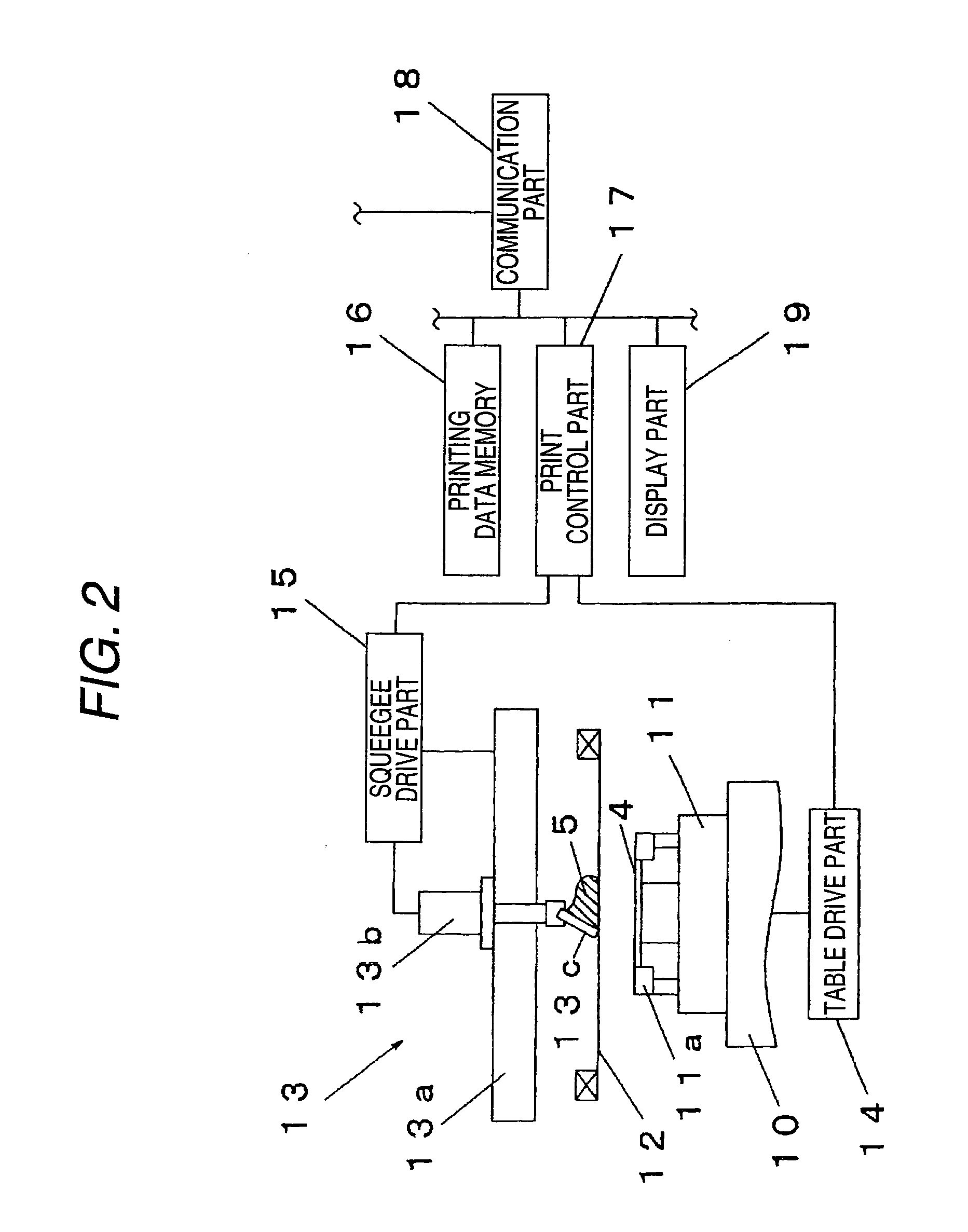

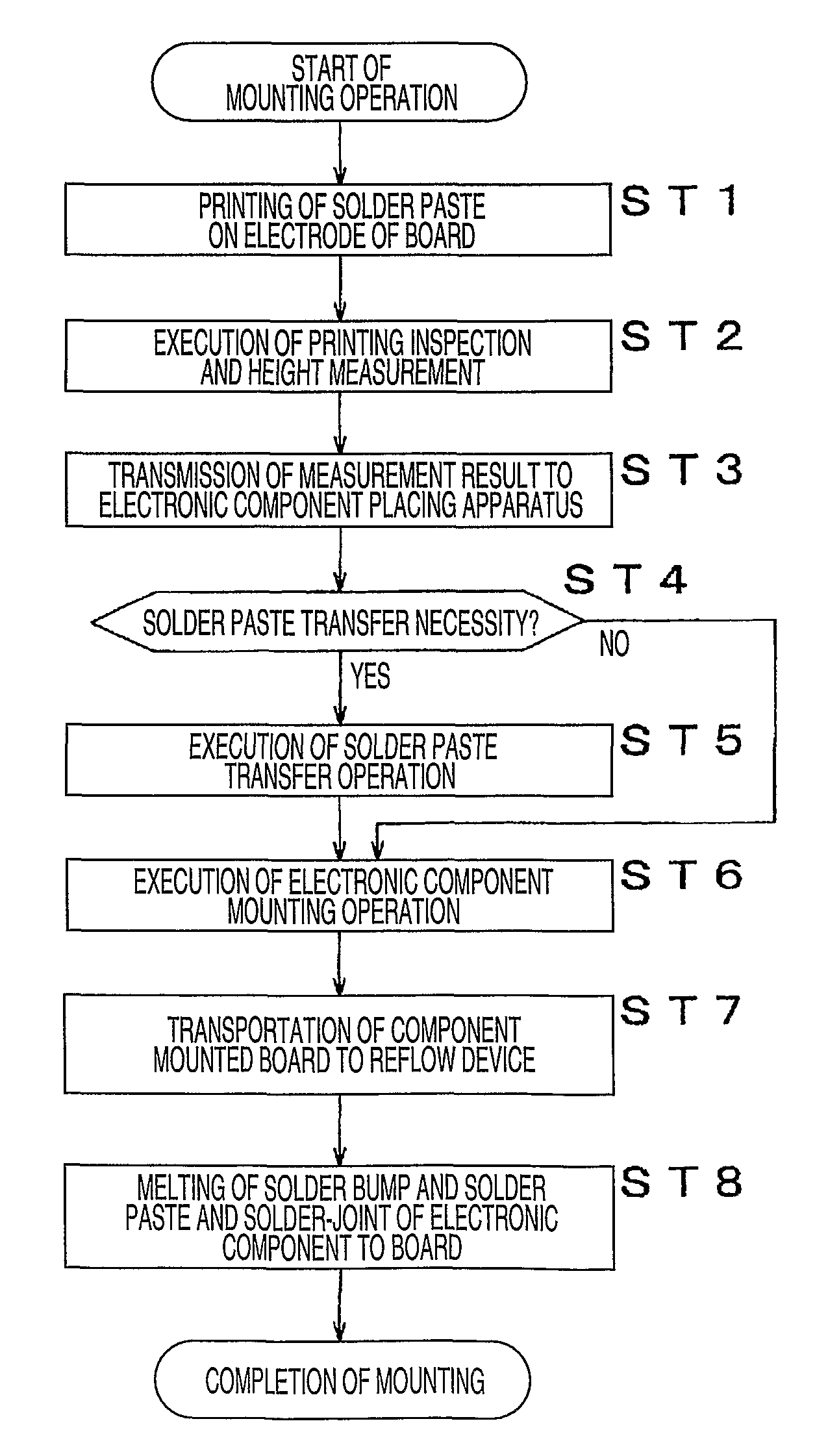

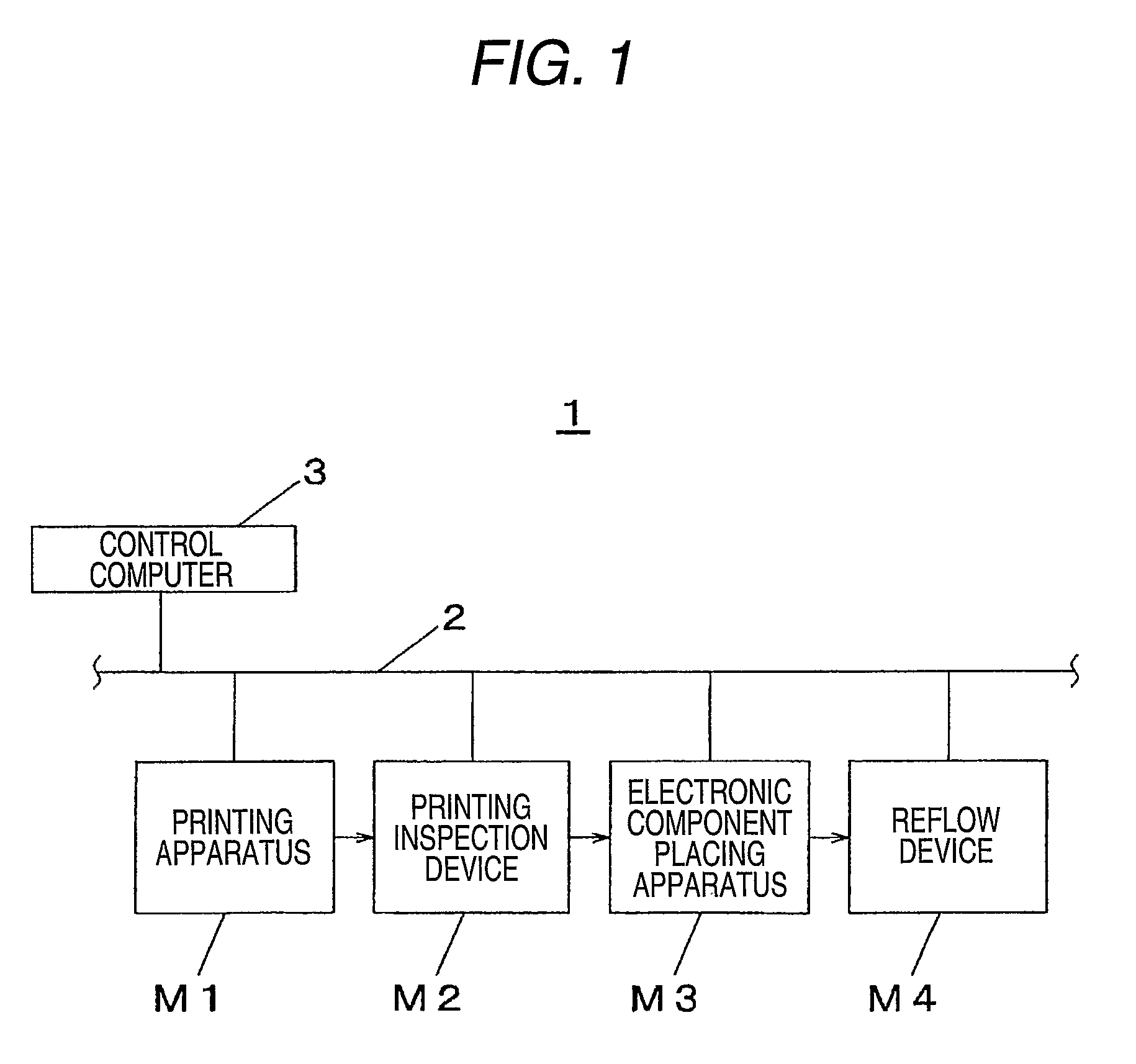

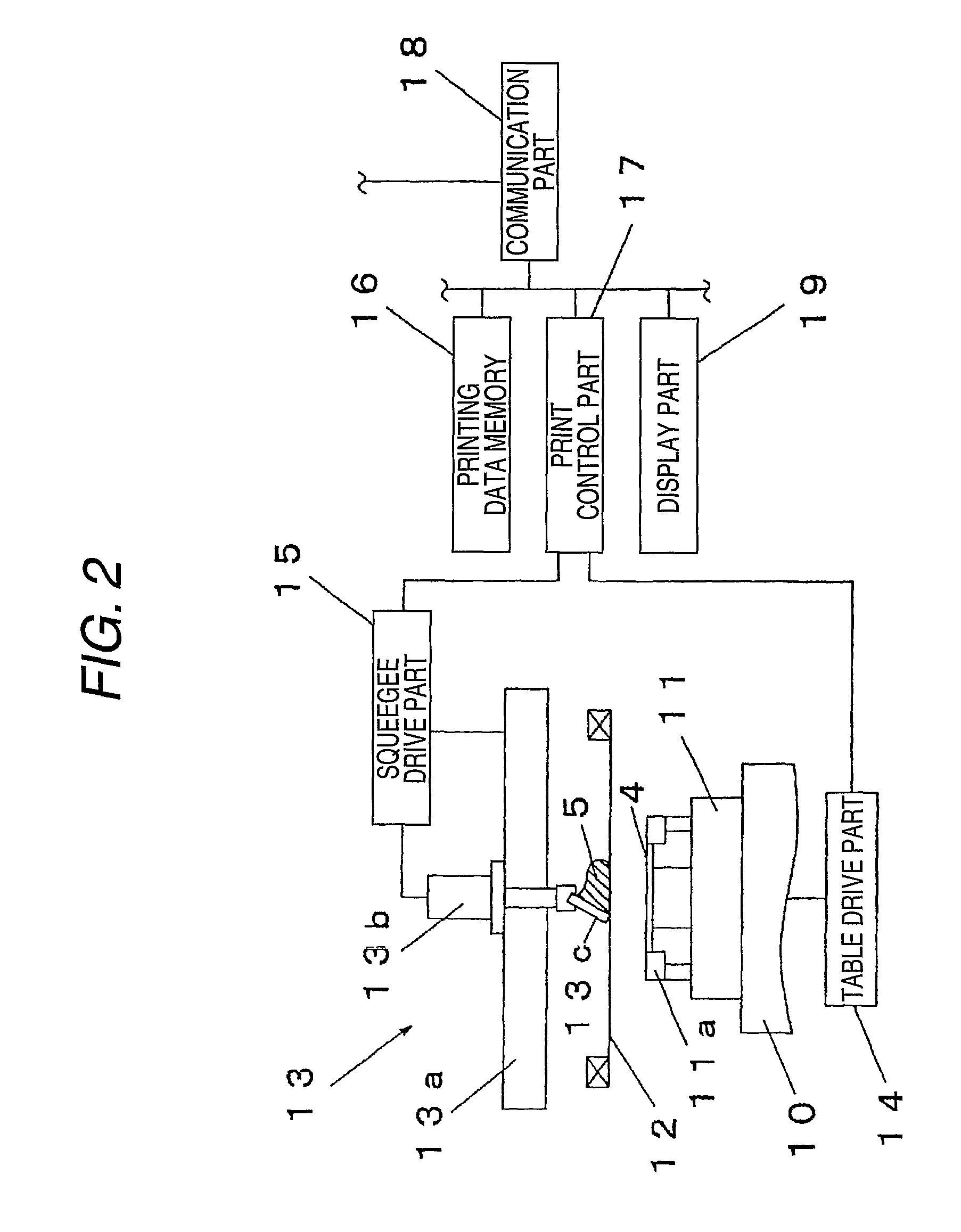

Electronic component mounting system, electronic component placing apparatus, and electronic component mounting method

ActiveUS20090014501A1Prevent poor jointReduce rigidityPrinted circuit assemblingFinal product manufactureSemiconductor packageEngineering

Regarding electronic component mounting in which an electronic component having plural solder bumps for external connection on its lower surface is mounted on a board, in an electronic component mounting operation of previously measuring the height position of solder paste on the board on which the solder paste has been printed, and mounting the electronic component on the board on which the solder paste has been printed by a loading head, whether the transfer of the solder paste to the solder bumps is necessary or not is judged on the basis of the measurement result of the height of the solder paste. In case that it is judged that the transfer is necessary, the transfer of the solder paste is executed, and thereafter the electronic component is mounted on the board. Hereby, it is possible to prevent the poor joint in case that a thin-sized semiconductor package which causes easily warp deformation is mounted on the board by solder-joint.

