Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139 results about "Asphalt shingle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An asphalt shingle is a type of wall or roof shingle that uses asphalt for waterproofing. It is one of the most widely used roofing covers in North America because it has a relatively inexpensive up-front cost and is fairly simple to install.

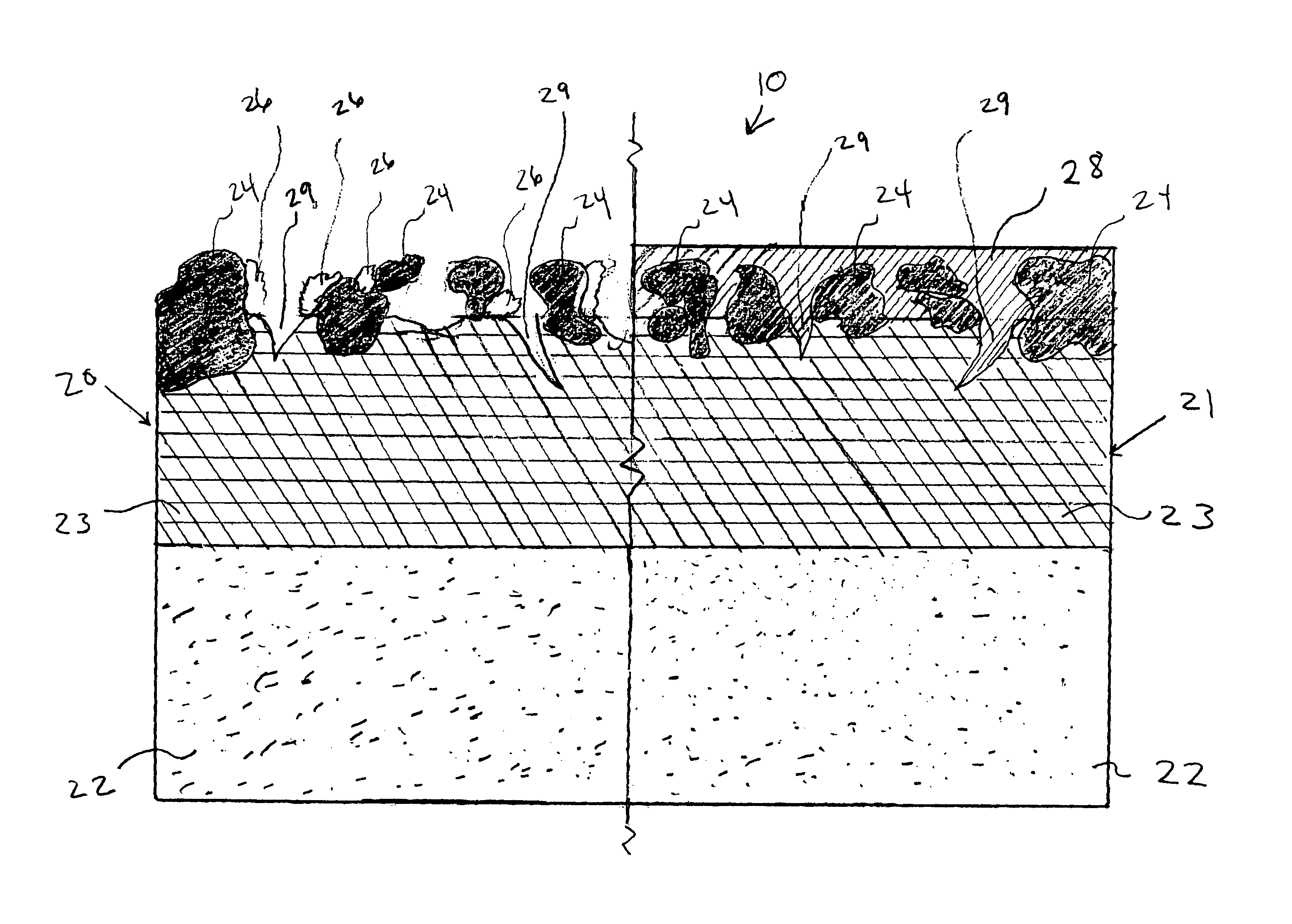

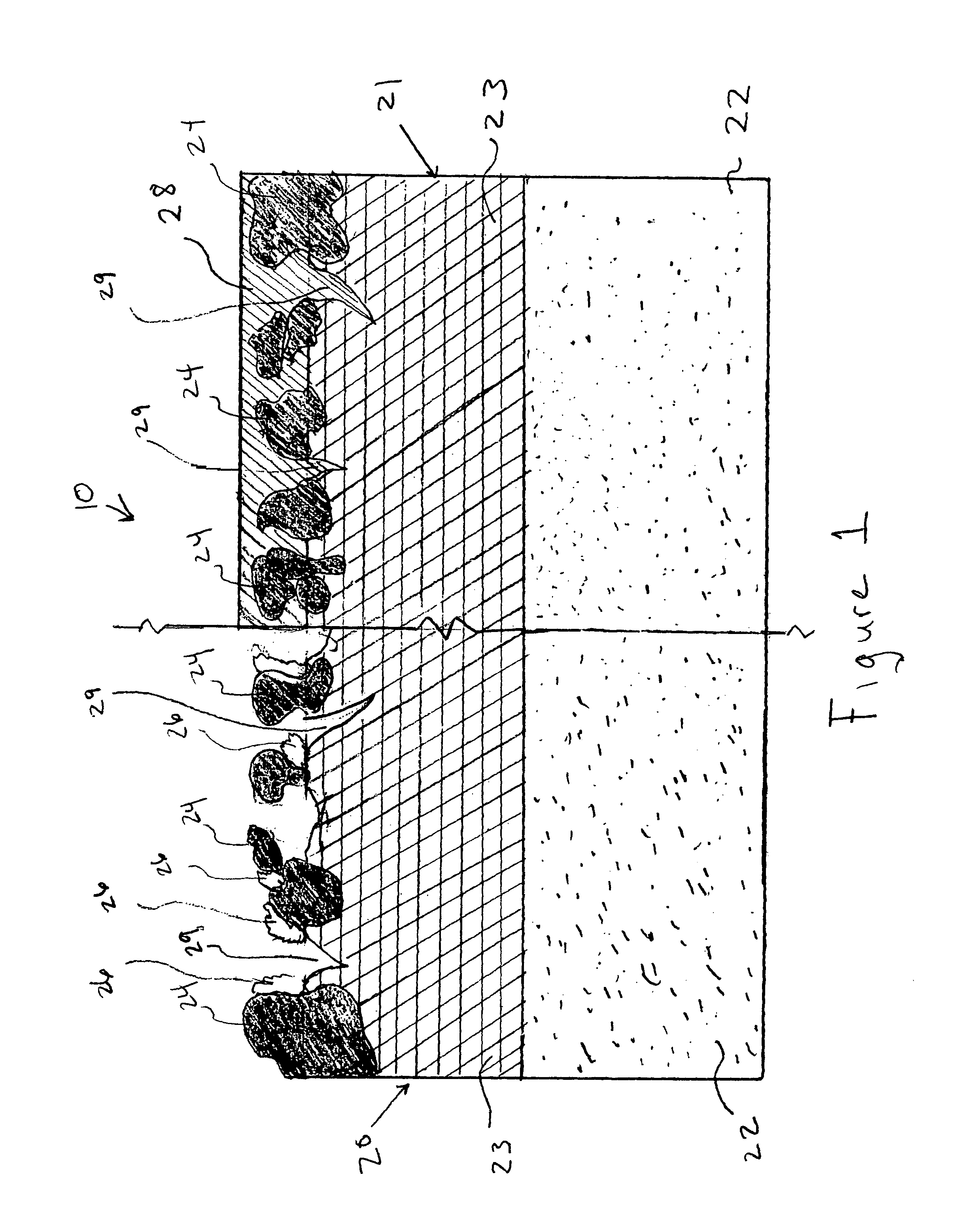

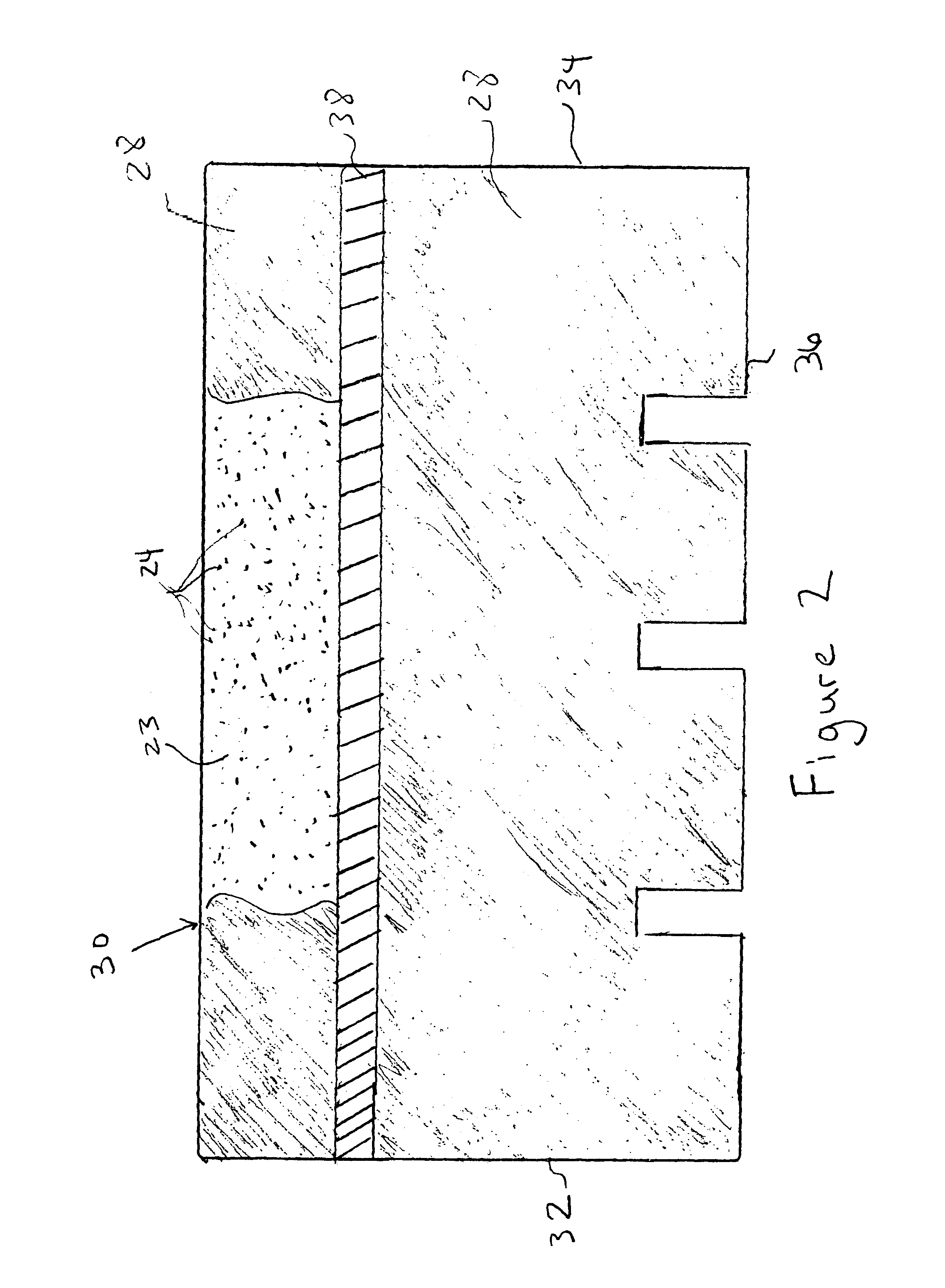

Composite roofing panel

InactiveUS20020040557A1Easy to installBetter imitate natural productsRoof covering using tiles/slatesNatural patternsAsphalt shingleNatural fiber

The present invention provides a composite panel for use in construction, and particularly for shingling, which comprises natural fiber and a polymer. Due to its composition and layout the construction panel provides all of the advantages of natural materials and high end roofing materials, particularly an attractive appearance, while at the same time allowing for ease of installation, little or no maintenance requirements, and providing superior impact and fire resistance when compared to other roofing materials. The construction panels can also be installed using conventional equipment and methods similar to the installation of 3-tab asphalt shingles with little or no learning curve.

Owner:COMPOSITECH

Manufacture of composite roofing products with matrix formulated microbiocide

InactiveUS6245381B1Good dispersionEliminate the problemBiocideLiquid surface applicatorsAsphalt shingleBlue green algae

This invention discloses improved residential roofing products with durable active protection against algae discoloration. Versatile organometallic salts and chelates for this purpose are incorporated in manufacture of composite concrete tile and asphalt shingle products via integrated process modifications. These chemically stable non-volatile microbiocides, with exceptional effectiveness against both green and blue green algae, are tailored for specific matrix compatibility. By virtue of their composition and surface activity they serve a dual function in process improvement and product performance. The control of microbiocide activity, long term, significantly advances the state-of-the-art protection against algae and the service life of these products.

Owner:TAMKO BUILDING PRODS

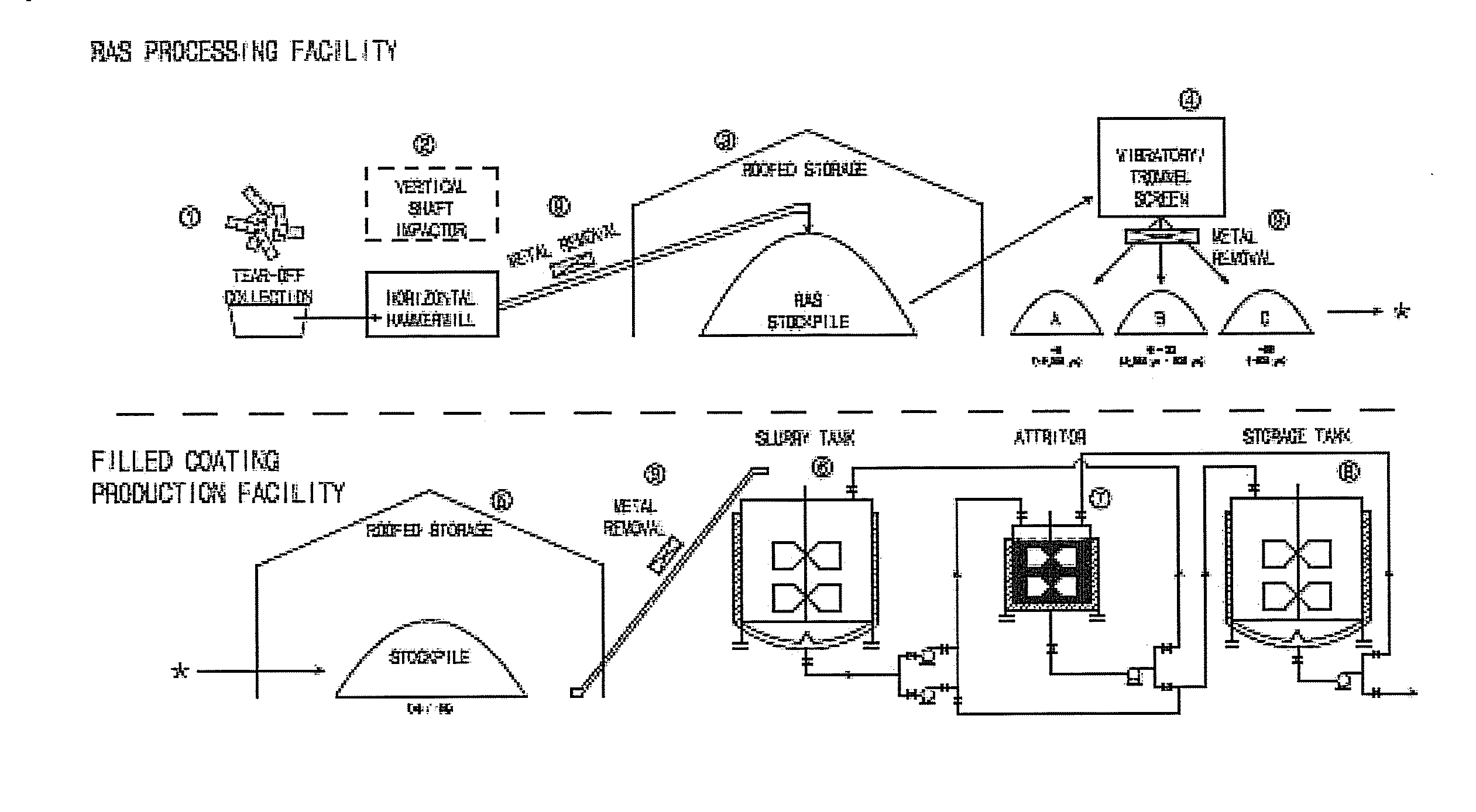

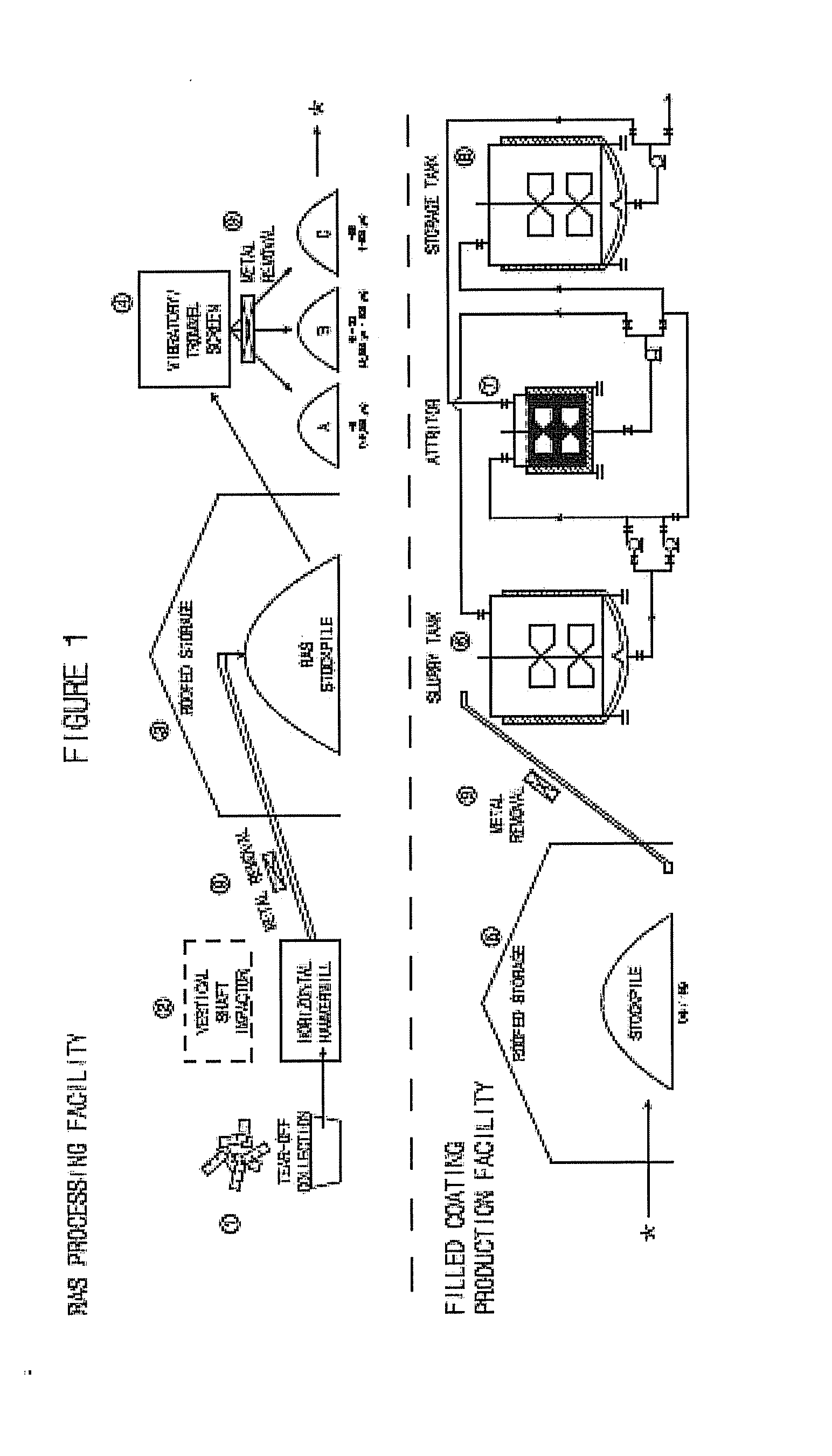

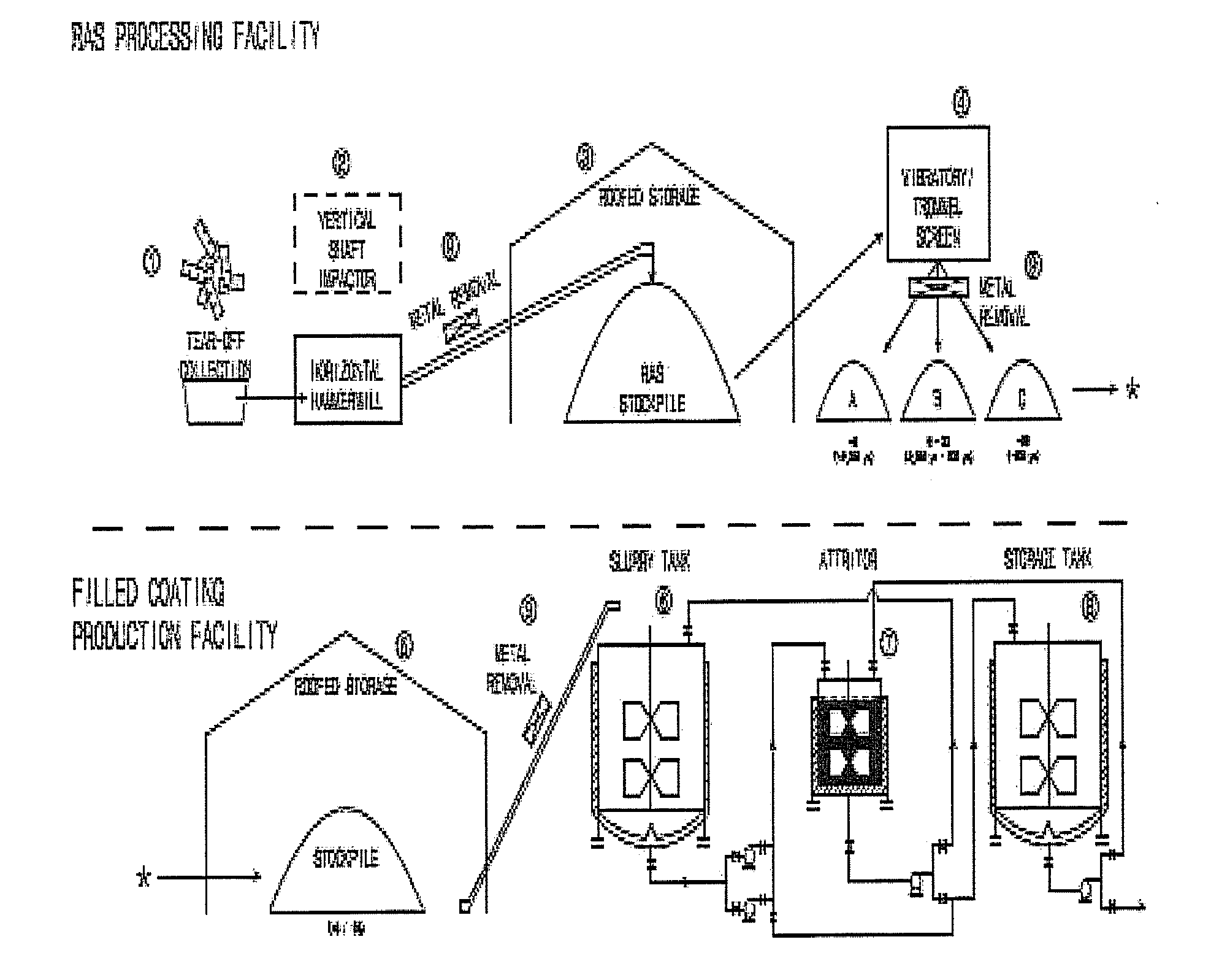

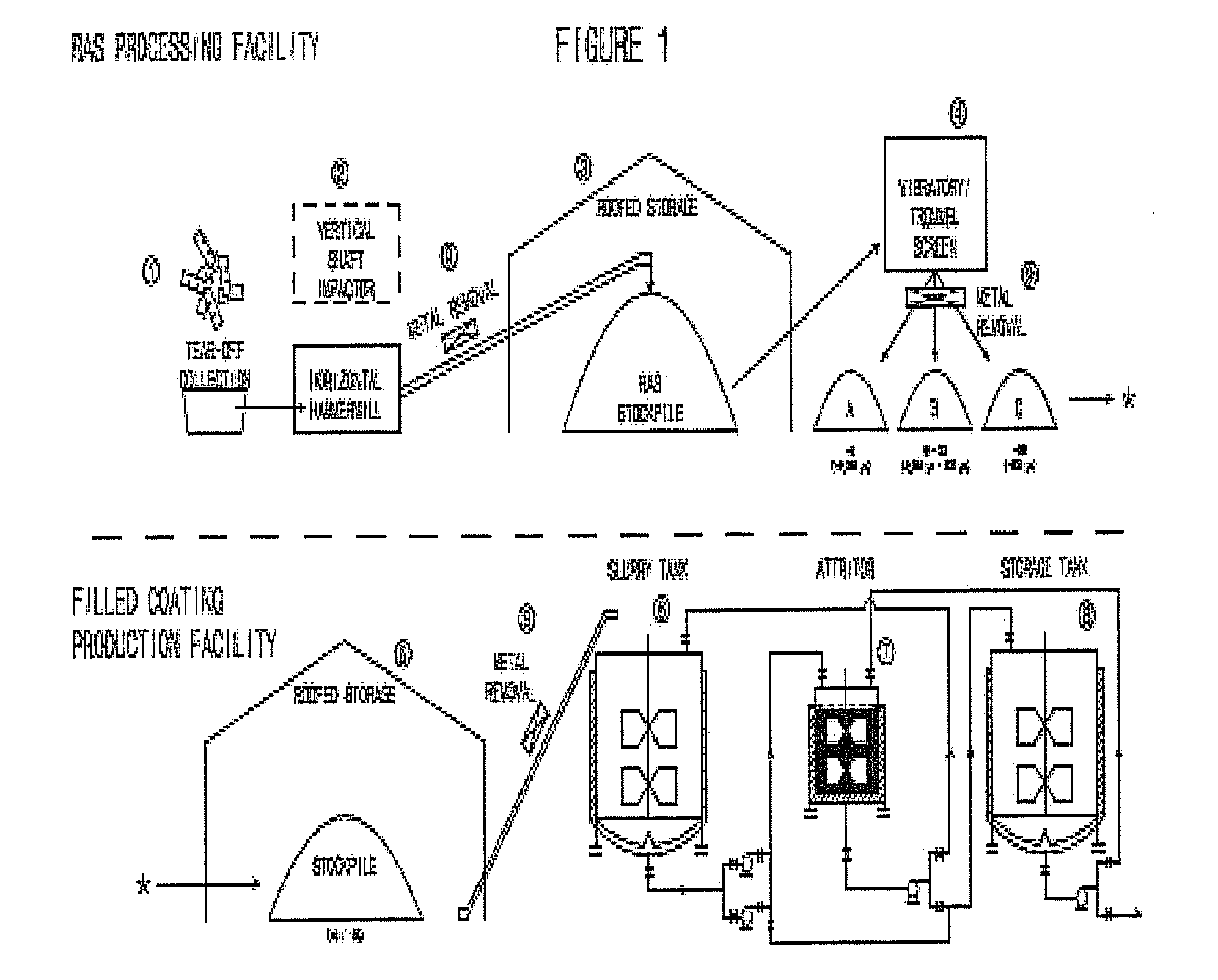

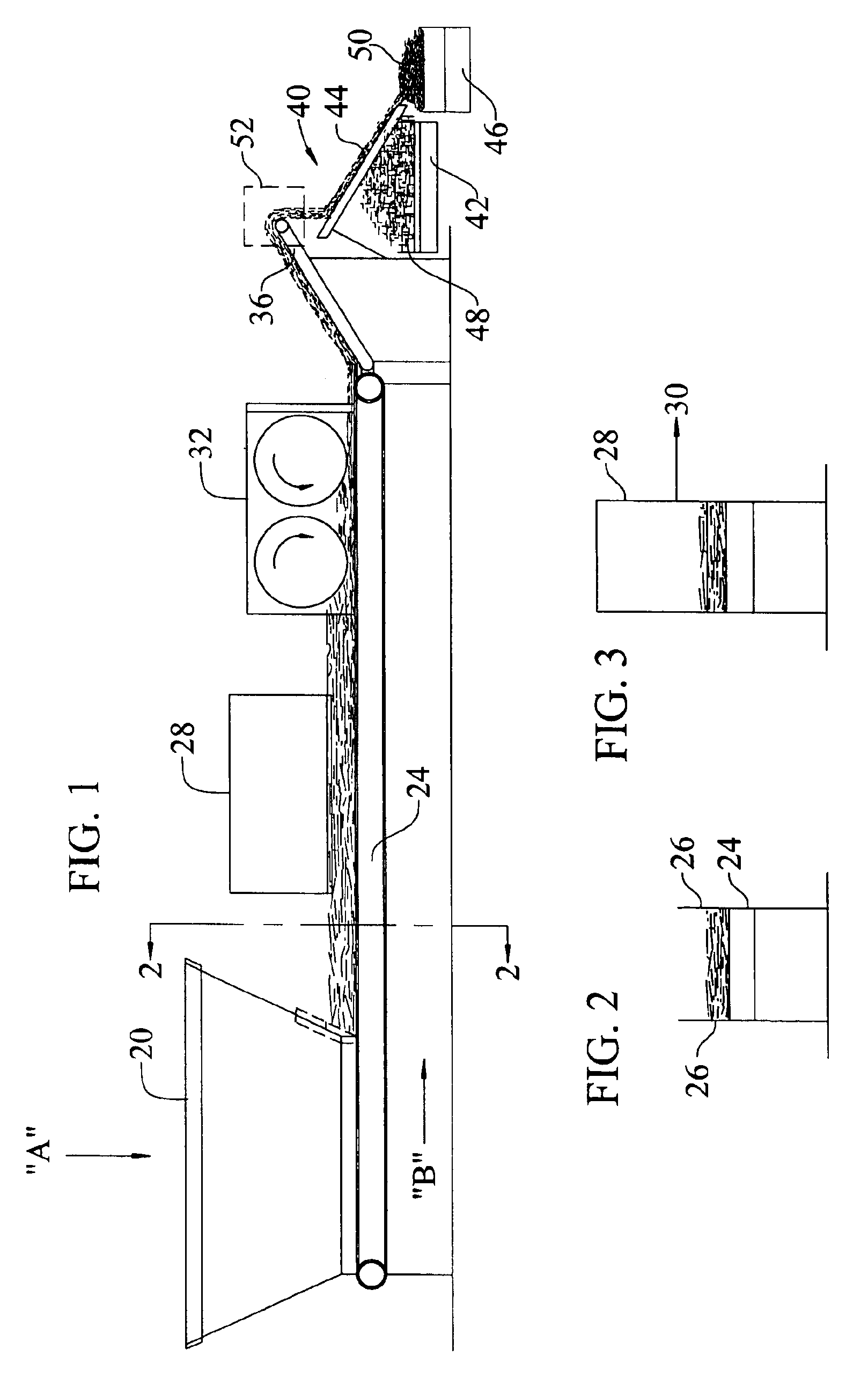

System and method for manufacturing asphalt products with recycled asphalt shingles

InactiveUS20140014000A1Minimize moisturePrevent excessive foamingIn situ pavingsRoof covering using tiles/slatesAsphalt shingleSlurry

A method for manufacturing a processed asphalt suspension is provided. The method includes dry grinding shingle waste material to a particle size of less than 1 cm, forming ground recycled shingle material, introducing virgin asphalt into a heated slurry tank and mixing the ground recycled shingle material with the virgin asphalt in the heated slurry tank, forming a mixed asphalt slurry, introducing the mixed asphalt slurry into a wet grinding machine, and recovering a processed asphalt suspension comprising particles having a size no greater than about 200 microns. Roofing and paving products manufactured from the processed asphalt suspension are also provided.

