Thermal-shrinkage waterproof sealing cap for high-voltage cable

A high-voltage cable and heat-shrinking technology, used in cable terminals, cable accessories, cable installation, etc., can solve the problems of fire-proof mud gaps or cracks, unreliable sealing, hidden safety hazards, etc., achieving low dependence and convenient disassembly and assembly. , the effect of easy reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

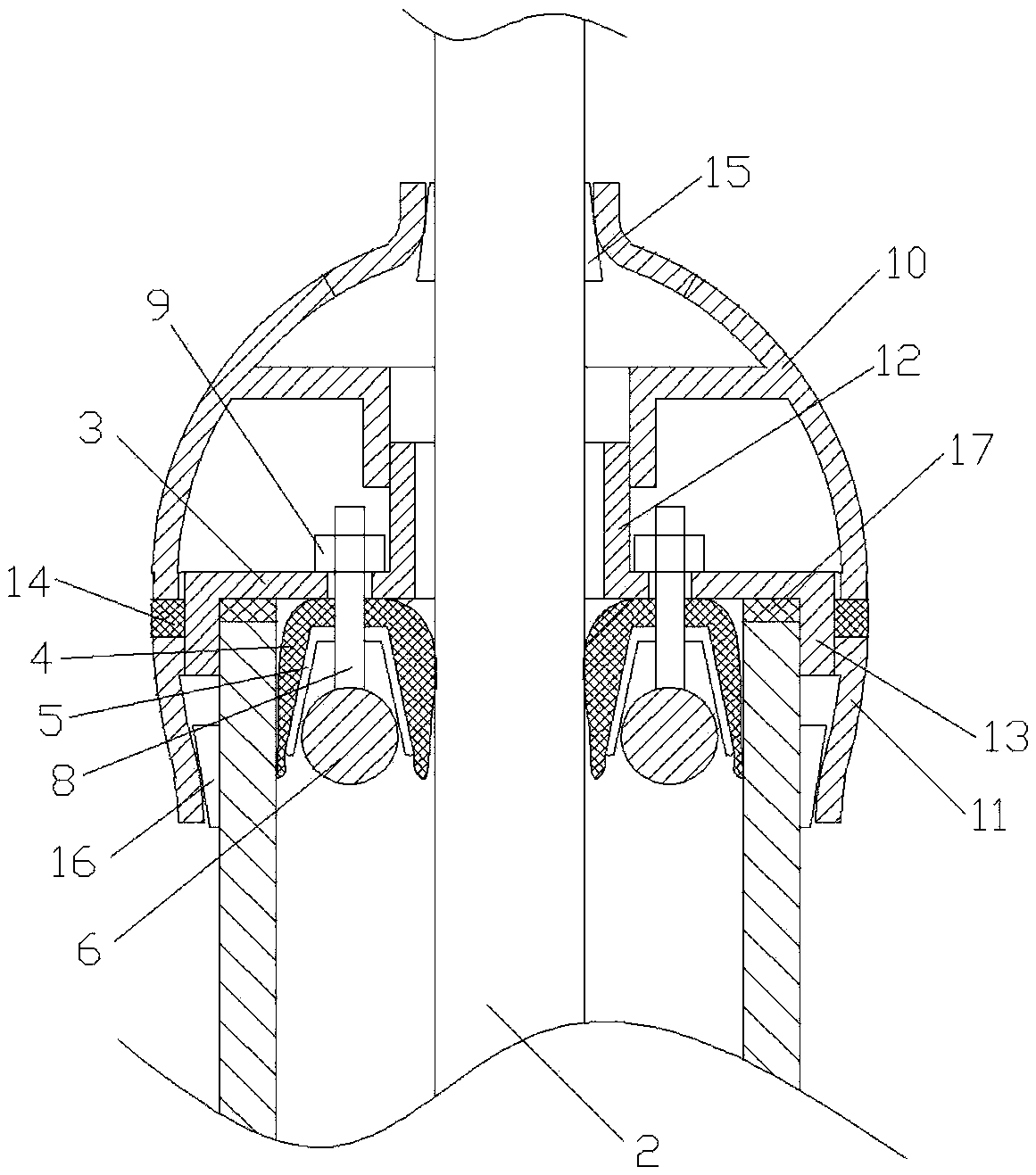

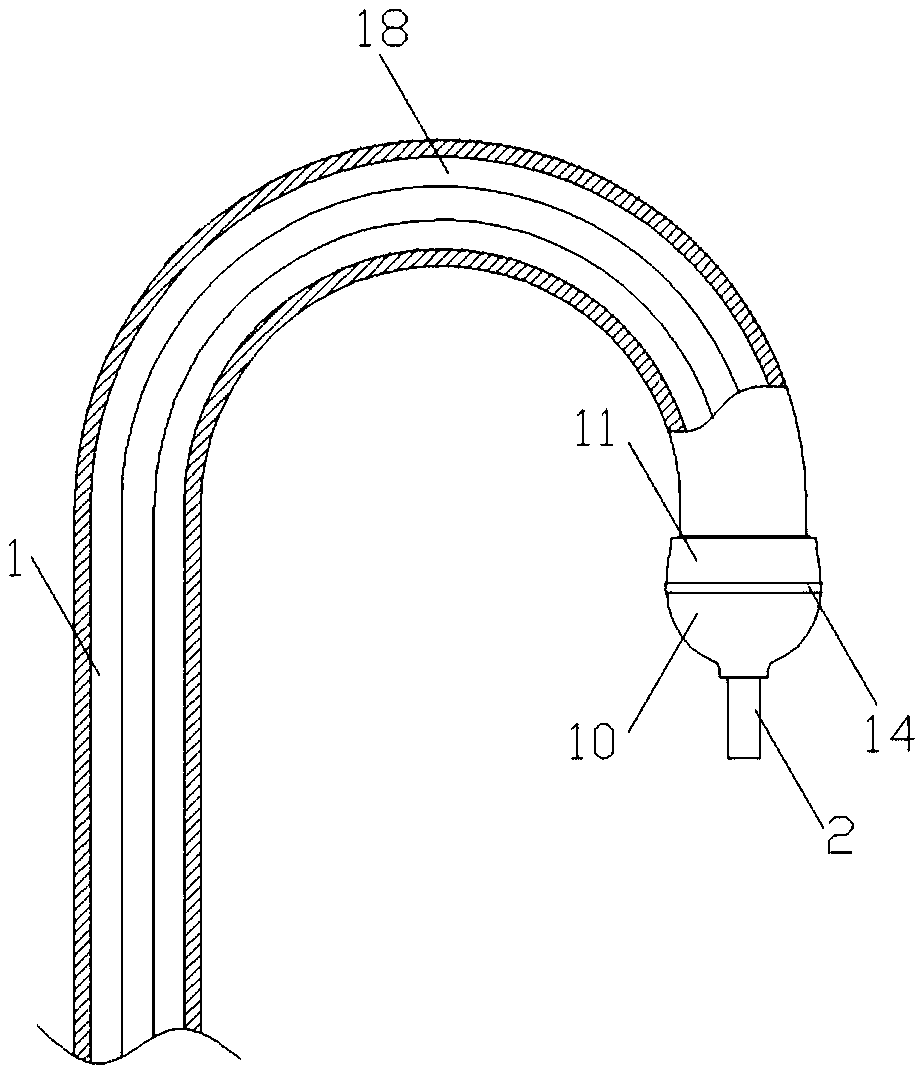