Owner:PANASONIC CORP

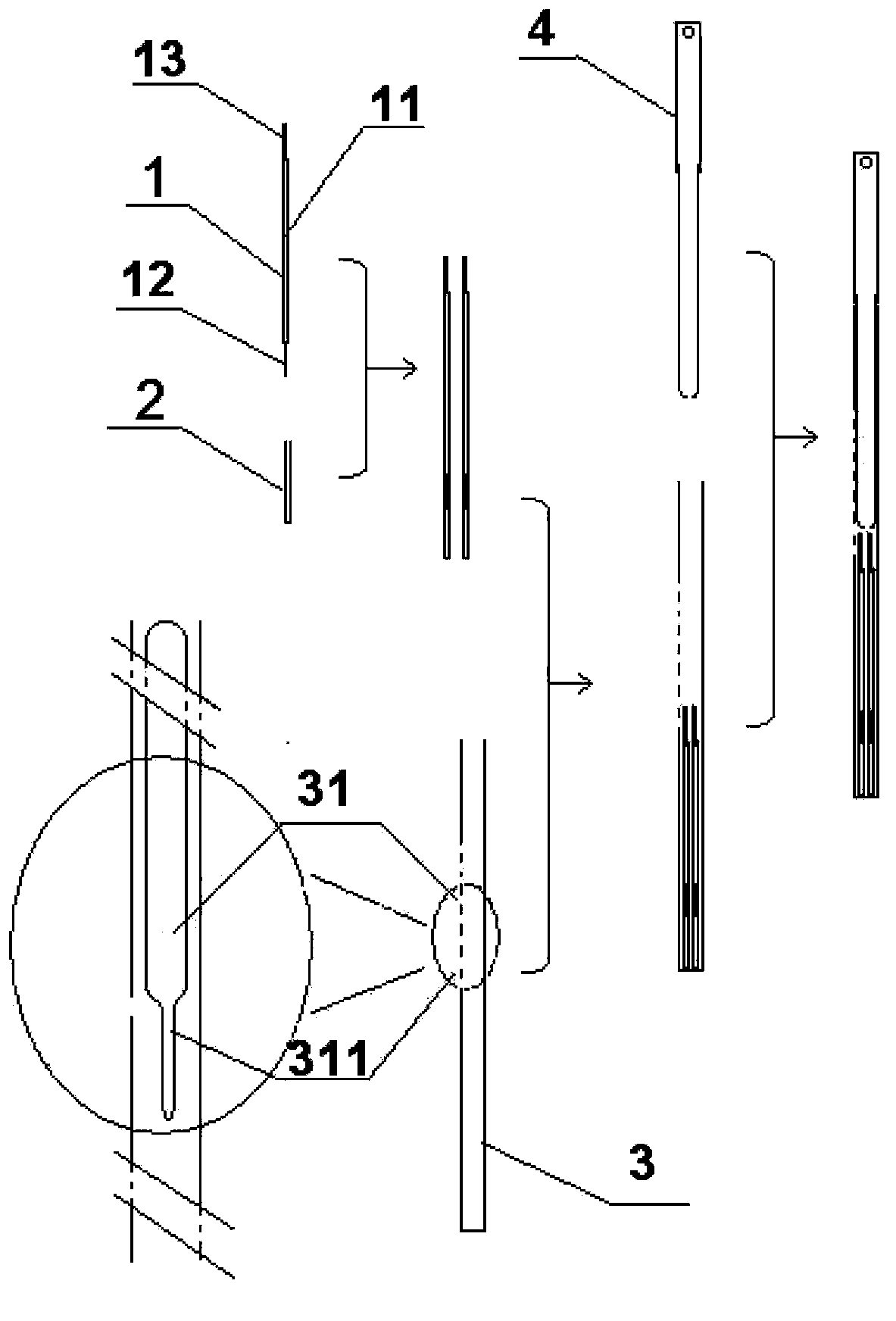

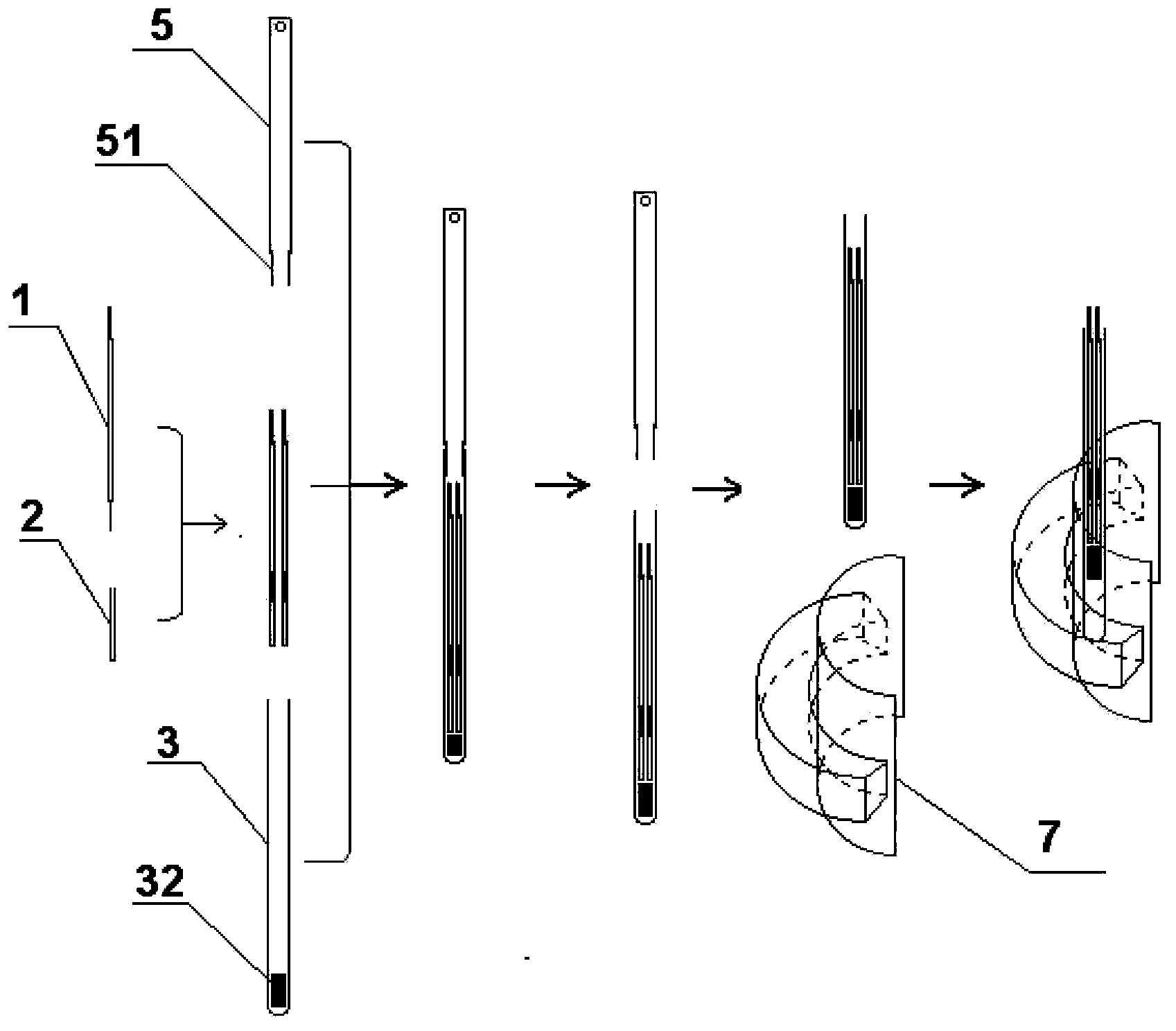

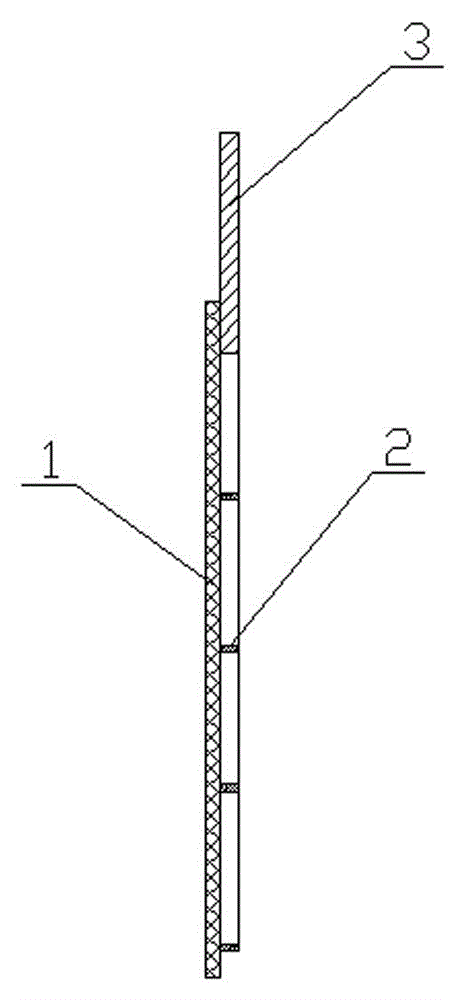

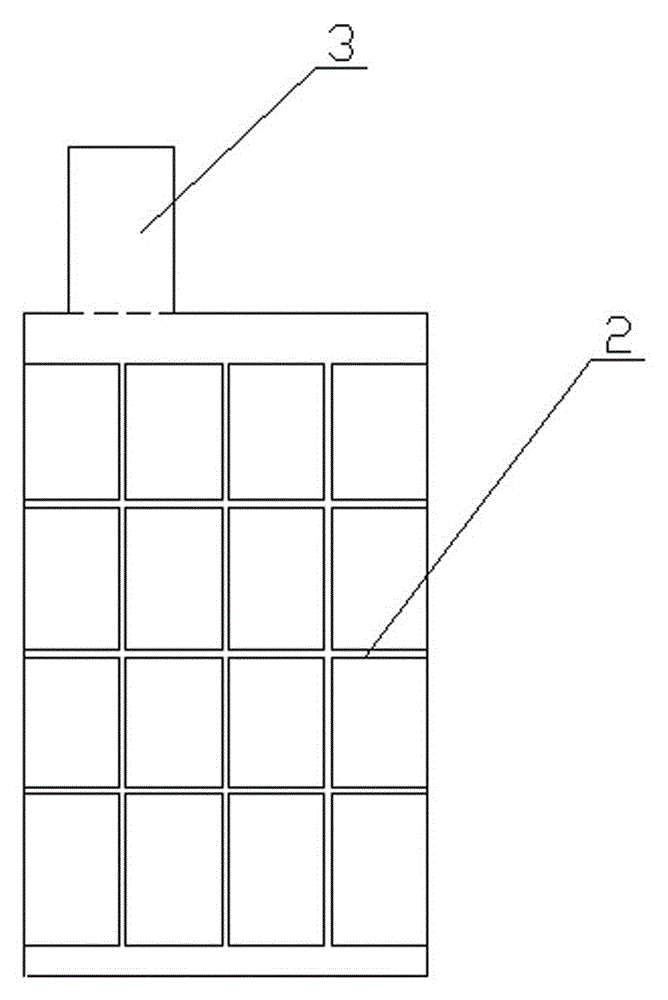

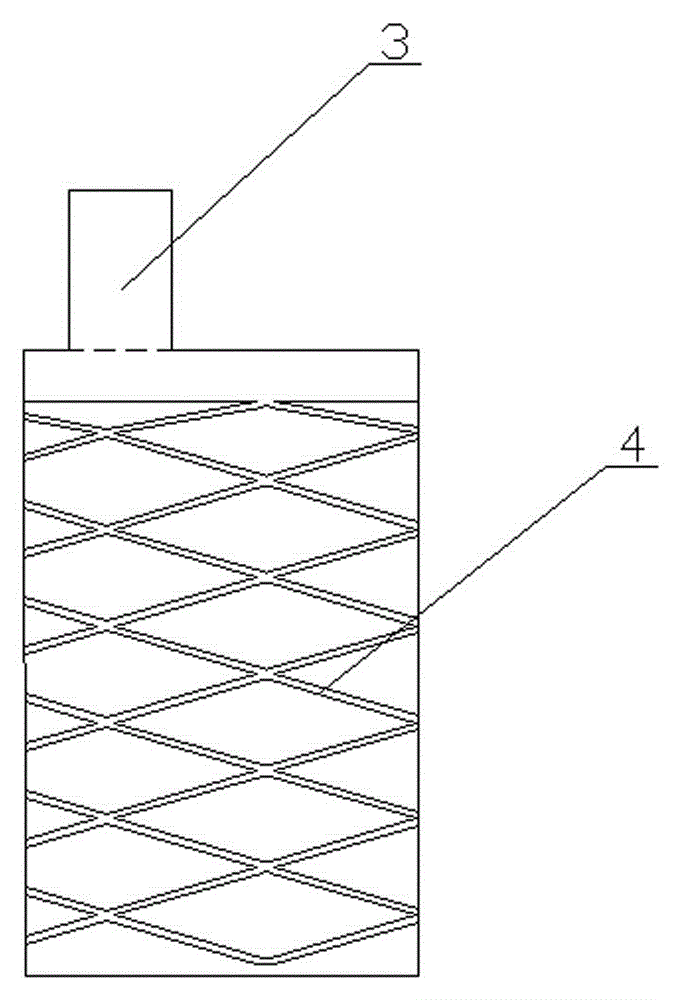

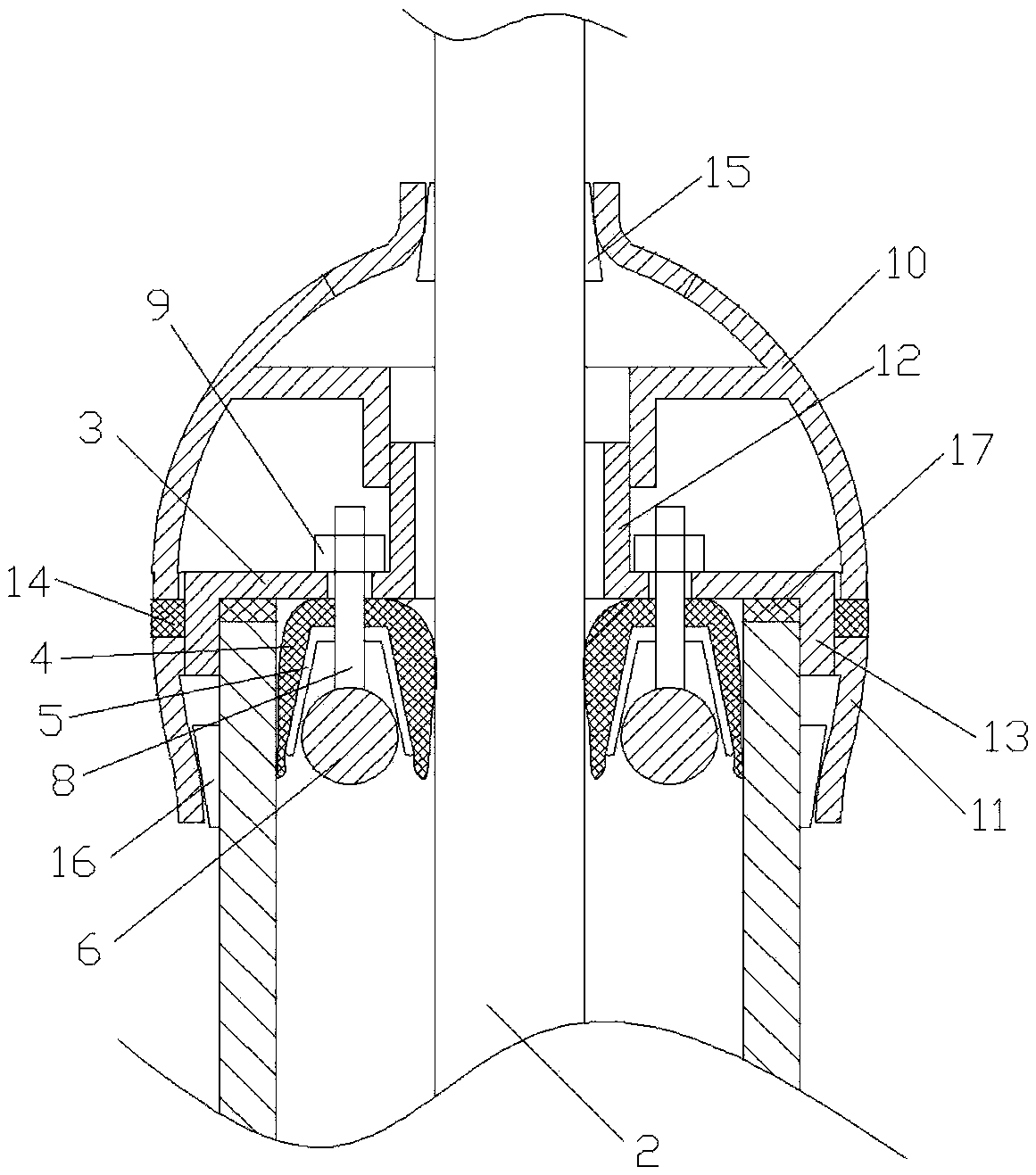

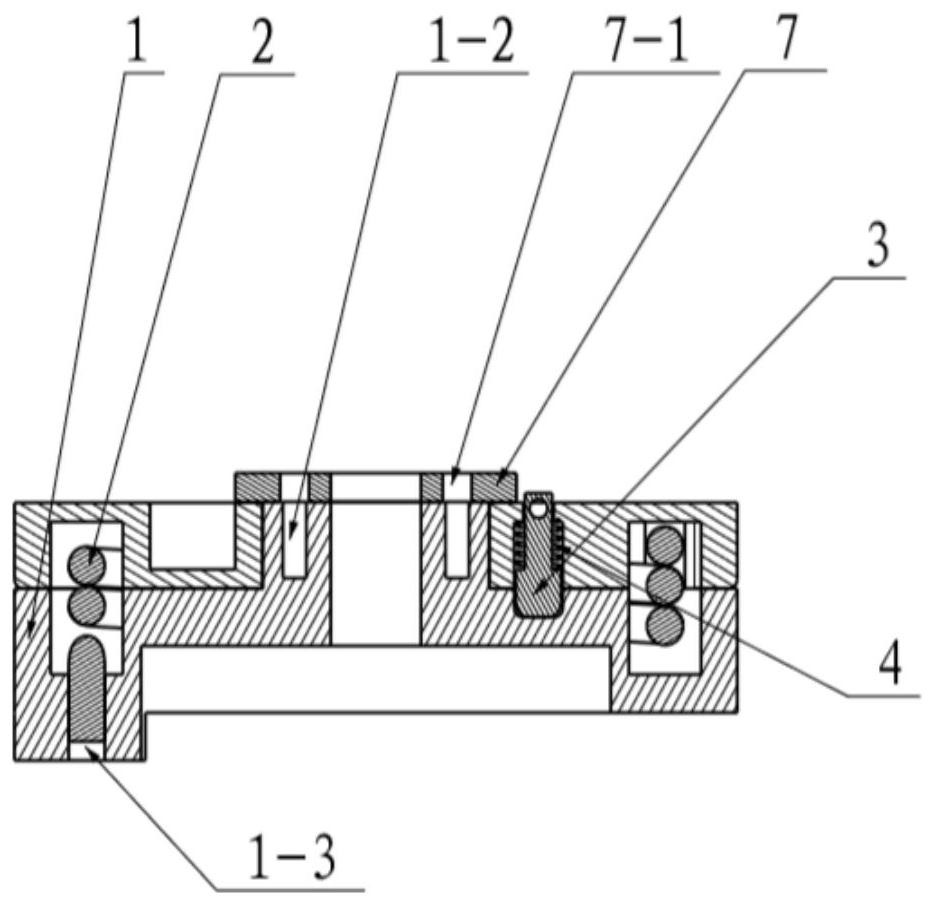

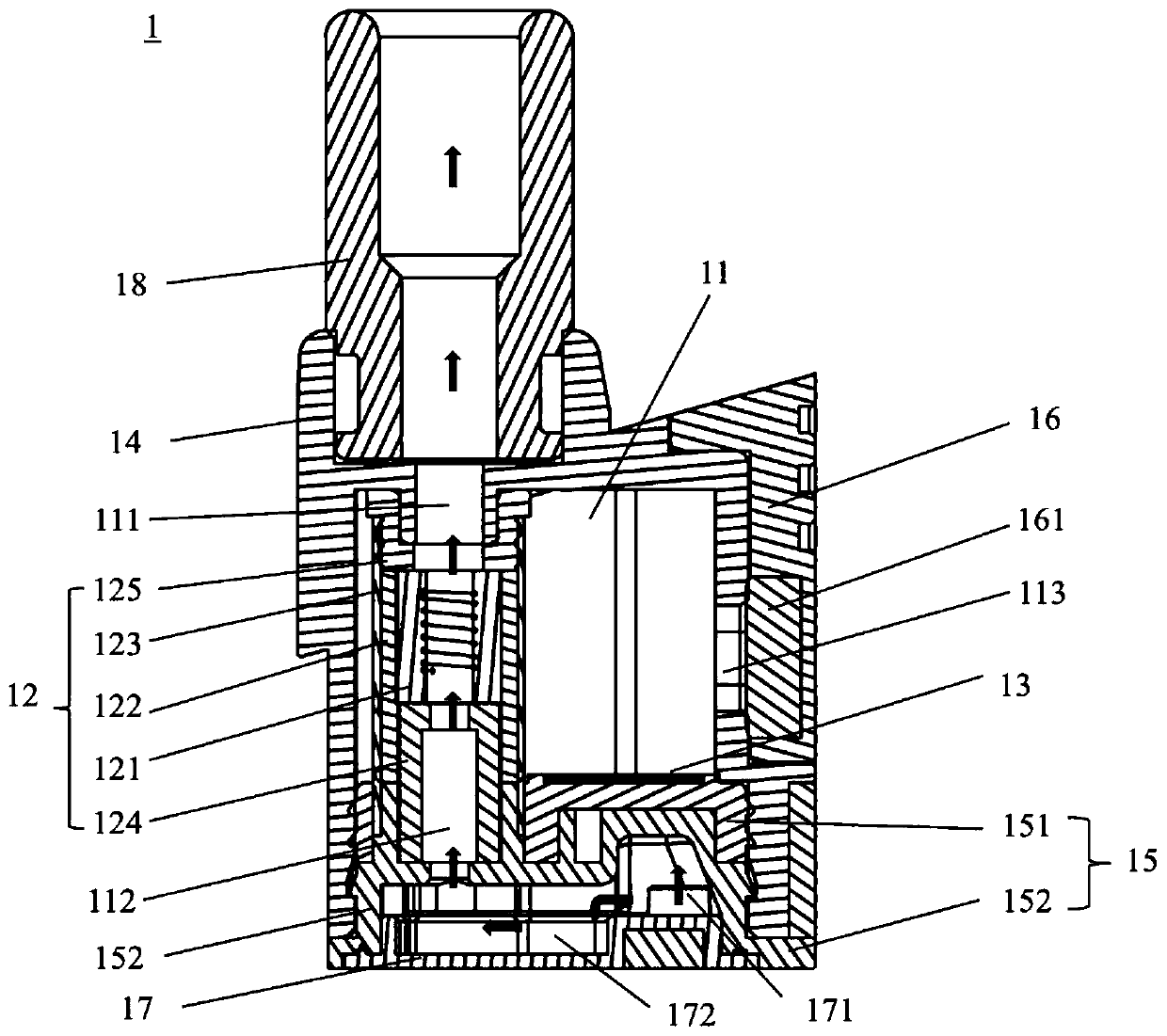

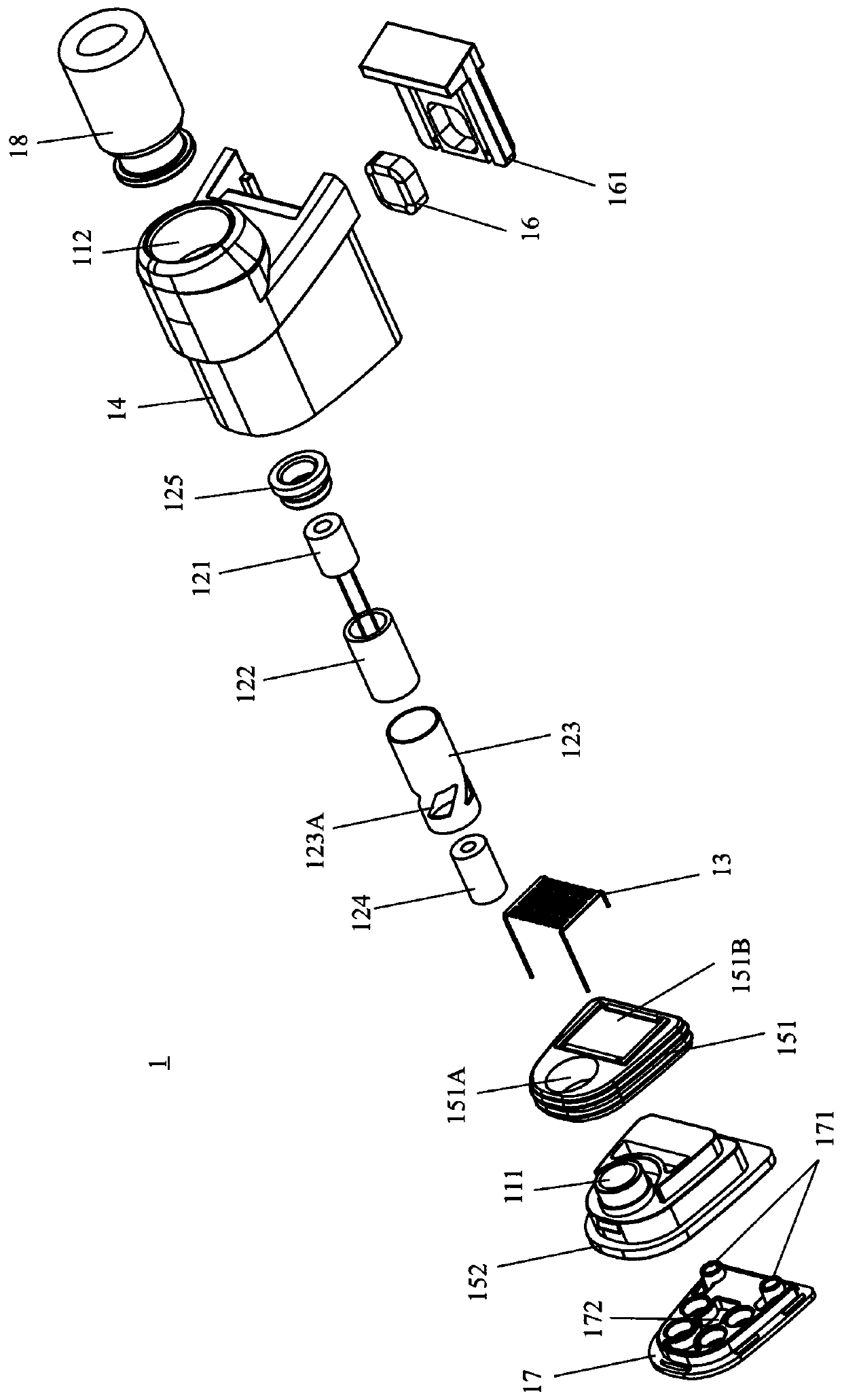

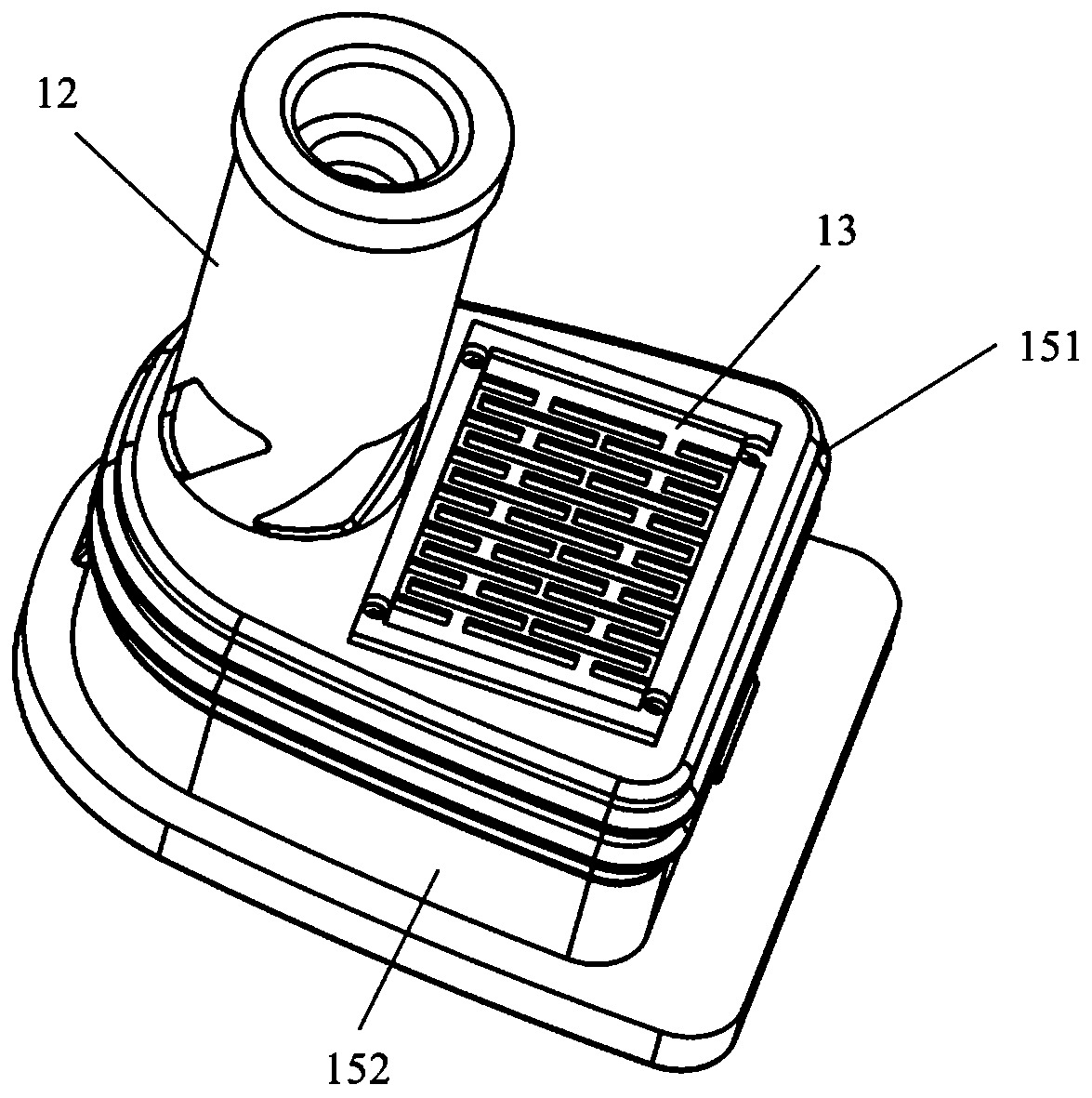

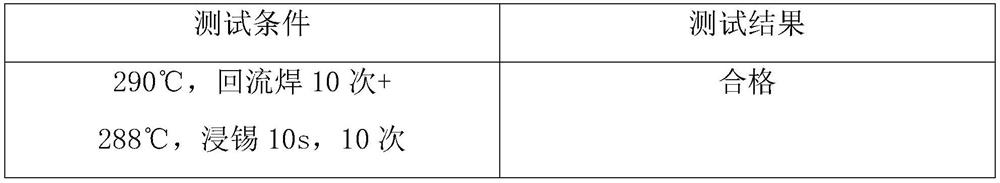

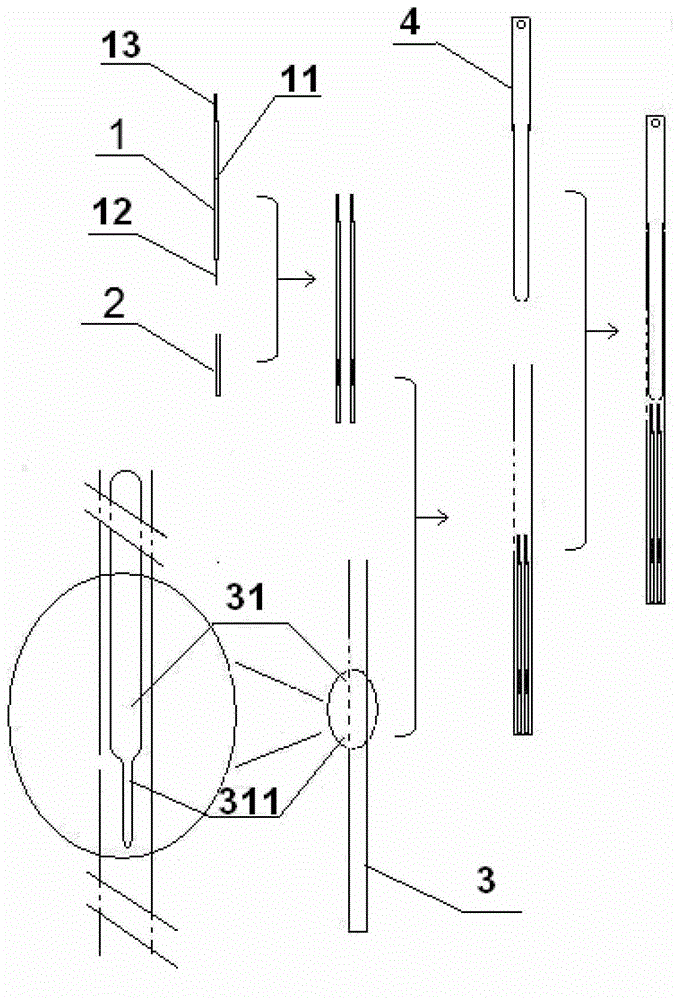

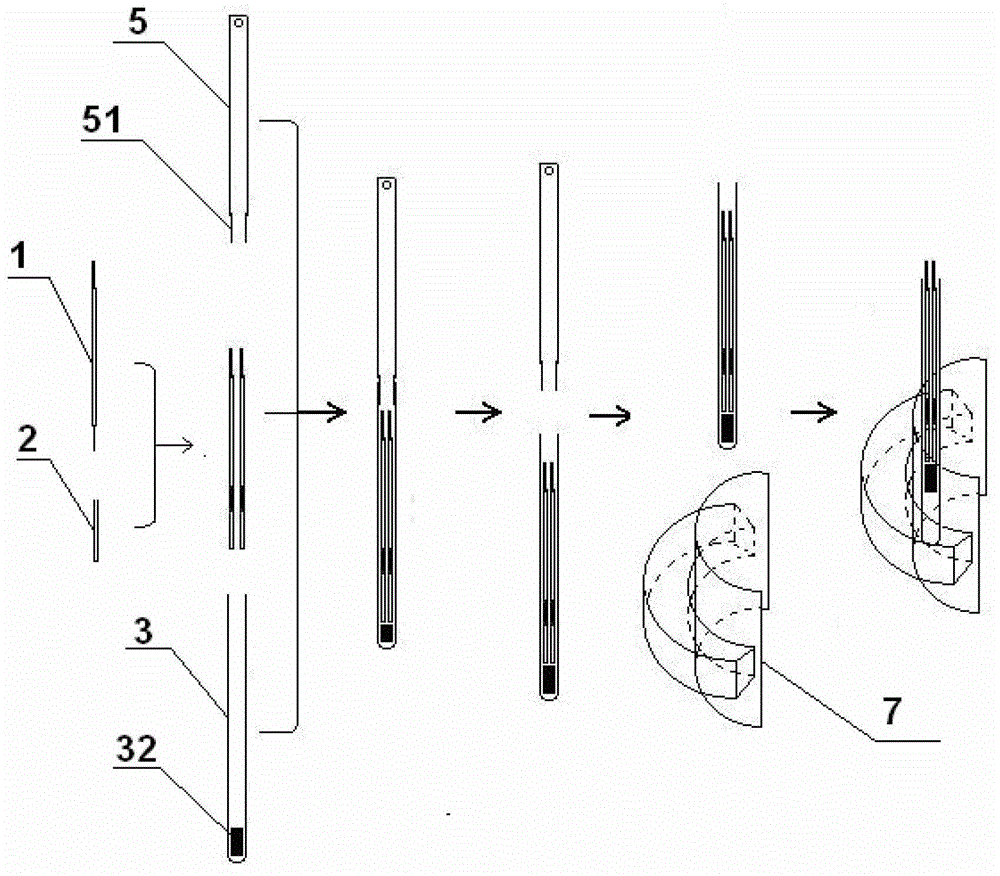

Miniature carrier system for cryopreservation of biological materials, bucket and cryopreservation method

ActiveCN103444699AThickness reductionSimple and fast operationDead animal preservationCarrier systemEmbryo

The invention provides a miniature carrier system for cryopreservation of biological materials and application of the carrier system. The miniature carrier system is mainly composed of a cryopreservation unit comprising a carrying pole, a carrying pole sleeve and a carrying pole cylinder, wherein the front end of the carrying pole is inserted into the carrying pole sleeve to form a flat and slender carrying unit, and then the carrying pole and the carrying pole sleeve are arranged in the carrier pole cylinder together; the carrier pole cylinder is a hollow pipe with the average outer diameter of less than 8.5mm, and at least the bottom end of the hollow pipe is closed; the top end or the side wall of the carrier pole cylinder is provided with a pole loading hole, through which a locating unit can be placed in and taken out of the carrier pole cylinder, and loading