High-temperature-resistant heat-insulation paint

A technology of heat insulation and high temperature resistance, applied in the field of materials, can solve the problems of high construction difficulty, low maximum temperature resistance and insufficient adhesion of inorganic high temperature resistant coatings, achieve good heat preservation effect, improve material strength and strong corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

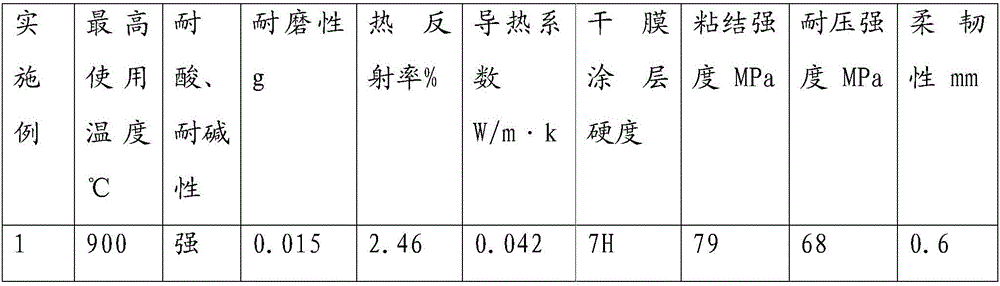

Embodiment 1

[0024] Stir 100g of sodium silicate and 200g of water-based phenolic resin evenly, the stirring temperature is 5°C to 30°C above the melting point of the water-based phenolic resin, the speed of the mixer is greater than 3500r / min, and the stirring time is 60min;

[0025] Add 20g of bentonite, 12g of aluminum oxide, 2g of dispersant, 2g of stabilizer, 2g of preservative, 2g of carboxymethylcellulose, 2g of pH regulator and 2g of coupling agent to the mixture obtained above, and stir evenly;

[0026] Add 350 g of ceramic hollow microspheres and 250 g of short ceramic fibers to the mixture obtained above, and continue to stir for more than 60 minutes to obtain a high-temperature-resistant heat-insulating coating.

[0027] The obtained coating is coated on the inner wall of the coke oven raw gas riser heat exchanger, and the coating thickness is 2mm.

Embodiment 2

[0029] Stir 100g of sodium silicate and 200g of water-based phenolic resin evenly, the stirring temperature is 5°C to 30°C above the melting point of the water-based phenolic resin, the speed of the mixer is greater than 3500r / min, and the stirring time is 80min;

[0030] Add 20g of bentonite, 12g of aluminum oxide, 2g of dispersant, 2g of stabilizer, 2g of preservative, 2g of carboxymethylcellulose, 2g of pH regulator and 2g of coupling agent to the mixture obtained above, and stir evenly;

[0031] Then add 800 g of ceramic hollow microspheres and 50 g of short ceramic fibers to the mixture obtained above, and continue to stir for more than 60 minutes to obtain a high-temperature-resistant heat-insulating coating.

[0032] The obtained coating is coated on the inner wall of the coke oven raw gas riser heat exchanger, and the coating thickness is 2mm.

Embodiment 3

[0034] Stir 150g of sodium silicate and 150g of water-based phenolic resin evenly, the stirring temperature is 5°C to 30°C above the melting point of the water-based phenolic resin, the speed of the mixer is greater than 3500r / min, and the stirring time is 100min;

[0035] Add 20g of bentonite, 12g of aluminum oxide, 2g of dispersant, 2g of stabilizer, 2g of preservative, 2g of carboxymethylcellulose, 2g of pH regulator and 2g of coupling agent to the mixture obtained above, and stir evenly;

[0036] Then add 800 g of ceramic hollow microspheres and 50 g of short ceramic fibers to the mixture obtained above, and continue to stir for more than 60 minutes to obtain a high-temperature-resistant heat-insulating coating.

[0037] The obtained coating is coated on the inner wall of the coke oven raw gas riser heat exchanger, and the coating thickness is 2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com