Owner:HERITAGE ENVIRONMENTAL SERVICES

Resaturation of asphalt shingles

InactiveUS6495074B1Efficient use ofExtended service lifeRoof covering using tiles/slatesOther chemical processesAsphalt shingleEmulsion

A method of maintaining as well as restoring the condition of weathered asphalt shingles and strips which are applied to flat roofs, pitched roofs, or vertical walls. The process involves applying resaturant neat or as a water emulsion. Suitable resaturants include fatty acid methyl esters, petroleum distillates, and water emulsions thereof. The process restores the suppleness and softness of the weathered shingles or strip and adds about three years to the lifetime of the roof. The process may be repeated for additional lifetime extension.

Owner:SHINGLE LIFE INC

Asphalt shingle recycling system and method

InactiveUS20100064937A1Improve consistencySmall particle sizeSolid waste disposalPlastic recyclingAsphalt shingleEngineering

A method of recycling asphalt roofing material is provided. The asphalt roofing material is delivered into a treatment chamber of a processor. A heat source is provided to the treatment chamber. Heat energy is transferred from the heat source to the asphalt roofing material to produce a heated product, and the heated product is removed from the treatment chamber.

Owner:HARMON THOMAS B +1

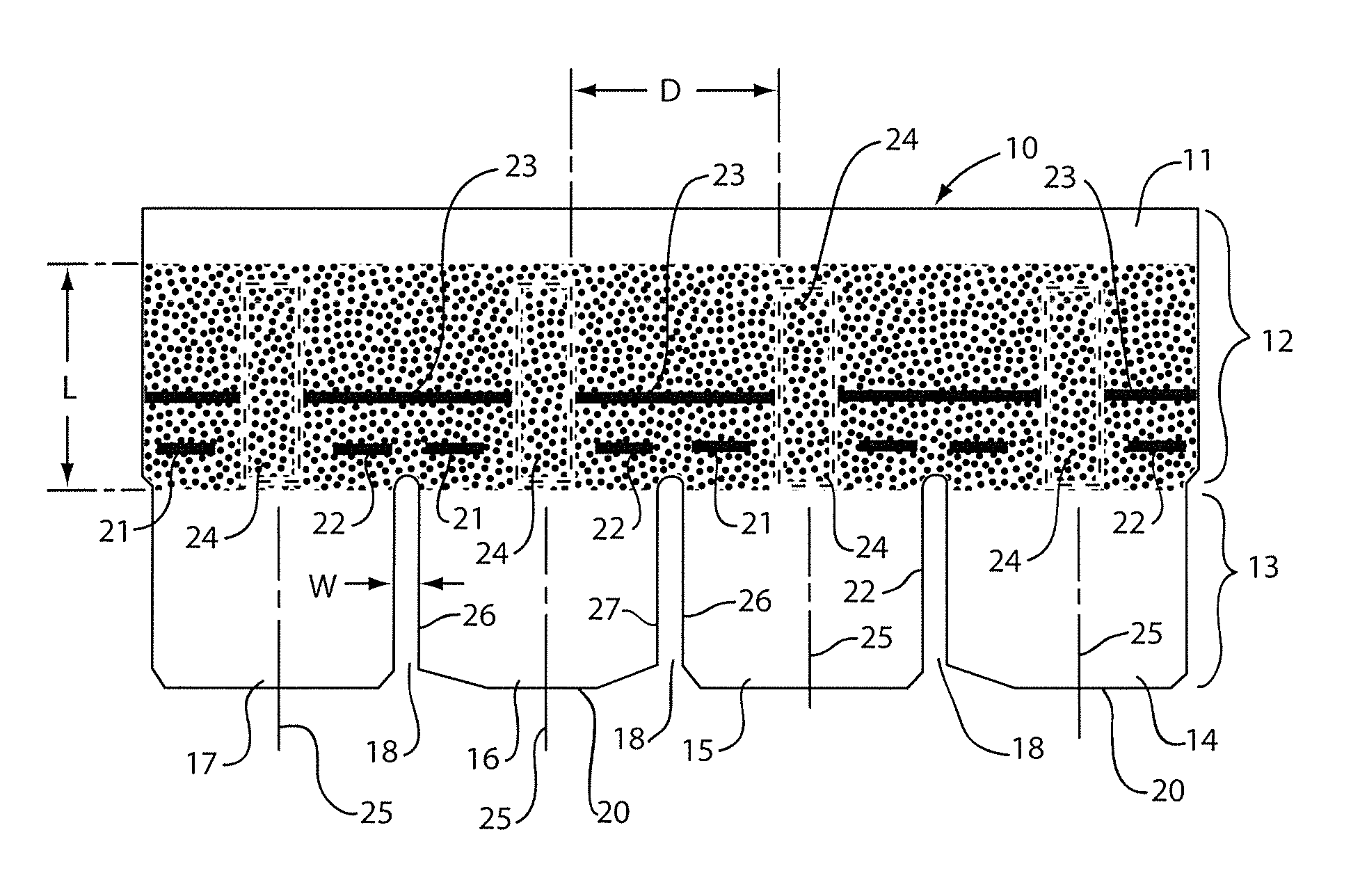

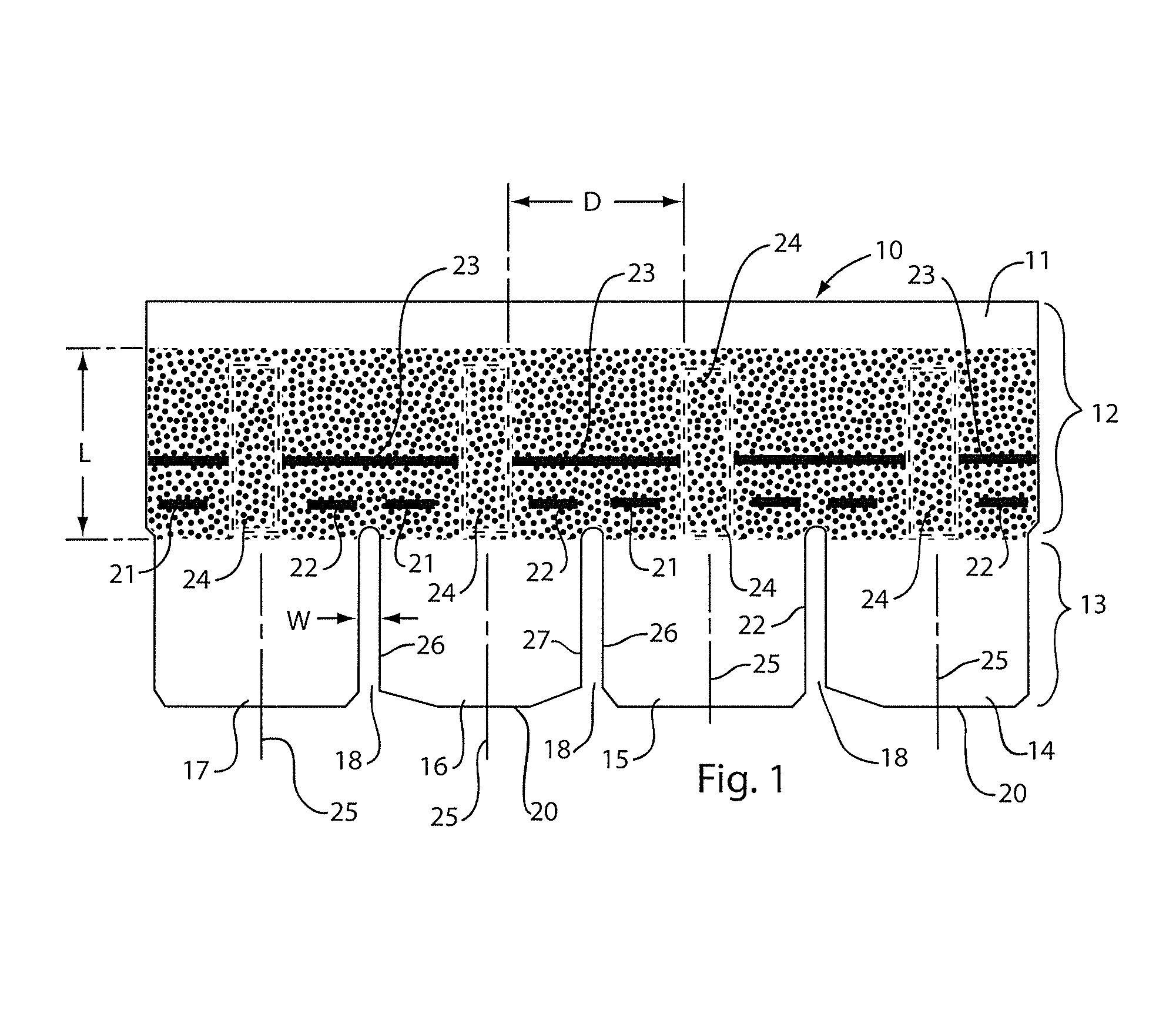

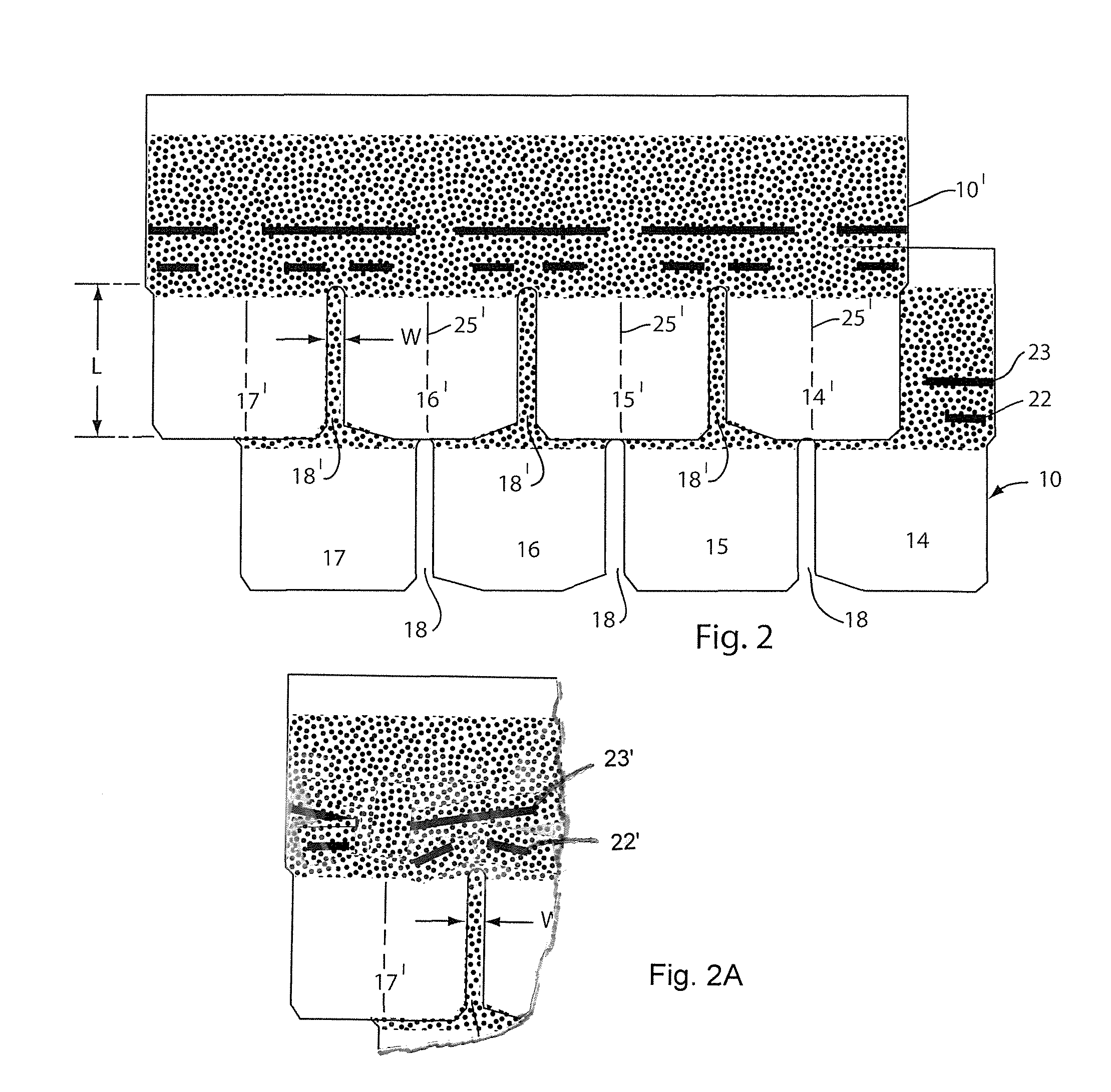

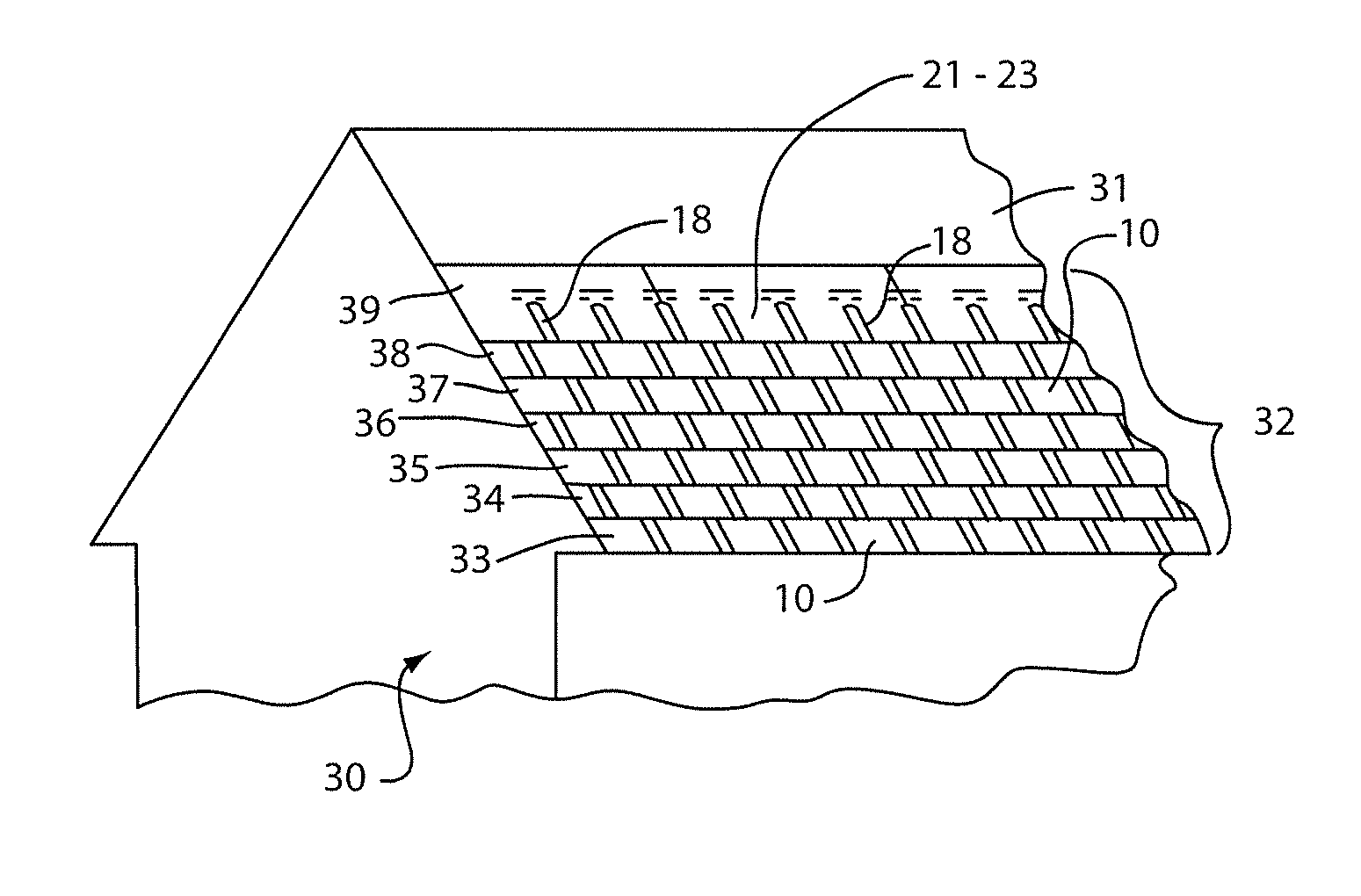

Asphalt shingle, roof covering therewith and method of making the same with synchronized adhesive positioning thereon

ActiveUS8915037B2Roof covering using tiles/slatesLamination ancillary operationsFree zoneAsphalt shingle

Owner:CERTAIN TEED LLC

Methods and Compositions for Recycled Asphalt Shingles Material

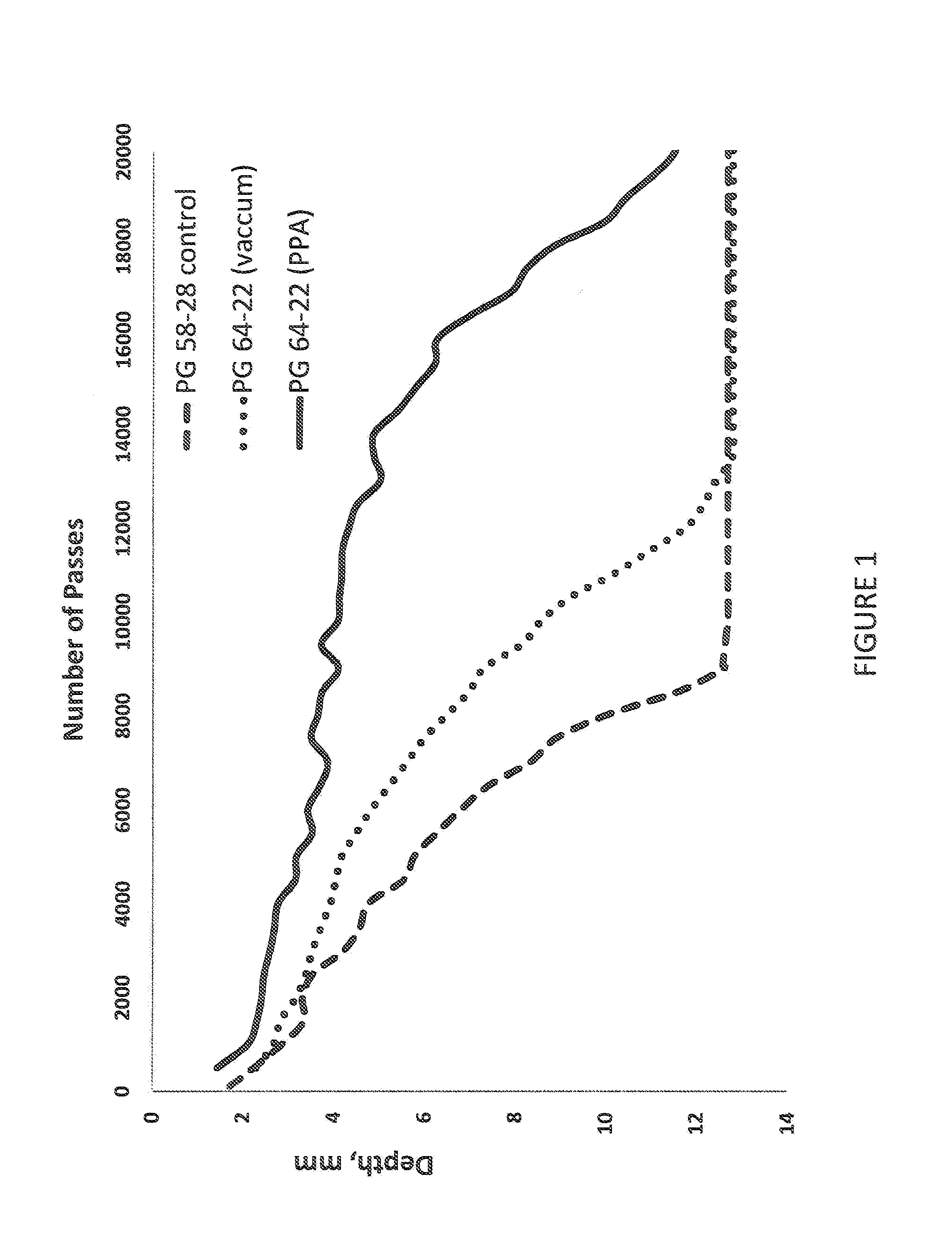

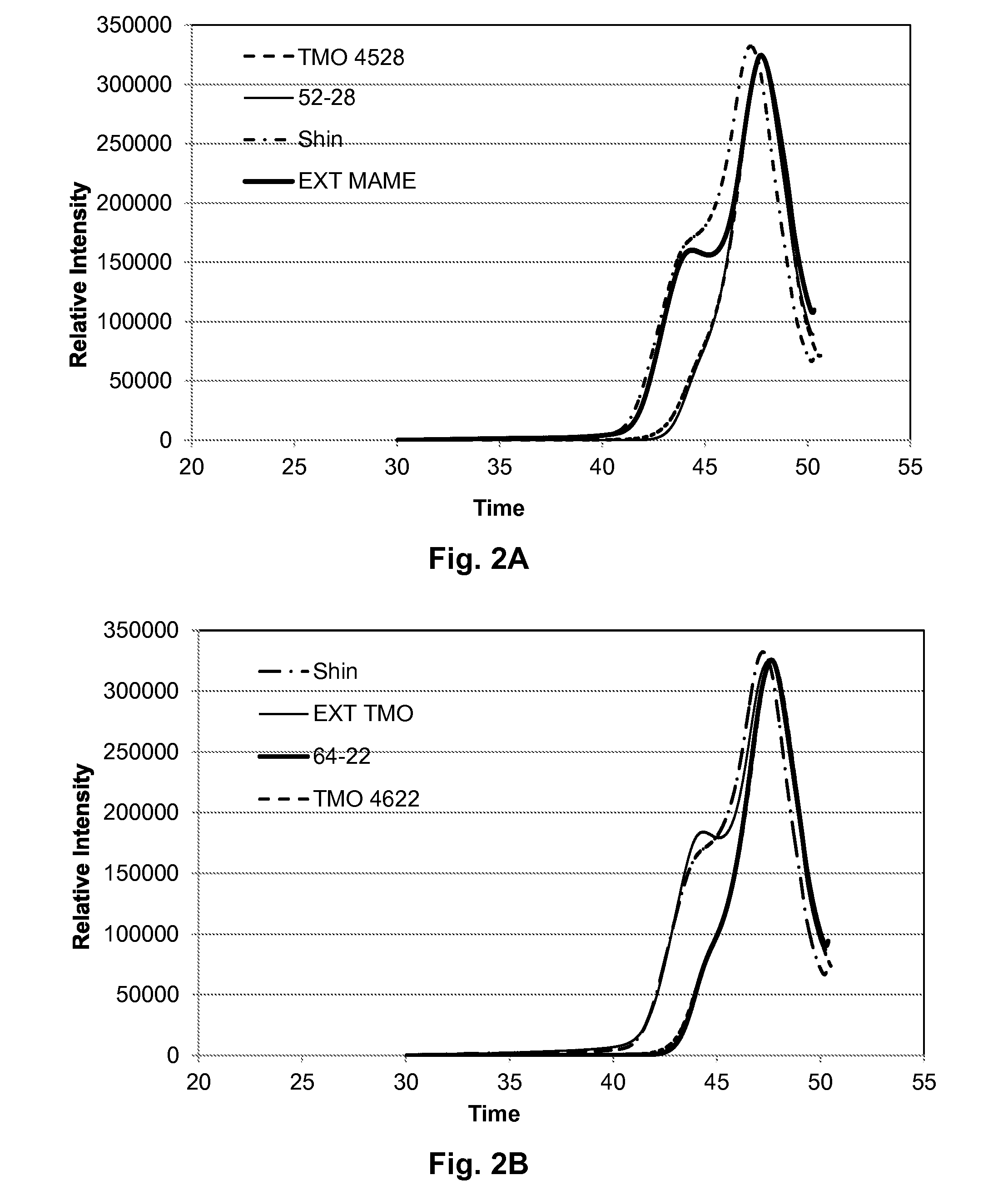

Certain aspects of the present invention are drawn recycled asphalt shingles-modified asphalt binder blends, mixes, and pavements, especially those comprising a mineral acid. Recycled asphalt shingles material may come from manufacturer asphalt shingle waste or from consumer asphalt shingle waste. It has been discovered that addition of a mineral acid significantly improves various rheological properties. Methods of making such asphalt binders, mixes, and pavements and their use are also disclosed.