protection and unloading technologies are implemented by virtue of the pole loading hole. On the basis of not influencing and even improving the use convenience of the miniature carrier system, space occupied for cryopreservation of a trace biological sample is reduced in multiples, and thus a floor space for cryopreservation is saved greatly. The miniature carrier system is especially suitable for cryopreservation of the trace biological materials such as embryos.

Owner:吕祁峰

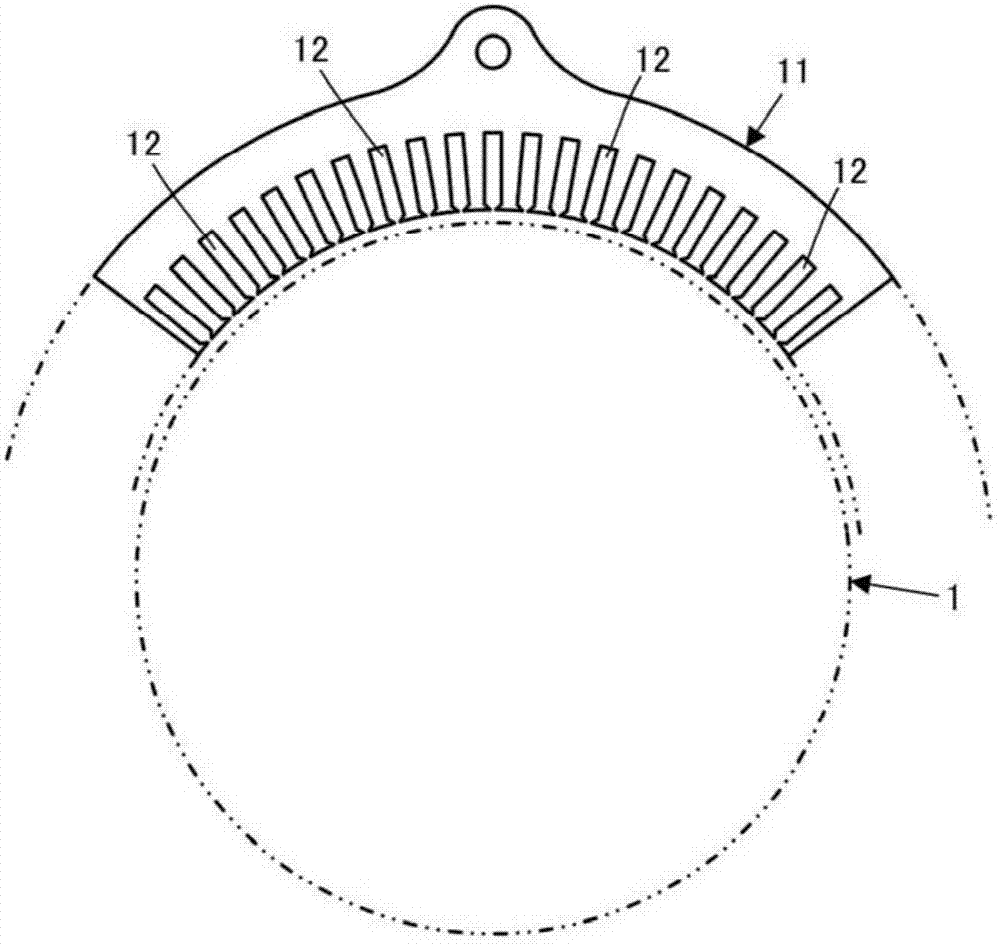

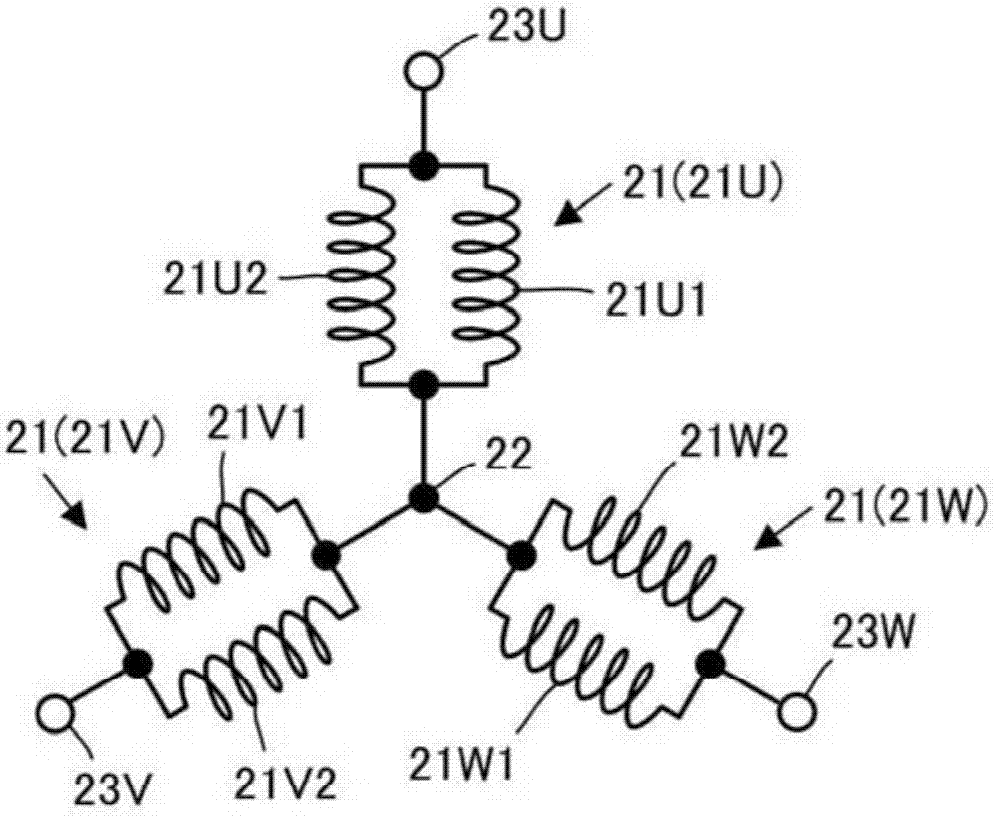

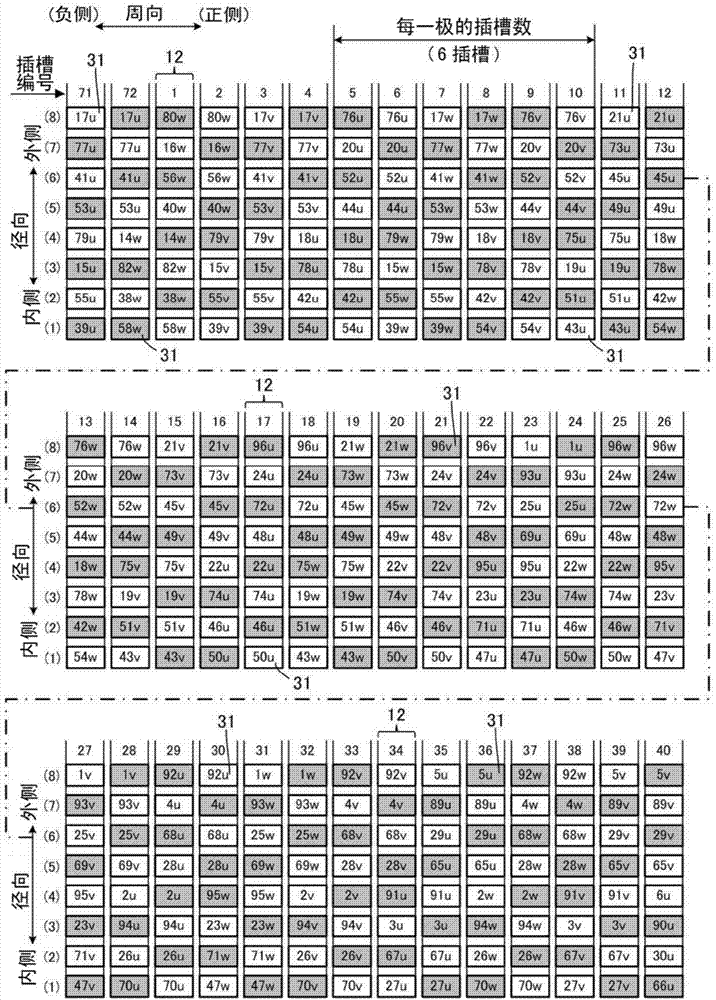

Coil structure for rotary electric machine

ActiveCN104300716AShorten the lengthMiniaturizationWindings conductor shape/form/constructionElectrical conductorElectric machine

A coil structure for a rotary electric machine includes phase coils for magnetic flux generation. Each of the phase coils includes a plurality of first element conductors, a plurality of second element conductors, a plurality of first crossover portions, and a plurality of second crossover portions. The plurality of second element conductors are provided in a plurality of second slots among slots. The second slots are provided in a circumferential direction of a stator at a pitch of a first predetermined interval. The second slots are shifted in phase by a second predetermined interval with respect to first slots in the circumferential direction of the stator. The first predetermined interval is set to be an interval equivalent to N times a unit pitch. The second predetermined interval is set to be an interval smaller than the first predetermined interval.

