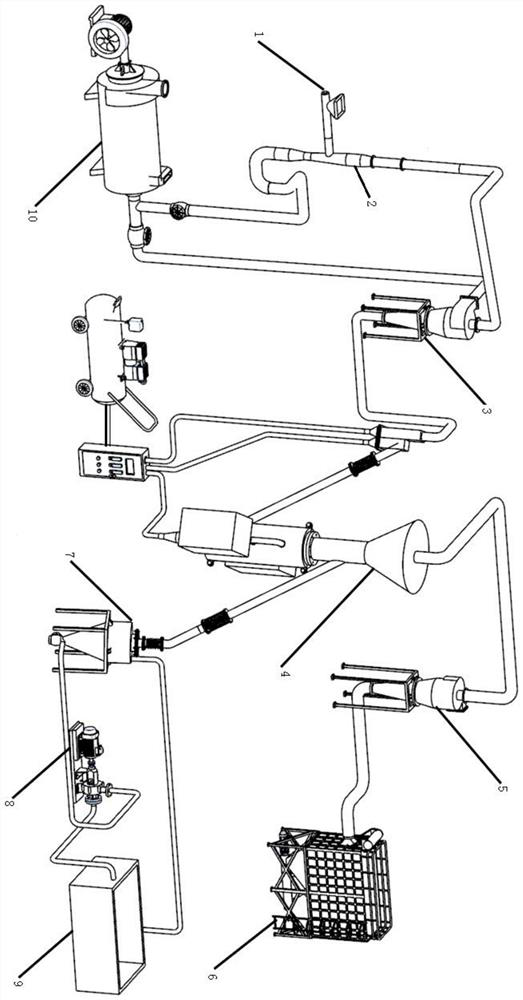

Device and method for microwave-enhanced fluidized phosphogypsum dehydration

A phosphogypsum and fluidization technology, which is applied in the field of microwave-enhanced fluidized phosphogypsum dehydration devices, can solve the problems of secondary pollution discharge, product instability, low production efficiency, etc., achieve low tail gas temperature and ensure product stability Sexuality and fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