Owner:ICL PERFORMANCE PROD

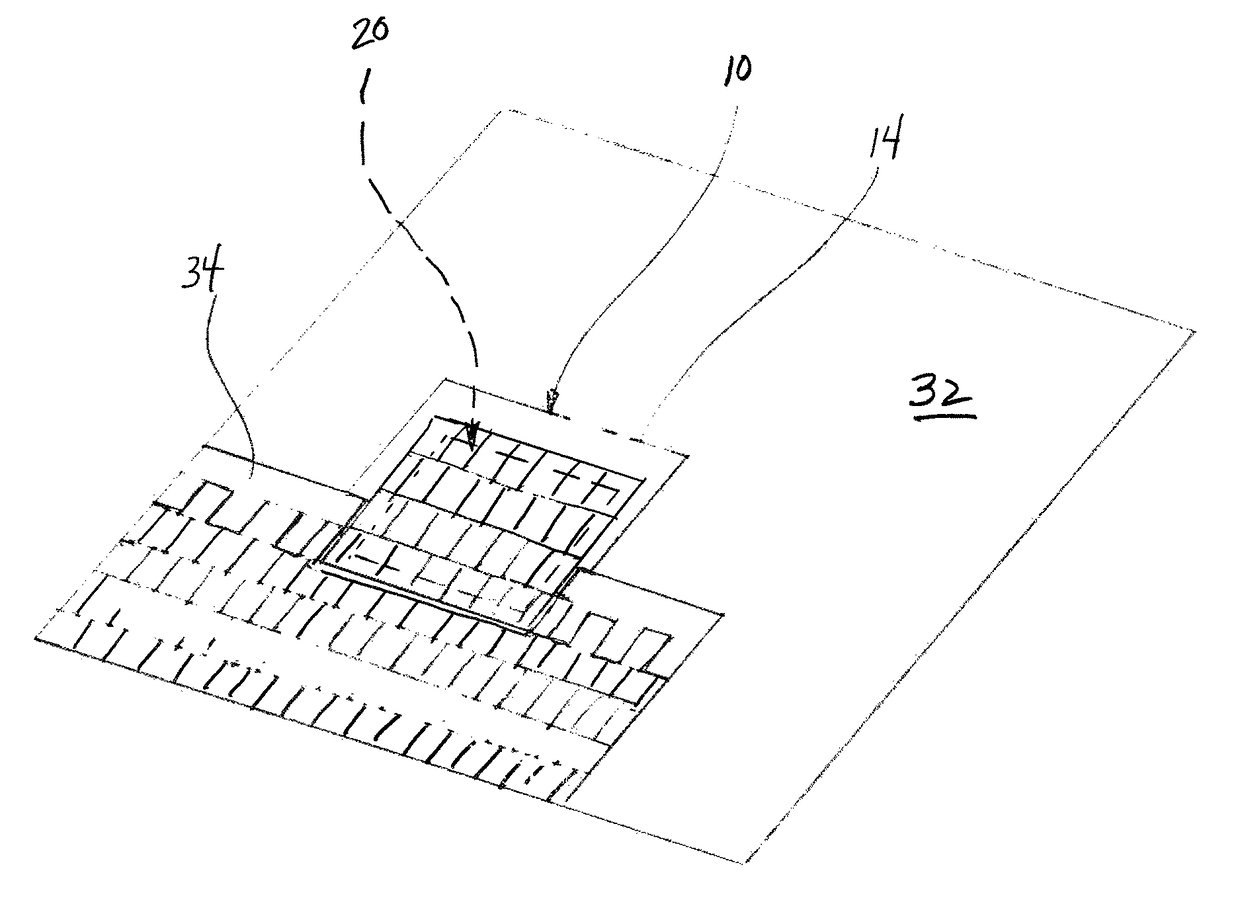

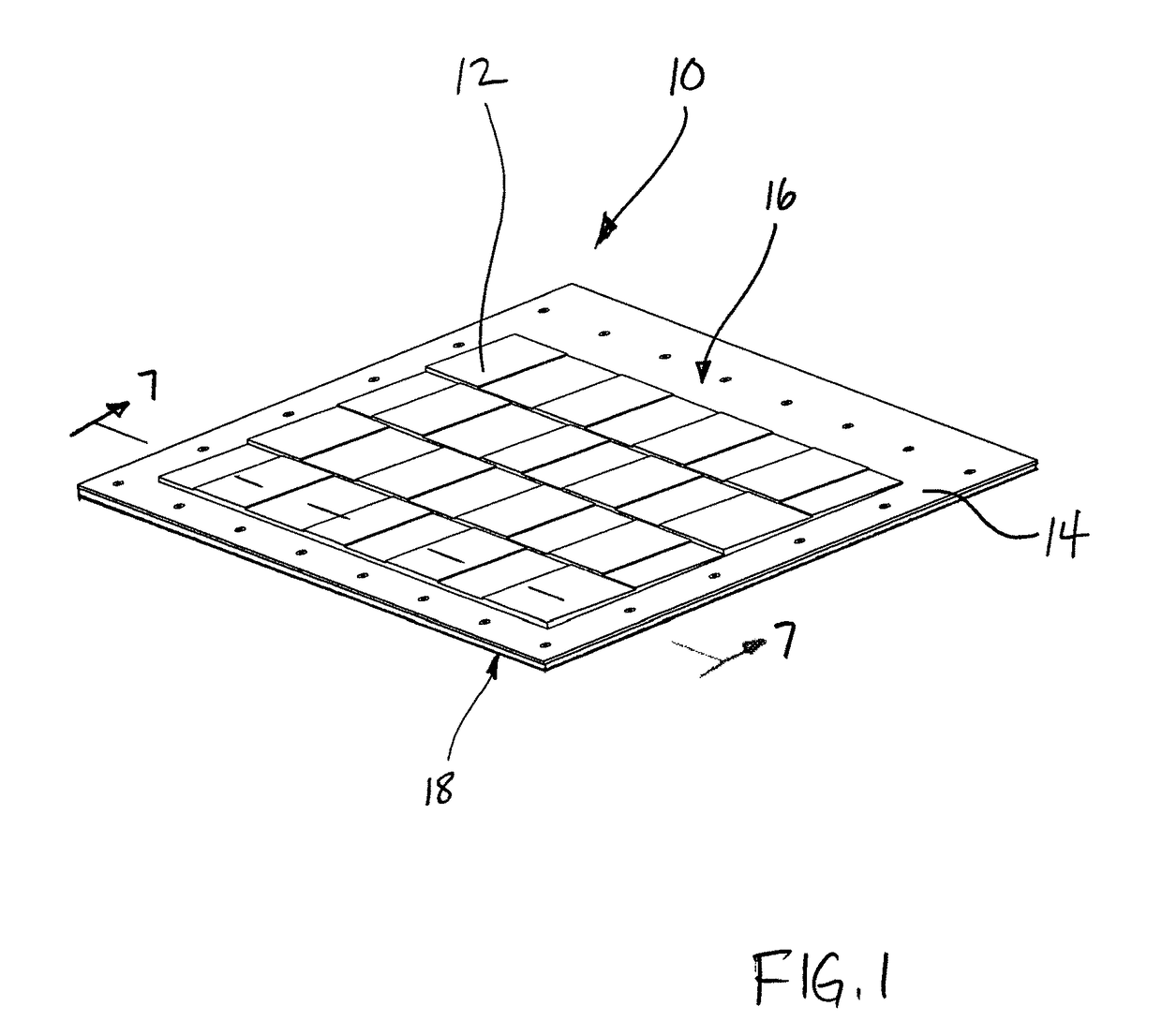

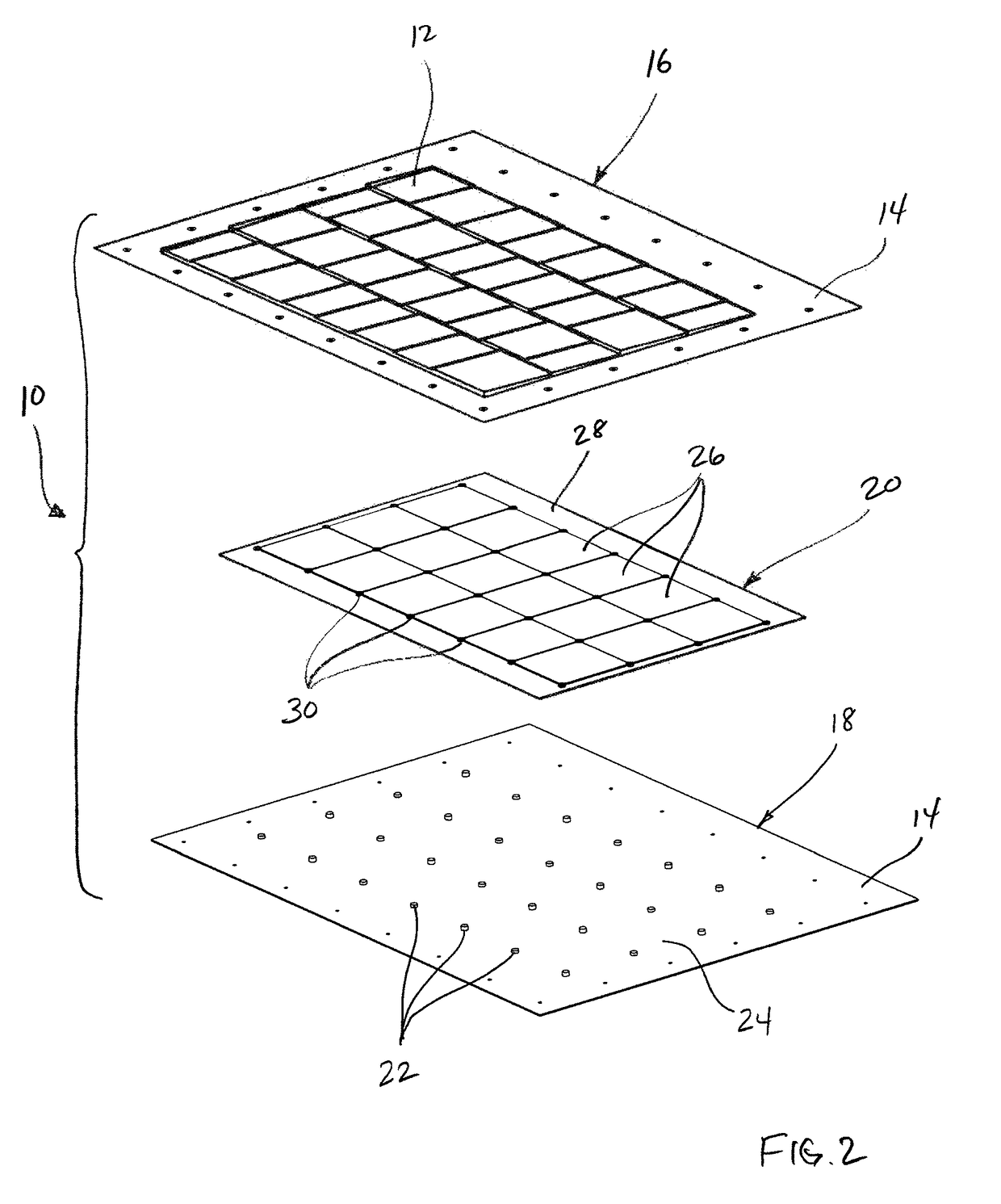

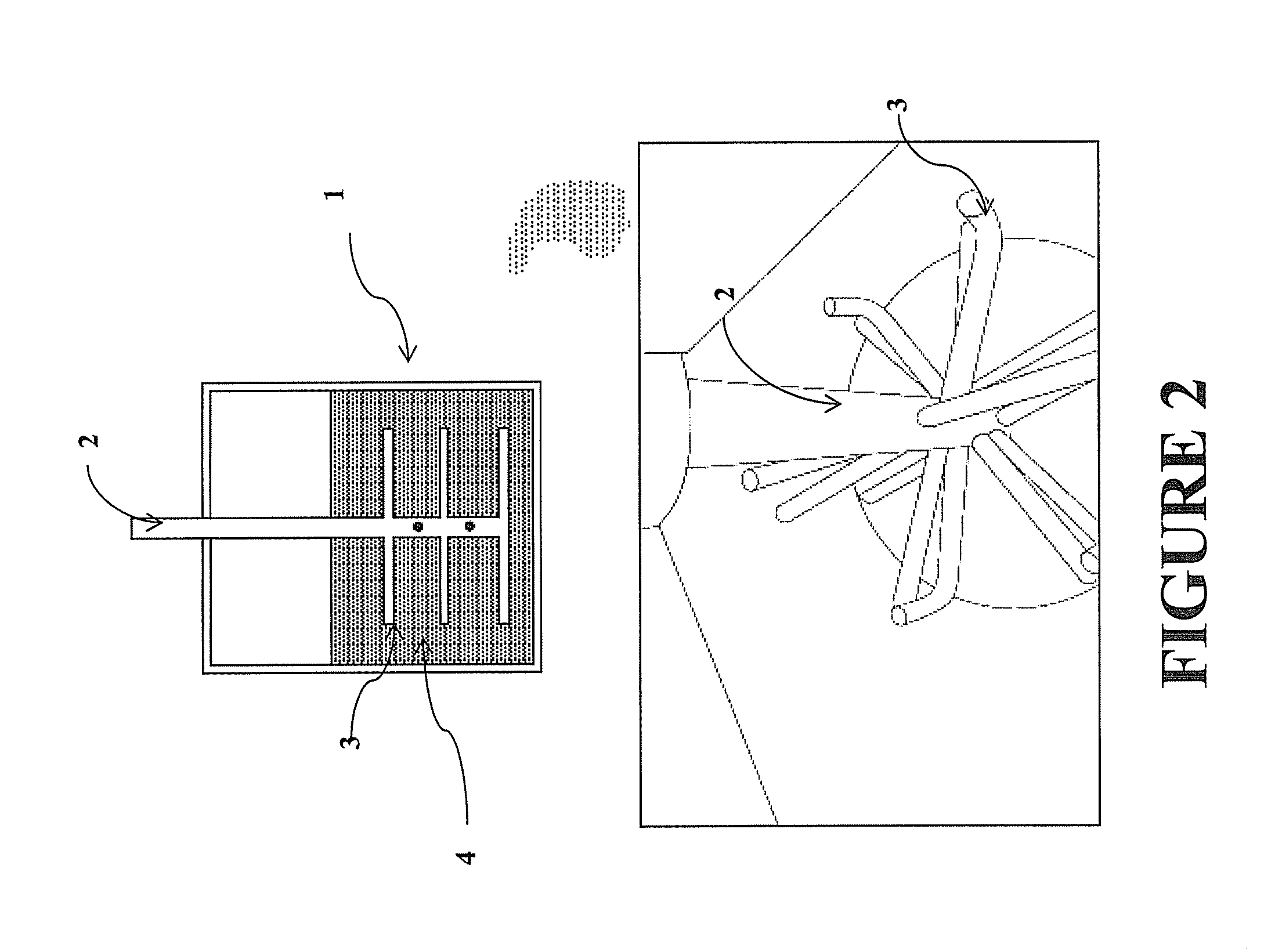

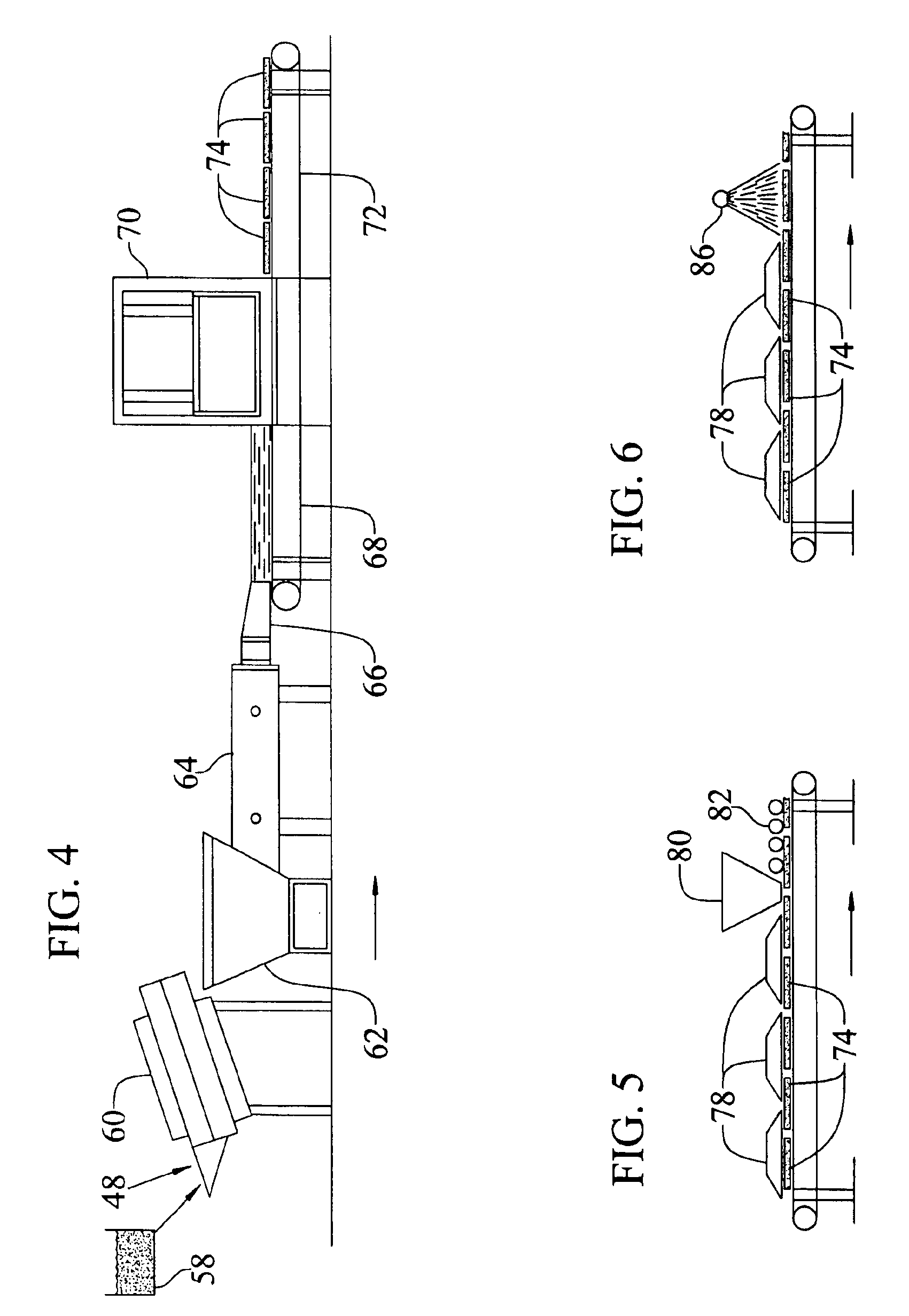

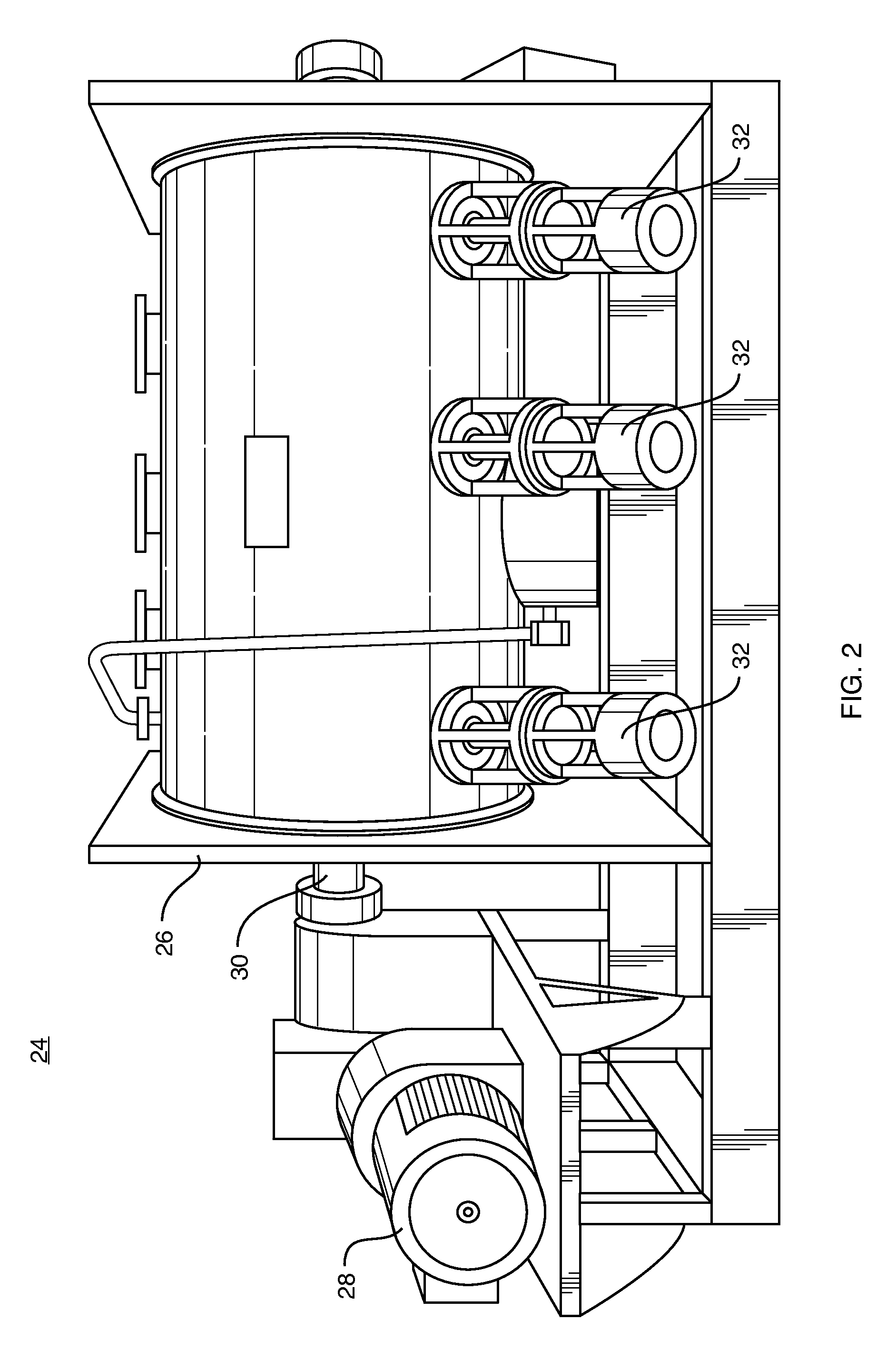

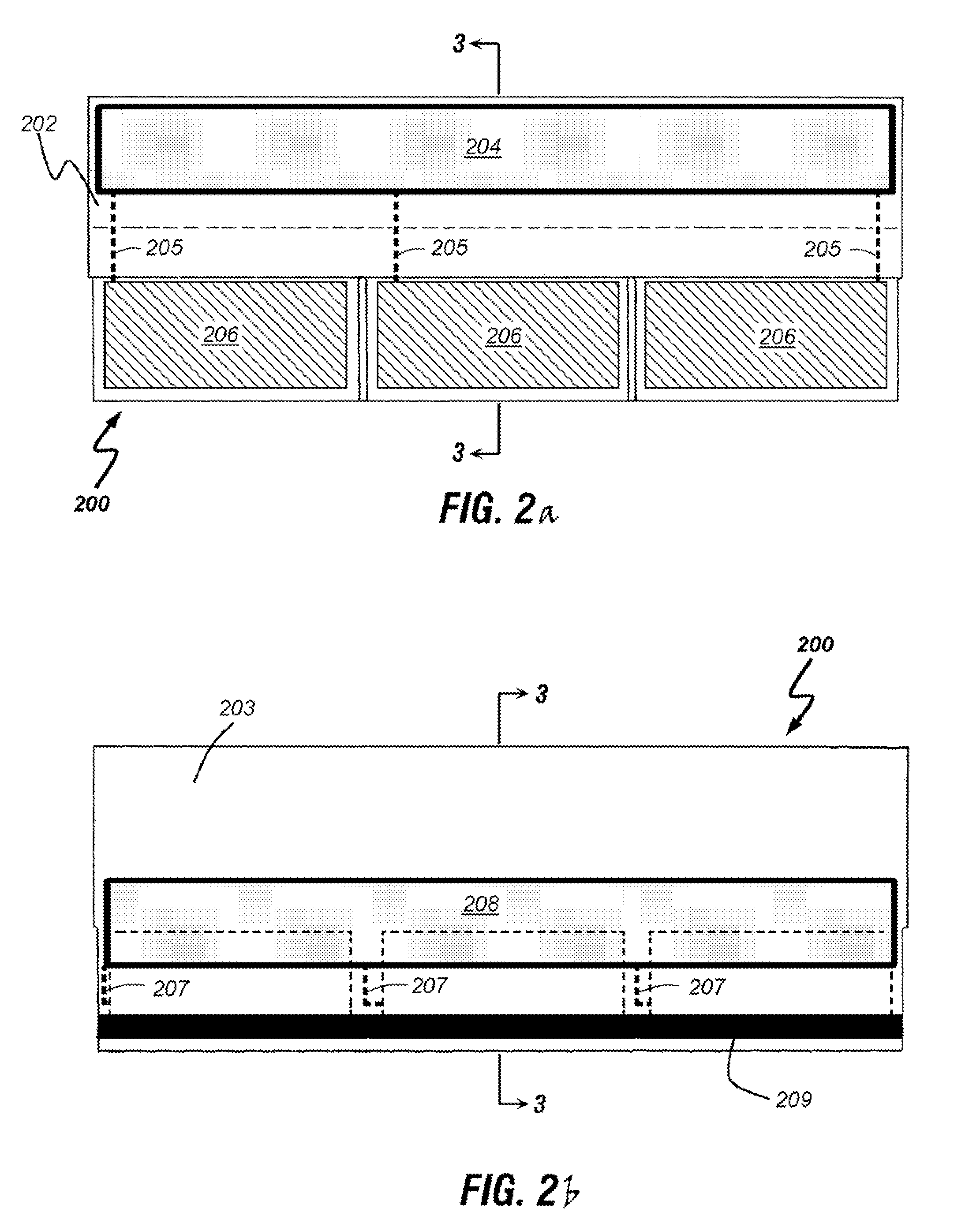

Roofing panels with integrated photovoltaic cells and method of installation

ActiveUS9825582B2Good dimensional stabilityEasy to installPhotovoltaic supportsRoof covering using slabs/sheetsAsphalt shingleSolar power

A photovoltaic roofing panel, method of making an method of installing a roofing panel is disclosed, which includes a bottom panel having a lower surface configured to be secured to the roof of a building; a top panel; and at least one photovoltaic cell captured between the top panel and the bottom panel, where the roofing panel is configured to be fastened directly to the roof, and roofing materials, such as asphalt shingles, are configure to abut the roofing panel, forming a more seamless and aesthetically pleasing roofing structure that also generates solar power.

Owner:COGITUR INC

Composition and method of sealing and protecting asphalt shingles or other porous roofing and construction materials

Sealing compositions and application methods for sealing and protecting asphalt roof shingles or other porous roofing and construction materials are described for eliminating algae, mold and mildew, increasing granular adhesion, providing additional UV protection and significantly increasing the wind resistance of the roof or other construction material. The sealing composition includes an acrylic polymer that has been modified by a silicone surfactant to alter its wetting properties so as to promote wicking of the sealer under asphalt shingles and at open edges to prevent curling and water infiltration. The method of applying the sealing composition promotes uniform distribution of the product on the surface of installed roofs as well as enhances bonding between individual shingles by improved penetration on and between shingle layers to increase adhesion area.

Owner:ENVIROSEAL LLC

System and method for manufacturing asphalt products with recycled asphalt shingles

ActiveUS20160362339A1Minimize moisturePrevent excessive foamingIn situ pavingsRoof covering using tiles/slatesAsphalt shinglePrill

A method for manufacturing a processed asphalt suspension is provided. The method includes dry grinding shingle waste material to a particle size of less than 1 cm, forming ground recycled shingle material, introducing virgin asphalt into a heated slurry tank and mixing the ground recycled shingle material with the virgin asphalt in the heated slurry tank, forming a mixed asphalt slurry, introducing the mixed asphalt slurry into a wet grinding machine, and recovering a processed asphalt suspension comprising particles having a size no greater than about 200 microns. Roofing and paving products manufactured from the processed asphalt suspension are also provided.