Owner:HONDA MOTOR CO LTD

Plate grid of negative plate for lead-acid storage battery

InactiveCN105280924AReduce weightReduce thicknessElectrode carriers/collectorsElectrical resistance and conductanceCarbon fibers

The invention provides a plate grid of a negative plate for a lead-acid storage battery. The plate grid comprises a tab and a frame, the improvement is that the frame is formed by welding aluminum alloy ribs and a conductive carbon fiber felt, the tab is exposed, the conductive carbon fiber felt is a polyacrylonitrile-based carbon felt, and the gram weight of the conductive carbon fiber felt is 100 to 1520 g / m<2>.mm. The plate grid is few in lead dosage, and is beneficial for weight reduction and environmental protection; particularly during the fabrication of the negative plate, carbon fiber in the conductive carbon fiber felt is in close contact with an active substance, large contact area, low resistance, high utilization rate of the active substance and favorable charging reception are achieved, sulfation is overcome, and the service lifetime of the battery is effectively prolonged.

Owner:SHUANGDENG GRP

Magnetic epoxy resin powder solvent and method for packaging inductor by utilization of same

ActiveCN103325515AShielding Flux LeakageIncrease the inductance valueOrganic/organic-metallic materials magnetismInductances/transformers/magnets manufactureEpoxyOrganic solvent

The invention relates to a magnetic epoxy resin powder solvent and a method for packaging an inductor by the utilization of the magnetic epoxy resin powder solvent. The magnetic epoxy resin powder solvent is characterized by comprising the following substances: 25-50% of epoxy resin powder coating material, 5-25% of curing agent, 20-50% of soft magnetic ferrite core ground powder particles and 20-50% of organic solvent. The method for packaging the inductor by the utilization of the magnetic epoxy resin powder solvent includes the following steps: performing full diluting with the organic solvent, enabling an inductance coil to face down, immersing the inductance coil into the magnetic epoxy resin powder solvent, then pacing the inductance coil on a baking rack to bake the inductance coil for 5-30min, sending the inductance coil into an oven, setting the temperature at 80-120DEG C, and baking the inductance coil for 1-3 hours. The magnetic epoxy resin powder solvent has the advantages of being capable of promoting the inductance of the inductor and saturation resistance of a current, low in consistence, good in mobility, easy to use for coating, free of sticking, and capable of promoting production efficiency; when heated, the magnetic epoxy resin powder solvent is directly solidified and will not flow, and thus uniformity of a coating can be kept; the inductance value is made to be stable, the change of error is small, quality is more reliable, and the magnetic epoxy resin powder solvent is mainly applicable to packaging of a direct-insertion inductor.

Owner:深圳市同利科斯电子有限公司

Electronic component mounting system, electronic component placing apparatus, and electronic component mounting method

ActiveUS8240543B2Reduce rigidityAdd featurePrinted circuit assemblingFinal product manufactureSemiconductor packageElectronic component

Regarding electronic component mounting in which an electronic component having plural solder bumps for external connection on its lower surface is mounted on a board, in an electronic component mounting operation of previously measuring the height position of solder paste on the board on which the solder paste has been printed, and mounting the electronic component on the board on which the solder paste has been printed by a loading head, whether the transfer of the solder paste to the solder bumps is necessary or not is judged on the basis of the measurement result of the height of the solder paste. In case that it is judged that the transfer is necessary, the transfer of the solder paste is executed, and thereafter the electronic component is mounted on the board. Hereby, it is possible to prevent the poor joint in case that a thin-sized semiconductor package which causes easily warp deformation is mounted on the board by soldering.

Owner:PANASONIC CORP

Sugar-free dietetic bread and method for producing the same

InactiveCN101461393ANot easy to ageStrong water absorptionBakery productsFood preparationYeastGluten

The invention relates to sugar-free nutritious bread, characterized by comprising the materials with the following components: high-gluten flour 1500-9000 parts, low-gluten flour 200- 800 parts, water-free ghee 50-200 parts, sugar-free modifier 50-200 parts, sugar-free milk 10-150 parts, egg 50-100 parts, bread modifier 1-20 parts, tomato juice 1000-2000 parts, salt 300-600 parts. The inventive technology avoids coldness or heat in fed materials contacted with yeast, causing the yeast to exert optimal fermentation ability. The prepared sugar-free nutritious bread is deeply favored by wide consumers.

Owner:天津金世制药有限公司

Capsule for nourishing liver and kidney and reducing blood pressure

InactiveCN101642542AIncrease vitalityThickness reductionAnthropod material medical ingredientsCapsule deliveryLiver and kidneyThirst

The invention provides a capsule for nourishing liver and kidney and reducing blood pressure, comprising the raw materials with the following parts by weight: 1 part of dogbane leaf, each 0.5-1.2 parts of holly leaf, earthworm and radix curcumae, each 0.5-2 parts of achyranthes and uncaria, 0.5-0.8 part of Salvia miltiorrhiza, 0.3-0.8 part of szechuan lovage rhizome, 0.5-1.5 parts of selfheal, each 0.5-1 part of sophora flower and kudzu-vine root, 0.1-0.5 part of borneol, 0.5-1 part of rhizoma cibotii, each 0.3-0.8 part of eucommia bark and dogwood, and each 0.5-1 part of Semen Cuscutae, spinadate seed and epimedium. The capsule is characterized by nourishing the liver and the kidney, improving the activity of human stem cell, calming the liver and detoxifying, being capable of obviouslyreducing the viscosity of blood, stabilizing the blood pressure, removing blood stasis and relieving pain, removing pathogenic heat from blood, nourishing Yin and nourishing the blood, and being capable of effectively curing hypertension, and symptoms such as headache and reel, pyreticosis and coma, obstruction of the circulation of vital energy and swoon, yin asthenia generating intrinsic heat, body fluid deficiency and thirst, dysphoria wakefulness, pavor and dreaminess, lassitude in waist and knees, etc.

Owner:张继成

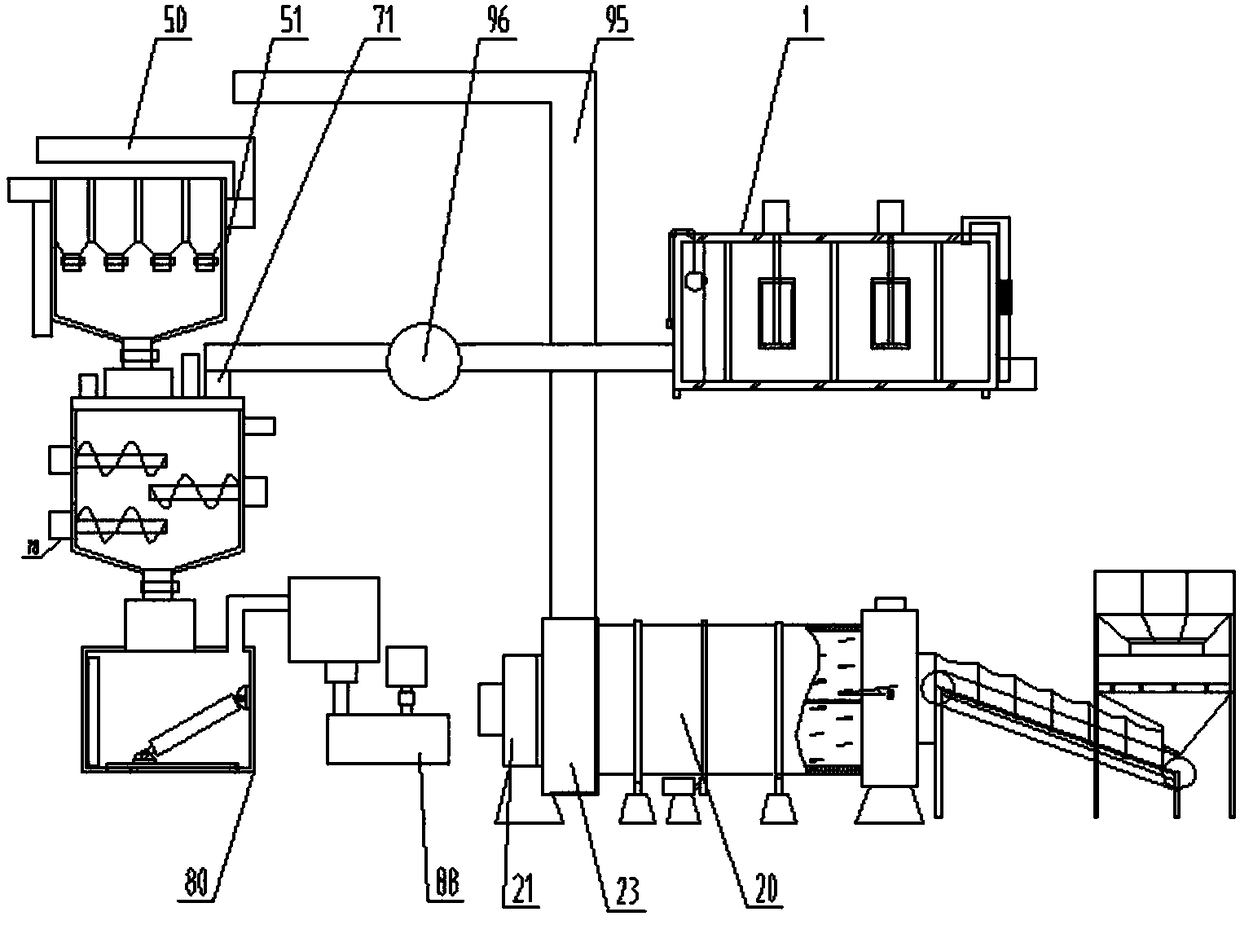

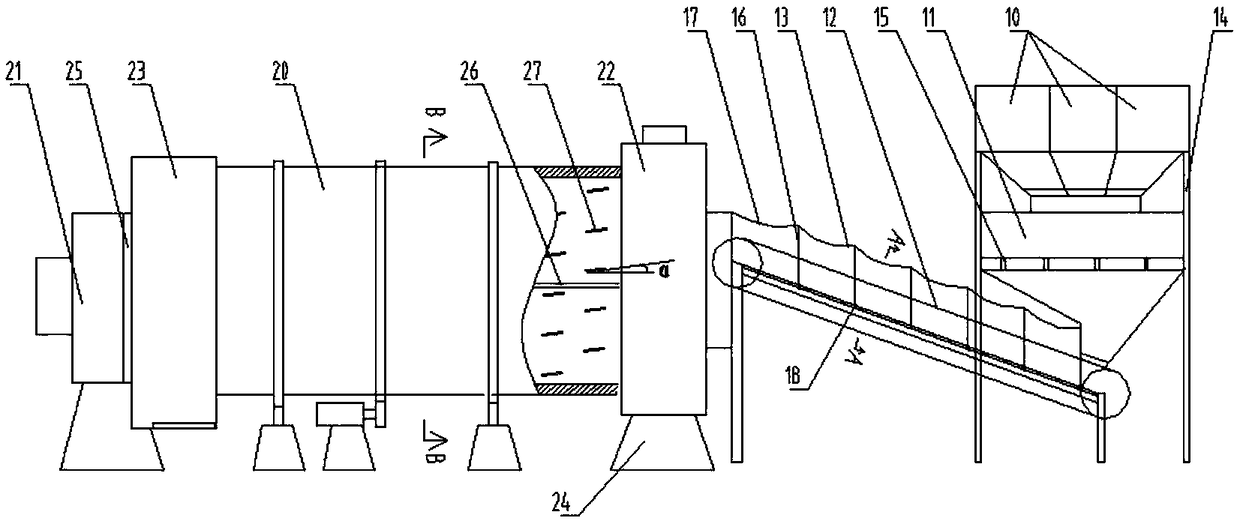

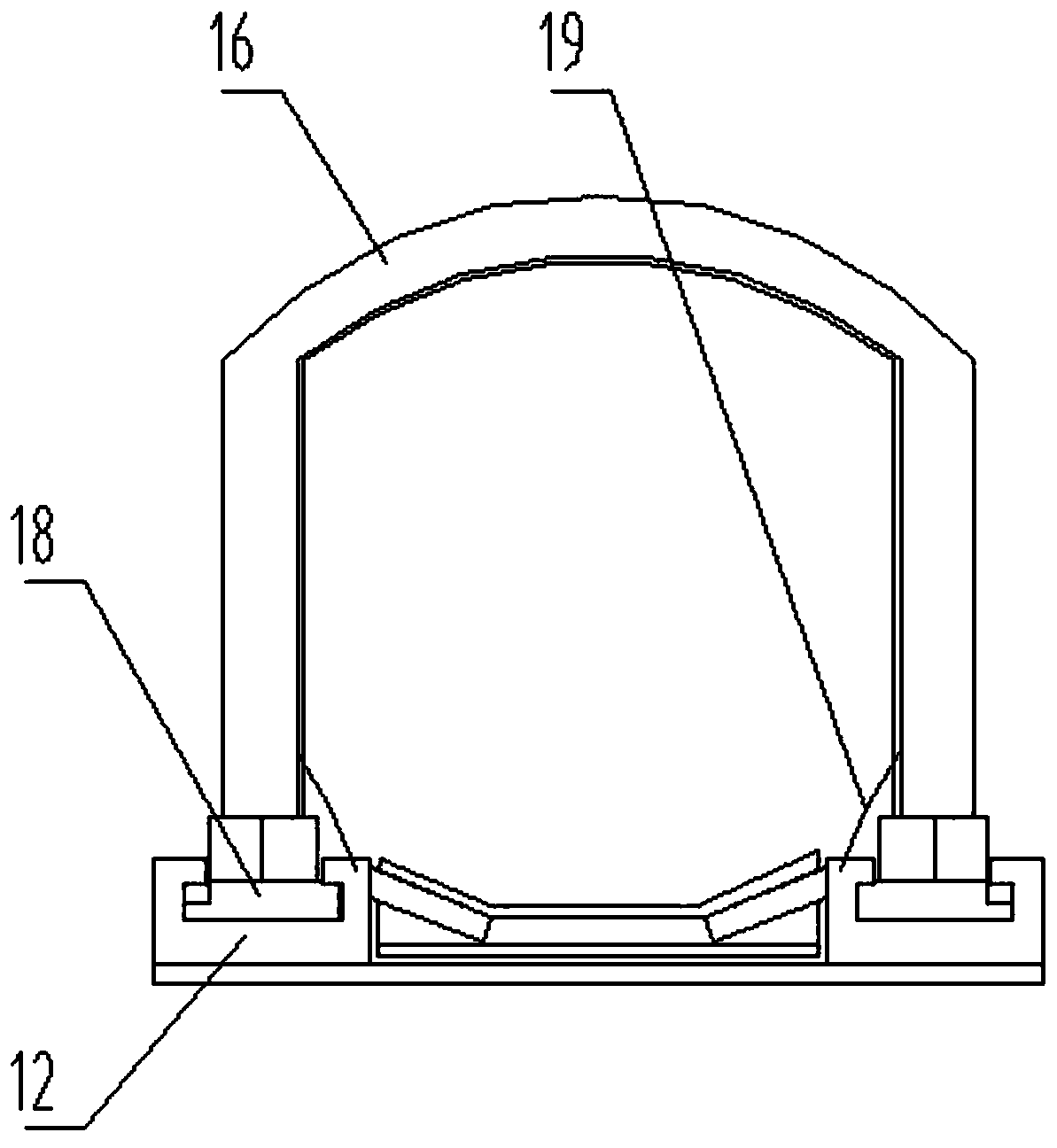

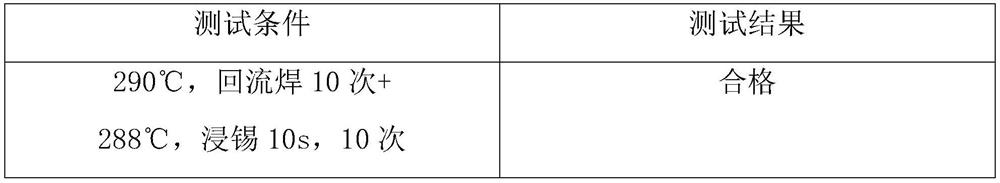

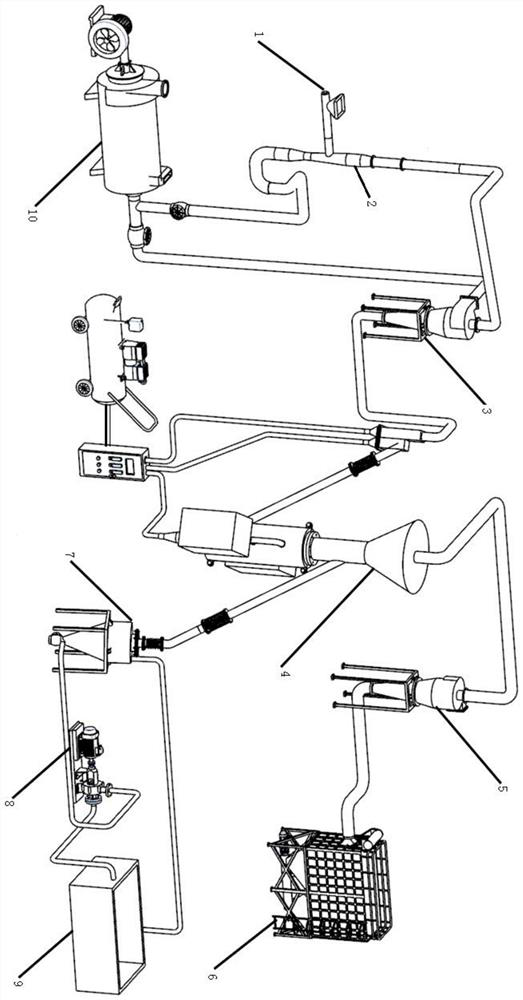

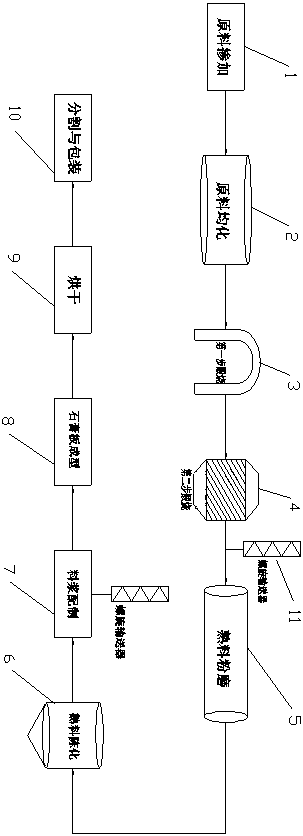

Modified asphalt production line

InactiveCN109423944AHigh degree of automationIncrease productivityRoads maintainenceEngineeringAsphalt

A modified asphalt production line is composed of a stone discharging and drying system, an asphalt tank, a stone hoist, an asphalt delivery pump and an asphalt dividing, mixing and discharging system. The stone discharging and drying system comprises a discharging device and a dryer, the discharging device comprises a set of hopper scales, a mixing hopper, a belt conveyor and a dust hood, the setof hopper scales and the mixing hopper are respectively installed on a rack, discharging openings of the set of hopper scales respectively communicate with the feeding end of the mixing hopper, the feeding end of the belt conveyor is positioned below the discharging opening of the mixing hopper, the positions, on two sides of the belt conveyor, of the rack are provided with inverted T-shaped sliding grooves, and the dust hood comprises a group of U-shaped skeletons and filter cloth connected with the U-shaped skeletons. The modified asphalt production line has reasonable structure design, high automation degree, high production efficiency and low dust raising, and has good practical value.