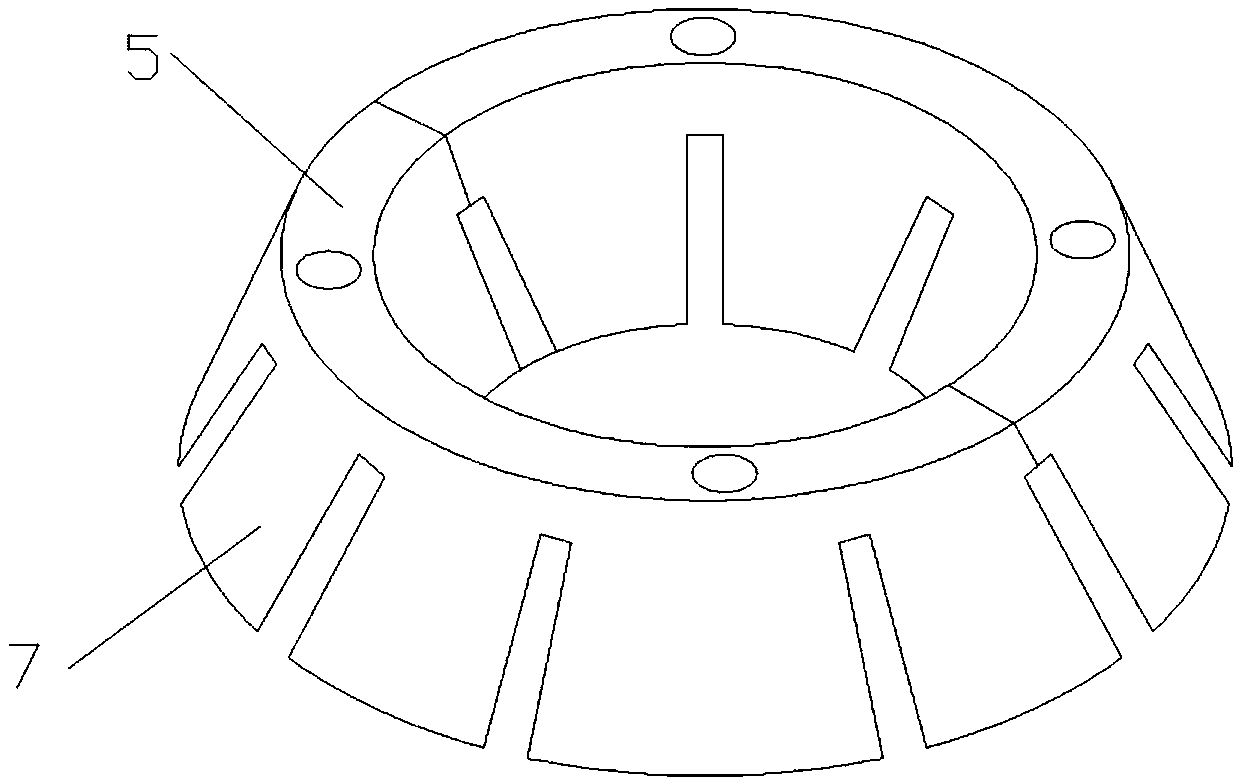

[0023] Specific embodiment 2, such as figure 2 As shown, the housing has an upper and lower split structure, including an upper casing 10 and a lower casing 11, and the end cover 3 is provided with an upper sealing screw sleeve 12 wrapped on the cable body 2, and The lower sealing screw sleeve 13 wrapped on the outer wall of the casing 1, the upper sealing screw sleeve 12 and the lower sealing screw sleeve 13 are provided with external threads, and the upper sealing shell 10 is connected with the upper sealing screw sleeve 12 and the end cap 3 are threadedly connected, and the lower casing 11 is threadedly connected with the end cover 3 by means of the lower sealing screw sleeve 13 . The upper casing 10 and the lower casing 11 are fixed by the external thread provided on the inner end cover 3, the overall appearance is neat, no metal parts are exposed outside, avoiding overlooking from rainwater, etc., the casing is made of fireproof material such as electrical wood, and has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com