Owner:HERITAGE RES GROUP LLC

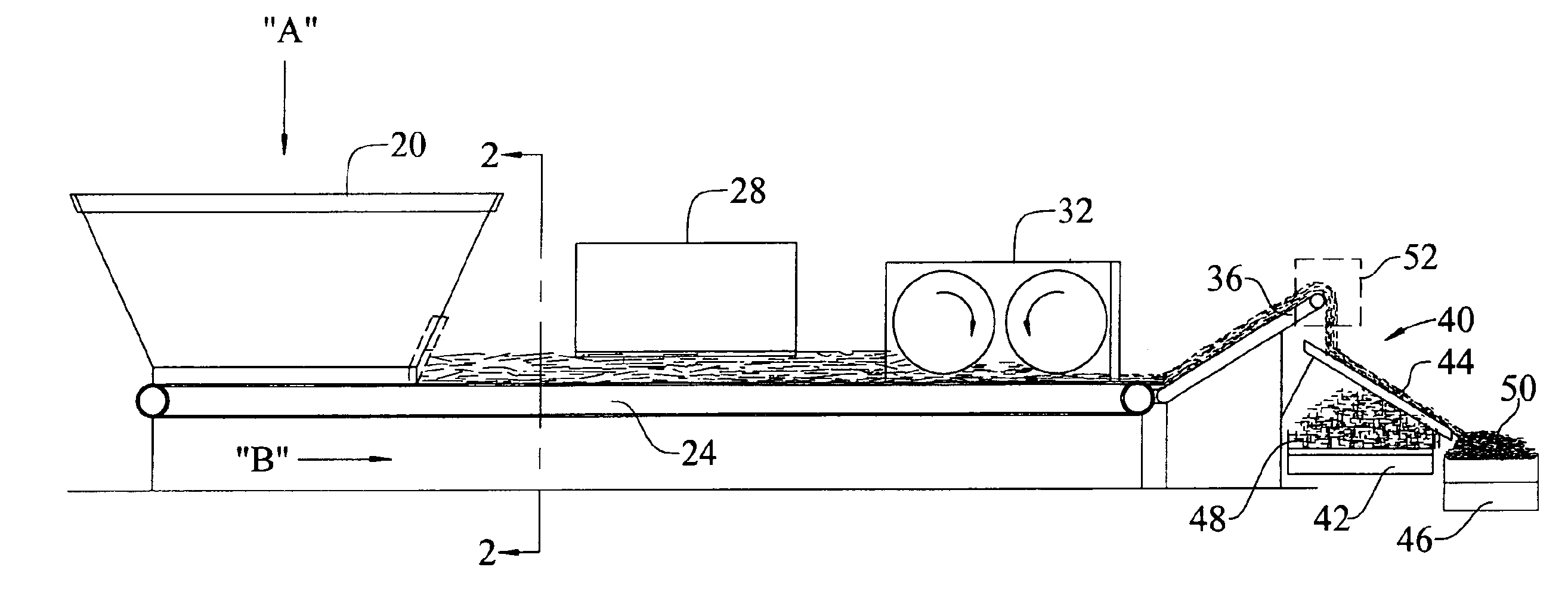

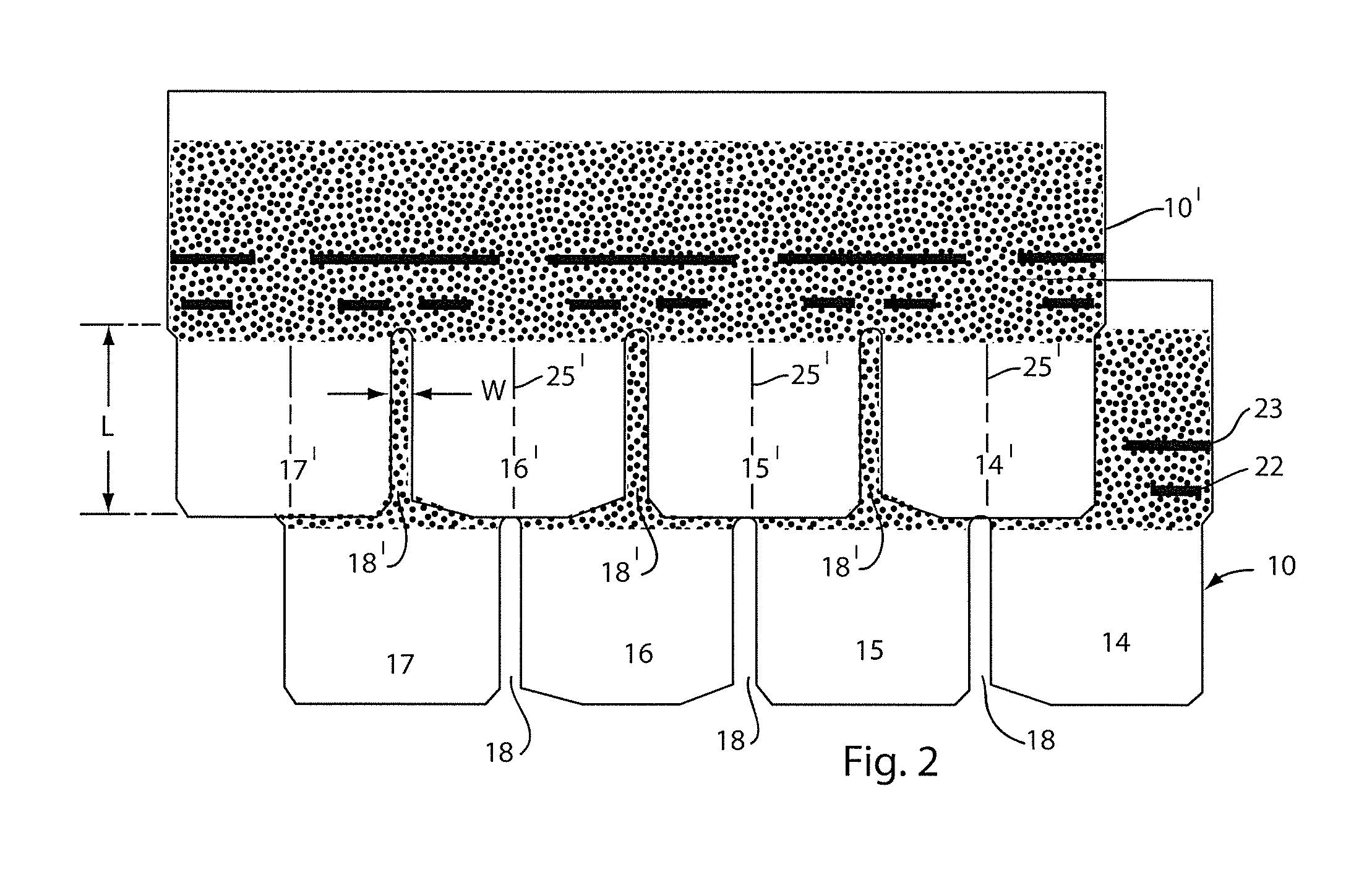

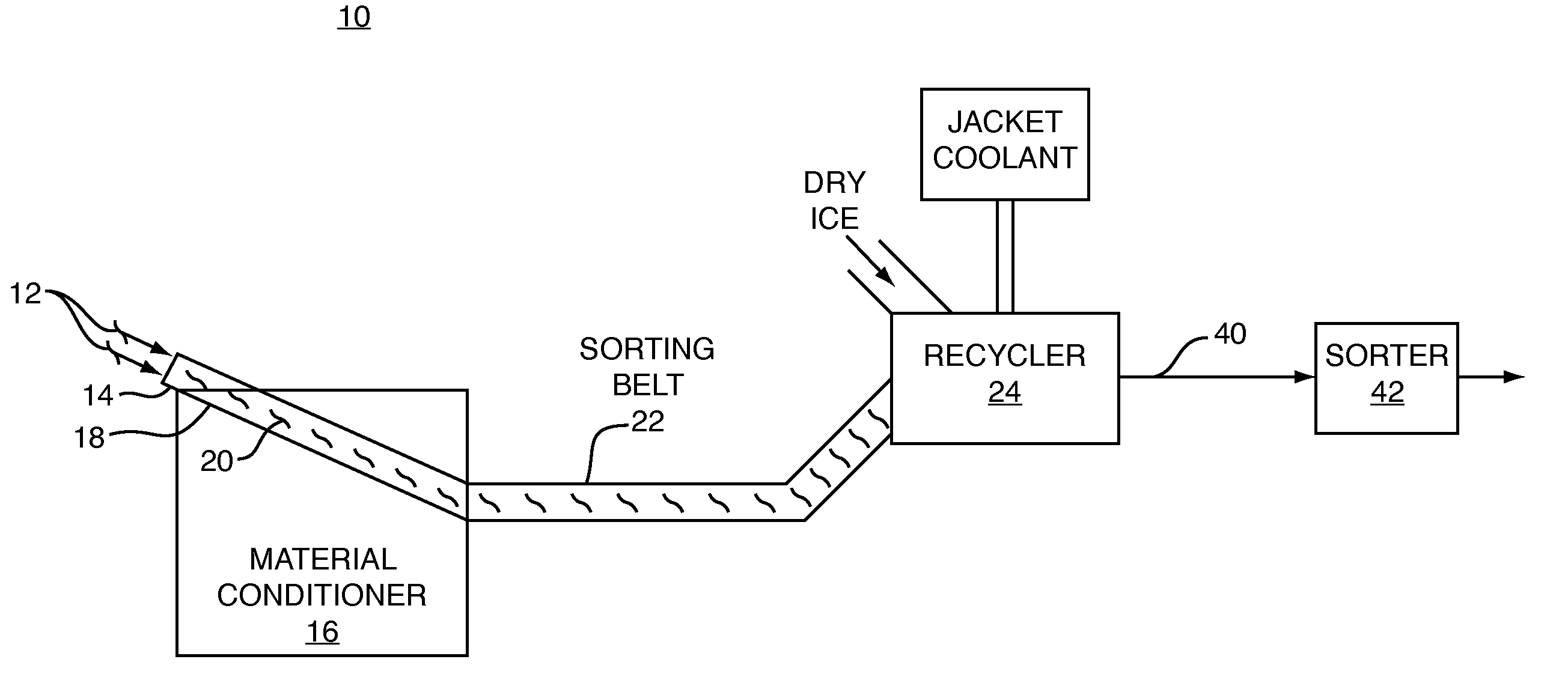

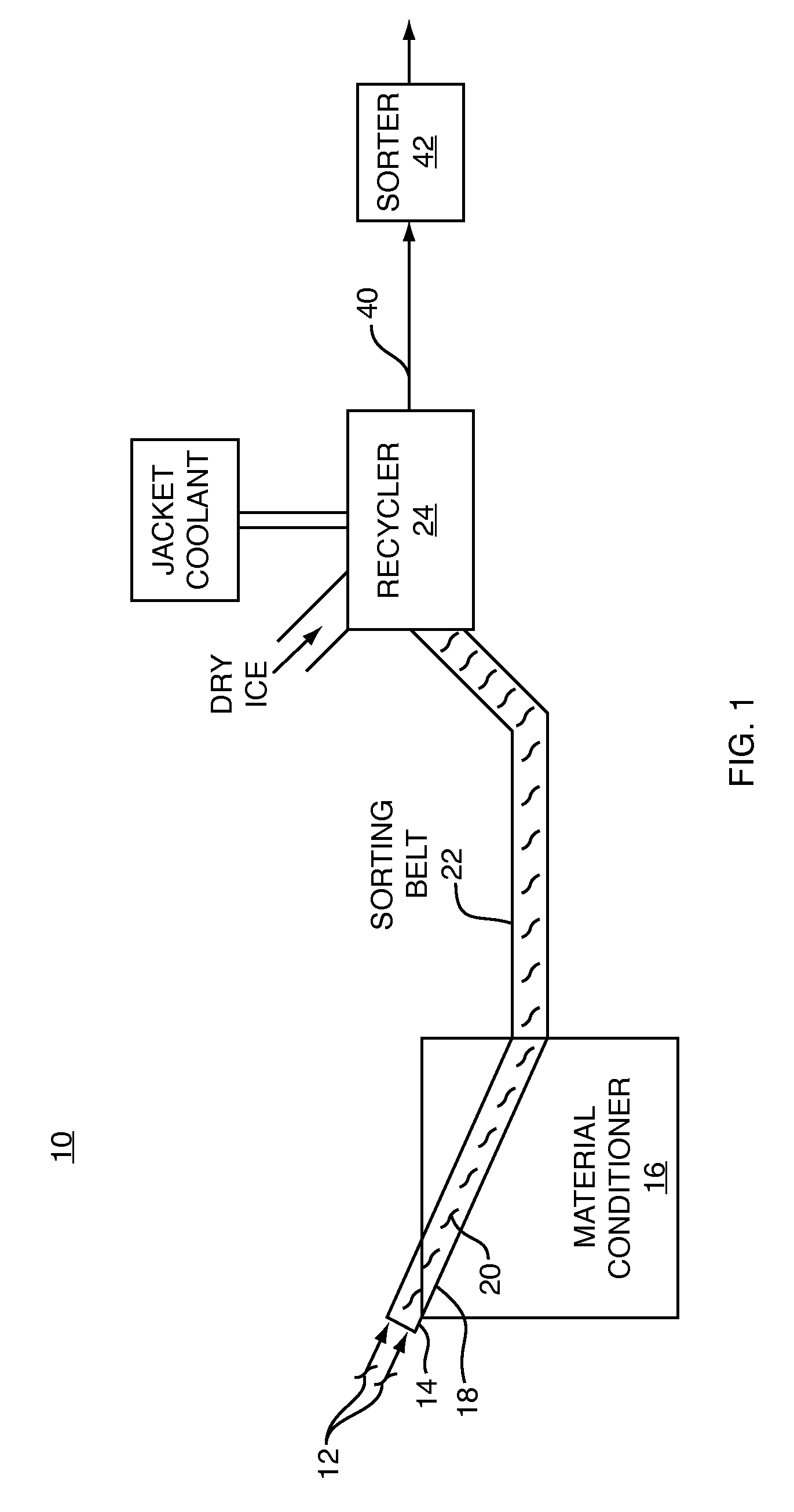

Asphalt shingle recycling system and method

ActiveUS20090229491A1Small particle sizeImprove consistencySolid waste disposalPlastic recyclingAsphalt shingleSolid particle

The asphalt roofing material is delivered into a treatment chamber of a processor. Hot oil is passed through a jacket surrounding the treatment chamber. Heated asphalt forms a hot solid and / or a liquefied slurry. The hot solid and / or the liquefied slurry is then removed from the treatment chamber. The asphalt roofing material in the treatment chamber can be agitated to promote mixing. The asphalt is heated to a temperature in the range from 200 degrees Fahrenheit to 650 degrees Fahrenheit within the treatment chamber. The solid and / or liquefied slurry is milled after it has been removed from the treatment chamber. The solid and / or the liquefied slurry is cooled after it exits the treatment chamber, preferably to a temperature in the range of approximately 90 degrees Fahrenheit to 110 degrees Fahrenheit. The hot solid and / or the liquefied slurry is passed through a hammer mill after the hot solid and / or the liquefied slurry exits the treatment chamber to reduce the particle size of the solid particles.

Owner:DUPPS

Asphalt Shingle with Lightweight Structural Aggregate and Method for Making Same

InactiveUS20120258282A1Overcome disadvantagesRoof covering using tiles/slatesTraffic signalsAsphalt shinglePolymer chemistry

A shingle includes a reinforcing mat layer, an asphalt layer and an exterior layer. The asphalt layer is on top of the mat layer. The exterior layer includes structural-grade lightweight aggregate granules that are disposed on top of the asphalt layer. In making a roofing shingle, a mineral composition is heated to cause the mineral composition to fuse. The fused and expanded mineral composition is milled to form lightweight structural-grade aggregate granules. An asphalt layer is deposited onto a top surface of a reinforcing mat layer. A layer of structural-grade lightweight aggregate granules is applied onto the top layer. An adhesive asphalt strip is applied onto the layer of structural-grade lightweight aggregate granules. A lightweight aggregate pulverized dust is applied to a bottom surface of the mat layer.

Owner:BIG RIVER INDS

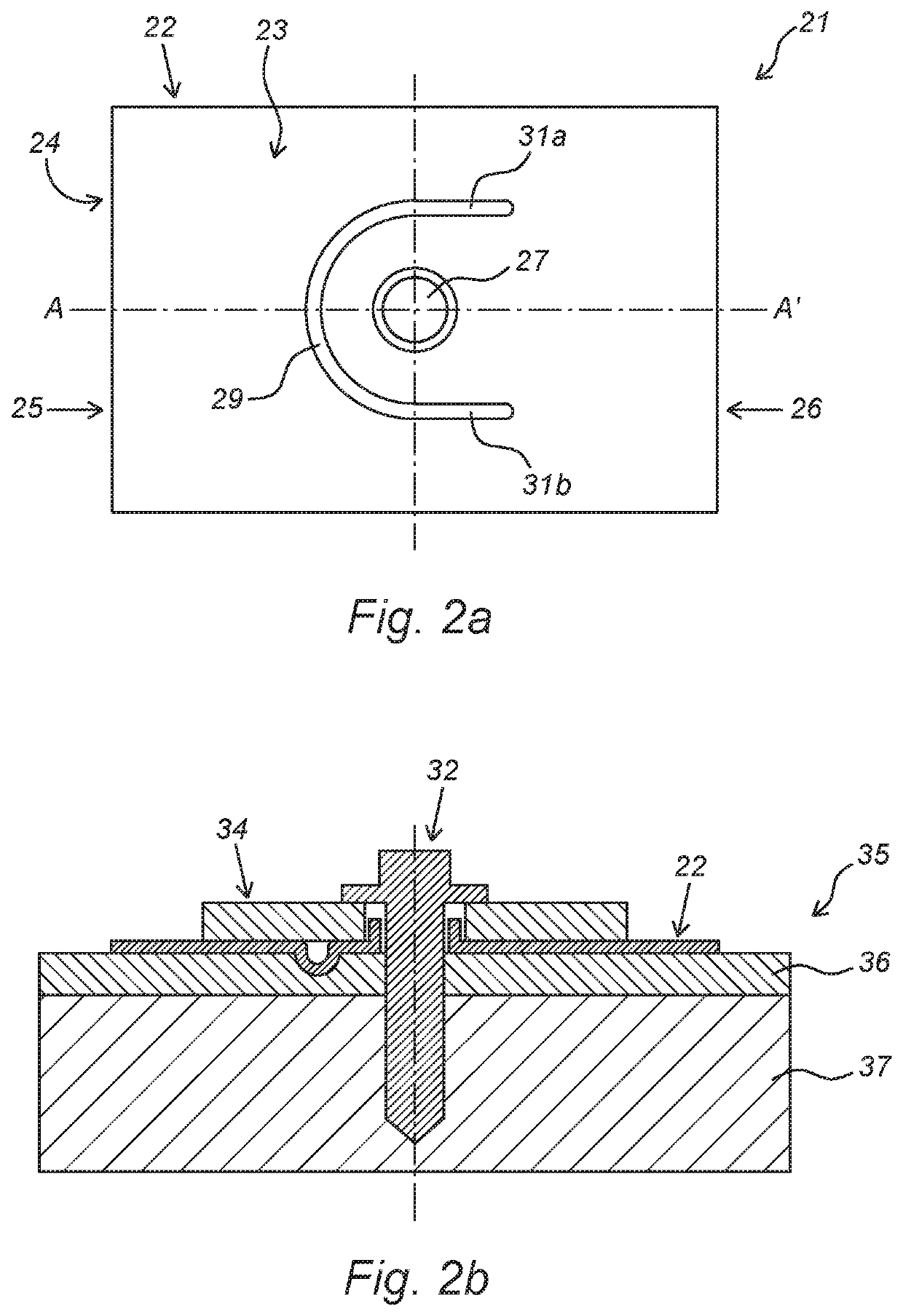

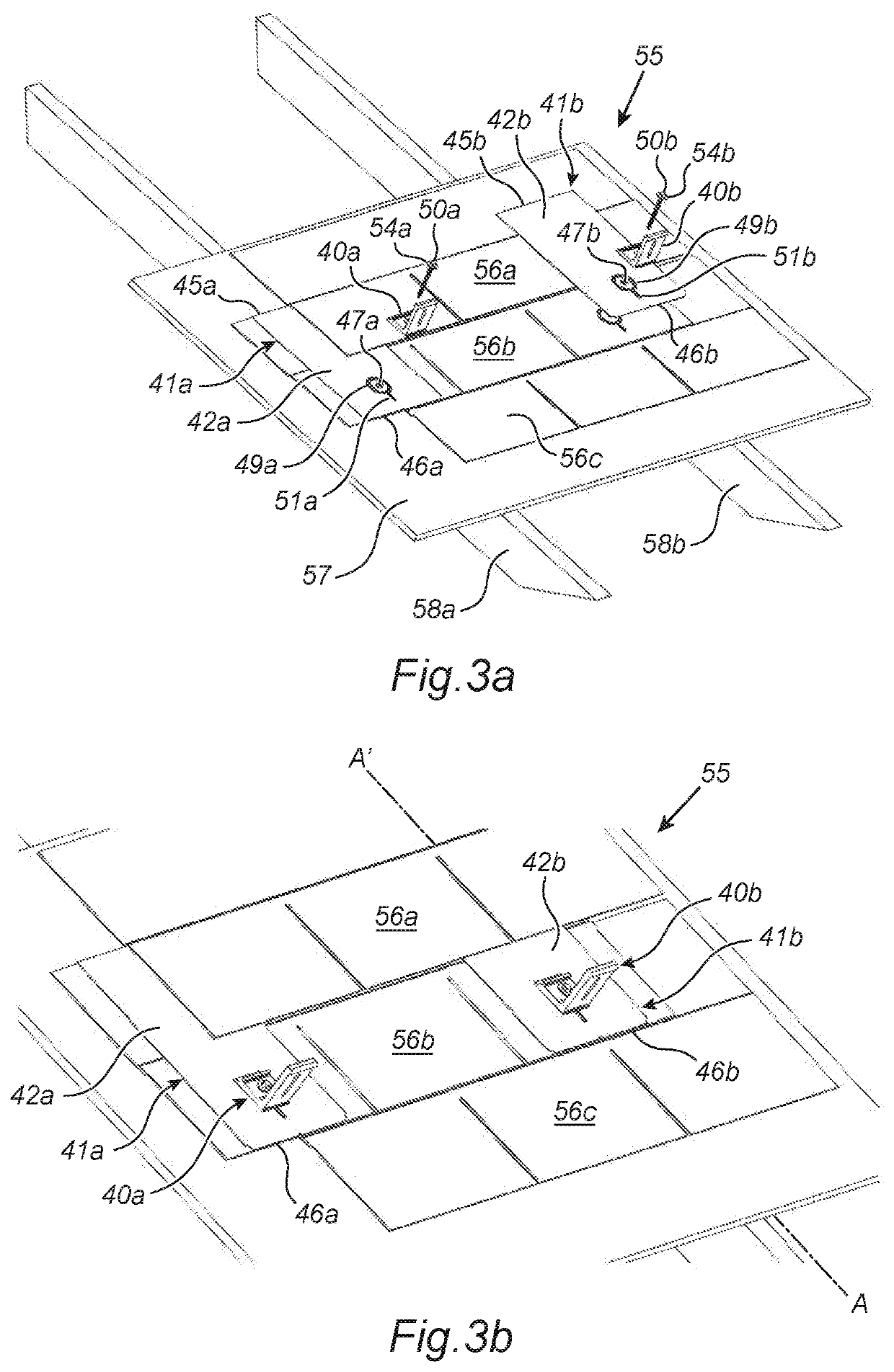

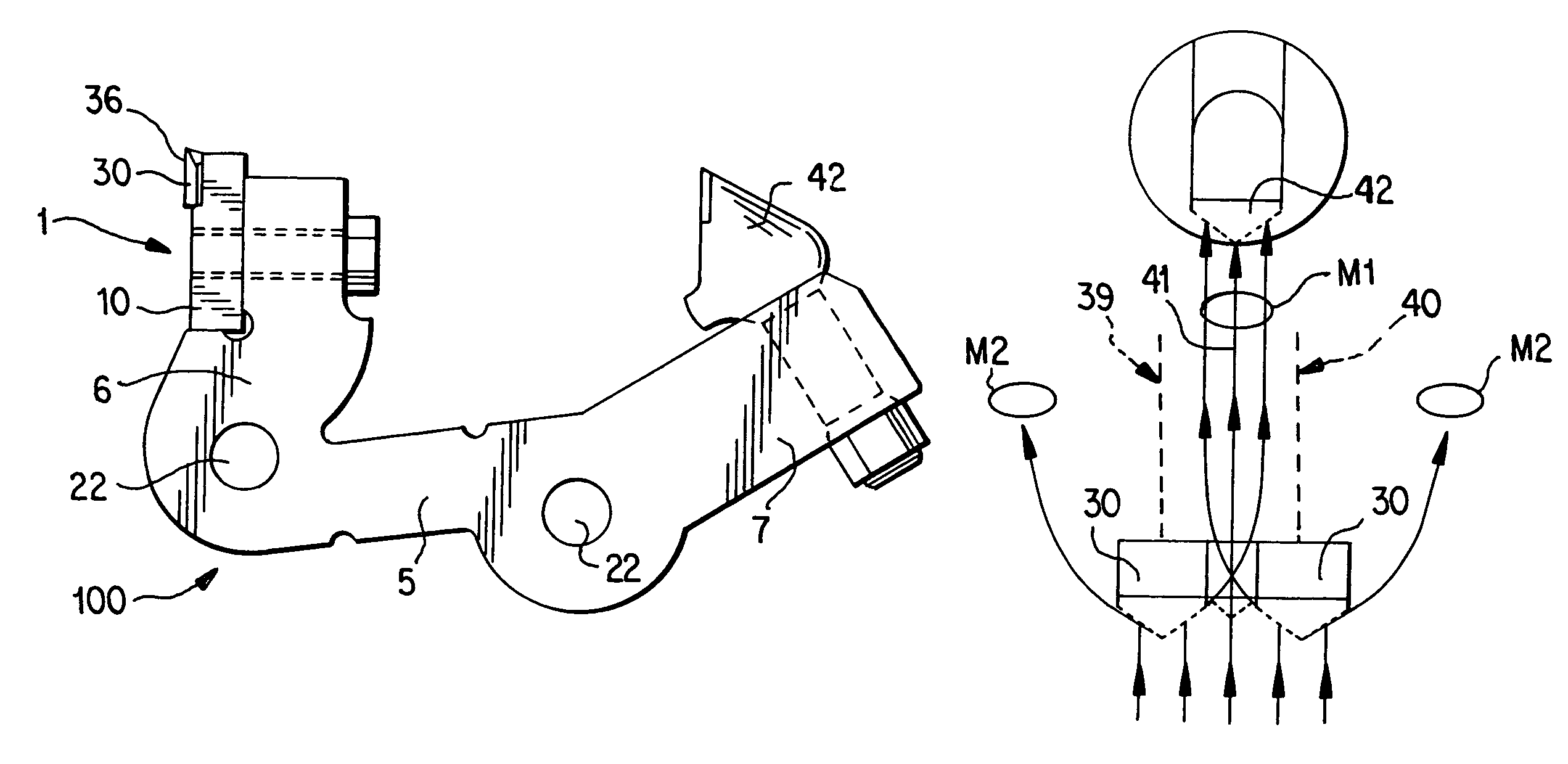

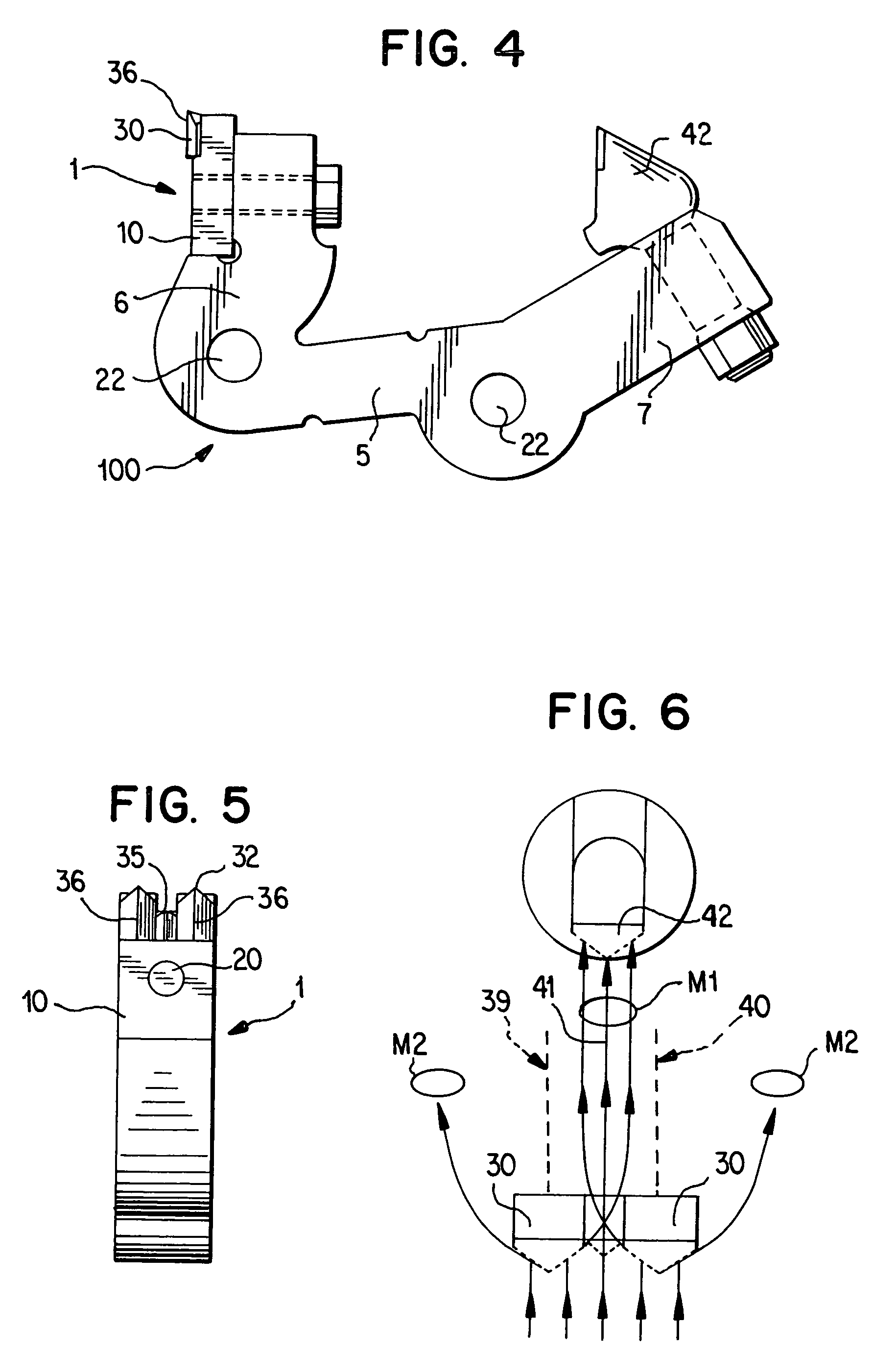

Fastening structure and method for fitting a coupling profile to a pitched roof covered with shingles

ActiveUS10551090B2Reduce riskEasy to drainPhotovoltaic supportsSolar heating energyAsphalt shingleMansard roof

The invention relates to a fastening structure for being able to fit a coupling profile, in particular for fastening solar panels, to a pitched roof covered with bituminous shingles. The invention also relates to an assembly which includes a fastening structure according to the invention. The invention further relates to a kit of components which includes a fastening structure according to the invention. The invention further relates to a method for fitting a coupling profile, in particular for fastening solar panels, to a pitched roof covered with bituminous shingles, by using a fastening structure according to the invention.

Owner:ESDEC

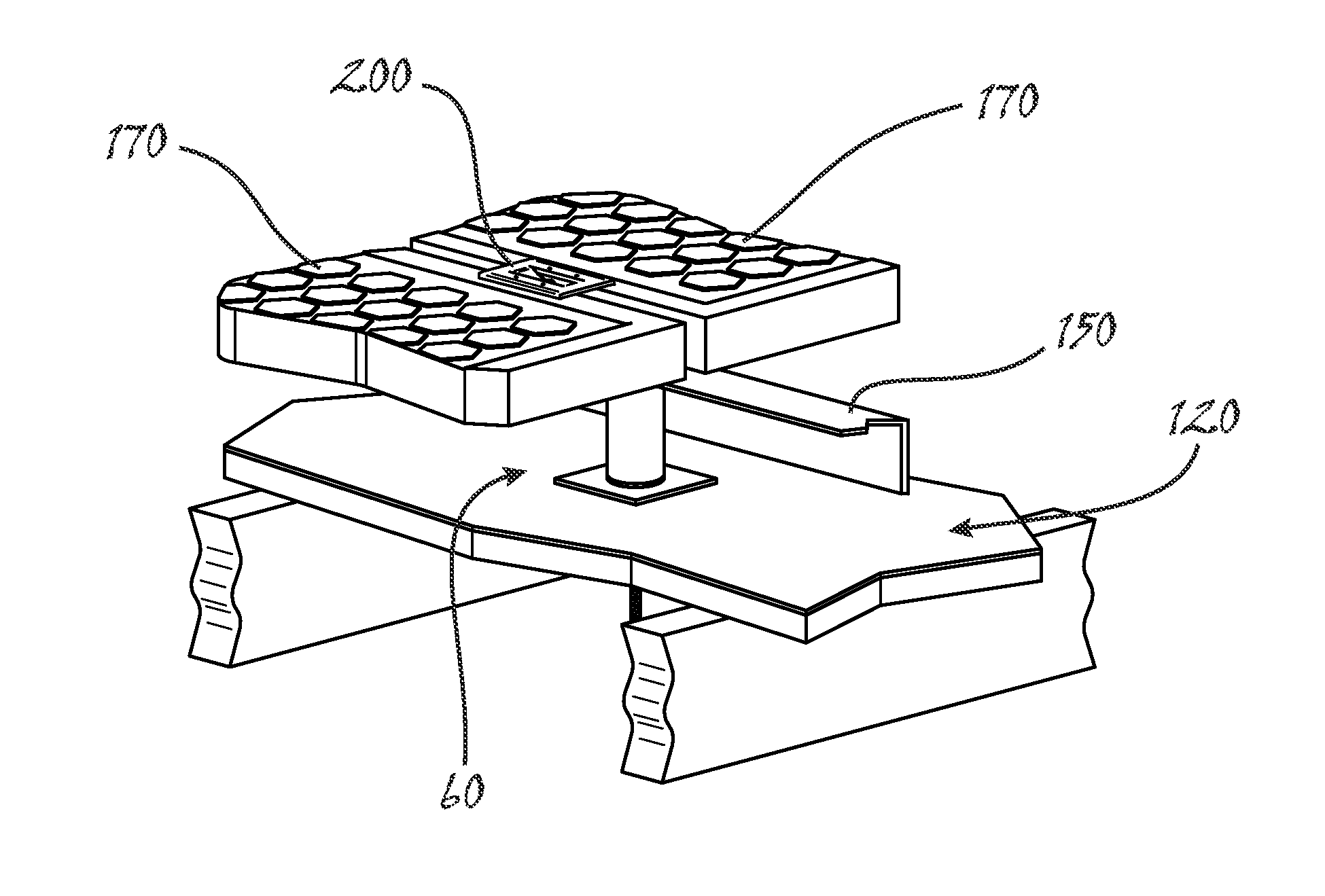

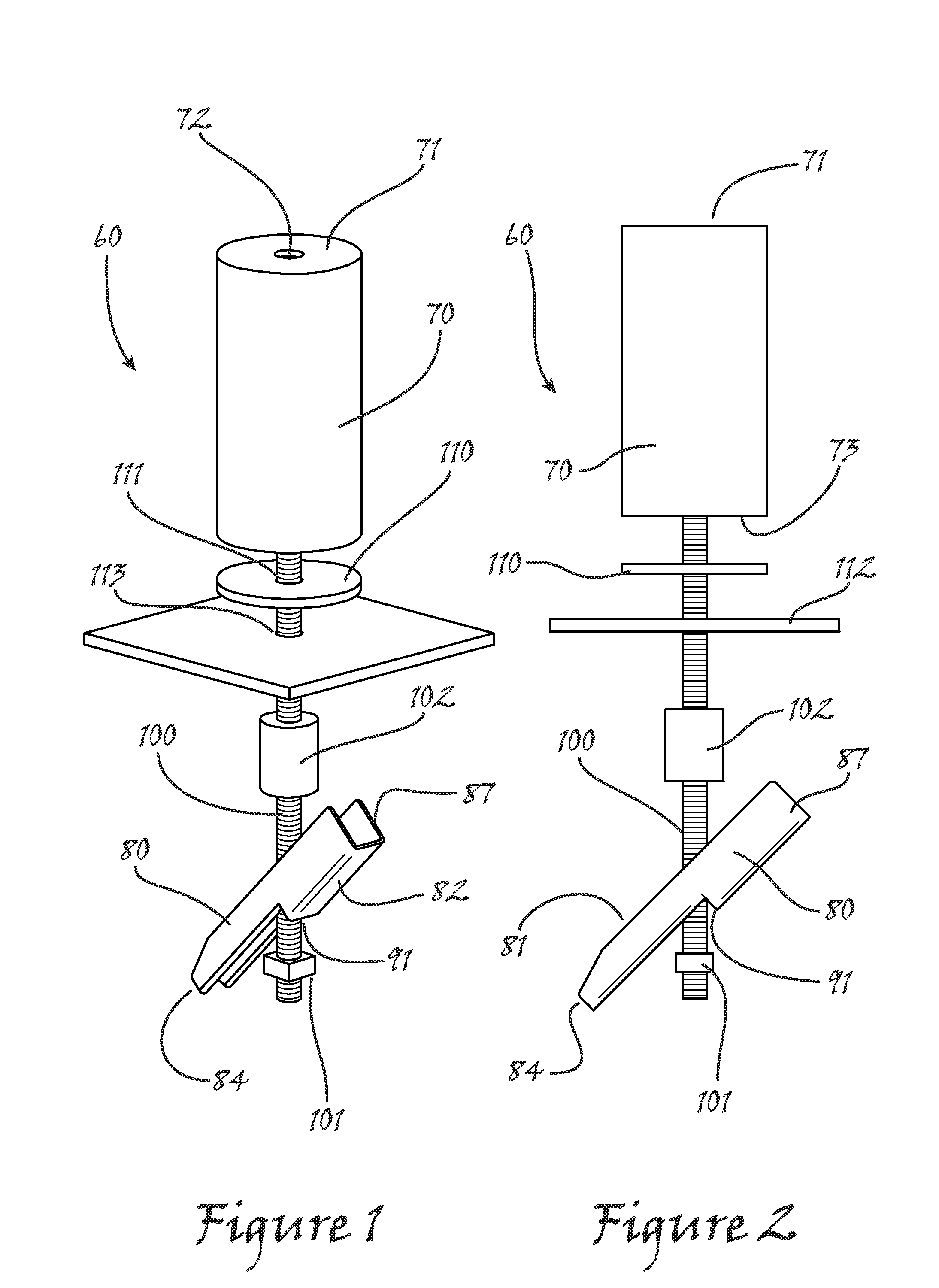

Photovoltaic panel racking assembly for use in connection with roof installation of panels

InactiveUS20130240466A1Help positioningImprove sealingPhotovoltaic supportsSolar heating energyAsphalt shingleEngineering

A photovoltaic panel racking assembly (60) includes a cylindrically shaped standoff (70) cooperatively adjoined to a specially formed toggle (80) through an all thread rod (100). A nut (101) is sized and shaped to operatively engage with the toggle (80) to fix the relative position of the toggle (80) and the nut (101). A rubber gasket (110) is provided in order to promote watertight sealing upon installation and during use of the racking assembly (60). A relief plate (112) may be provided in order to prevent installation damage to more generally fragile roofing materials such as asphalt shingles or like composite roofing (128). A rubber sleeve (102) is provided in order to facilitate positioning of the toggle (80) during installation of the racking assembly (60). Brackets (180, 200) are described for affixing one or more photovoltaic panels (170) to the racking assembly (60).