Owner:诸暨马谷亲科技有限公司

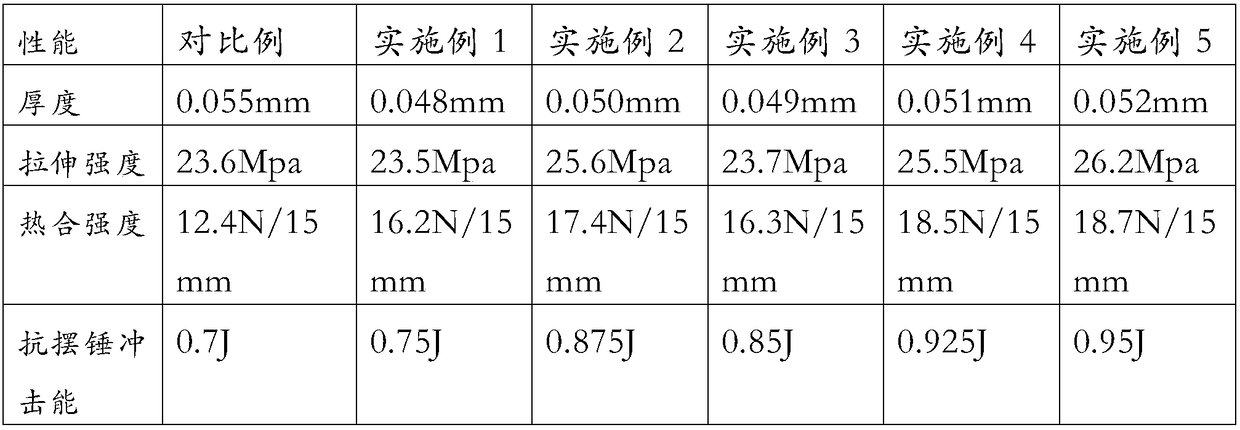

Plastic film and a courier bag

InactiveCN109016761AReduce thicknessGood combinationSynthetic resin layered productsBagsHigh-density polyethyleneLow-density polyethylene

The invention discloses a plastic film and a courier bag. The plastic film is formed by co-extrusion blow molding of three layers, namely a bottom layer, an intermediate layer and an upper layer. Theraw materials of the upper layer include linear low density polyethylene, bimodal polyethylene and metallocene; the raw materials of the intermediate layer include linear low density polyethylene, high density polyethylene HDPE and metallocene; and the raw materials of the bottom layer include linear low density polyethylene containing a slip agent, low density polyethylene wire containing a slipagent and metallocene. The courier bag is prepared from the plastic film. Due to different components of each layer of the plastic film, thickness of the plastic film is finally reduced. The plastic film can be used as a courier bag. Since the upper layer contains bimodal polyethylene which can be well combined with an express delivery sheet, the express delivery sheet can be firmly glued.

Owner:SF EXPRESS

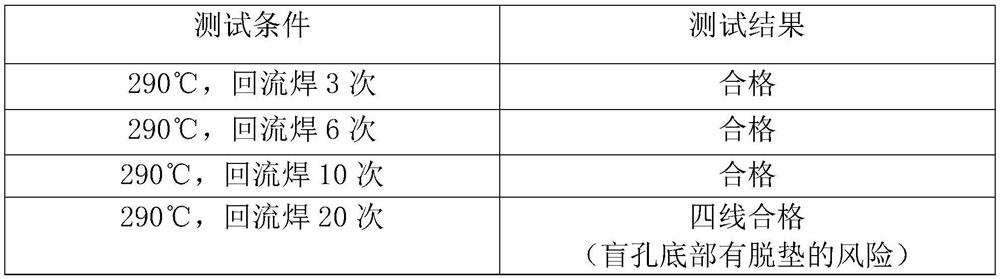

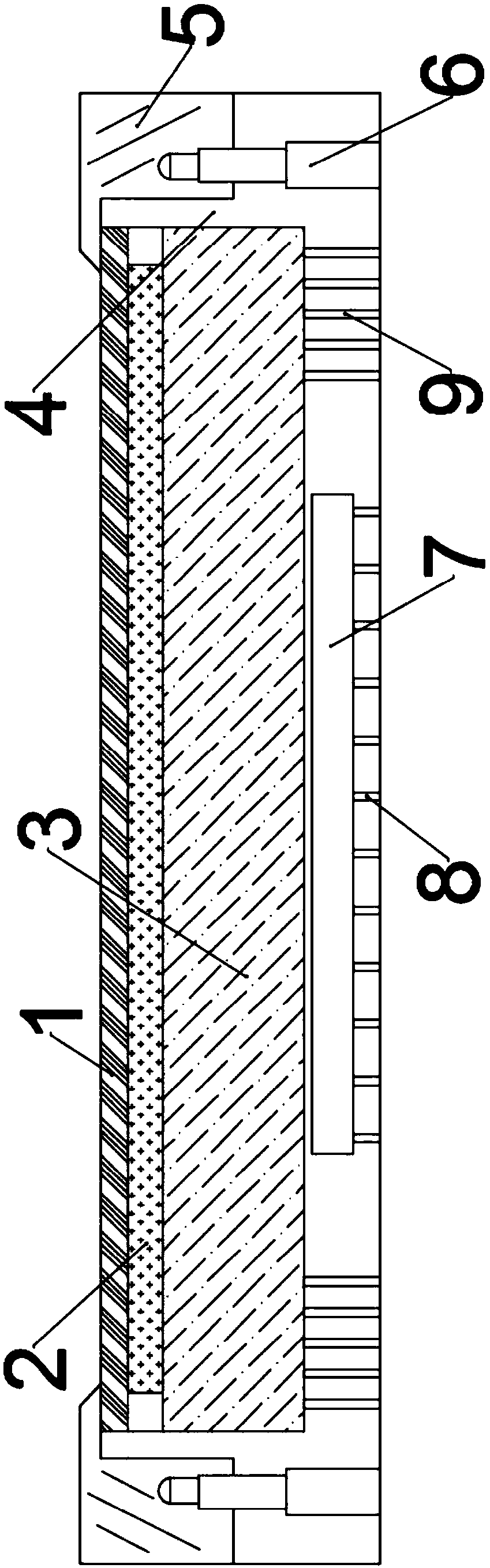

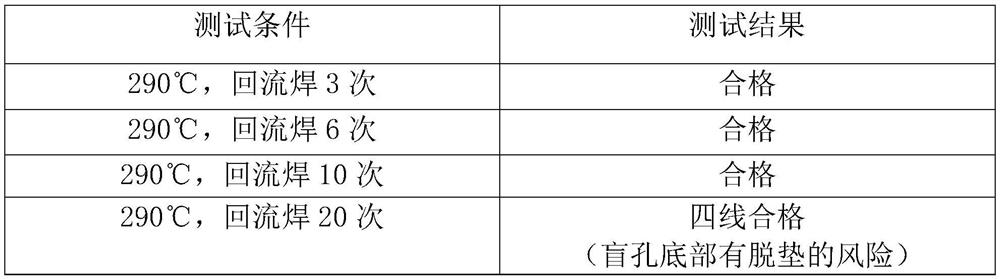

Method for improving pad-off phenomenon of blind holes in multi-stage circuit board, and multi-stage circuit board

ActiveCN112752435ASmall aspect ratioGood for copper platingPrinted circuit aspectsMultilayer circuit manufactureDaughterboardCopper foil

The invention discloses a method for improving the pad-off phenomenon of blind holes in a multi-stage circuit board, and the multi-stage circuit board. The method comprises the following steps: drilling a plug hole in a core board, metalizing the plug hole, filling the plug hole with resin, and metalizing the surface of the resin after grinding the board with an abrasive belt; manufacturing an inner-layer circuit on the core board; pressing the core plate and a copper foil into a first daughter board; drilling a first blind hole and a first-order blind hole in the first daughter board, and subjecting the first blind hole and the first-order blind hole to filling and levelling-up; pressing the first sub-plate and another copper foil into a second sub-plate; drilling a second blind hole and a second-order blind hole in the second daughter board in a depth-controlled mode, and subjecting the second blind hole and the second-order blind hole to filling and levelling-up; pressing the second daughter board and another copper foil into a production board; drilling a third-order blind hole and a through hole in the production board in a depth-controlled mode, and subjecting the third-order blind hole and the through hole to metalization; and sequentially carrying out subsequent processes on the production board to obtain the multi-stage circuit board. According to the method, dielectric thickness between the blind hole layers can be reduced, so the thickness-diameter ratio of the blind holes is reduced, and the problem of poor open circuit caused by the pad-off phenomenon caused by overlarge dielectric thickness between the blind hole layers is solved.

Owner:珠海崇达电路技术有限公司 +1

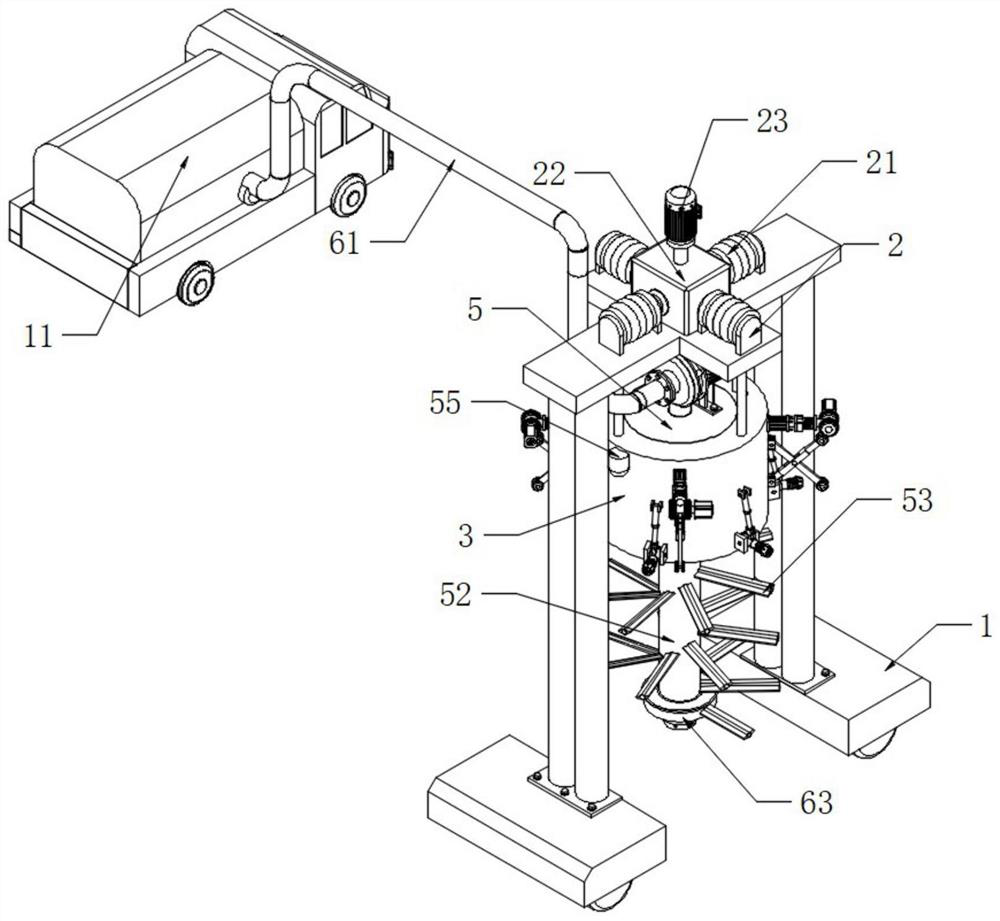

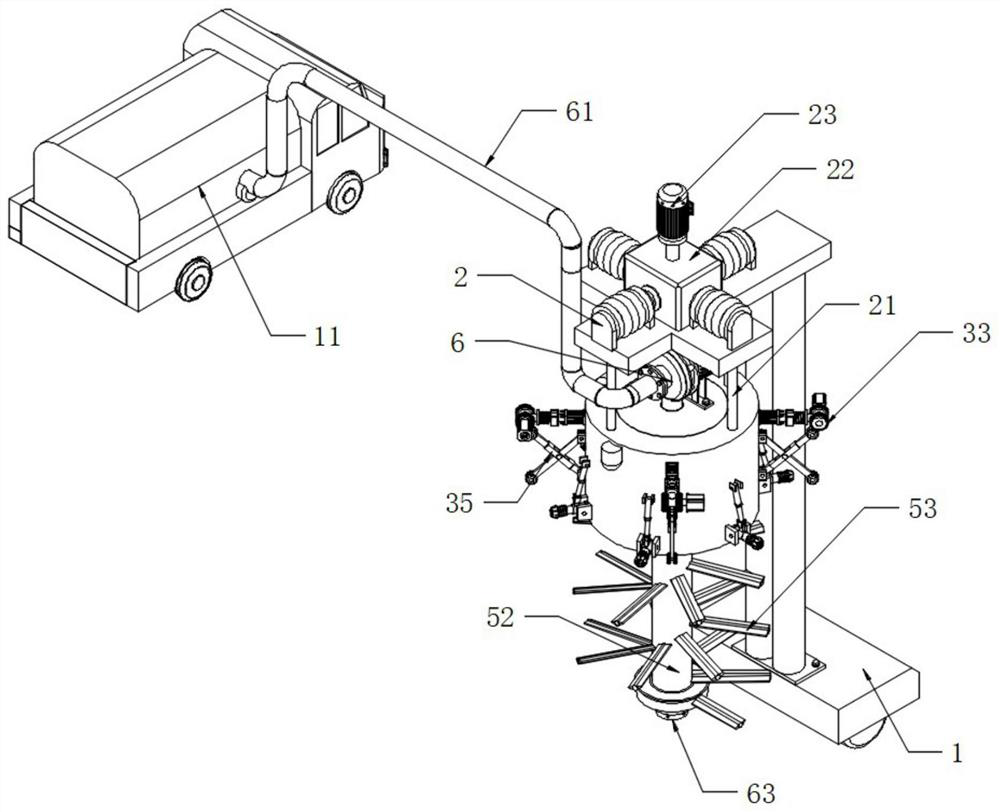

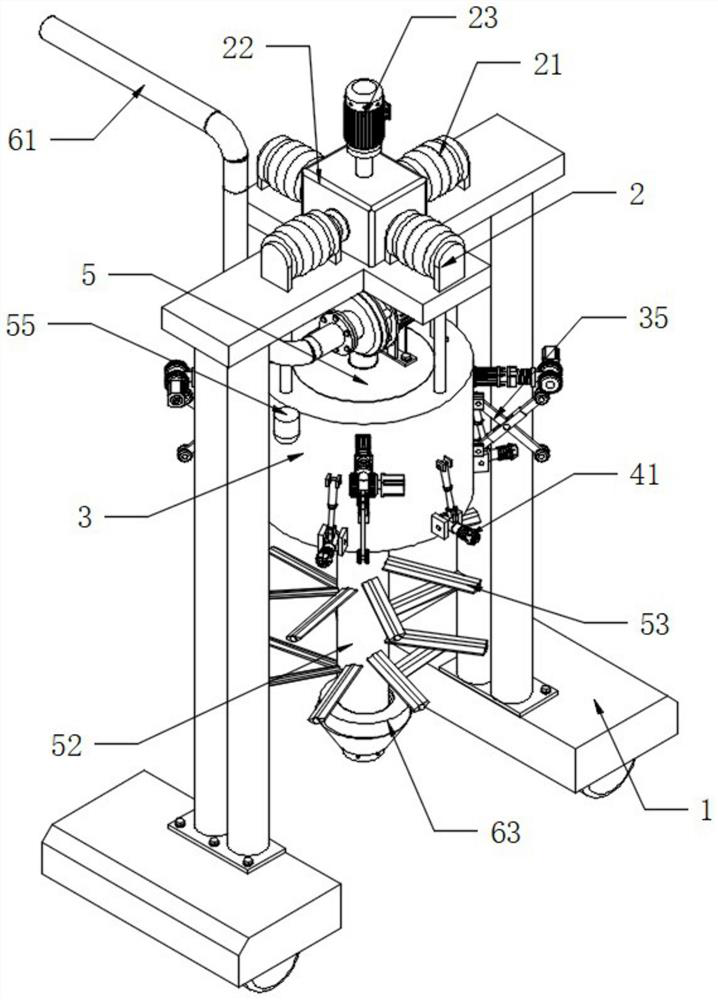

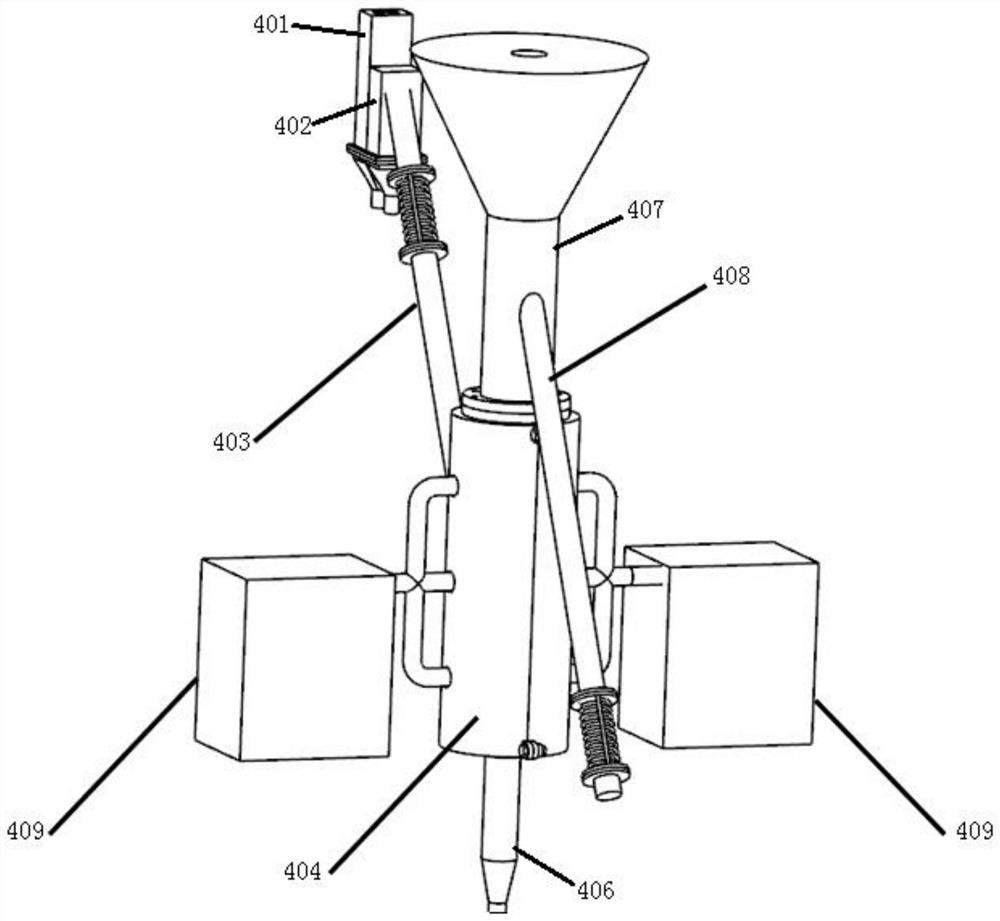

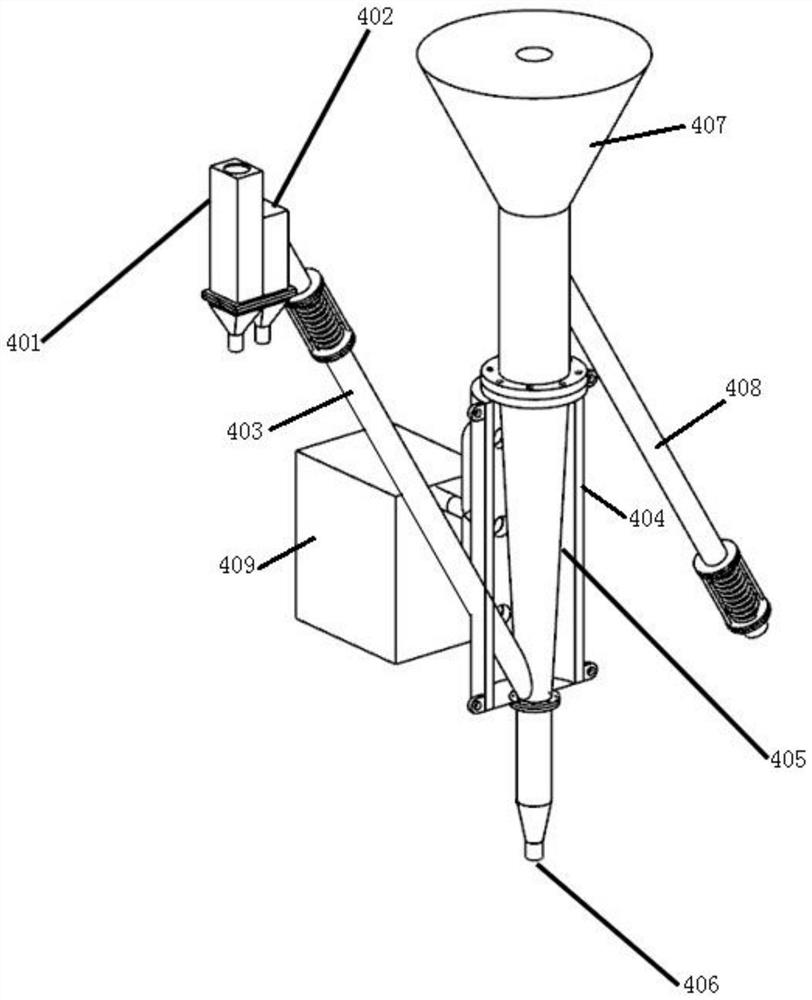

Vertical urban kitchen waste pollution discharge well blockage dredging equipment

