Insulation board production device

A technology for production equipment and thermal insulation boards, applied in thermal insulation, building components, etc., can solve the problems of reduced waterproof and fireproof performance, inability to absorb products, and reduced use effects, etc., to achieve the effects of reducing losses, good waterproof and fireproof performance, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

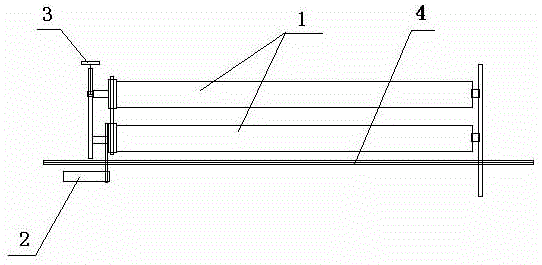

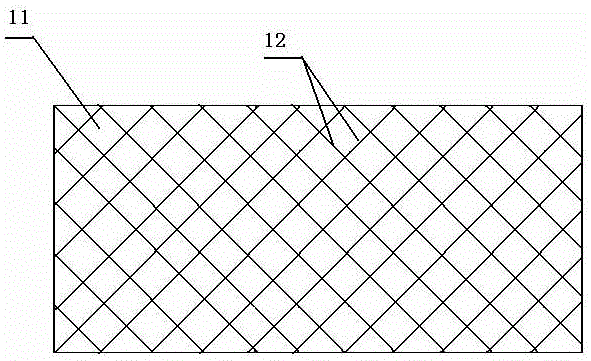

[0017] Such as Figure 1-3 As shown, a heat preservation board production equipment includes a frame, and a pair of pressure rollers 1 are arranged on the frame, and the pair of pressure rollers 1 are arranged up and down on the frame, and are connected by transmission. The roller 1 is also connected with the motor 2 through transmission. The surface of the pair of pressure rollers 1 is provided with raised extrusion stripes, and the extrusion stripes are provided with several pieces, and are arranged obliquely on the left and right to form several diamond-shaped structures. Wherein, the thickness of the stripes is 2 millimeters.

[0018] An adjustment block is arranged at the end of the pressure roller located above, and the adjustment block is connected with the adjustment bolt 3, so that the distance between a pair of pressure rollers can be adjusted to realize the adjustment of the thickness of the insulation board.

[0019] The outlet end of the pressure roller 1 is prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com