Owner:SPONSELLER GREGORY W

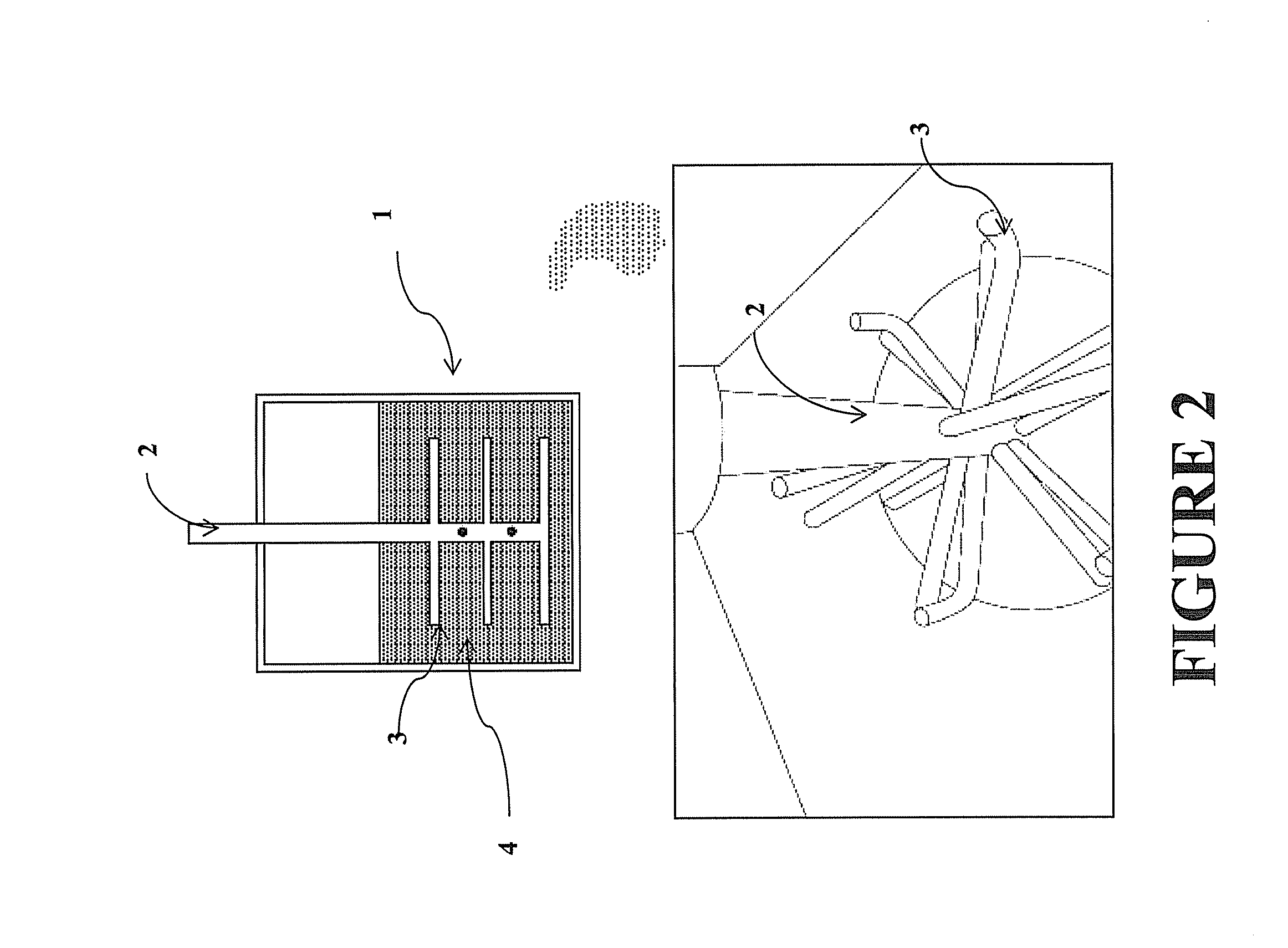

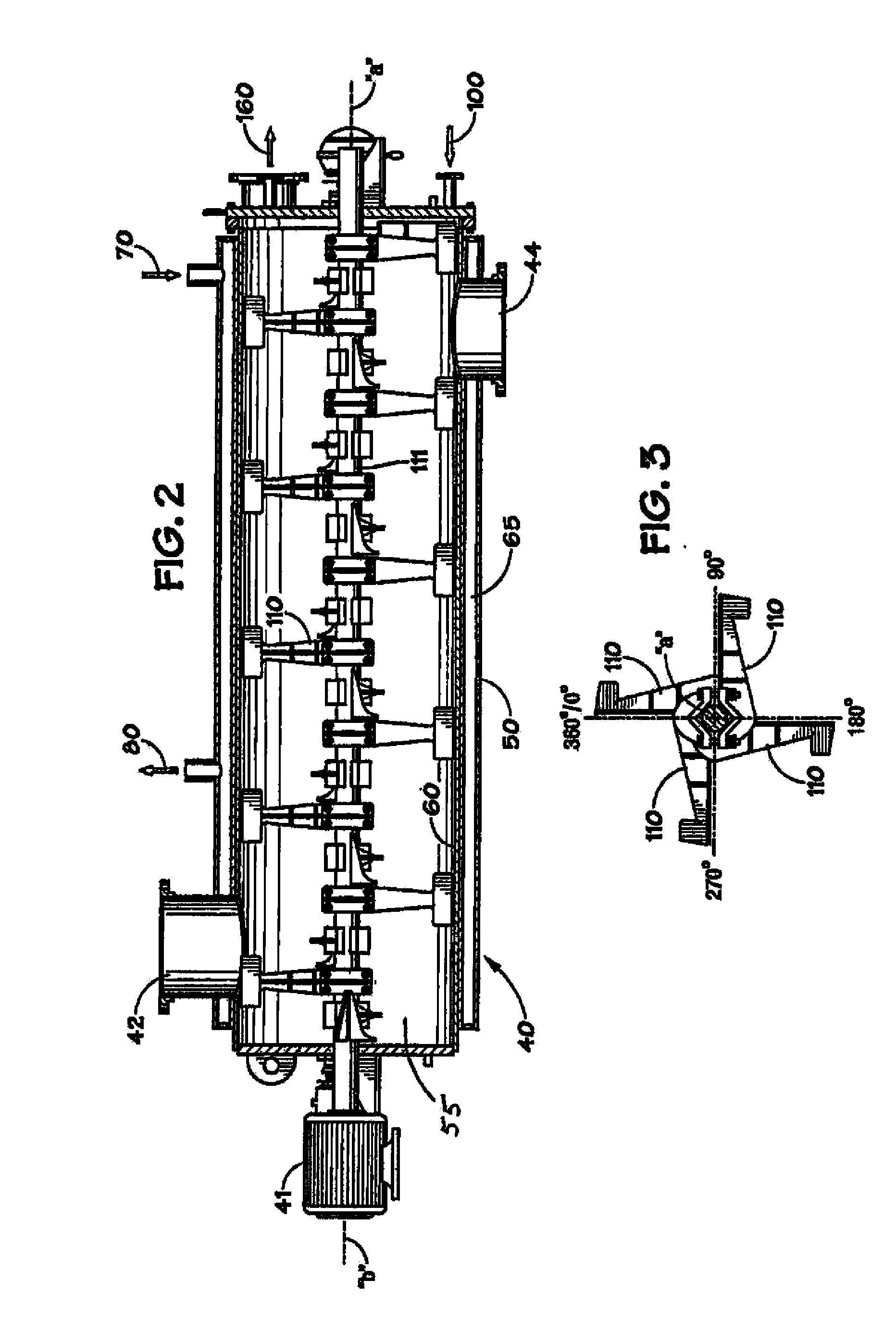

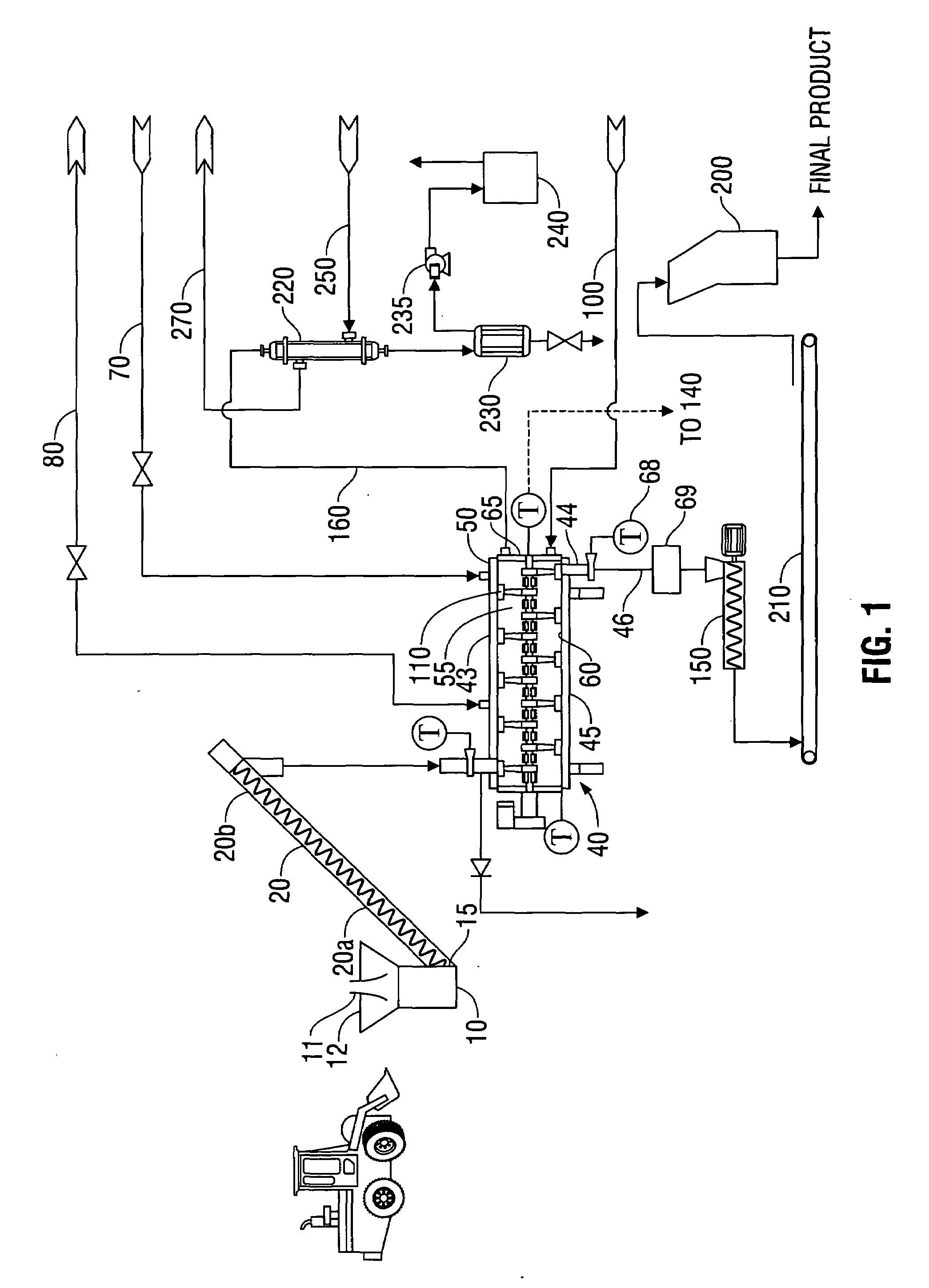

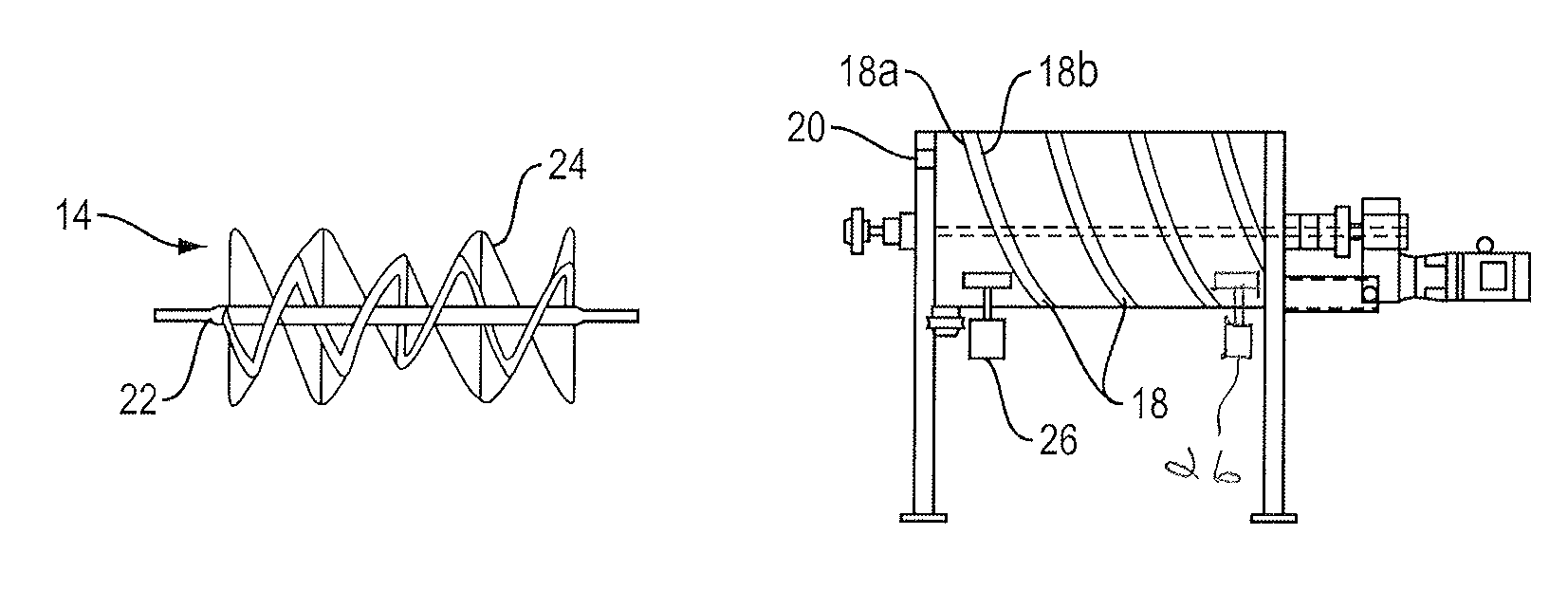

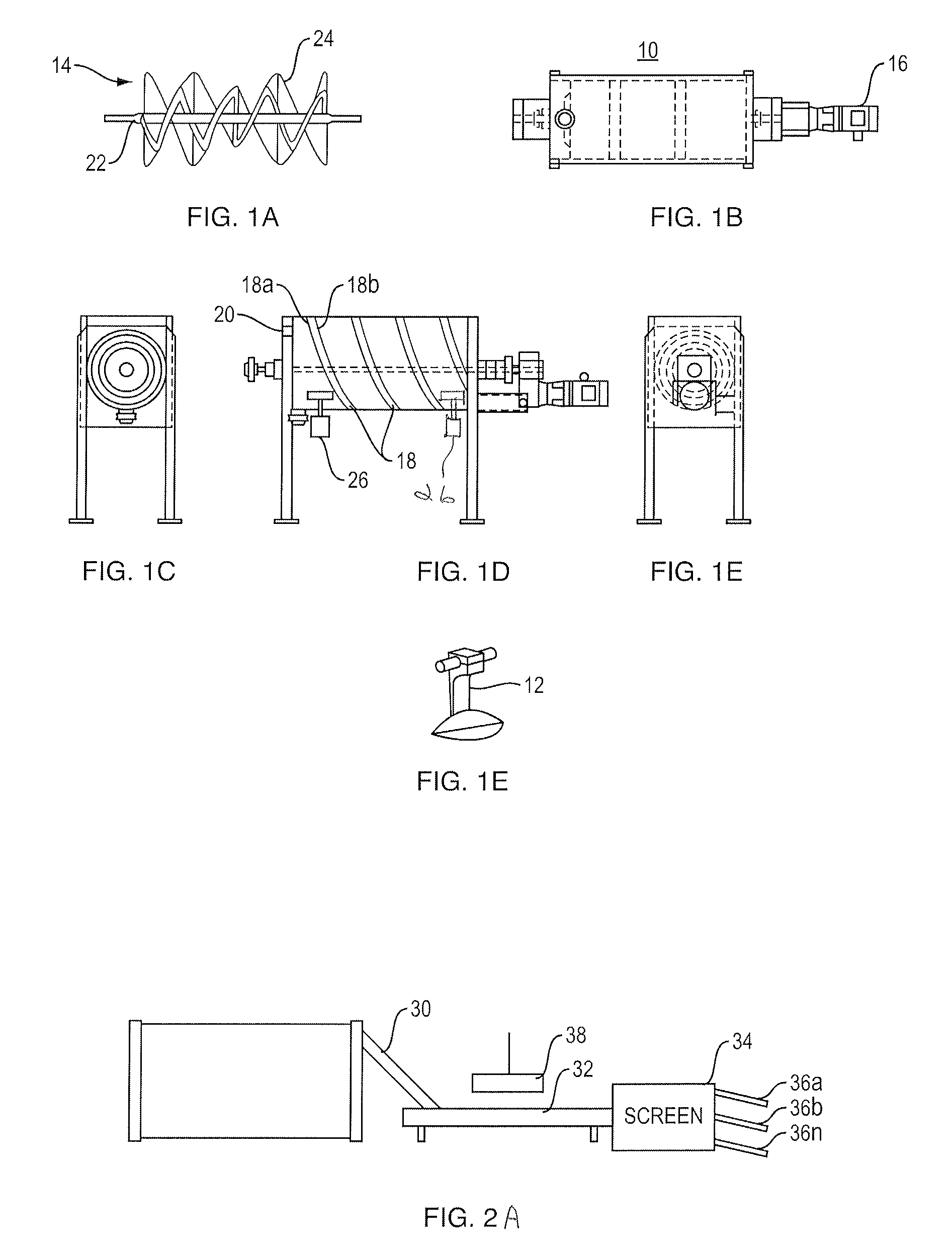

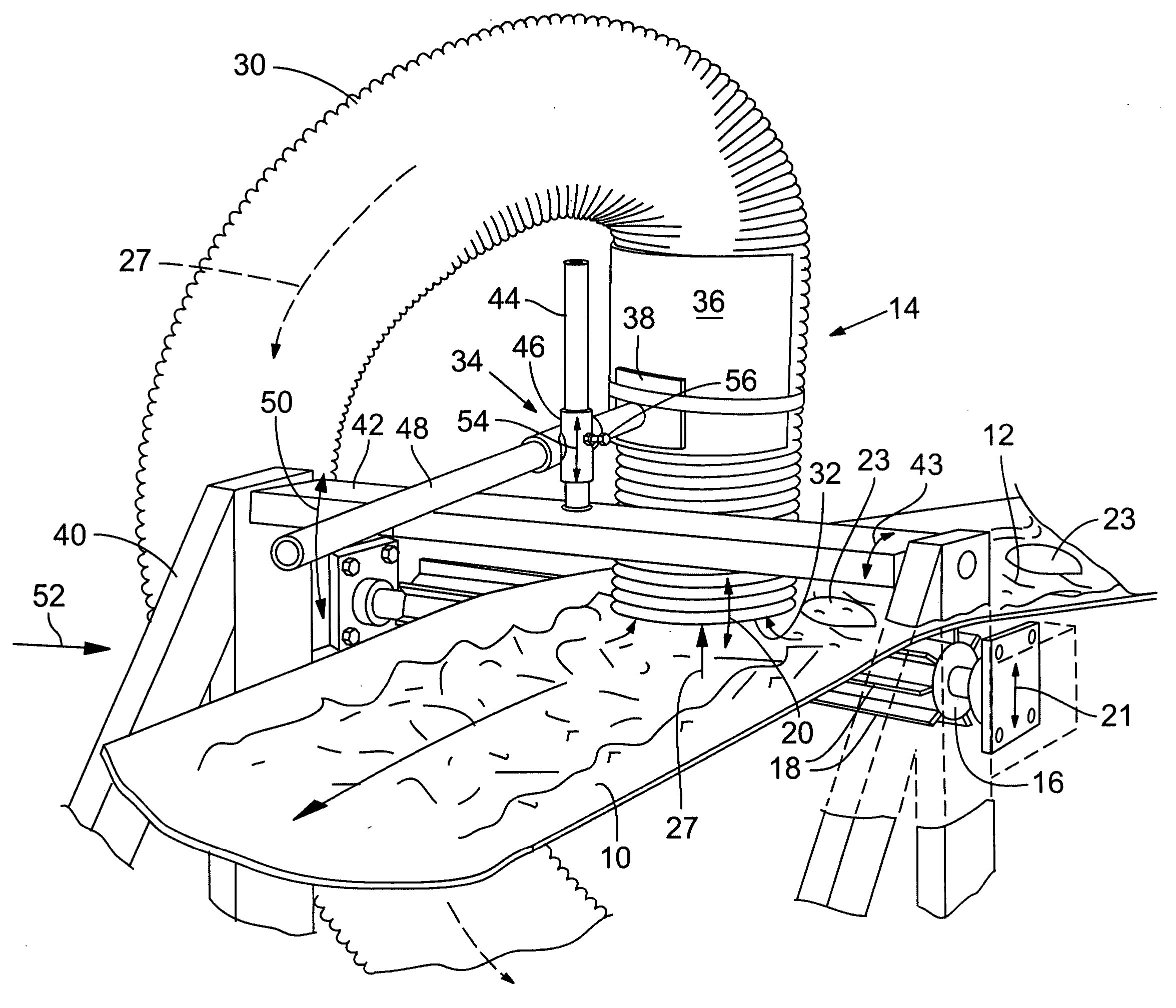

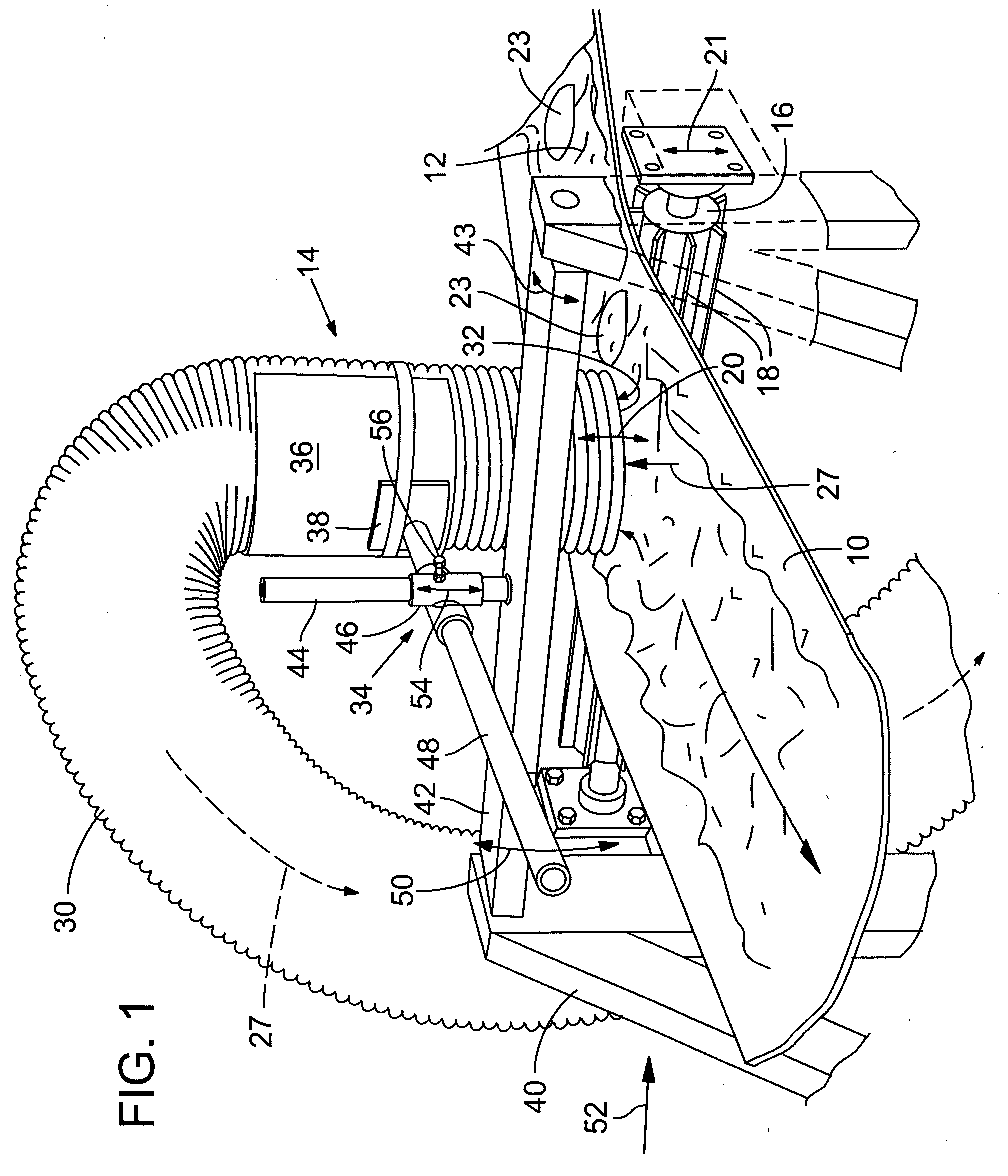

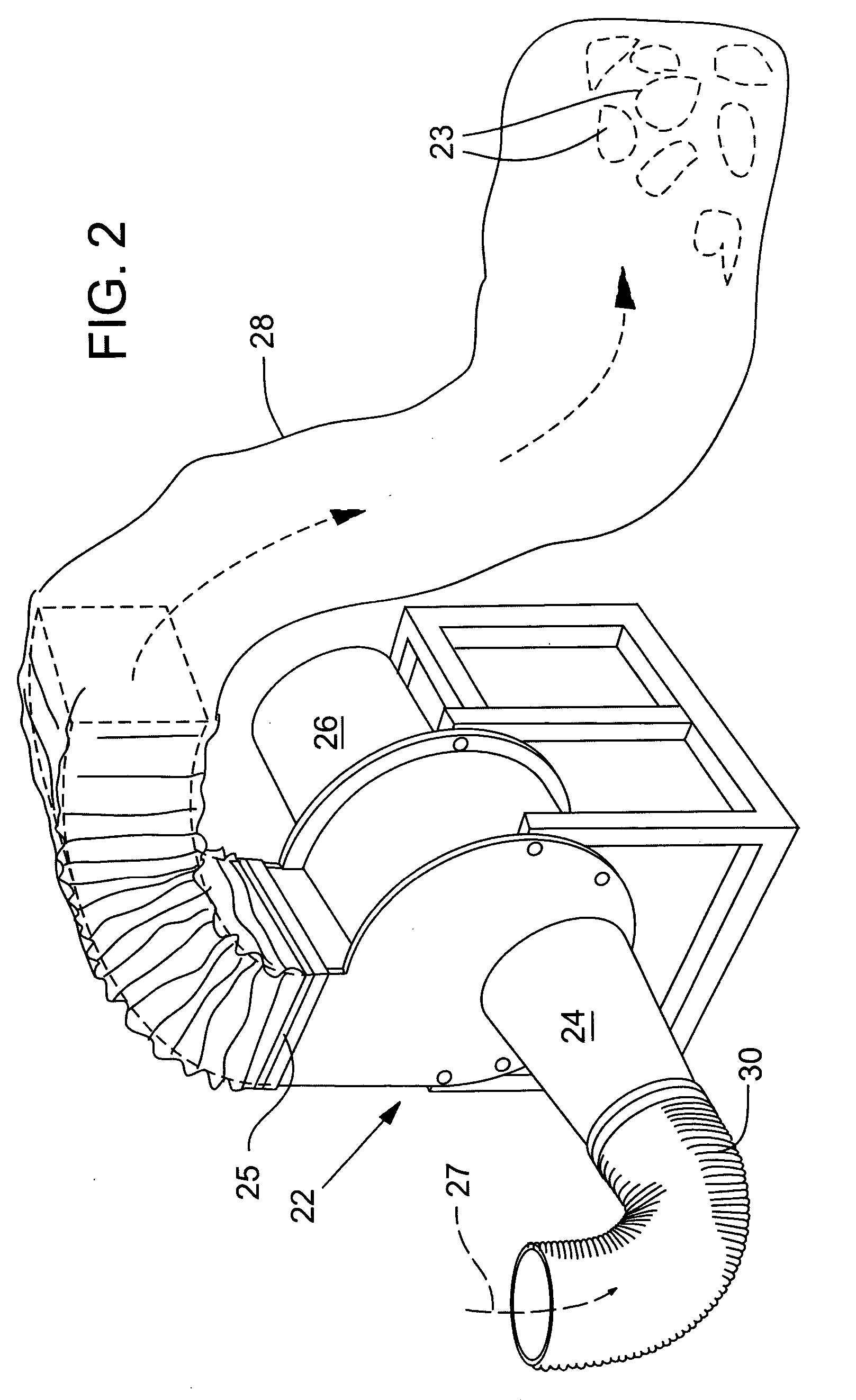

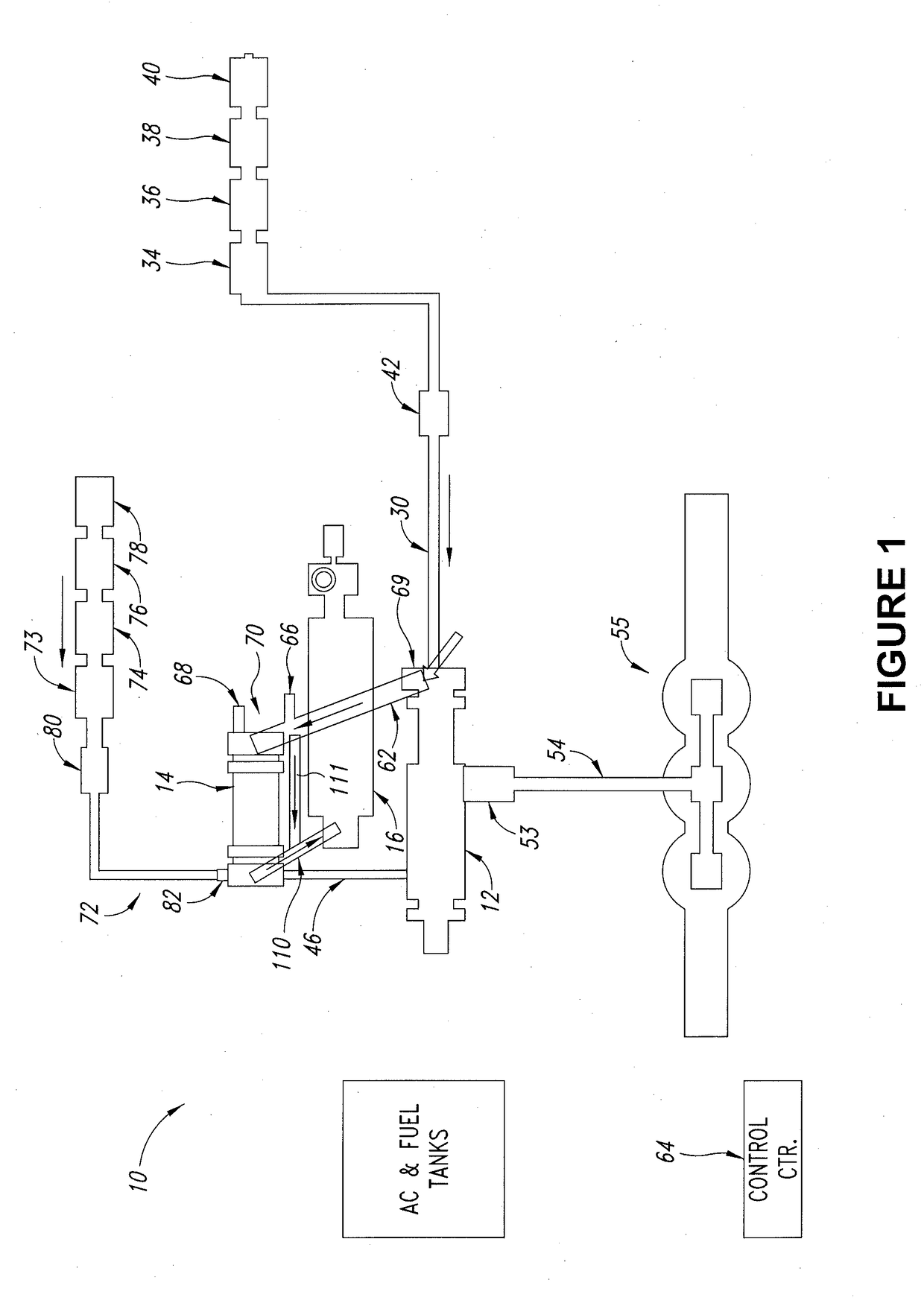

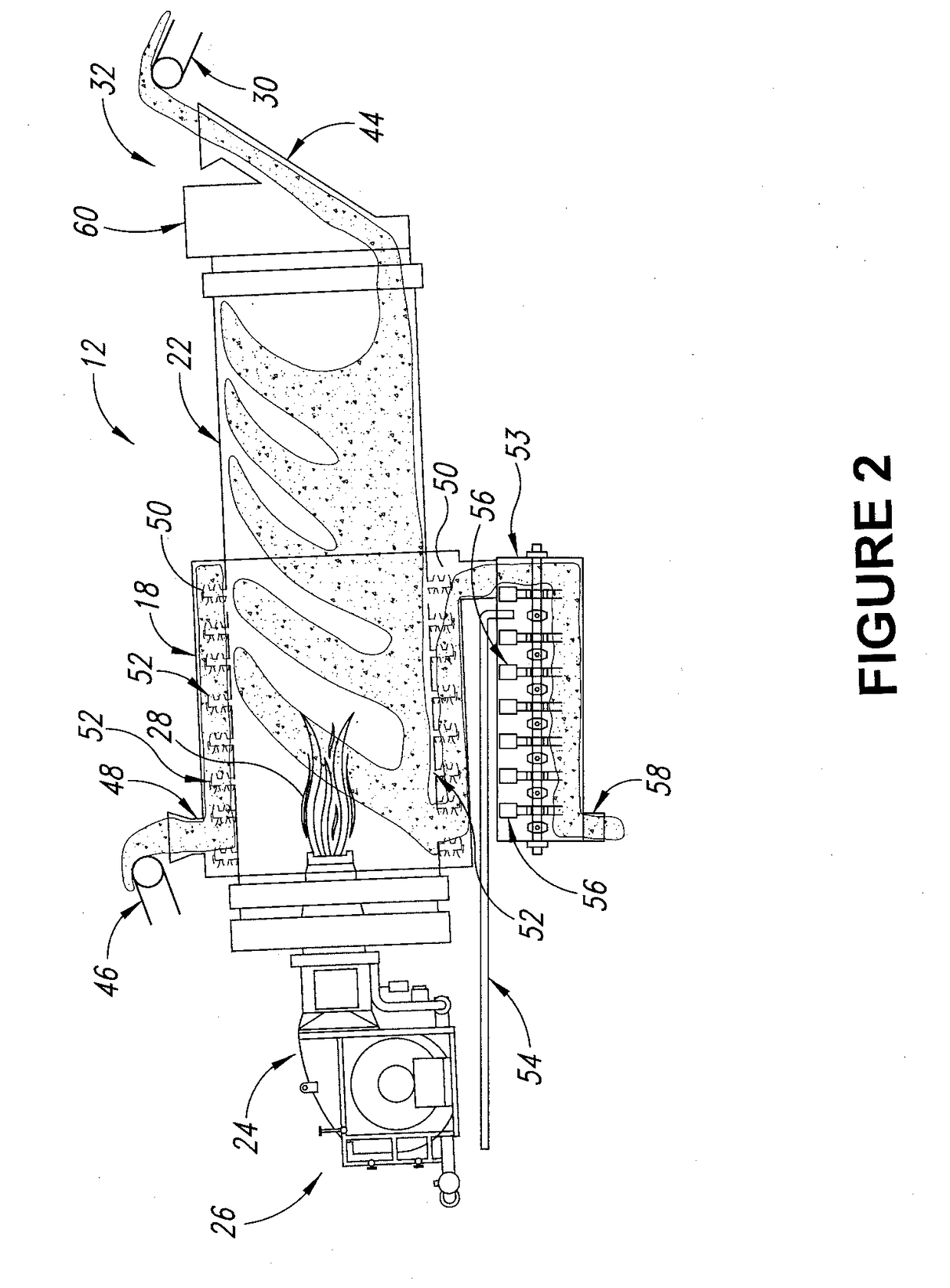

Horizontal mixer

InactiveUS9295992B2Less overall consumptionMaximizes recovery and useRoads maintainenceGrain treatmentsAsphalt shingleProcess engineering

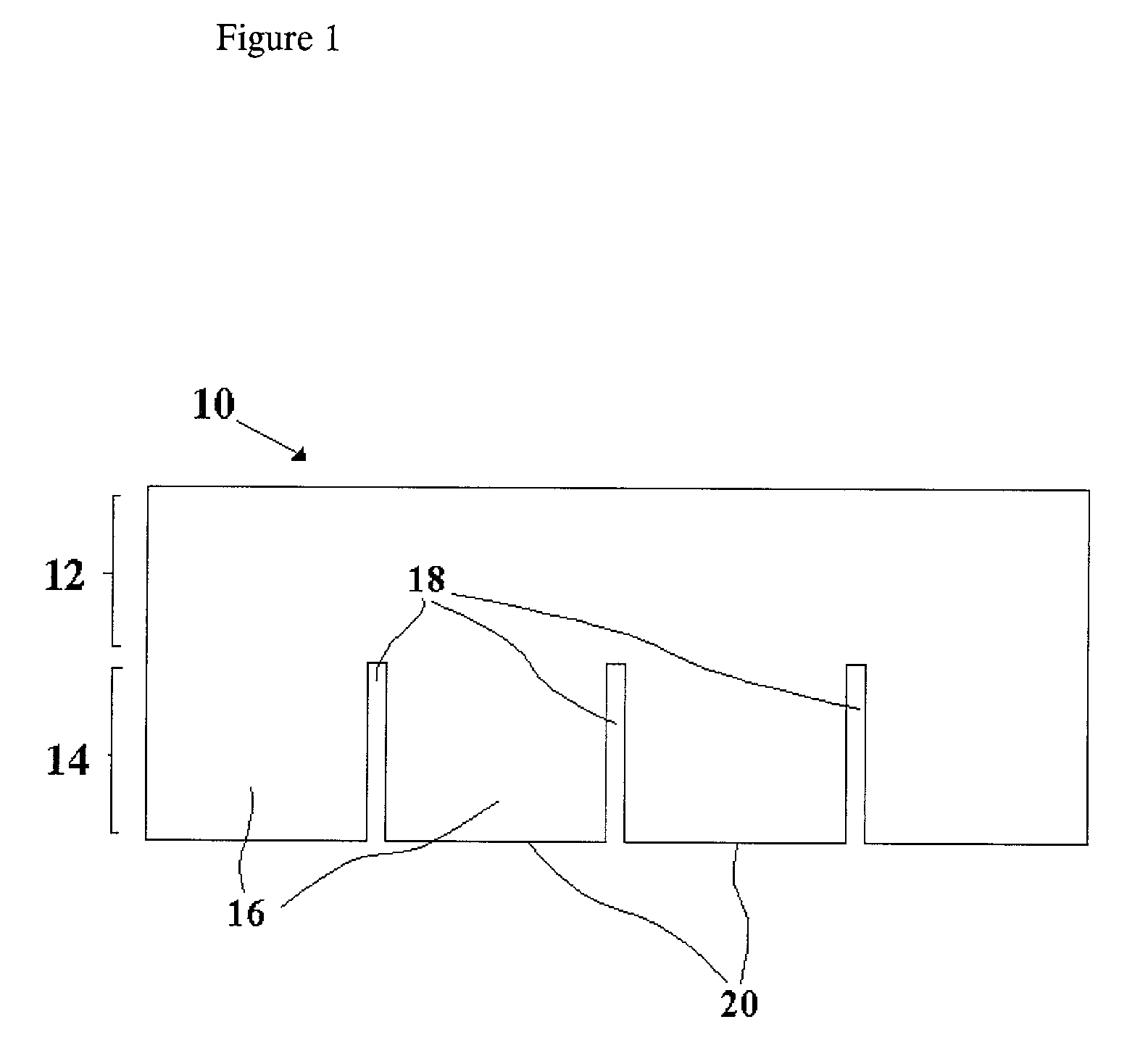

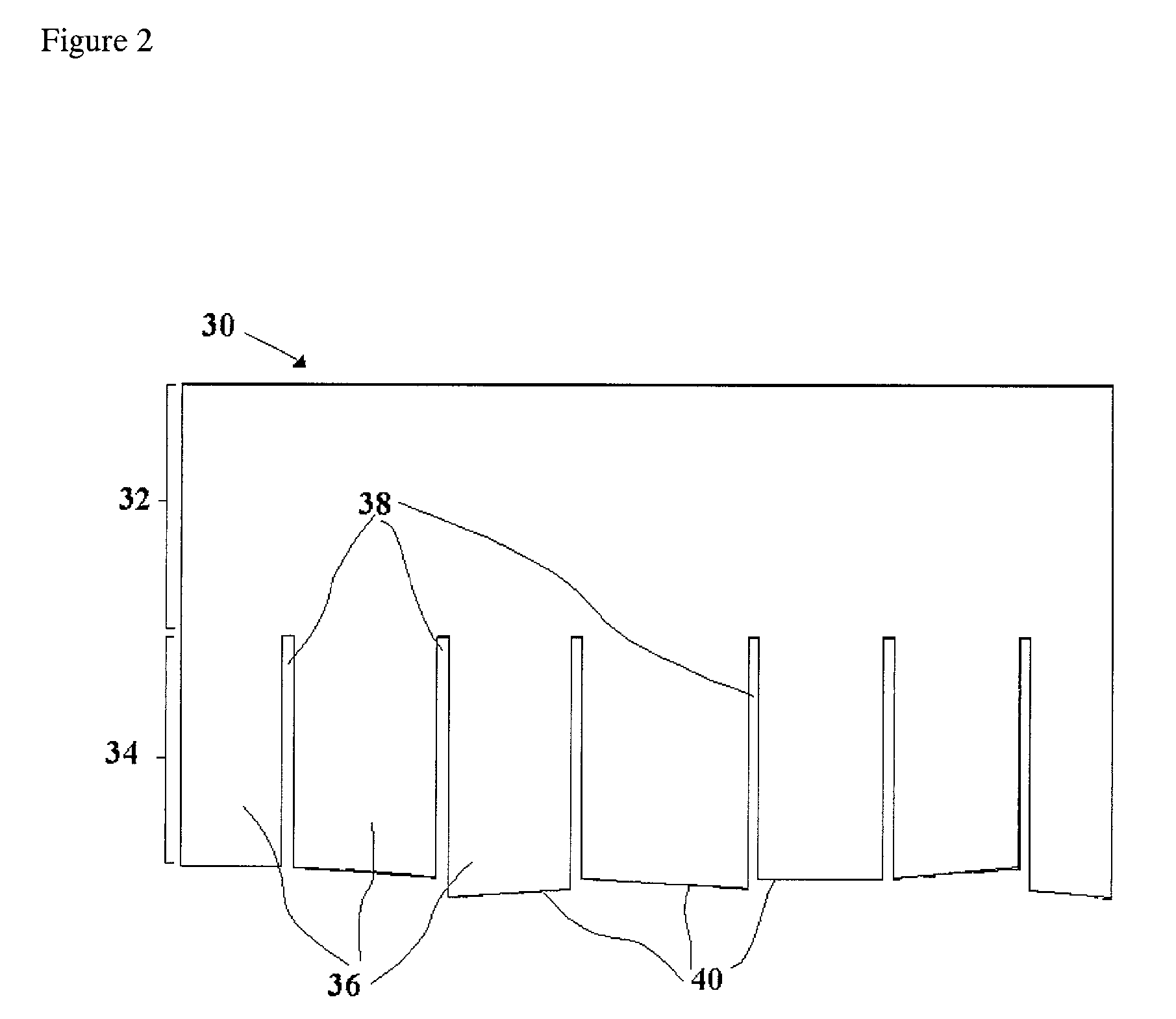

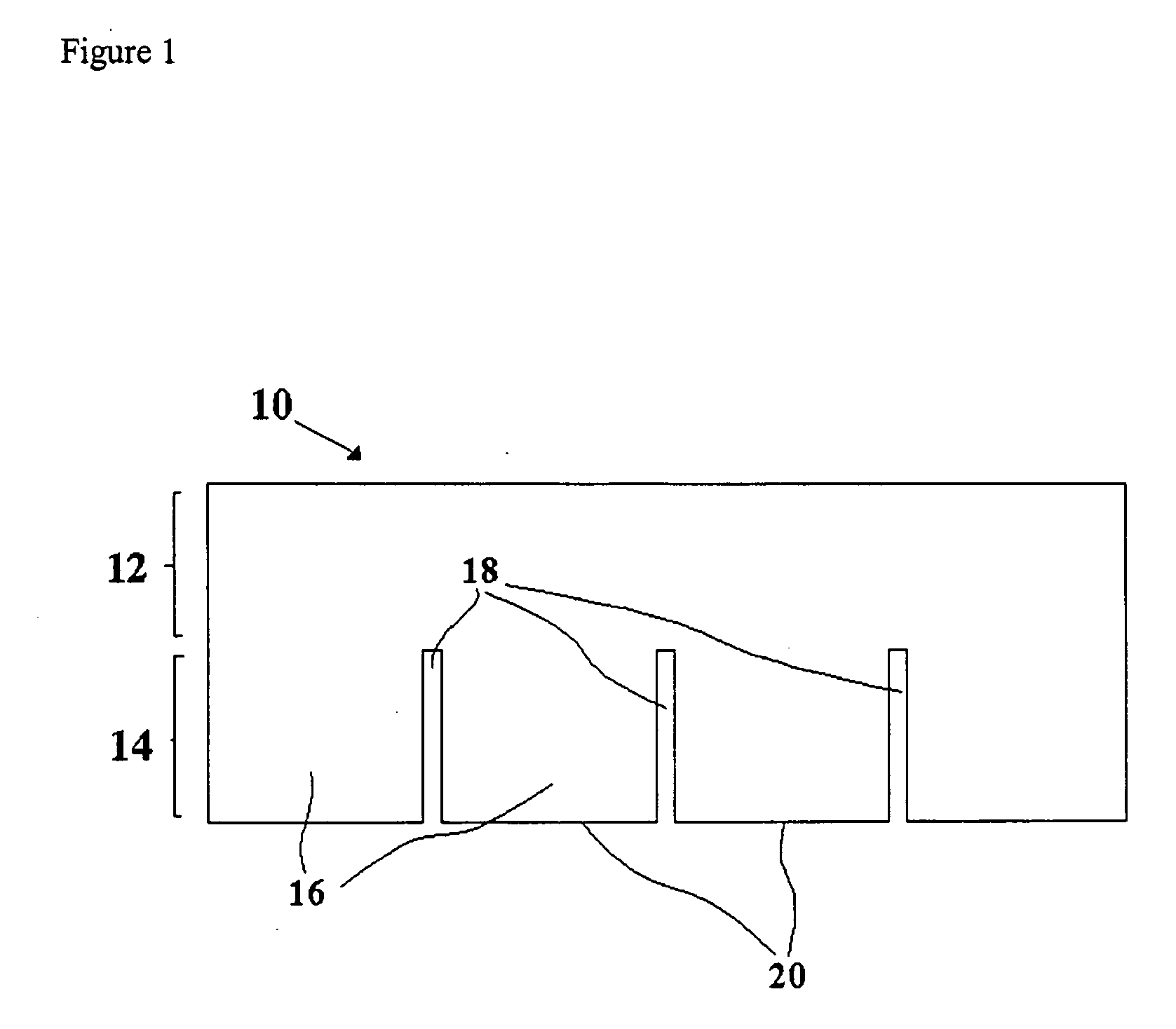

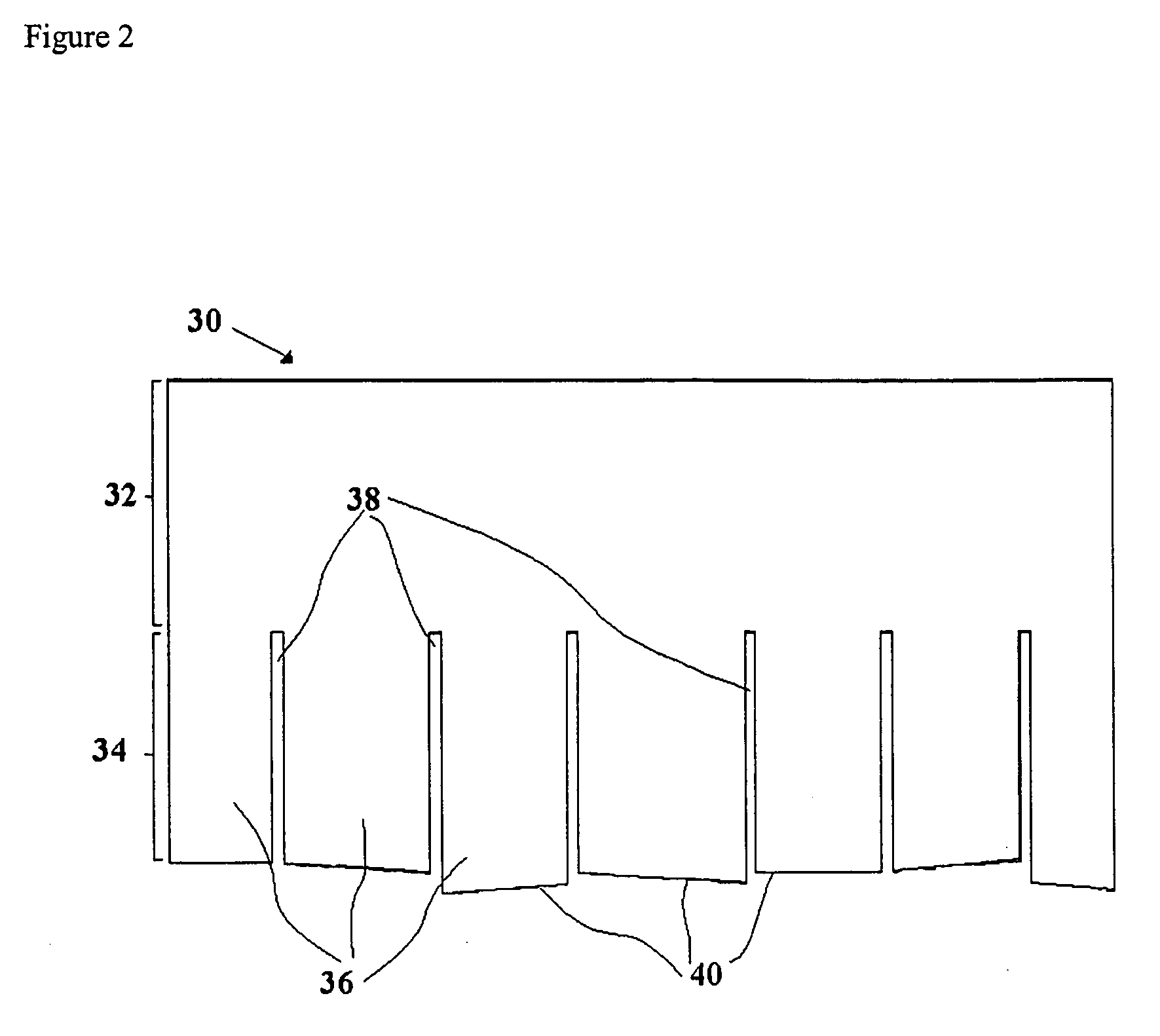

A system (10) for recycling asphalt shingle scrap. There is a cold process, hot process, and a separation process. In the hot process, all of the components are ground except for the course surface granules. In the cold process, a type of grind is formed that is the same as the hot process except it is a dry powder. A horizontal mixer (20) can be used either hot or cold. The hot process and cold process can be run in combination with one another or independently. The component