The invention belongs to the technical field of pollution discharge wells, and particularly relates to vertical urban kitchen waste pollution discharge well blockage dredging equipment which comprises a support and a dredging vehicle. The dredging vehicle is arranged on one side of the support, a lifting supporting mechanism is fixedly mounted on the upper surface of the support, and the lifting supporting mechanism supports and lifts the dredging equipment. According to the vertical urban kitchen waste pollution discharge well blockage dredging equipment, by arranging a stirring mechanism, sludge in a sewage disposal well can be stirred, and wastes with overlarge volumes in the sludge is crushed through stirring blades, so that suction of a dredging pipeline is facilitated; and a stirring motor drives a stirring pipe to rotate through a bevel gear set, and the stirring blades are arranged along the thread line in a path array manner, so that the sludge can be conveniently stirred, the blockage of the dredging pipeline caused by the wastes with overlarge volumes can be prevented, and the technical problem that existing sludge suction pump type dredging equipment is easily blocked by the wastes with overlarge volumes is solved.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

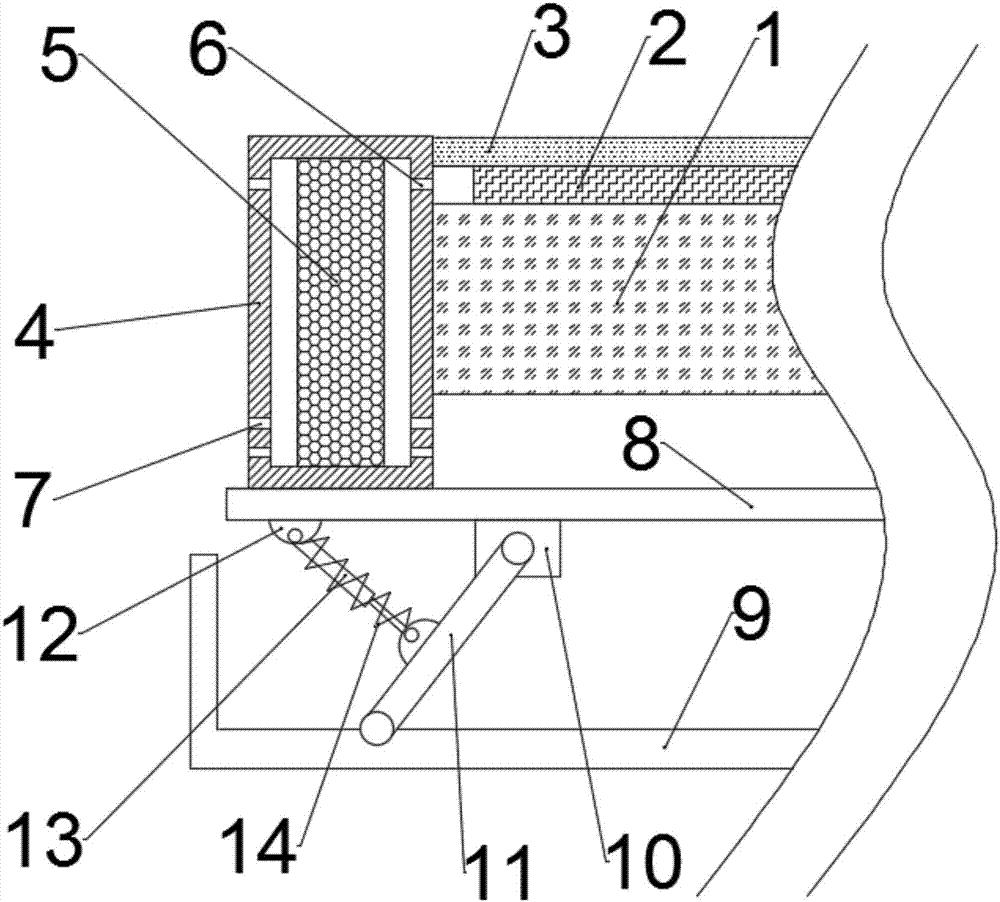

Device and method for microwave-enhanced fluidized phosphogypsum dehydration

The invention discloses a device and method for microwave-enhanced fluidized ardealite dehydration. The method comprises the following steps: ardealite is added into a system through a screw feeder; hot air provided by a hot blast stove is subjected to venturi drying, attached water in phosphogypsum is removed by a cyclone preheater, and then the hot air enters a wave-transparent heating section of the fluidized bed together with a wave-absorbing powder substance for mixing fluidization; and microwaves penetrate through the wave-transparent heating section in the resonant cavity and are absorbed by the wave-absorbing powder substance and the ardealite, and the removal of ardealite crystal water is simultaneously realized in solid-solid, gas-solid and microwave heating modes by utilizing heat generated by high-speed movement of molecules. Due to the change of the fluidization height of the ardealite without crystal water, the ardealite is separated from the wave-absorbing powder substance. The method and the device are wide in applicability, can realize continuous production of two products by one set of device, and are high in heat efficiency, high in heating speed, uniform in material heating, high in product stability, enhanced in polar component on the surface of hemihydrate gypsum molecules, reduced in contact angle, low in tail gas temperature and small in heat loss.

Owner:云南云天化环保科技有限公司

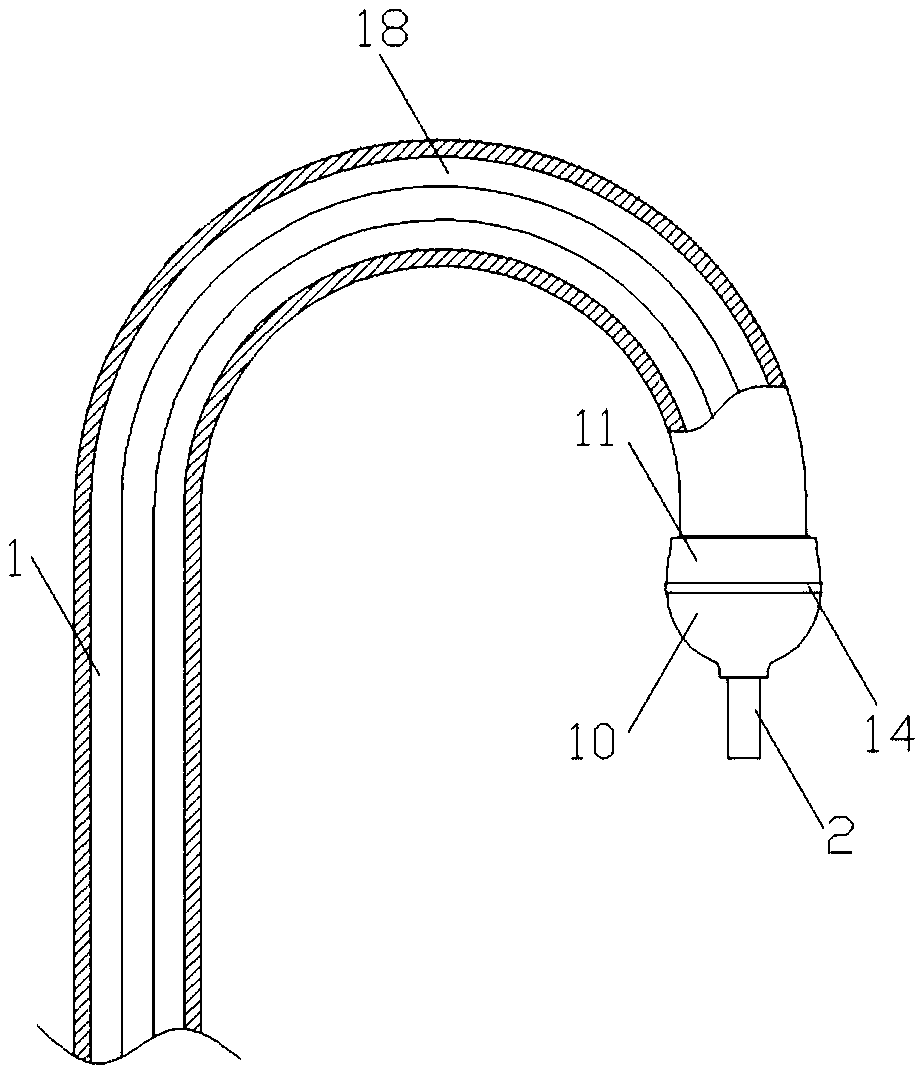

Thermal-shrinkage waterproof sealing cap for high-voltage cable

The invention belongs to the field of waterproof sealing caps for sealing cable pipe orifices, and specifically relates to a thermal-shrinkage waterproof sealing cap for a high-voltage cable. The sealing cap is low in dependence on the diameter of the cable and the diameter of a casing pipe, and can achieve the better sealing of guide cables and casing pipes in various sizes. The sealing cap employs an insulating material, and a fire retardant is added for preparation, so the waterproof performance is excellent. The sealing cape is suitable for the protection and sealing of various types of cable pipe orifices, such as a cable protection tube and a cable incoming and outgoing mouths of a transformer substation. The sealing cab can achieve the waterproof, fireproof and insulating functionsat the same time, facilitates the early construction operation and the later maintenance management, and no metal part is exposed outside. The sealing cap is good in aging resistance, insulating performance, waterproof and fireproof performances, is good in corrosion resistance, and is good in application prospect.

Owner:STATE GRID HEBEI ELECTRIC POWER CO LTD +2

Sugar-free lieba bread and method for producing the same

The invention relates to a sugar-free ukleba bread and preparation method, characterized by comprising the materials with the following components: A: high-gluten flour 1000-1500 parts, yeast 10-20 parts, bread modifier 1-20 parts, light milk 50-100 parts, sugar-free modifier 20-100 parts; B: egg 50-200 parts, water 1000-1500 parts; C. butter 50-200 parts; D: salt 5-20 parts; E. walnut kernel 10-50 parts. The inventive sugar-free ukleba bread is soft and crisp, fragrant and sweet, deeply favored by wide consumers.

Owner:天津金世制药有限公司

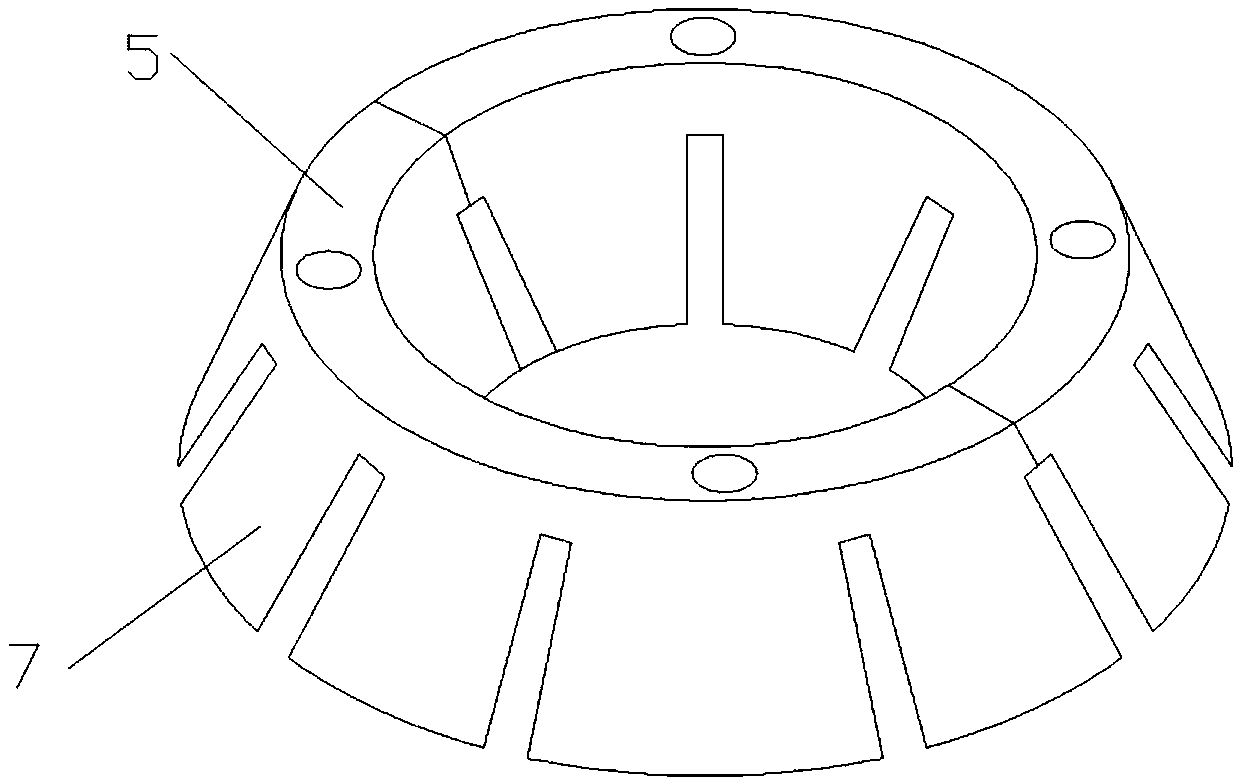

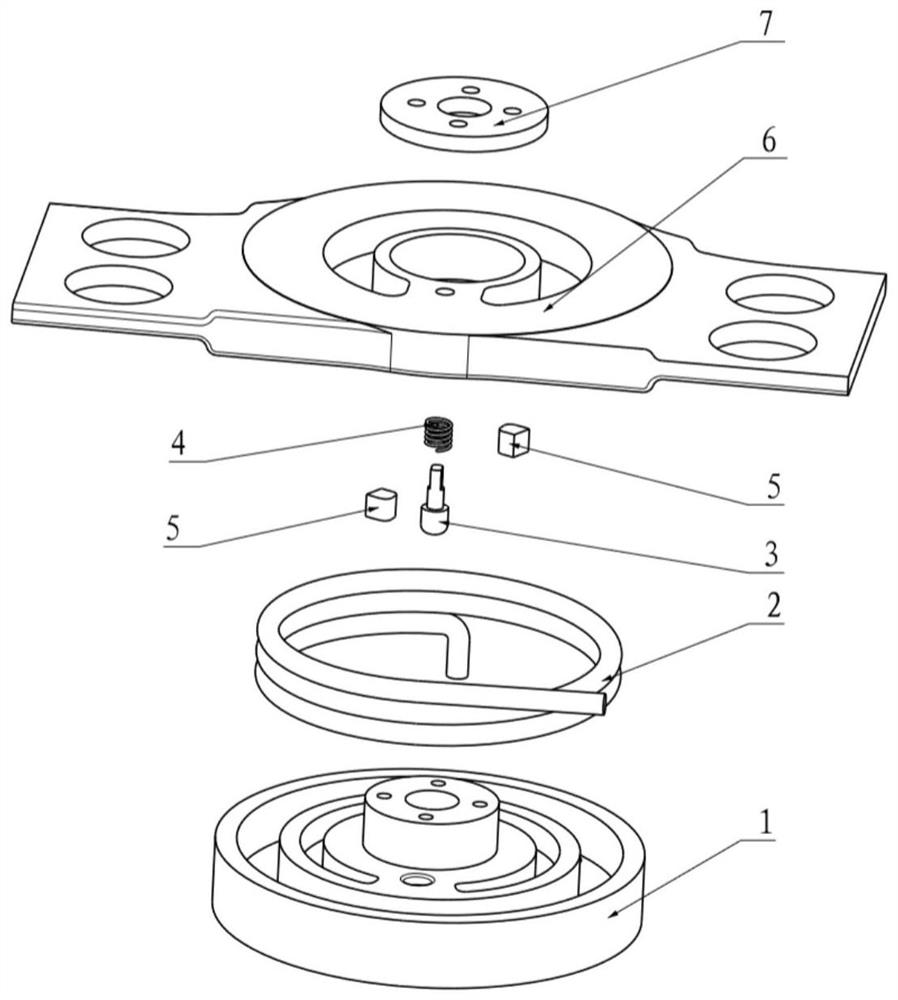

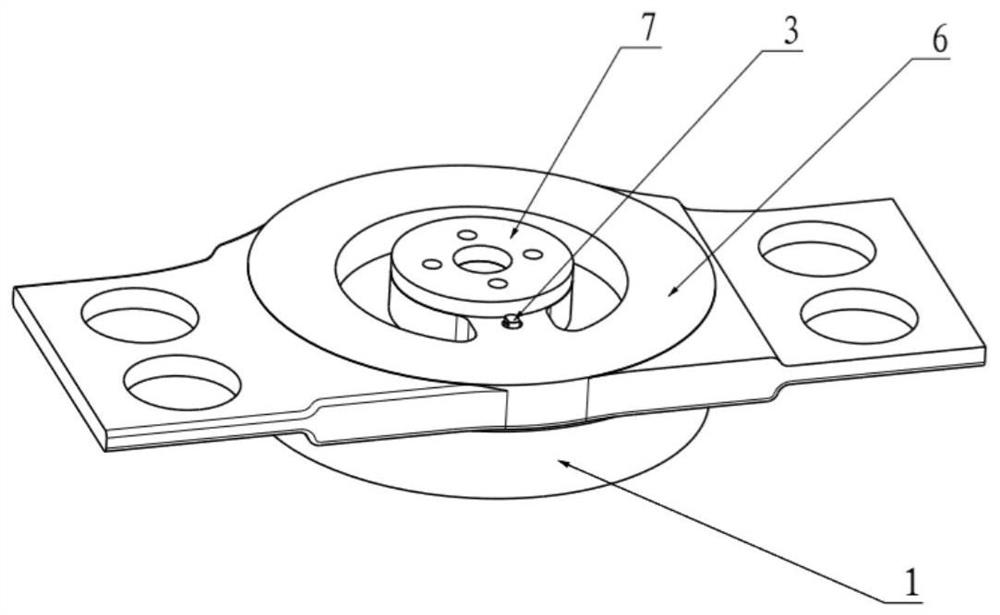

Rotary locking mechanism for wings of barrel-shooting type unmanned aerial vehicle

PendingCN112407240AReasonable designThickness reductionWing adjustmentsFuselagesUncrewed vehicleTorsion spring

The invention discloses a rotary locking mechanism for wings of a barrel-shooting type unmanned aerial vehicle. The rotary locking mechanism comprises a base, a driving torsional spring, a locking pin, a locking pin compression spring, a shock-proof rubber pad, a rotating wing connector and a cover plate. The driving torsional spring is placed in a driving torsional spring mounting groove, the locking pin is arranged in a locking pin limiting hole, and the upper end of the locking pin is sleeved with the locking pin compression spring; a rotary wing connector is arranged on the upper surface of the base, a driving torsional spring mounting groove is formed in the side of the top end of the rotary wing connector, and a locking pin limiting hole is formed in the side of the top end of the rotary drum sleeve. Rapid unfolding of wings can be realized, accurate positioning and reliable locking are realized, in addition, the design is reasonable, the application is convenient and fast, and the shape is regular. According to the design concept of a single torsion spring, the thickness of the whole rotary locking mechanism is effectively reduced, the effective use space of the unmanned aerial vehicle is increased, the limiting locking mechanism is small in occupied space and firm in locking, and when the wings are completely unfolded, the locking pins are pressed into the locking pin limiting holes by the locking pin compression springs to lock the wings.

Owner:SUZHOU RES INST OF NUAA +1

Electronic cigarette and atomizing device thereof

PendingCN109730364AThickness reductionImprove experienceTobacco devicesElectronic cigaretteAuxiliary heating

The invention relates to an atomizing device of an electronic cigarette. The atomizing device comprises a liquid storage cavity for storing a liquid and a main heating member arranged in the liquid storage cavity. The atomizing device is characterized by comprising an auxiliary heating member arranged in the liquid storage cavity, and the auxiliary heating mechanism is located in the bottom of theliquid storage cavity and is arranged on the outer side of the main heating member. According to the atomizing device, the consistency of the liquid can be reduced before the liquid is conducted to the main heating member, so that the liquid can be imported into the main heating member immediately and effectively, and therefore, an expected atomizing effect is achieved.