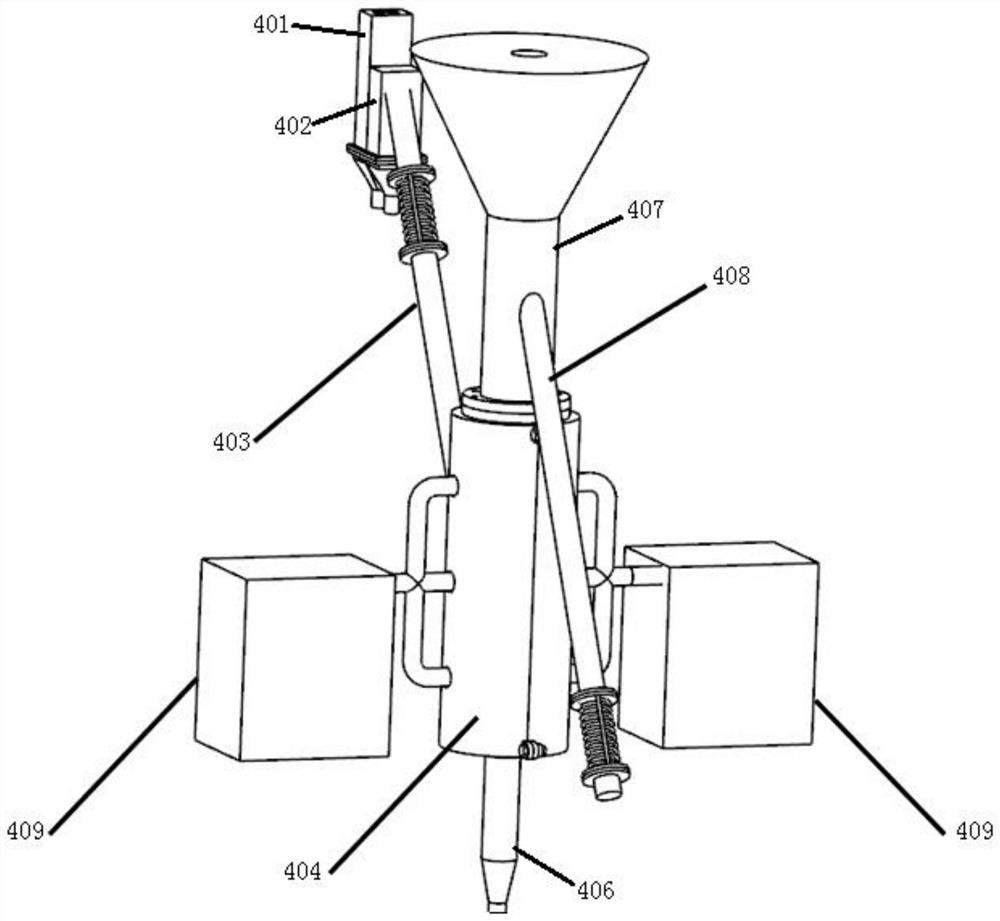

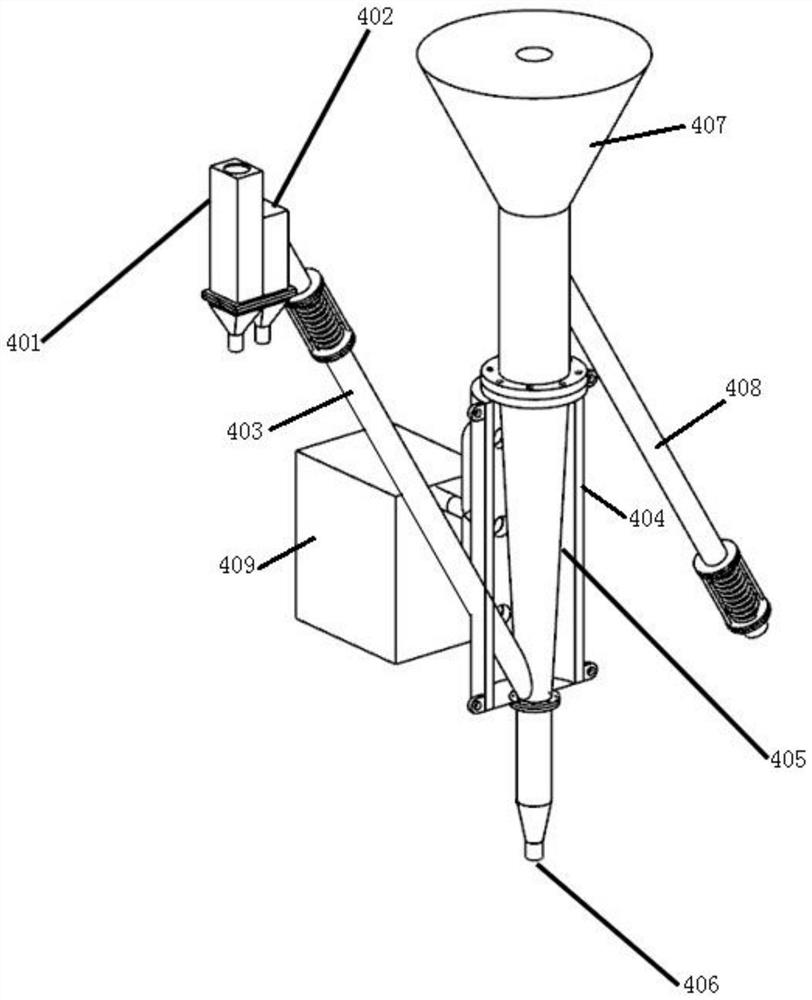

Method used

Image

Examples

Embodiment 1

[0035] Example 1: This Example The present embodiment treatment target is a phosphite produced during phosphoric acid in a phosphate wet method, and the analysis results are as follows.

[0036] Test items Attach water Crystalline water grade pH result 22 17.3 85 3.4

[0037] (1) After the water phase is removed: After washing the phosphite from the filter turntable, after the water is pulsed, the spiral feed is entered into the venturi tube, and the hot air is supplied 330 ° C hot air and 12m 3 The flow of / h enters the bottom of the venturi tube to remove the water in the ketzeplant, and the cake is dispelled, and the residence time of the phosphite in Wenqiao is 90s, and then the phosphite enters the cyclone preheater. In the hot air furnace, the hot air of 210 ° C is provided and 8m 3 The flow rate of / h further removes water, the phosphite residence time is 120s, and finally the water content of the phosphite is maintained at about 1-3%.

[0038] (2...

Embodiment 2

[0049] Example 2: The present embodiment processes the phosphite stacked in a phosphite slag library, and the results are as follows.

[0050] Test items Attach water Crystalline water grade pH result 12 18.6 89 4.8

[0051] (1) After the water phase is removed: After washing the phosphite water in the residue, the spiral feed is entered into the venturi tube, and the hot air supply is supplied with heat and air and at 12m. 3 The flow of the / h enters the bottom of the venturi tube to remove the water at the bottom of the phosphite at the same time, the cake is disperse, the residence time of phosphite in Wenqiao is 110s, and then phosphite enters the cyclone preheater. The hot air furnace provides hot air in 195 ° C and 8m 3 The flow rate of / h further removes water, the phosphite residence time is 130s, and finally the water content of the phosphite is maintained at 1% to 3%.

[0052](2) Six fluidization stage: SiC powder with a mass of 600 g, particle...

Embodiment 3

[0059] Example 3: This embodiment handles the desulfurization gypsum generated by the flue gas desulfurization of a chemical plant, and the results are as follows.

[0060] Test items Attach water grade pH result 8 92 5.1

[0061] (1) Remove the water stage: Enter the desulfurized gypsum into the venturi tube by the spiral feed, and the hot air is provided at 250 ° C hot air and 12m. 3 The flow of the / h enters the bottom of the venturi tube to remove the water at the bottom of the phosphite at the same time, the cake is dispelled, and the residence time of the phosphite in Wenqi is 80s, and then the phospantine enters the cyclone preheater. In the hot air furnace, heat air is supplied with 180 ° C and 8m 3 The flow rate of / h further removes water, the phosphite residence time is 100s, and finally the water content of the phosphite is maintained at about 1-3%.

[0062] (2) Mix fluidization stage: Si of 500g of mass, particle size is 15-140μm 3 N 4 After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com