separation process uses a screen or the like (34) to separate the cold process material into surface granules, filled asphalt coating, and saturated felt component, while a magnet (38) may be used to help separate nails and other metal objects from the mixture.

Owner:RECYCLED ASPHALT SHINGLE TECH

Methods and apparatus for recycling asphalt shingle material into shaped products

Used and manufacturing scrap asphalt shingle material processed into a fine material comprising smaller sized pieces of shingle material with a relatively high aggregate content is finish processed into shaped products by grinding and heating the aggregate and smaller sized pieces of asphalt shingle material into a homogenous mixture, extruding the homogenous mixture, and forming the shaped products via molding or cutting the extruded mixture. A surface treatment material may be embedded into a softened surface of the shaped products.

Owner:AMERICAN BUILDERS & CONTRACTORS SUPPLY

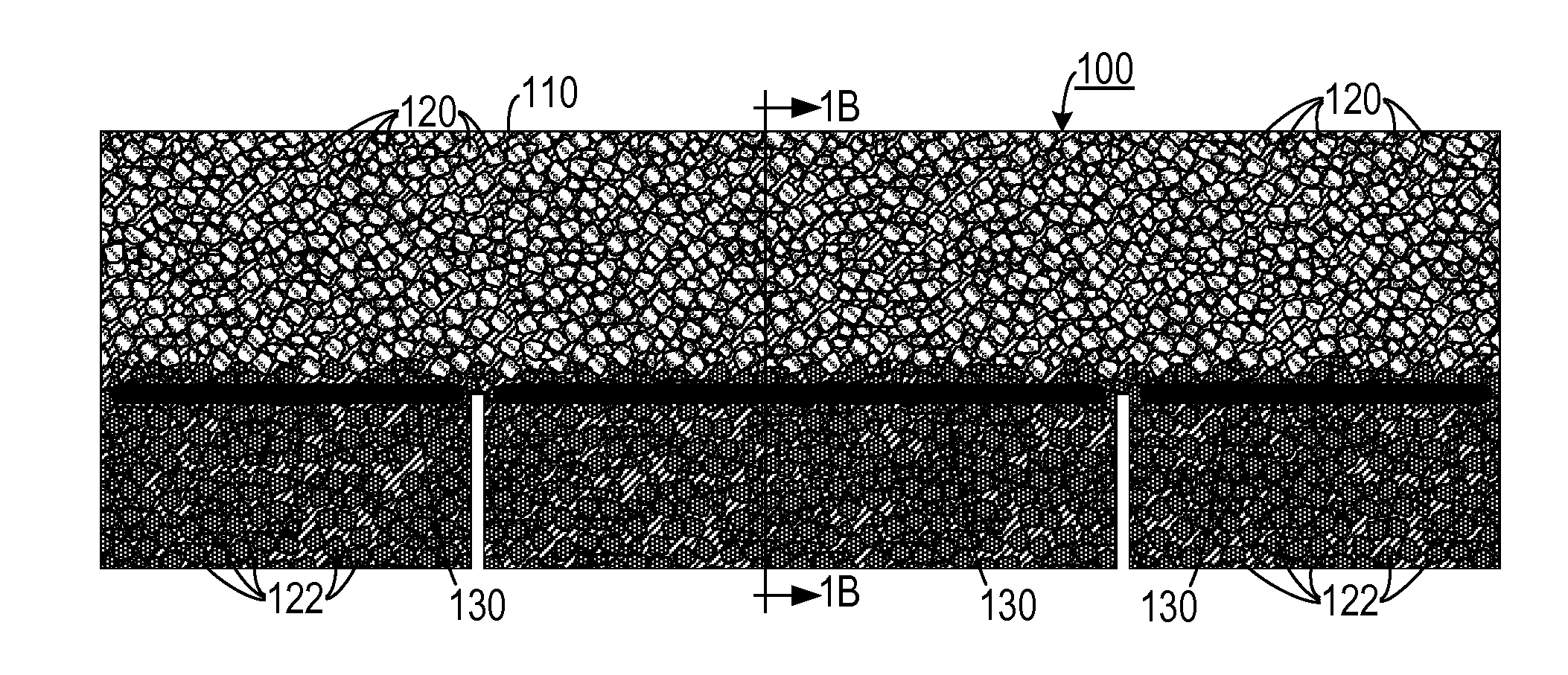

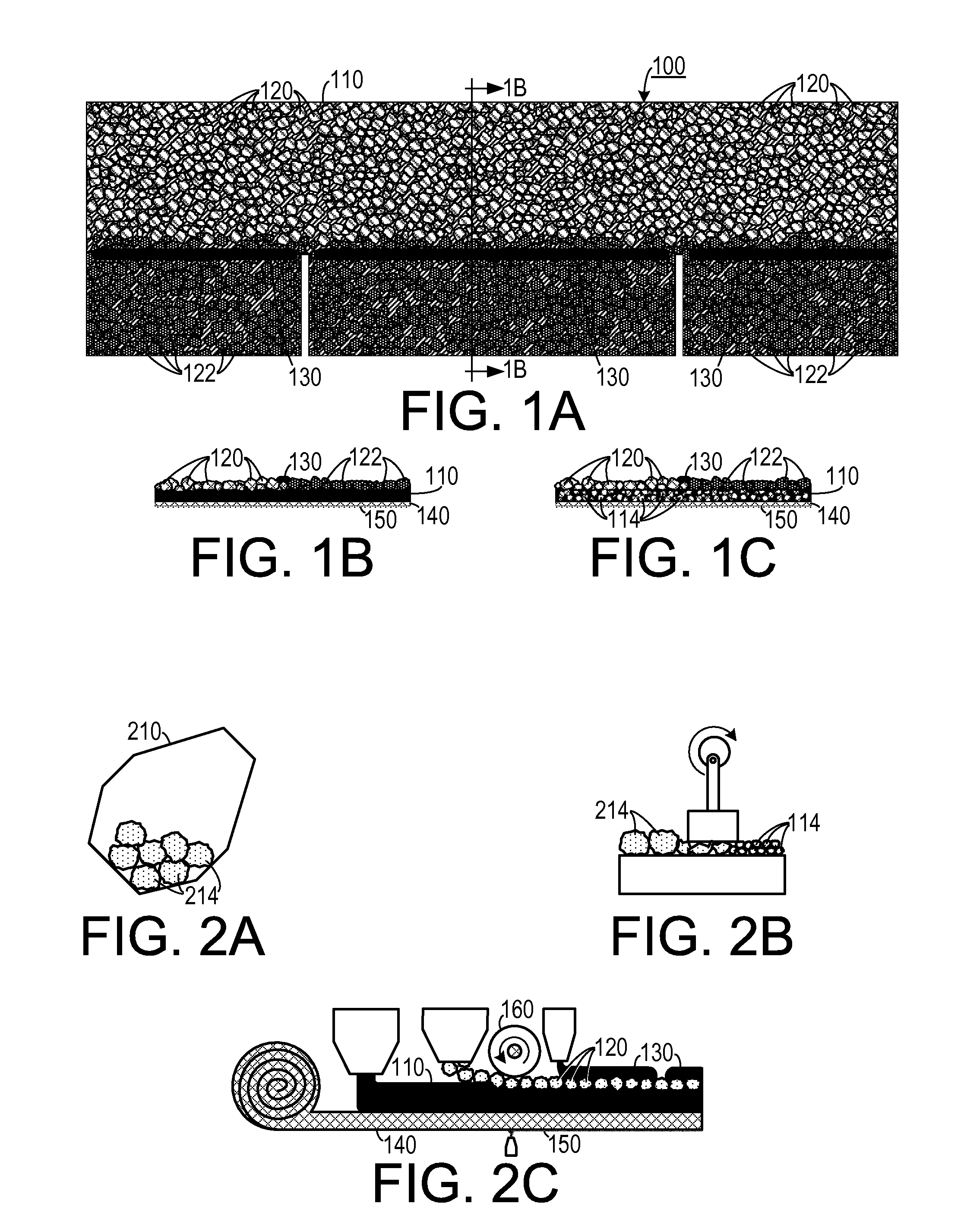

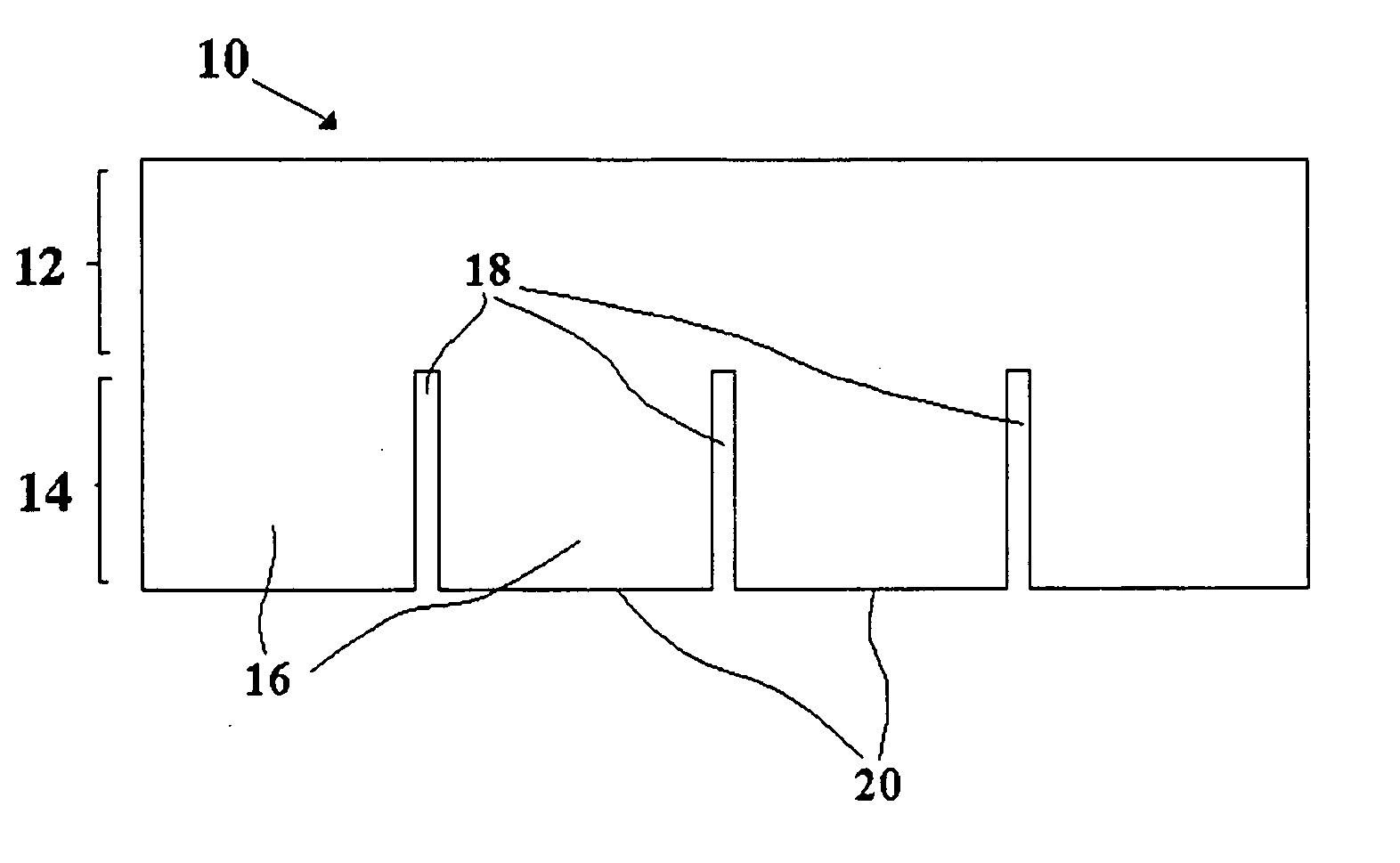

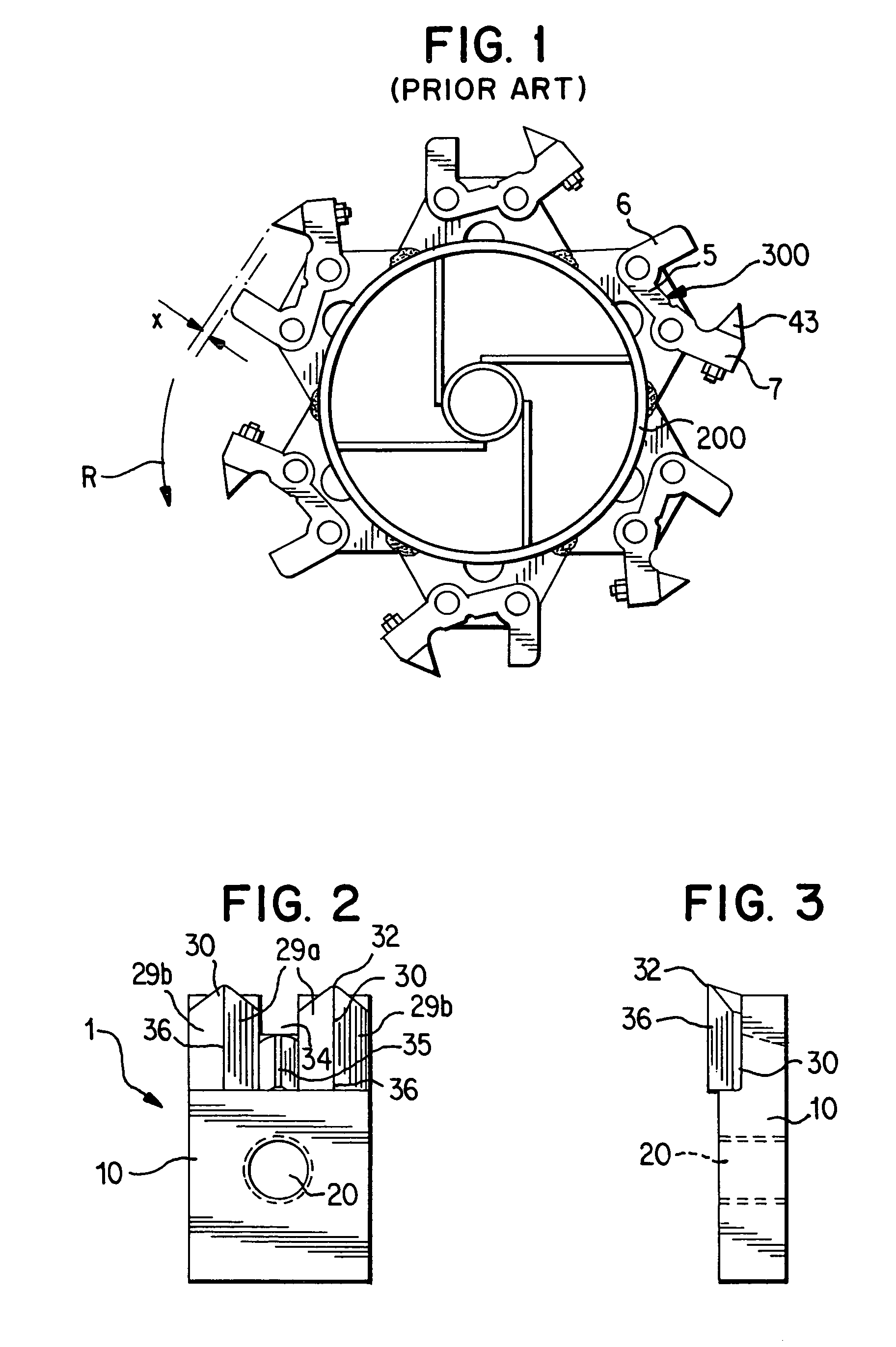

Asphalt Shingle, Roof Covering Therewith And Method Of Making The Same With Synchronized Adhesive Positioning Thereon