Owner:SHENZHEN KANGER TECH CO LTD

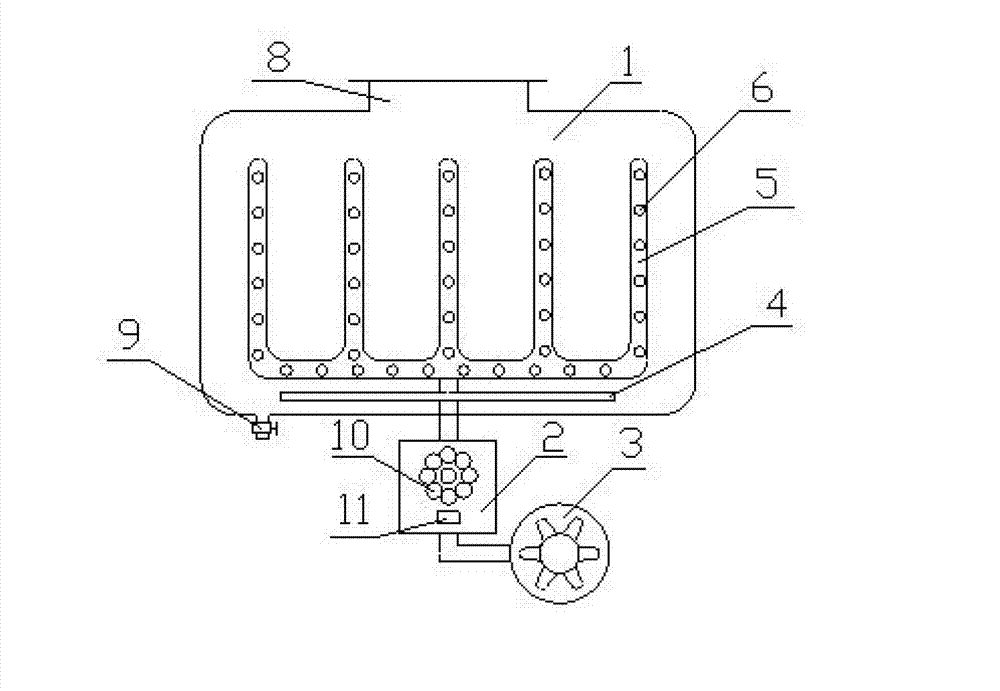

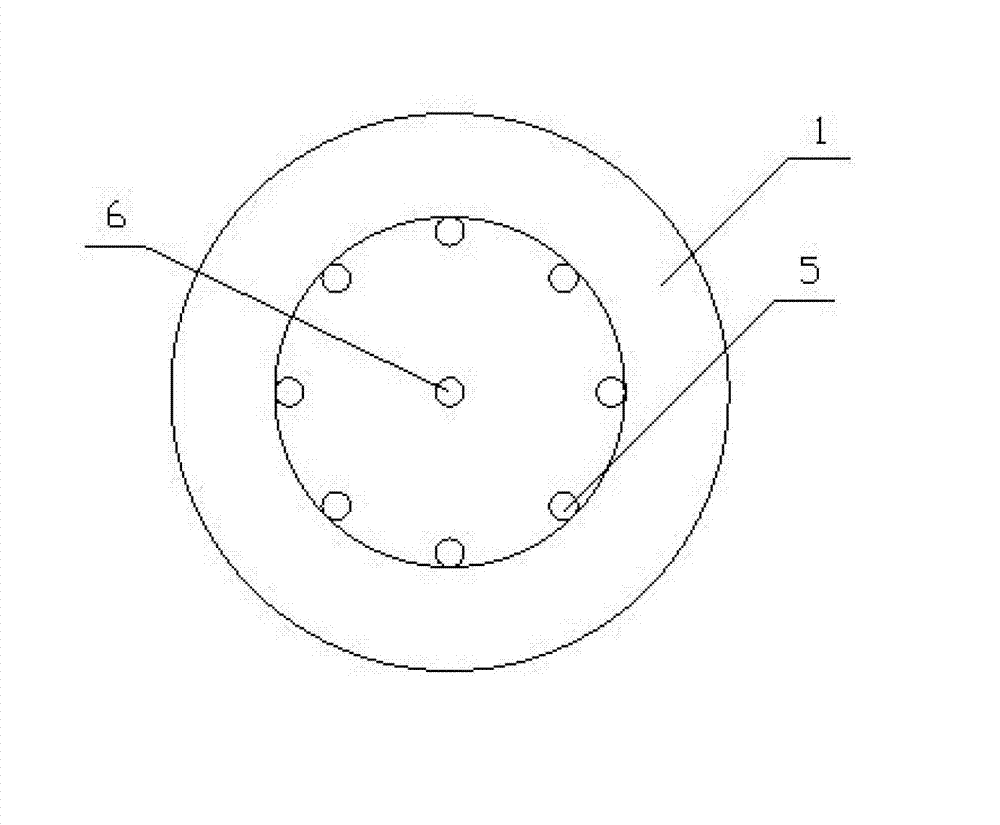

Novel air-assisted stirrer

InactiveCN103706276ASimple structureEasy to operateTransportation and packagingMixersEngineeringSlurry

The invention provides a novel air-assisted stirrer. The novel air-assisted stirrer comprises an air-assisted stirrer body, a program controller and a fan, the bottom end of the air-assisted stirrer body is sequentially connected with the program controller and the fan, the bottom of the air-assisted stirrer body is provided with a disc, the disc is provided with eight circularly-standing blow tubes and a centrally-standing blow tube, the centrally-standing blow tube is arranged in the middle of the disc, the circularly-standing blow tubes form a circle with the centrally-standing blow tube as a center, each of the blow tubes is provided with a plurality of blow nozzles, the top end of the air-assisted stirrer body is provided with a feeding port, the left edge of the bottom of the air-assisted stirrer body is provided with a discharging valve, the program controller is provided with switch control valves of all the blow tubes and a solenoid directional valve, and the positions of the switch control valves on the program controller correspond to the positions of all the blow tubes. The novel air-assisted stirrer a simple structure, is convenient to operate, ensures the long-term stable running of slurry stirring, and utilizes air force to carry out the slurry stirring in order to effectively reduce the product concentration and realize product uniformity.

Owner:天津市华创盛达科技有限公司

Method for producing gypsum plaster board by using calcium lignosulphonate/naphthalene-series composite water-reducing agents

The invention provides a method for producing a gypsum plaster board by using calcium lignosulphonate / naphthalene-series composite water-reducing agents. The method comprises the following steps: adding raw materials into desulfurized gypsum, allowing the added raw materials to enter a silo, carrying out homogenizing and uniform mixing, subjecting the uniformly-mixed raw materials to primary calcination so as to obtain a clinker, subjecting the clinker obtained by primary calcination to secondary calcination, allowing an obtained clinker to enter a ball mill for grinding to obtain clinker powder, and adding a quantitative calcium lignosulphonate water-reducing agent through a screw conveyor; placing obtained clinker powder into a material storage bin, subjecting the clinker powder to aging, after the clinker powder is aged, adding water, carrying out batching so as to prepare a slurry, and adding a quantitative naphthalene water-reducing agent at the same time; and after the slurry isprepared, carrying out molding of a gypsum board, drying, segmenting and packaging so as to complete production of the gypsum plaster board. According to the invention, the calcium lignosulphonate water-reducing agent is added through the screw conveyor before the clinker is ground into powder, so standard thickness of gypsum powder is reduced, and the evaporation amount of used water is decreased; the naphthalene water-reducing agent is added in the preparation process of the slurry through the screw conveyor, so the usage amount of water for production is reduced; and the method provided bythe invention is applicable to production of the gypsum plaster board.

Owner:泰山石膏(辽宁)有限公司

Modern universal-precaution TFT-LCD

The invention discloses a modern universal-precaution TFT-LCD. The modern universal-precaution TFT-LCD comprises a TFT-LCD display, a touch screen sensor and a sealing top cover are arranged above the screen of the TFT-LCD display, a dehumidification cylinder is fixedly arranged in the end position of both ends of the TFT-LCD display and the sealing top cover, a cylinder cavity of the dehumidification cylinder is of a hollow structure, a hygroscopic sponge block is arranged in the inner cavity of the cylinder cavity, a buffering shock-absorption spring is arranged on the outer ring of a guiding telescopic rod in a sleeving mode, and the touch screen sensor is integrated on the lower surface of the sealing top cover, that is to say, the touch screen sensor is integrated in the inner cavity of the sealing structure of the TFT-LCD display. According to the modern universal-precaution TFT-LCD, it is ensured that the interior of the TFT-LCD is always in a dry state, the TFT-LCD cannot be affected by a humid environment, and the integral display screen can always maintain a certain balance effect; moreover, production procedures of a traditional display are simplified, the production efficiency and the acceptability of finished products are improved to some extent, and higher production requirements are satisfied.

Owner:HEFEI HUIKE PRECISION DIE CO LTD

Novel lubricating material and manufacturing process thereof

InactiveCN111793517AImprove adhesionThickness reductionLubricant compositionButanedioic acidGlycerol

The invention discloses a novel lubricating material and a preparation process thereof. The novel lubricating material is prepared from butter, naphthenic oil, glycerol, polyoxyethylene hydrogenated castor oil, methyl citrate, monomethyl citrate, lupeol palmitate, succinimide succinate-based thioester, talcum powder, graphite, paraffin base, fatty soap and polyalkenyl succinimide. The novel lubricating material disclosed by the invention is relatively low in consistency, so the resistance of a mechanical transmission mechanism is reduced, and the load of machine operation is reduced; in addition, the lubricating material is large in adhesive force and can be easily attached to the surface of metal, so the lubricating material is attached to the mechanical transmission mechanism, the mechanical transmission mechanism smoothly operates, the resistance is further reduced, a mechanical structure can be protected, and abrasion is reduced; and the lubricating material has application and popularization value.

Owner:JIANGSU SECURITY TECH CARRER ACADEMY

Air-permeable and heat-radiating AMOLED display device more streamlined in process

InactiveCN107742674AThinReduce usageSolid-state devicesSemiconductor/solid-state device manufacturingManufacturing efficiencyEngineering

The invention discloses an air-permeable and heat-radiating AMOLED display device more streamlined in process. The device comprises a tempered glass frame and an anti-explosion plastic base which cooperate with each other, the anti-explosion plastic base and the end faces of the two ends of the tempered glass frame are connected together through fastening bolts, multiple middle cooling holes are uniformly formed between the bottom end face of a battery panel groove and the bottom side wall of the anti-explosion plastic base at equal intervals in a run-through mode, side edge cooling holes areformed in the two sides of the battery panel groove and the top side wall and the bottom side wall, corresponding to the anti-explosion plastic base, inside the battery groove, a touch screen sensor is integrated on the lower portion of a packaging top cover, that is to say, the touch screen sensor is integrated in an inner cavity of the packaging structure of the AMOLED displayer. Accordingly, heat generated by a battery and an inner cavity screen can continuously pass through the holes to be emitted out, the phenomenon that the heat is accumulated for a long time, and physical elements are damaged is avoided, the manufacturing process of a traditional displayer is simplified, the manufacturing efficiency is improved to some extent, and the qualified rate of finished products is increasedto some extent.

Owner:HEFEI HUIKE JINYANG TECH

A method for improving blind hole pad removal of multi-level circuit boards and multi-level circuit boards

ActiveCN112752435BSmall aspect ratioGood for copper platingPrinted circuit aspectsMultilayer circuit manufactureCopper foilDaughterboard

The invention discloses a method for improving blind hole degassing of a multi-stage circuit board and a multi-stage circuit board. The method includes the following steps: drilling a plug hole on a core board and metallizing the plug hole, then filling the plug hole with resin, and using an abrasive belt Metallize the surface of the resin after grinding the board; make the inner layer circuit on the core board; press the core board and copper foil into the first sub-board; drill the first blind hole and the first-order blind hole on the first sub-board, The first blind hole and the first-order blind hole are filled and leveled; the first sub-board and copper foil are pressed into the second sub-board; the second blind hole and the second-order blind hole are drilled on the second sub-board with controlled depth, and the second Blind holes and second-order blind holes are filled and leveled; the second sub-board and copper foil are pressed into a production board; third-order blind holes and through-holes are drilled on the production board with controlled depth, so that the third-order blind holes and through-hole metal Chemical; sequentially carry out subsequent processes on the production board to make a multi-level circuit board. The method of the invention can reduce the interlayer thickness of the blind hole, reduce the thickness-to-diameter ratio of the blind hole, and solve the problem that the blind hole is poorly opened due to excessive interlayer thickness.

Owner:珠海崇达电路技术有限公司 +1

Magnetic epoxy resin powder solvent and its method for packaging inductance

ActiveCN103325515BShielding Flux LeakageIncrease the inductance valueOrganic/organic-metallic materials magnetismInductances/transformers/magnets manufactureEpoxyOrganic solvent

The invention relates to a magnetic epoxy resin powder solvent and a method for packaging an inductor by the utilization of the magnetic epoxy resin powder solvent. The magnetic epoxy resin powder solvent is characterized by comprising the following substances: 25-50% of epoxy resin powder coating material, 5-25% of curing agent, 20-50% of soft magnetic ferrite core ground powder particles and 20-50% of organic solvent. The method for packaging the inductor by the utilization of the magnetic epoxy resin powder solvent includes the following steps: performing full diluting with the organic solvent, enabling an inductance coil to face down, immersing the inductance coil into the magnetic epoxy resin powder solvent, then pacing the inductance coil on a baking rack to bake the inductance coil for 5-30min, sending the inductance coil into an oven, setting the temperature at 80-120DEG C, and baking the inductance coil for 1-3 hours. The magnetic epoxy resin powder solvent has the advantages of being capable of promoting the inductance of the inductor and saturation resistance of a current, low in consistence, good in mobility, easy to use for coating, free of sticking, and capable of promoting production efficiency; when heated, the magnetic epoxy resin powder solvent is directly solidified and will not flow, and thus uniformity of a coating can be kept; the inductance value is made to be stable, the change of error is small, quality is more reliable, and the magnetic epoxy resin powder solvent is mainly applicable to packaging of a direct-insertion inductor.

Owner:深圳市同利科斯电子有限公司

Microcarrier system, bucket and cryopreservation method for biological material cryopreservation

ActiveCN103444699BThickness reductionSimple and fast operationDead animal preservationCarrier systemEngineering

The invention provides a miniature carrier system for cryopreservation of biological materials and application of the carrier system. The miniature carrier system is mainly composed of a cryopreservation unit comprising a carrying pole, a carrying pole sleeve and a carrying pole cylinder, wherein the front end of the carrying pole is inserted into the carrying pole sleeve to form a flat and slender carrying unit, and then the carrying pole and the carrying pole sleeve are arranged in the carrier pole cylinder together; the carrier pole cylinder is a hollow pipe with the average outer diameter of less than 8.5mm, and at least the bottom end of the hollow pipe is closed; the top end or the side wall of the carrier pole cylinder is provided with a pole loading hole, through which a locating unit can be placed in and taken out of the carrier pole cylinder, and loading protection and unloading technologies are implemented by virtue of the pole loading hole. On the basis of not influencing and even improving the use convenience of the miniature carrier system, space occupied for cryopreservation of a trace biological sample is reduced in multiples, and thus a floor space for cryopreservation is saved greatly. The miniature carrier system is especially suitable for cryopreservation of the trace biological materials such as embryos.

Owner:吕祁峰

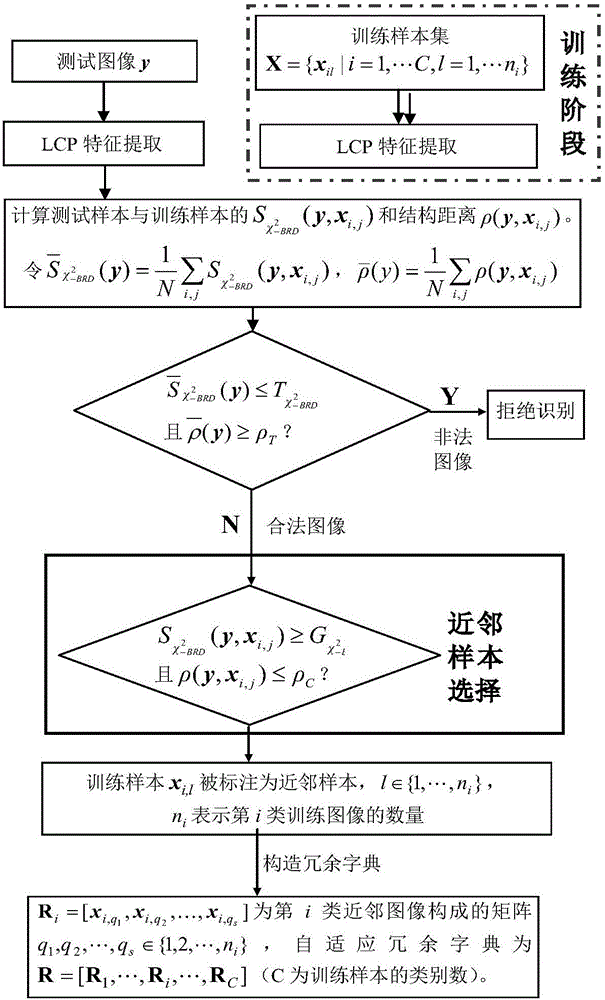

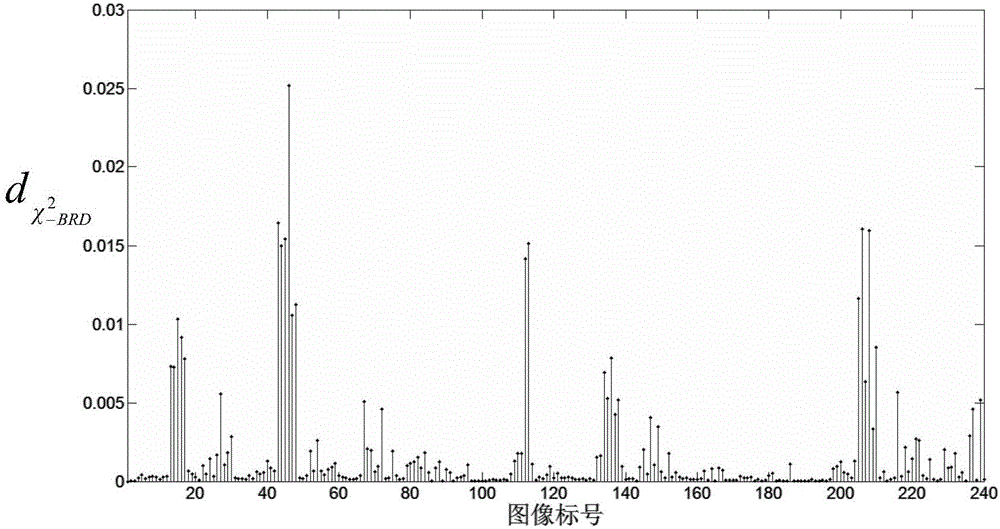

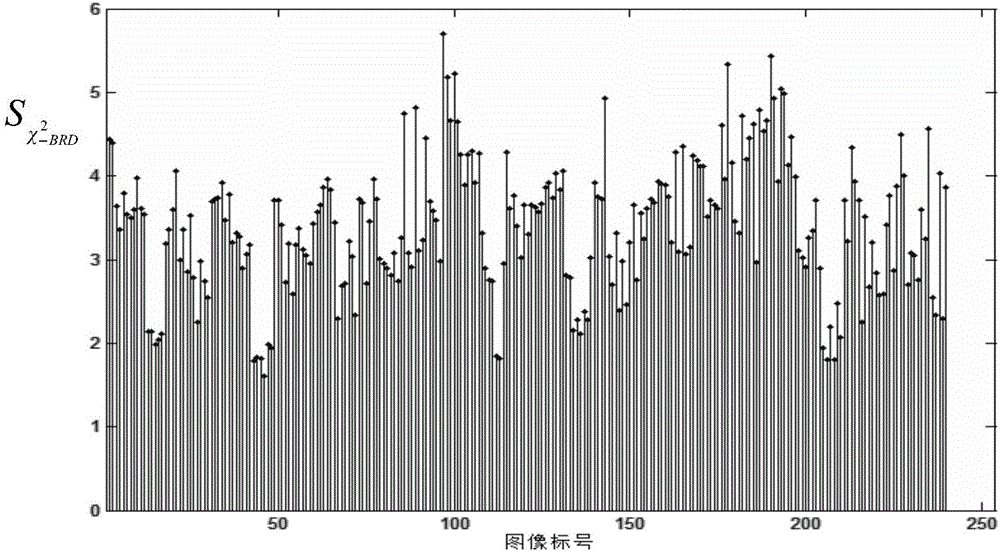

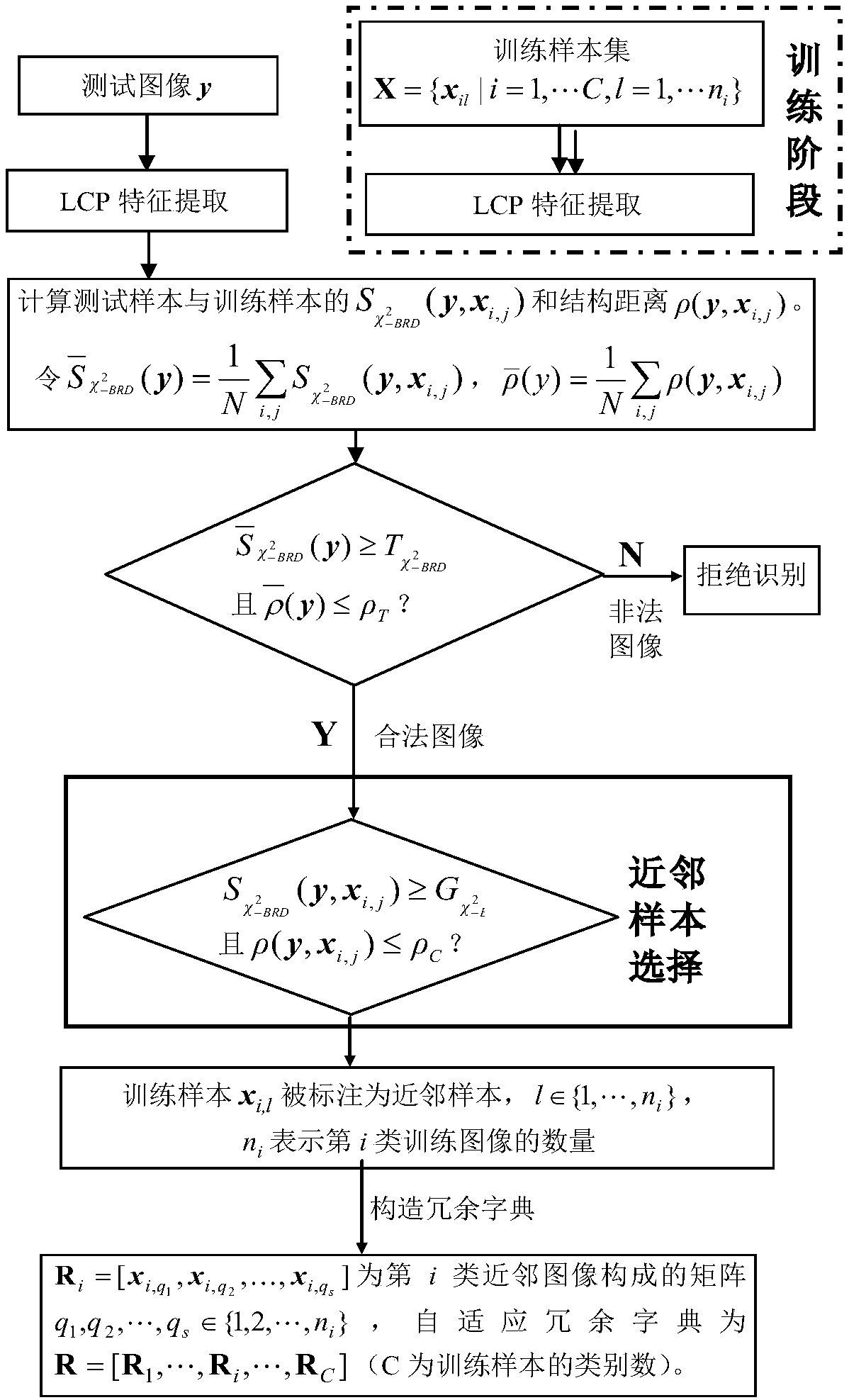

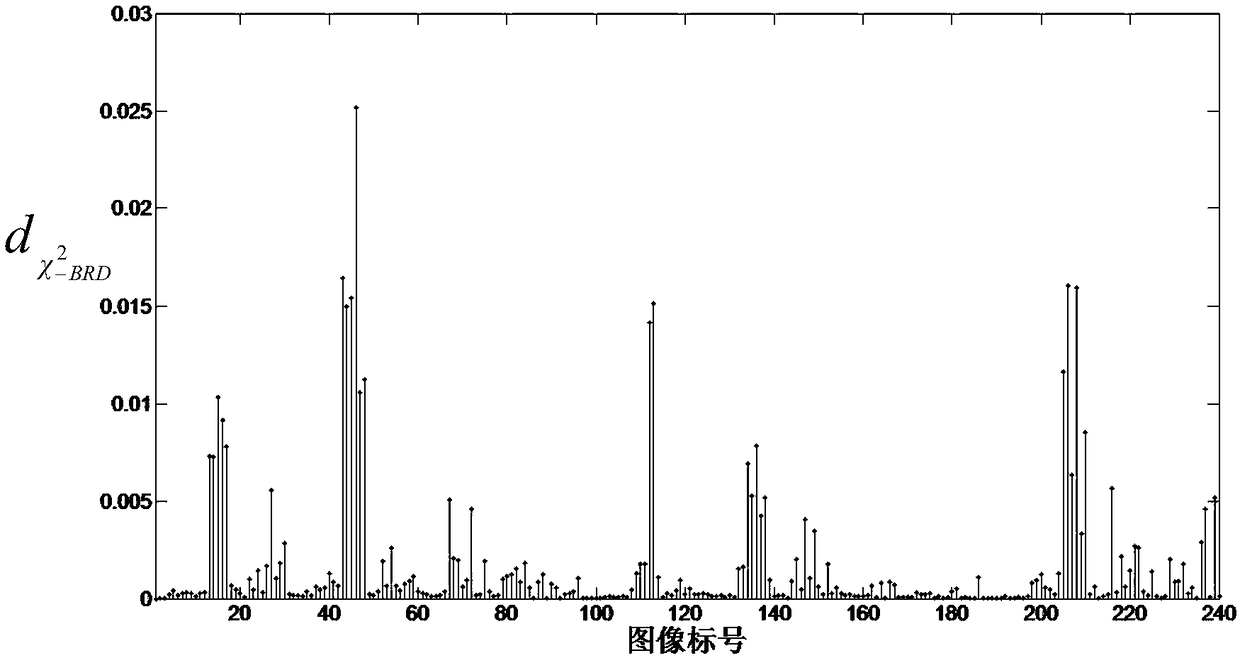

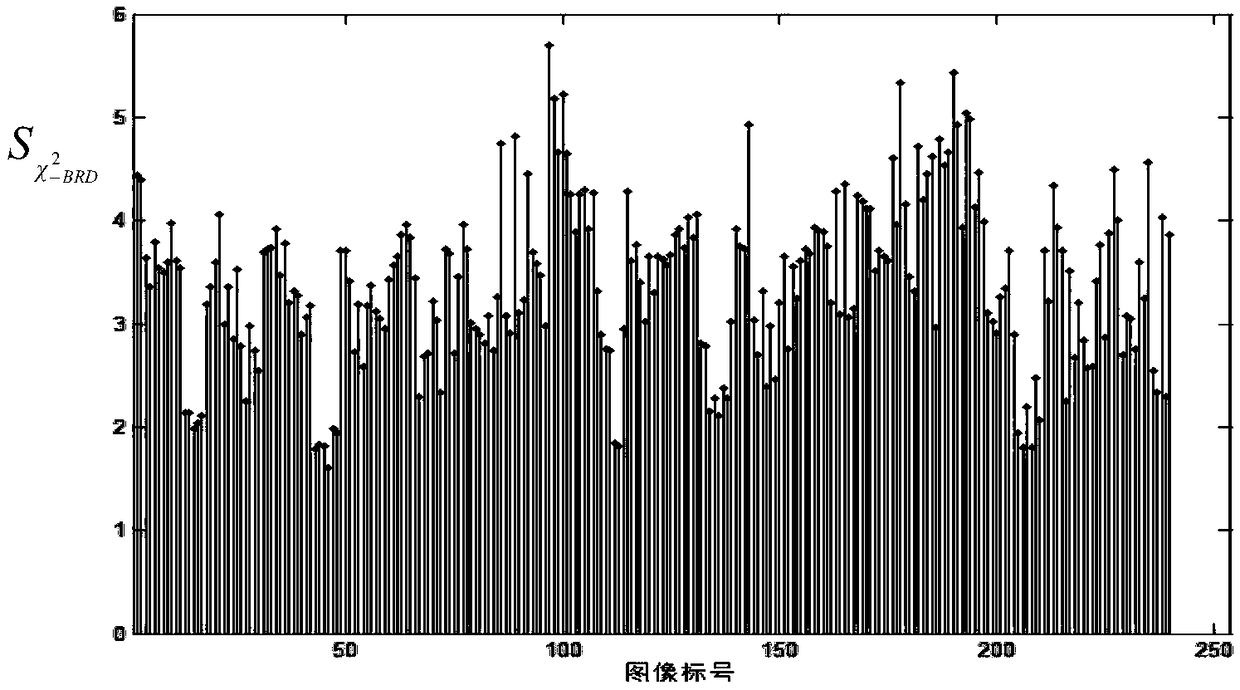

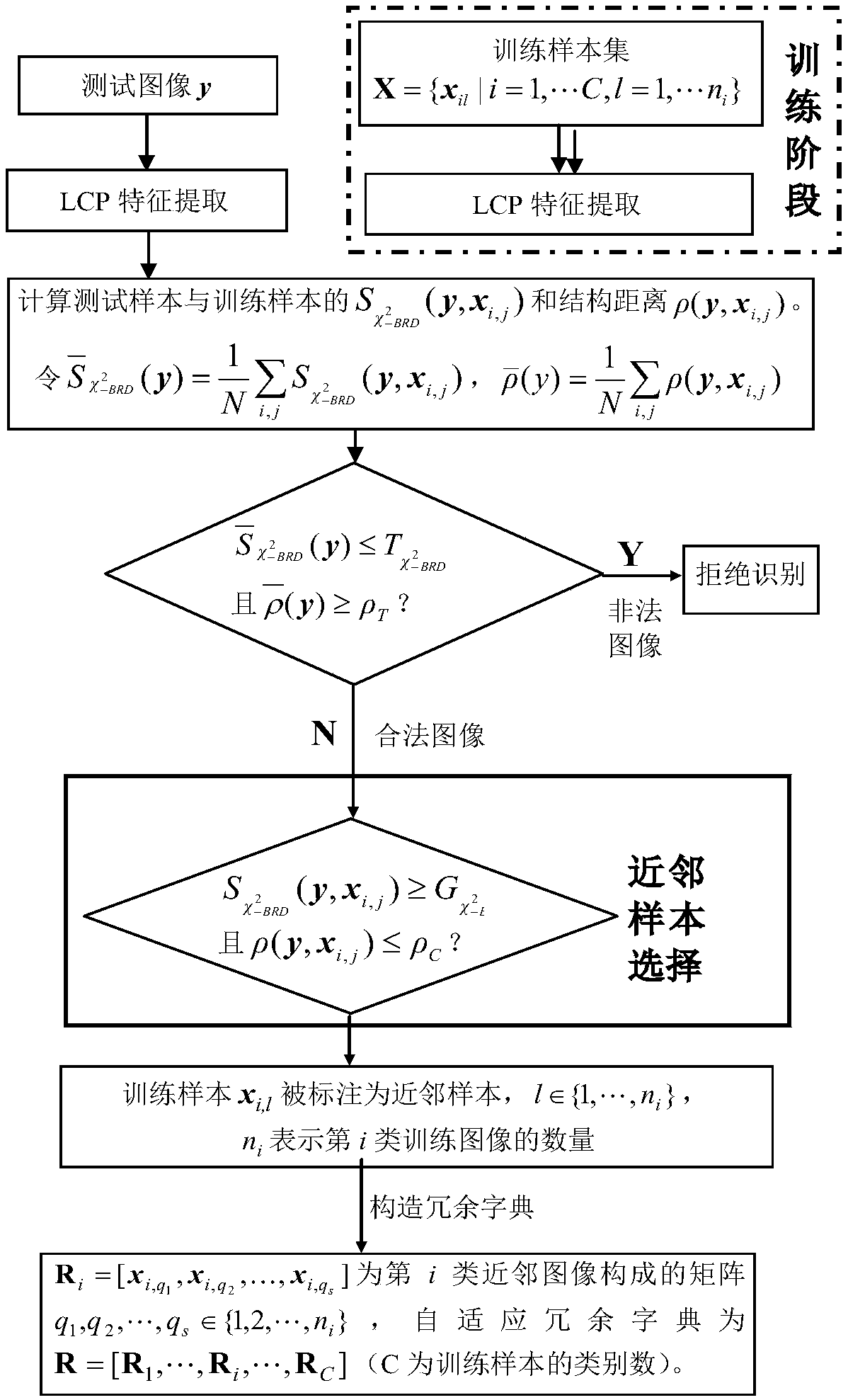

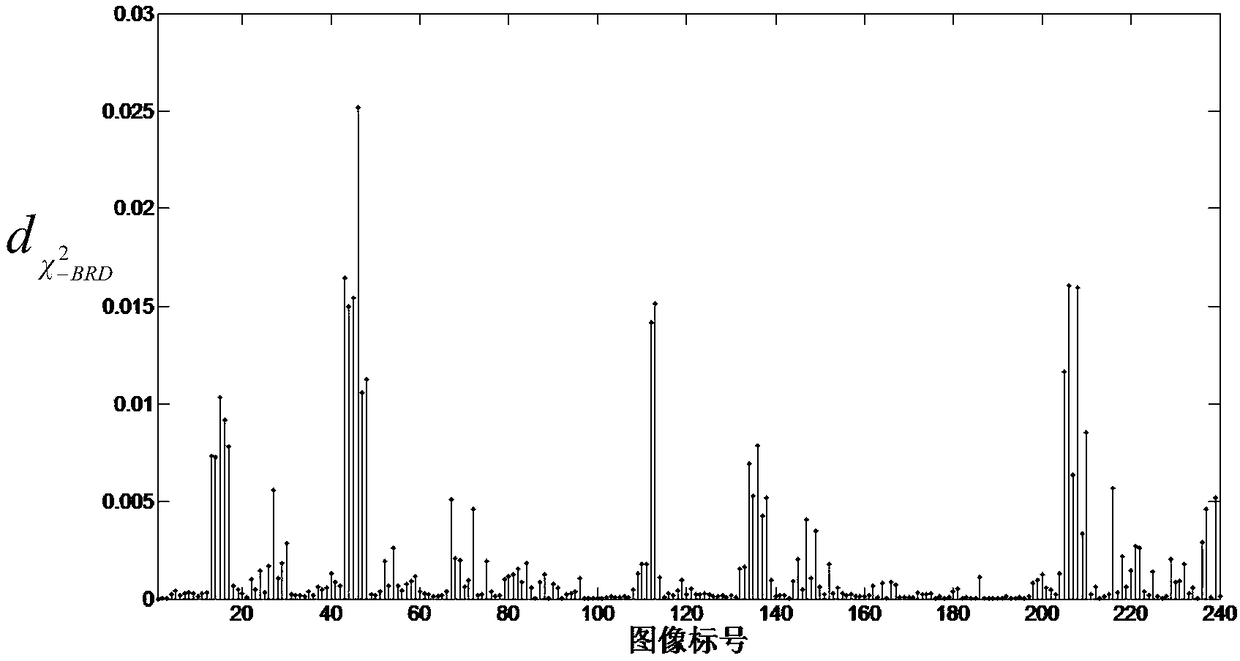

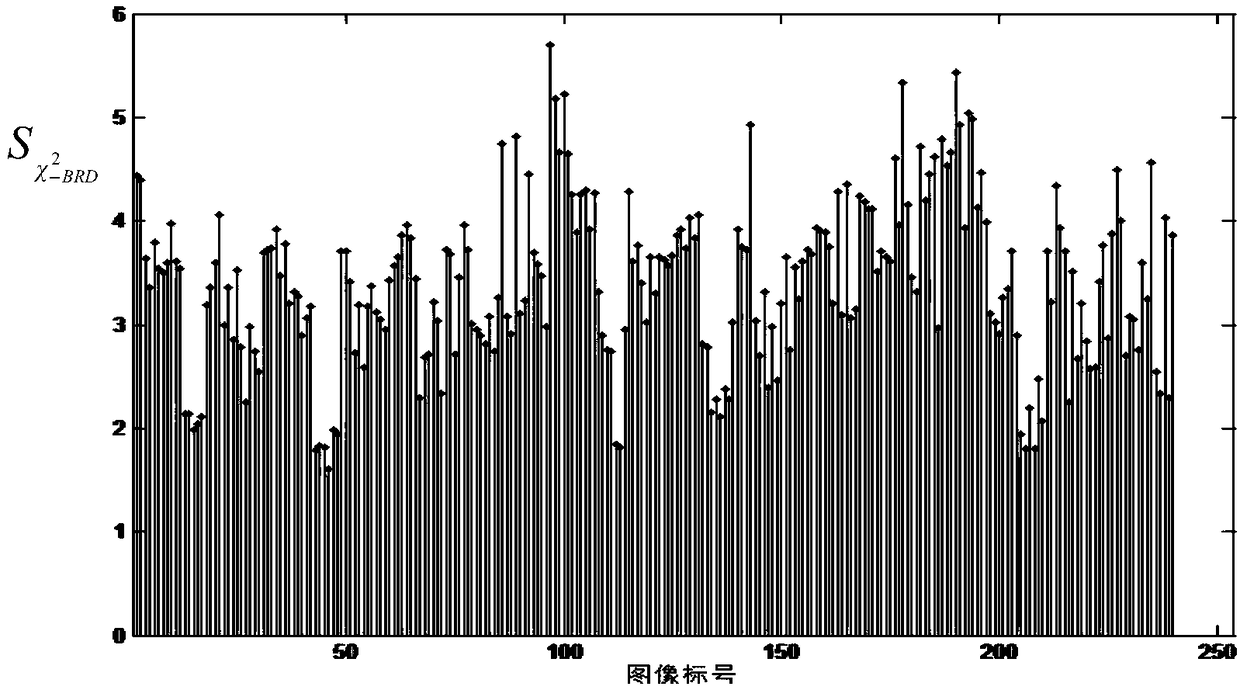

Adaptive dictionary construction method for sparse representation of face recognition

ActiveCN106295517A"Thickness reductionHigh similarityCharacter and pattern recognitionPattern recognitionFace perception

Owner:SHANDONG NORMAL UNIV

An Adaptive Redundant Dictionary Construction Method for Face Recognition

ActiveCN106250841B"Thickness reductionHigh similarityCharacter and pattern recognitionPattern recognition

Owner:SHANDONG NORMAL UNIV

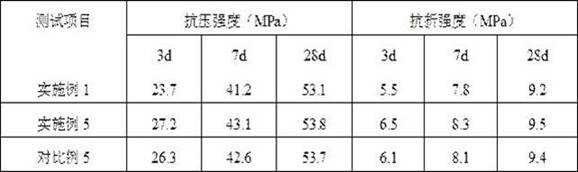

A method for preparing solid waste-based cementitious materials by ultra-low carbon and ultra-low emission cascade grinding

ActiveCN114180862BHigh activityHigh compressive strengthCement productionSlagUltimate tensile strength

The invention relates to the technical field of solid waste resource utilization, and proposes a method for preparing solid waste-based cementitious materials through ultra-low-carbon and ultra-low-emission cascade grinding, including the following steps: S1, mixing slag with grinding aids, and then pulverizing Grind to specific surface area ≥ 600m 2 / kg, to obtain the first slag; S2, mix the slag with grinding aid, and grind until the specific surface area is 500m 2 / kg‑600 m 2 / kg to obtain the second slag; S3, after mixing the steel slag and desulfurized gypsum, grind until the specific surface area is ≥450m 2 / kg, to obtain the third powder; S4, mixing the first slag, the second slag, and the third powder to obtain a solid waste-based cementitious material. Through the above technical solution, the problem of low activity and strength of the solid waste-based gelling material in the related art is solved.

Owner:SHEXIAN QINGZHANG CEMENT MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com