ActiveUS20120174517A1Roof covering using tiles/slatesLamination ancillary operationsAsphalt shingleAdhesive

An asphalt shingle is provided, in which a base mat is impregnated with an asphalt material and has headlap and tab portions, with the tab portion being a plurality of tabs separated by slots, with adhesive applied to the top surface of the shingle in the headlap portion and above the upper ends of the slots, but wherein the headlap portion of the shingle has adhesive-free zones above the centers of the tabs.A roof covering is provided with the shingles being in overlying and underlying courses, with shingles in each course being laterally offset and with the adhesive-free zones being such that no adhesive on a shingle in an underlying course is visible through slots of shingles in a next-overlying course.The method of making the asphalt shingles includes applying a substrate to a layer of shingle-forming material, the substrate having indicators at predetermined spaced-apart distances, with the indicators being sensed as the shingle-forming layer is moved along a predetermined path, with adhesive zones being applied to the shingle such that the application of the adhesive zones is synchronized in response to sensing the locations of the indicators, and with the shingle-forming layer then being cut into individual shingles.

Owner:CERTAIN TEED LLC

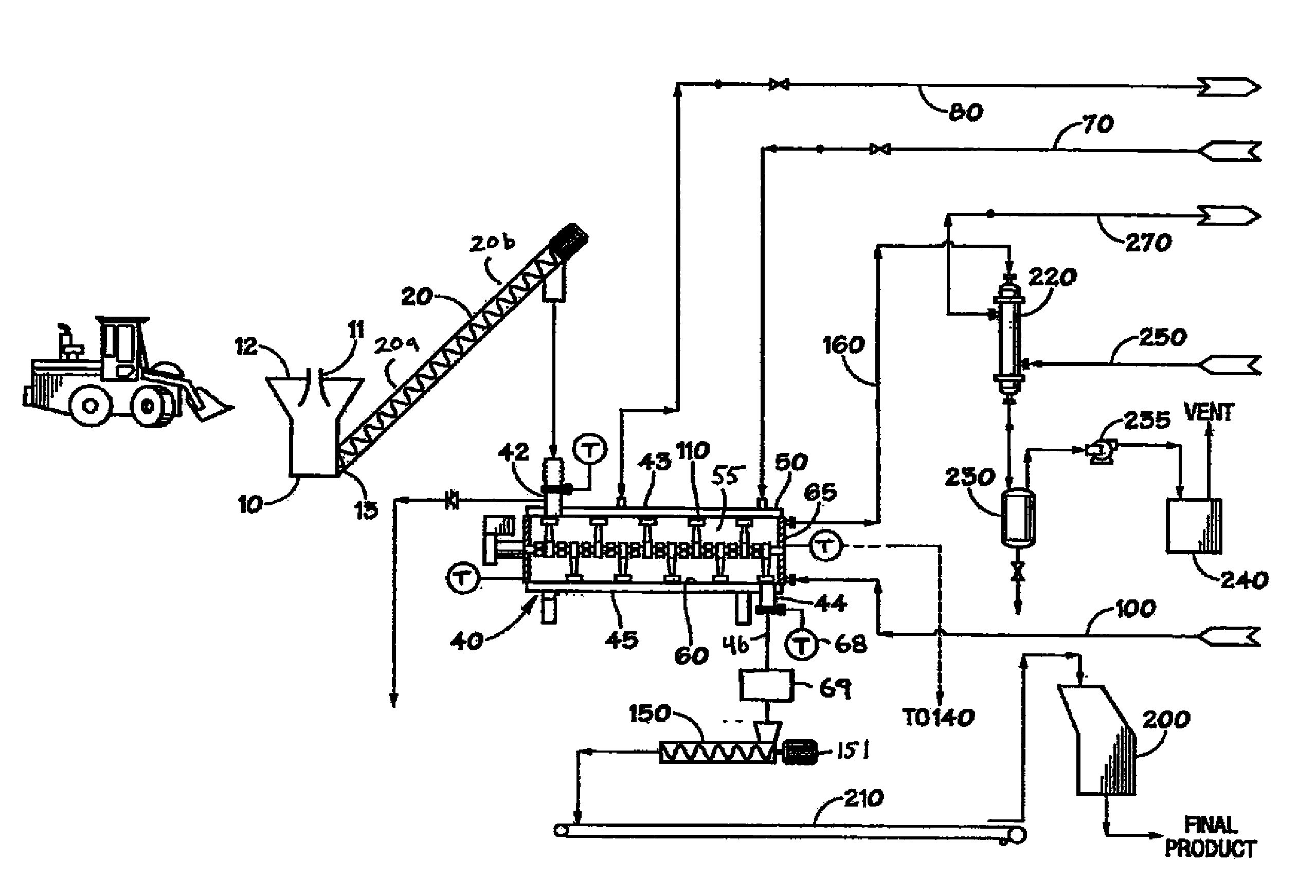

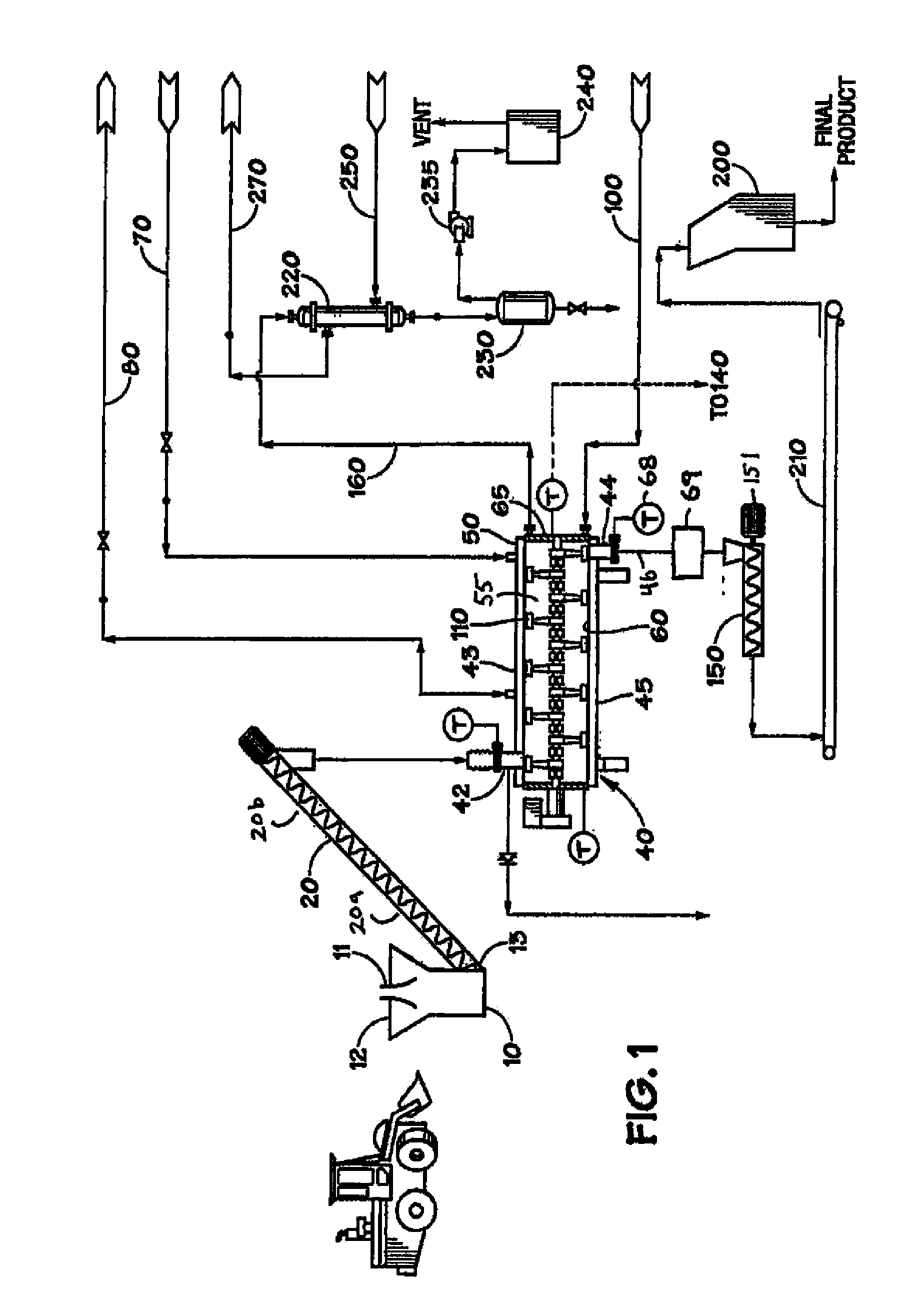

Asphalt material recycling system and method

InactiveUS20110049275A1Increase in asphalt viscosityEasily stored outsideRoads maintainenceSortingFiberAsphalt shingle

An asphalt roofing material recycling system and method is used to recycle new and used (post consumer) asphalt materials, such as asphalt shingles, rolled roofing and tar paper that may include granules, fibers or other particles. The asphalt material, which may be in bundles, is broken up and separated and then provided to a cooled recycling vessel. Dry ice is added along with the asphalt material to be recycled. The dry ice removes any moisture present and super-cools the material making it brittle and easier to chip and break up. The recycle vessel includes a number of high speed shippers having tulip hear chipping teeth as well as one horizontal mixer element which stirs the material and makes sure all material is ground. The resulting course to fine powder can be separated by screening and stored as power or compressed into bricks or briquettes.

Owner:RECYCLED ASPHALT SHINGLE TECH

Recycled asphalt paving formulation and method of making same

An asphalt paving mixtures suitable for roadway paving is formulated by mixing very soft penetration asphalt having a penetration value on the order of 300 to 400 and a melt point of 110° F. with recycled or reclaimed asphalt roofing shingles and / or recycled or reclaimed asphalt pavement granule material having a much higher melt point and a much lower penetration value. 10% to 30% of the recycled or reclaimed asphalt material in the final mixture will bring the formulation into compliance with PG grade paving asphalt. The asphalt paving mixture may utilize recycled asphalt shingle granules of approximately 50 mesh in size and preferably between 10 and 50 mesh while a powder may be utilized that is sized below 50 mesh.

Owner:RECYCLED ASPHALT SHINGLE TECH

Solar shingle system

InactiveUS20100325976A1Easy to installEasy to drainPhotovoltaic supportsRoof covering using slabs/sheetsElectricityAsphalt shingle

The present invention comprises an asphalt roofing shingle with integrated thin film solar cells that is easy to install and scalable to each particular application. The system of the present invention comprises a standard asphalt roofing shingle manufactured with an integrated thin film solar cell connected to two electrodes configured on opposing sides of the shingle. The shingle is dimensioned to that of a standard asphalt shingle. Roofing nails, which are used to install the shingle to the roof, physically attach the shingle to the roof, may also establish an electrical connection between the electrodes of the respective shingles creating a unified electrical circuit amongst the attached solar shingles.

Owner:DEGENFELDER JEFFREY G +1

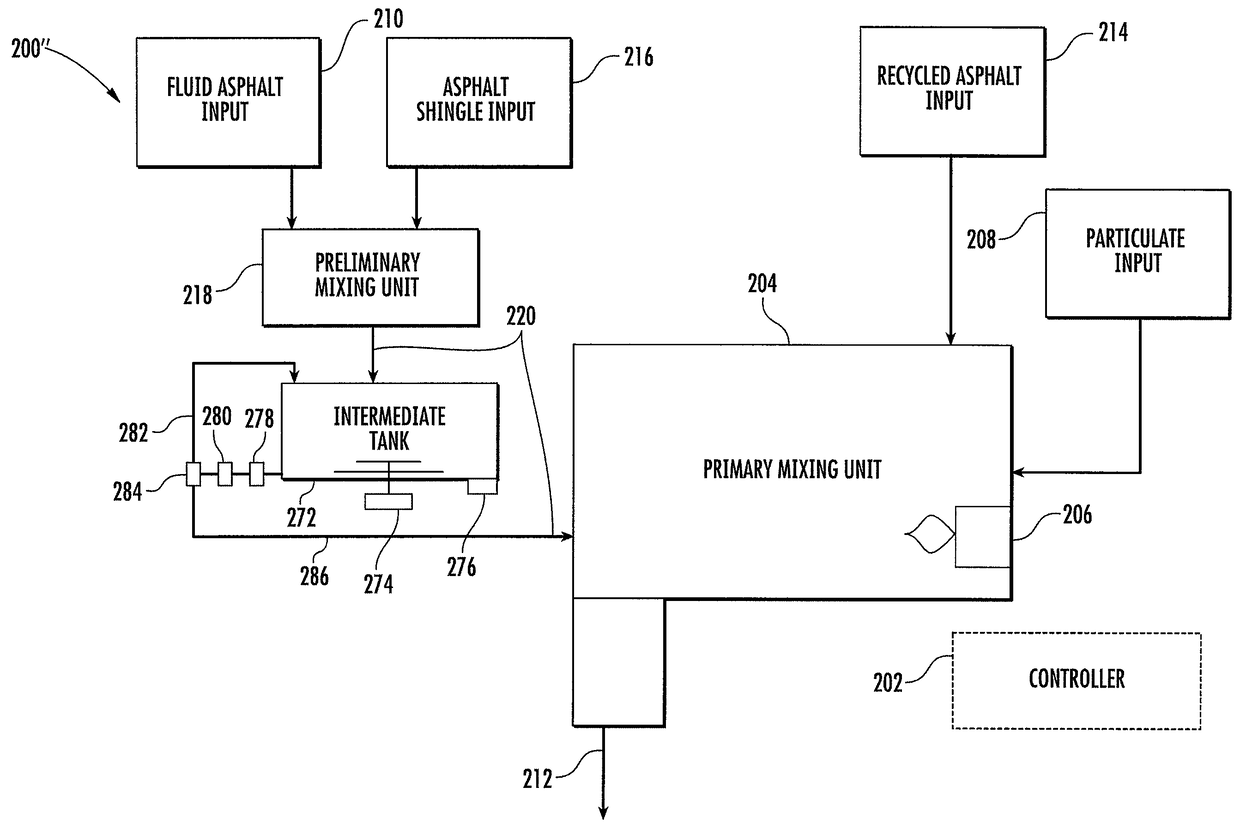

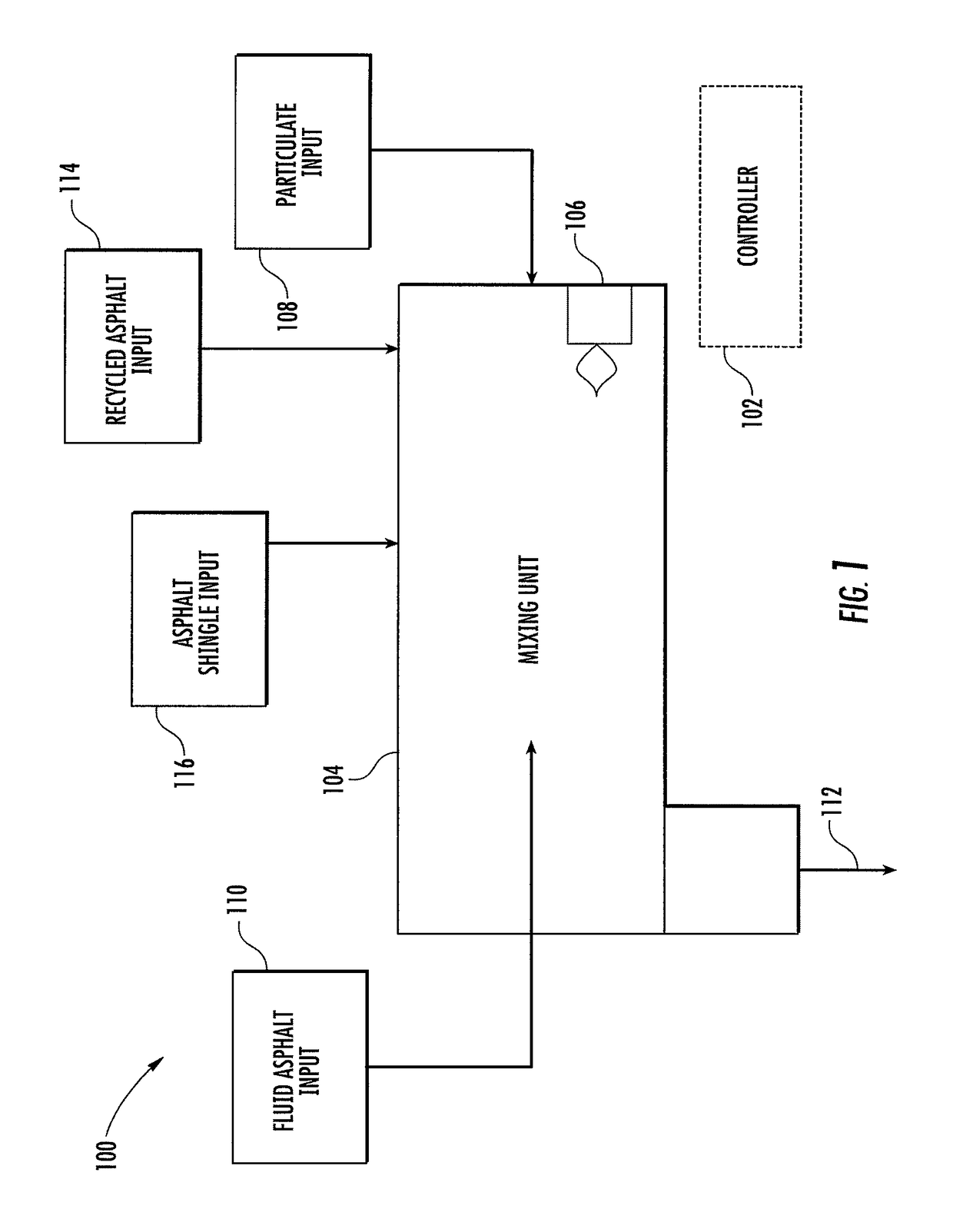

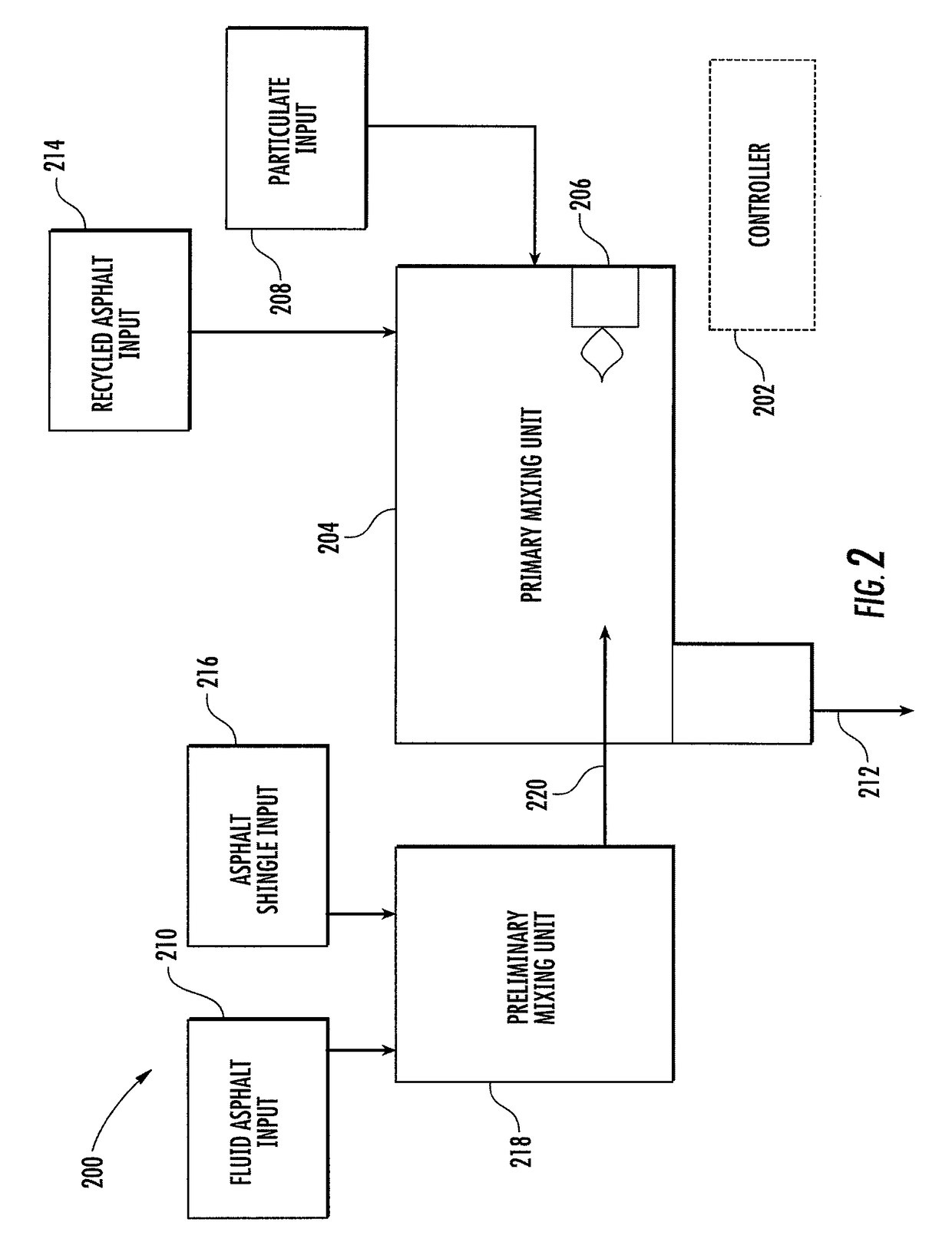

System, method, apparatus, means, and computer program product for recycling asphalt shingles

A system for producing an asphalt mix output suitable for use as an asphalt pavement is provided. The system may include a preliminary mixing unit configured to mix asphalt shingles with hot fluid asphalt to melt the asphalt shingles. The molten asphalt formed from the asphalt shingles and the hot fluid asphalt may be mixed with aggregate material and / or recycled asphalt material to form an asphalt mix output. An intermediate tank may store the molten asphalt prior to mixing with the aggregate material and / or the recycled asphalt material.

Owner:RUSSELL ATLAS JAMES

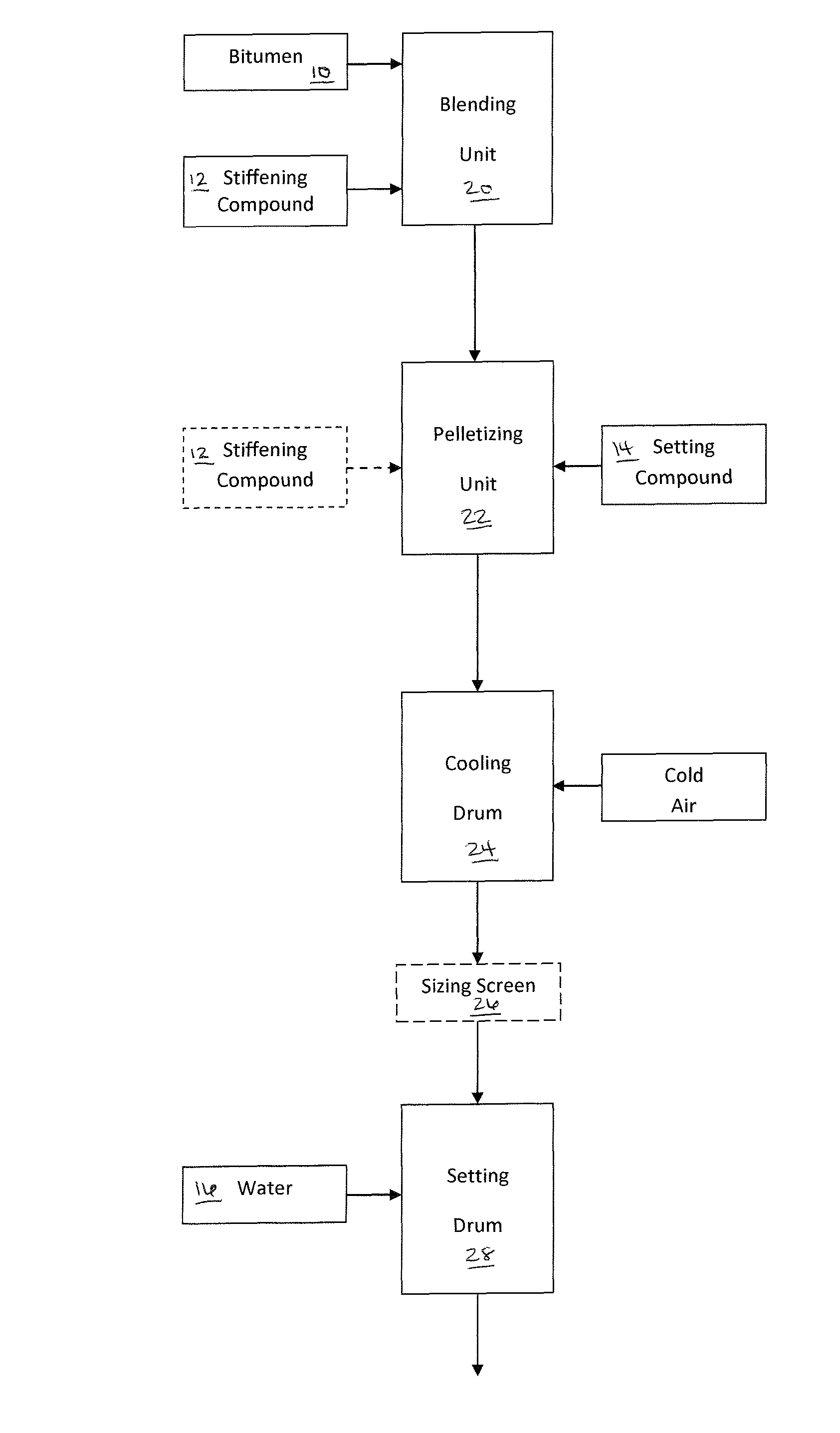

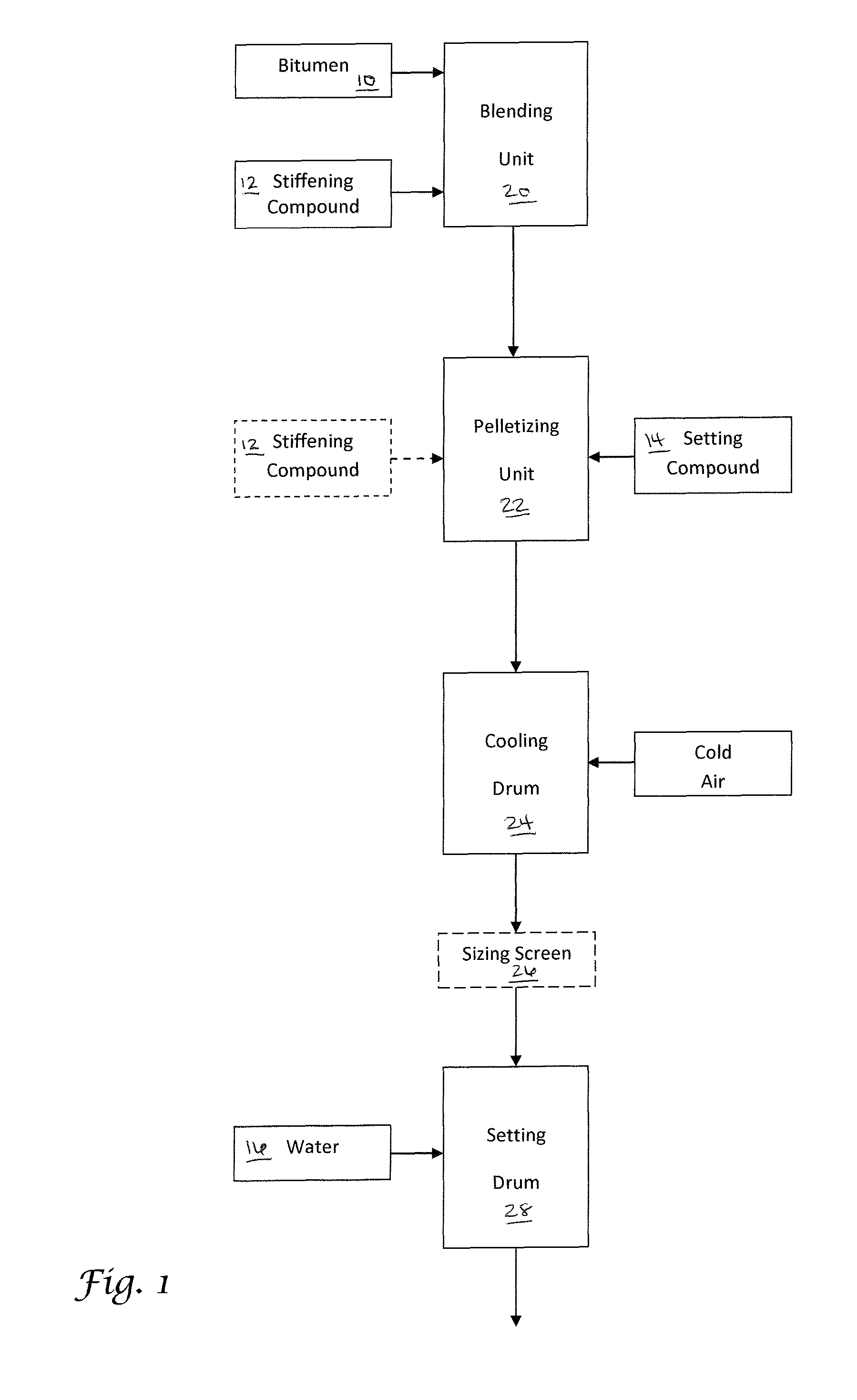

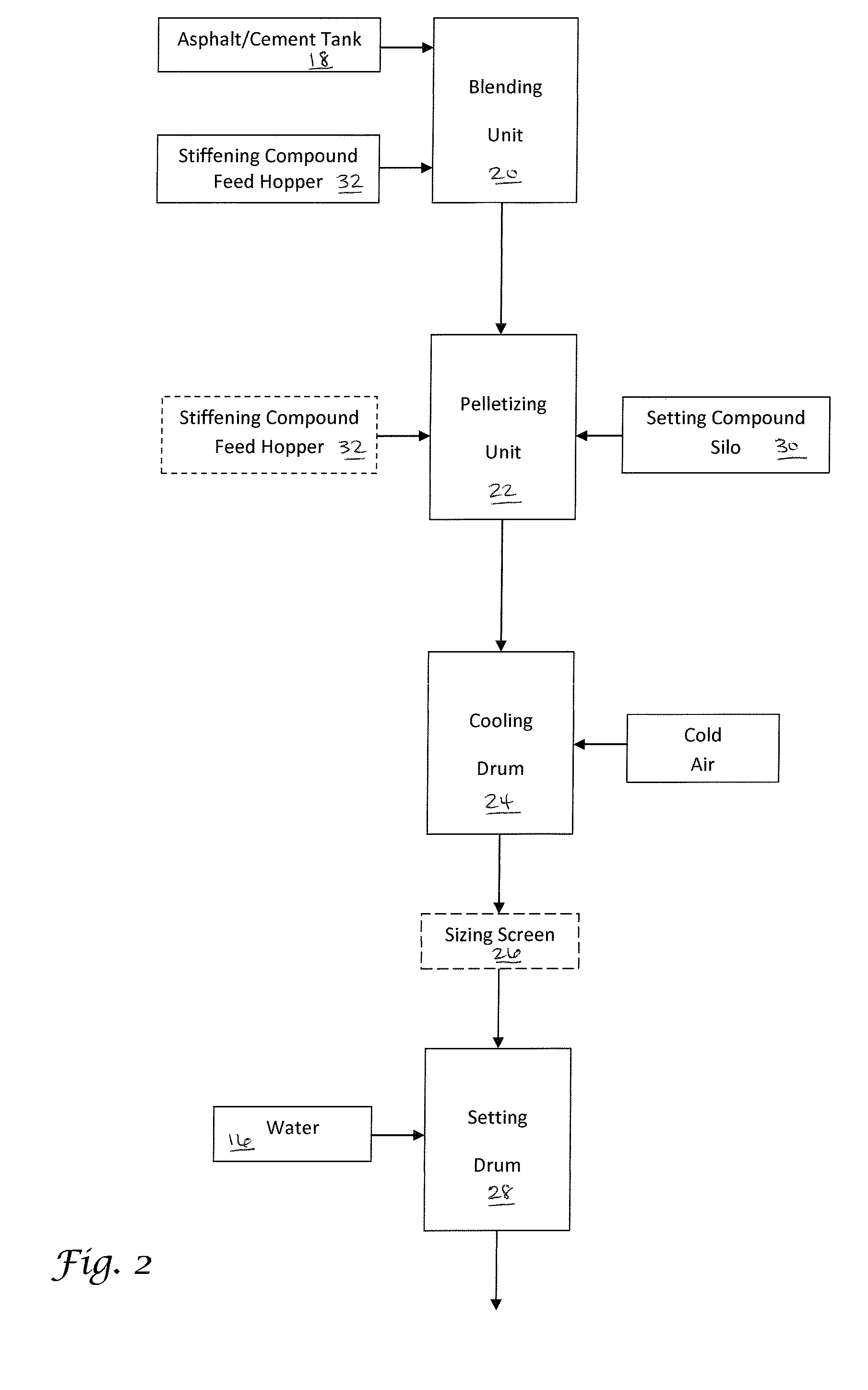

Composition for pelletized bitumen and method for preparing the same

A composition for pelletized bitumen and a method for preparing the same is disclosed. The composition is comprised of: between approximately 30% to approximately 40% by weight of bitumen; between approximately 15% to approximately 30% by weight of stiffening compound; between approximately 35% to approximately 45% by weight of setting compound; and approximately 0.05% by weight of water. The stiffening compound is comprised of between approximately 10% to approximately 20% by weight of ground asphalt shingles; between approximately 5% to approximately 10% by weight of vulcanized rubber; between approximately 1% to approximately 2% by weight of uintahite; and up to approximately 0.5% by weight of zeolite. And the stiffening compound may be Type II Portland cement.

Owner:PHOENIX IND INC

System for removing plastic from recycled material

A system for separating pieces of plastic bag from ground yard debris and the like, e.g., asphalt shingles. A conveyor conveys the debris material along a conveyor path and an agitator bounces the conveyor to cause the lighter plastic to reposition to the top of the material on the conveyor. A suction tube end is positioned over the debris material following agitation to draw the plastic off the top of the material. The tube end is selectively adjustable to enable discriminate suction effect to draw off a maximum amount of plastic and a minimal amount of nonplastic recyclable debris.

Owner:HAWKER CORP

Composite roofing panel

InactiveUS20050257465A1Better imitate natural productsRoof covering using tiles/slatesNatural patternsAsphalt shingleNatural fiber

The present invention provides a composite panel for use in construction, and particularly for shingling, which comprises natural fiber and a polymer. Due to its composition and layout the construction panel provides all of the advantages of natural materials and high end roofing materials, particularly an attractive appearance, while at the same time allowing for ease of installation, little or no maintenance requirements, and providing superior impact and fire resistance when compared to other roofing materials. The construction panels can also be installed using conventional equipment and methods similar to the installation of 3-tab asphalt shingles with little or no learning curve.

Owner:FELTON COLIN C

Wet Process for Recycling Asphalt Shingle in Asphalt Binder for Asphalt Paving Applications

InactiveUS20140299018A1Increase surface areaEnhanced mixing processIn situ pavingsRoads maintainenceAsphalt shingleRoad surface

A method is disclosed for recycling asphalt roofing shingles and incorporating them into hot mix asphalt for use in applications such as asphalt pavement construction. Unlike previous methods, the asphalt from ground shingles is mixed with and becomes an integral component of the asphalt binder, instead of acting primarily as part of the aggregate. The asphalt content of the shingles mixes with heated asphalt binder to produce a single asphalt phase, and the asphalt from the shingles acts as asphalt in the final composite.

Owner:BOARD OF SUPERVISORS OF LOUISIANA STATE UNIV & AGRI & MECHANICAL COLLEGE

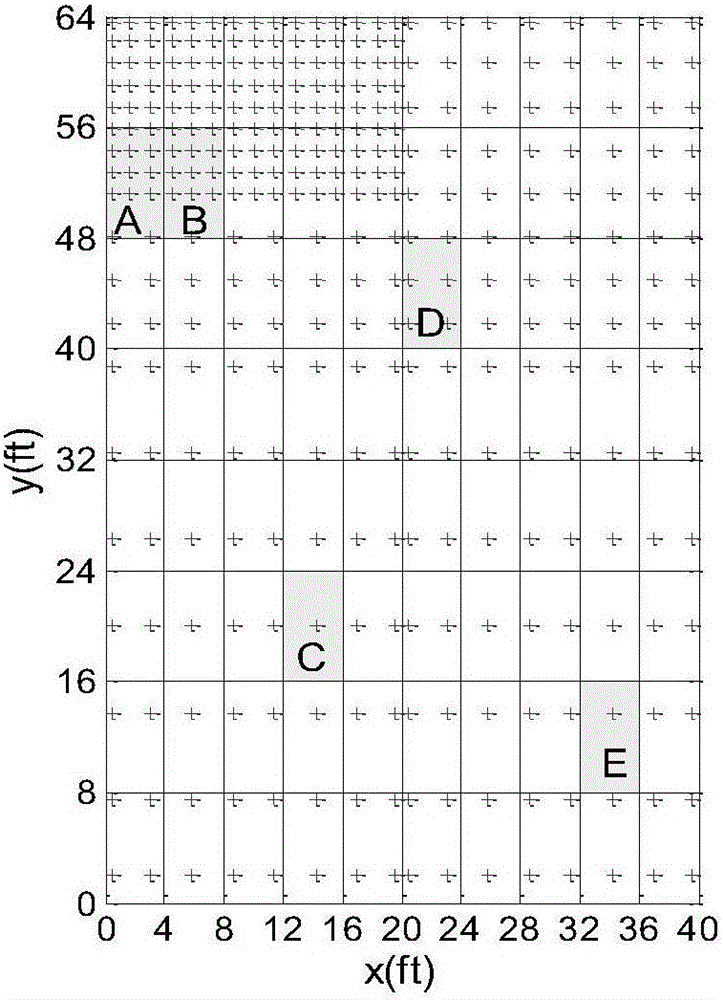

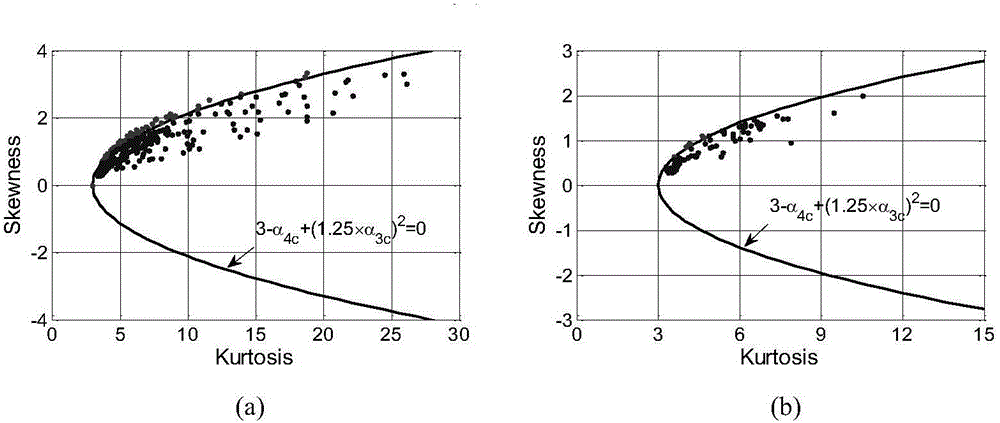

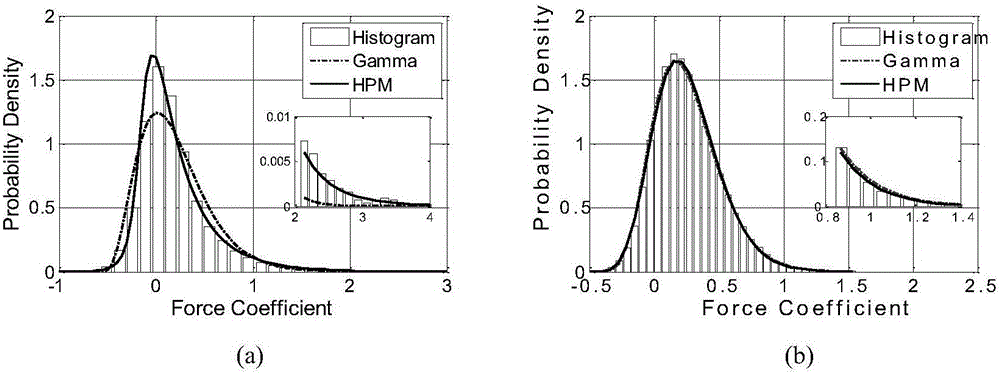

Data-based method for estimating loss of roof sheathings by considering wind load correlativity

InactiveCN106126787AGeometric CADSpecial data processing applicationsAsphalt shingleComputation process

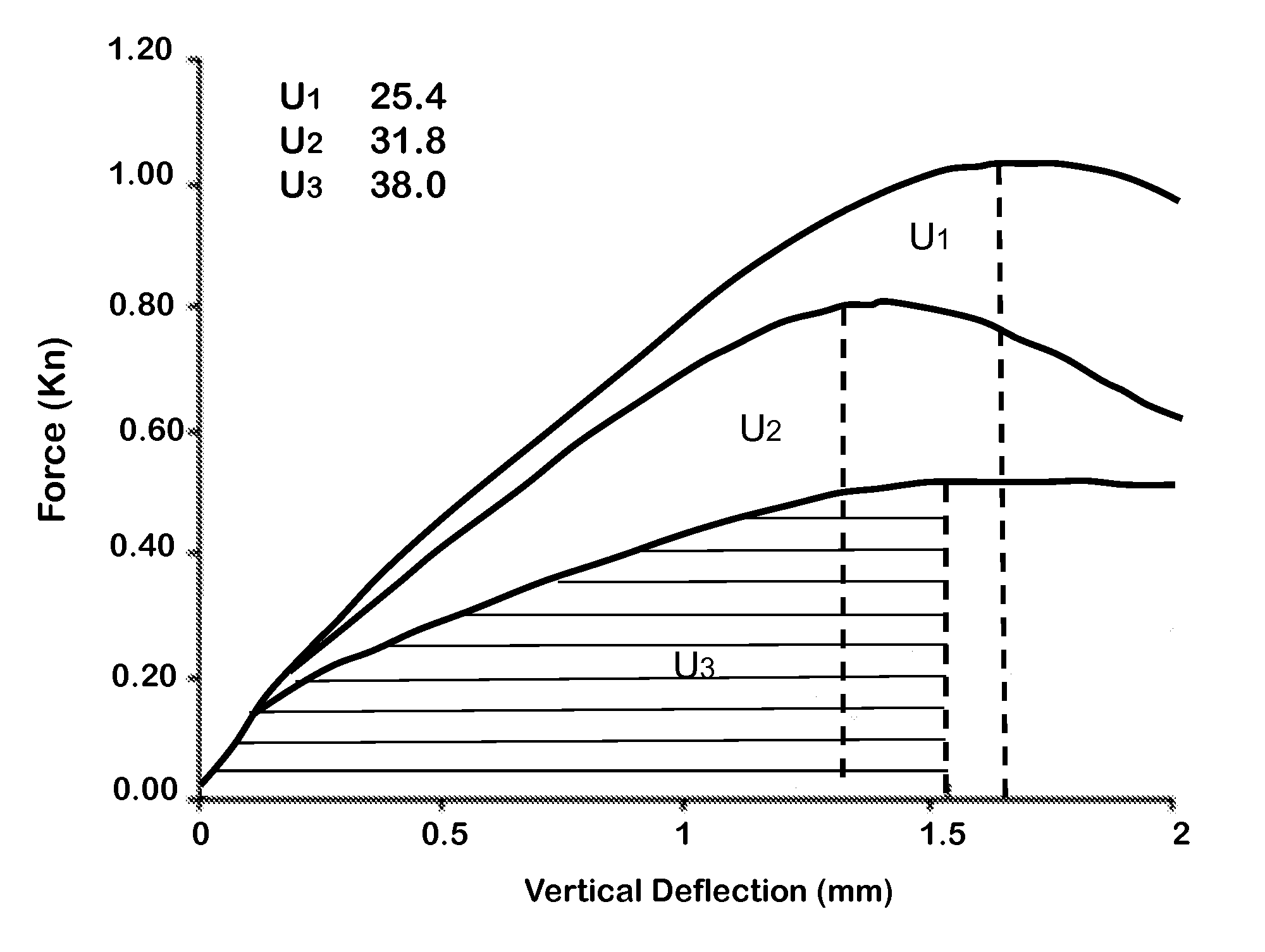

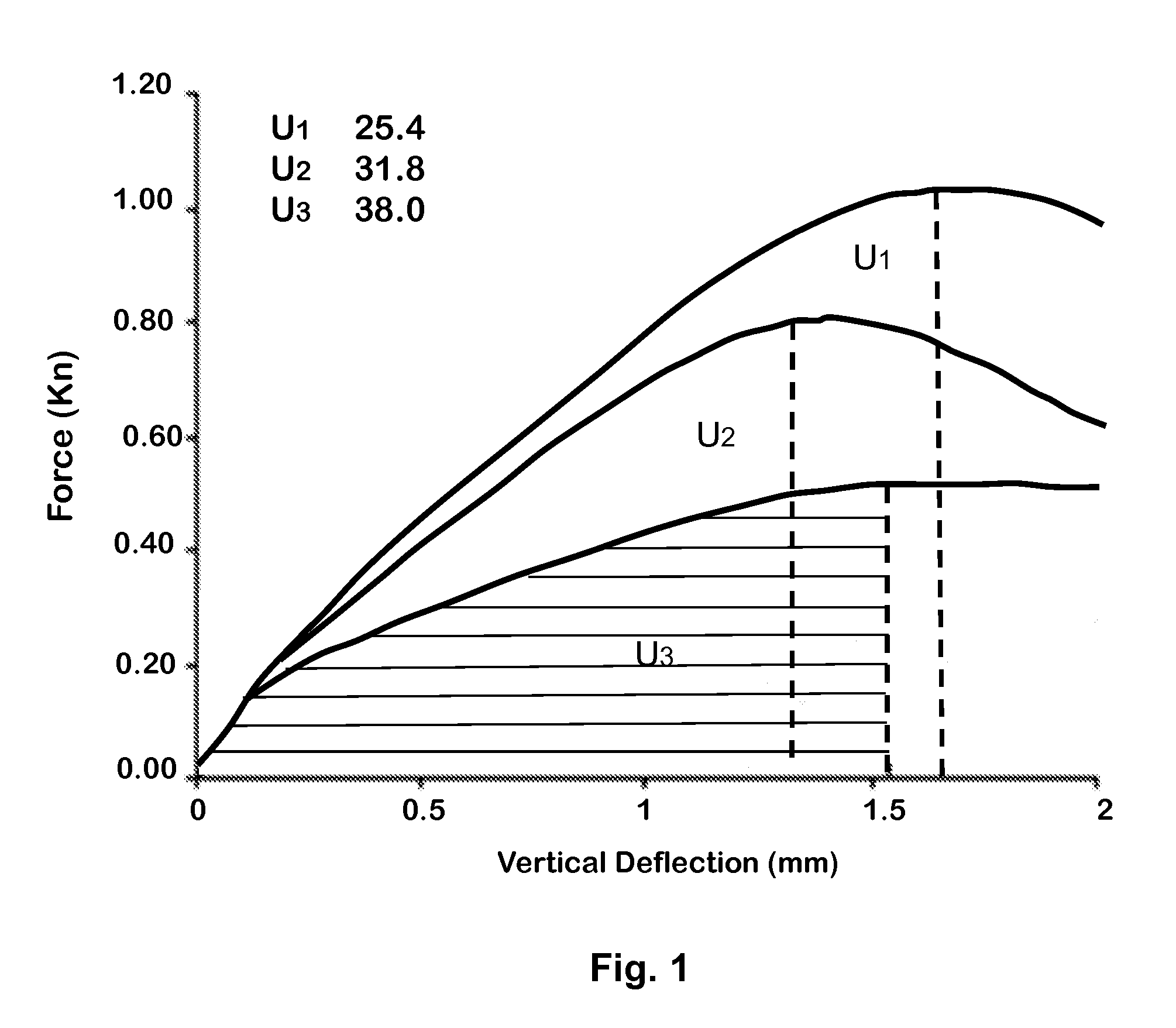

The invention discloses a data-based method for estimating loss of roof sheathings by considering wind load correlativity. The method is used for estimating the wind-induced loss of the roof sheathings adopting wood structures. In a calculation process, a probability density function of wind loads on the roof sheathings is estimated first and then extreme value distribution of the wind loads is obtained according to a conversion process method; extreme states of the roof sheathings are expressed by using relationships between extreme values of the wind loads on the roof sheathings and a resistance force, and then a destruction probability of the roof sheathings is calculated; and finally the loss of a whole roof is estimated. The method has the characteristics that a joint probability density function of the wind loads is obtained through Nataf change, so that the correlativity existent between the wind loads is considered and the influence of the wind load correlativity on wind-induced loss assessment of the roof sheathings is quantified. Meanwhile, the method can be expanded to the wind-induced loss estimation of other roof members such as asphalt shingles.

Owner:SOUTHWEST JIAOTONG UNIV

Shingle processing tool and method

InactiveUS7487931B2Efficiently cutting asphalt shinglesEfficient productionMetal sawing devicesCocoaAsphalt shingleEngineering

A cutting tool for attachment to the leading area of a base is provided. The cutting tool includes a holder base having two substantially parallel cutting teeth extending from the holder base, the cutting teeth each having a cutting edge and an opening between the teeth. The cutting teeth define first and second cutting paths. The cutting teeth impact and cut asphalt shingles, and funneling surfaces of the teeth funnel the cut shingle material toward and through the opening, and into the path of the rear cutting member which cuts the material a second time. Thus, asphalt shingles are processed more efficiently, thereby creating less frictional heat and avoiding melting of the asphalt shingles.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Asphalt tile

ActiveCN103821282AGood weather resistanceGood performance and stabilityRoof covering using tiles/slatesSynthetic resin layered productsGlass fiberAsphalt shingle

The invention discloses an asphalt tile. The asphalt tile is of a multilayer structure, and consists of a mineral particle layer, a glass fiber felt, modified asphalt coating layers and an isolation material layer from top to bottom, wherein the mineral particle layer and the glass fiber felt are arranged on the upper surface, the modified asphalt coating layers are arranged at the two surfaces of the glass fiber felt, and the isolation material layer is arranged on the lower surface. The asphalt tile has the advantages that the good mineral particle adhering performance, anti-aging performance and flame-retardant performances are realized; the asphalt tile can be applied to various types of building roofs, especially the slope roofs of civil houses and villas.

Owner:东方雨虹建筑修缮技术有限公司

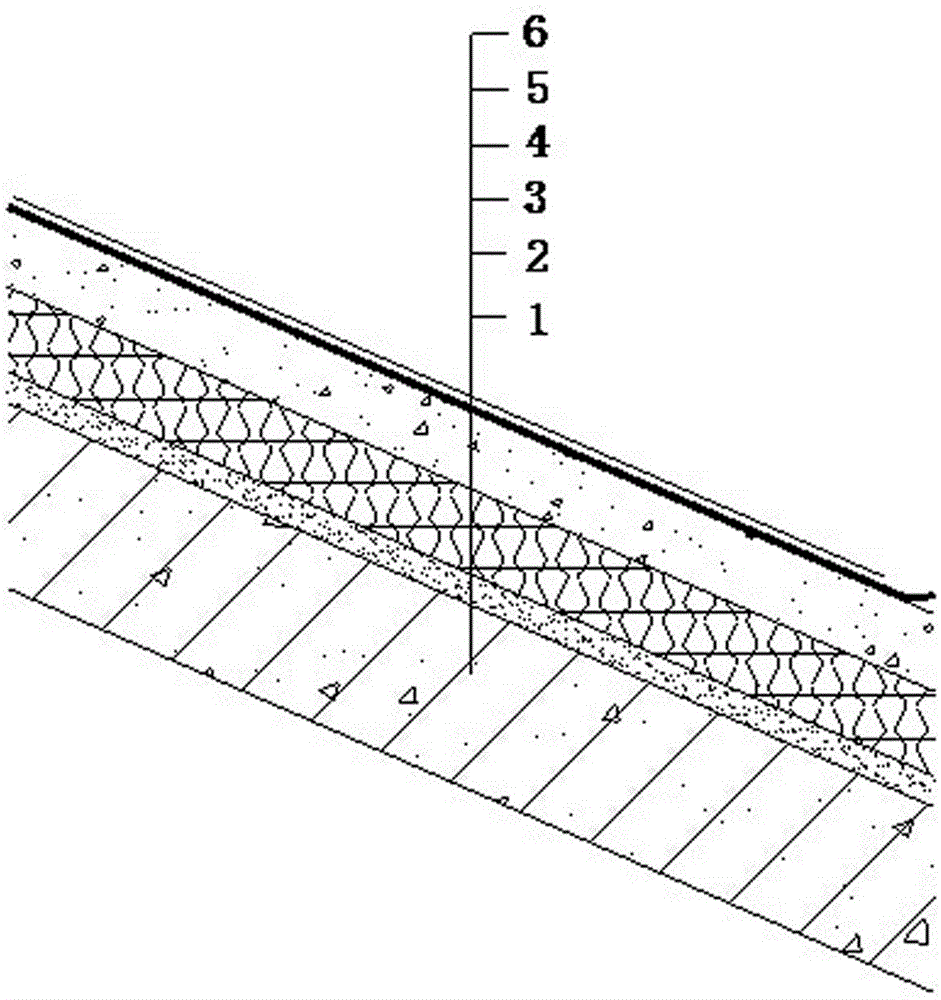

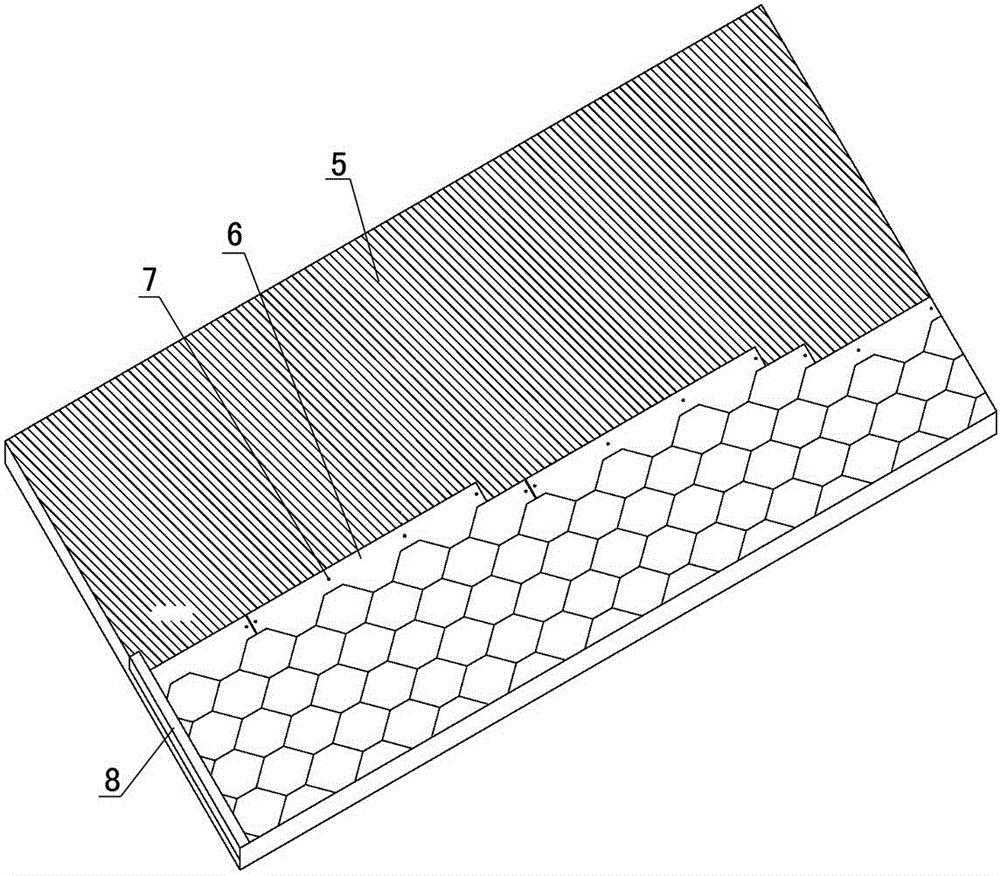

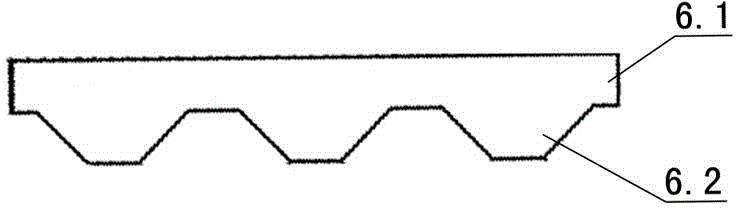

Asphalt shingle roof waterproof system of sloping roof high-rise building and construction method of asphalt shingle roof waterproof system

ActiveCN104153522AFeatured self-healing functionImprove waterproof performanceRoof covering using flexible materialsBuild-up roofsSelf-healingAsphalt shingle

The invention discloses an asphalt shingle roof waterproof system of a sloping roof high-rise building and a construction method of the asphalt shingle roof waterproof system. The asphalt shingle roof waterproof system of the sloping roof high-rise building comprises a reinforced concrete floor, a mortar leveling layer, an insulating layer, a concrete base, a double-faced self-adhesion waterproof roll layer and asphalt shingles from bottom to top in sequence. The construction method comprises the following steps of base constructing, base processing and checking, base treating agent painting, additional layer pasting, self-adhesion waterproof roll paving and asphalt shingle paving. According to the asphalt shingle roof waterproof system, the elasticity and a good extension rate of self-adhesion rolls are utilized so that the self-adhesion rolls can be connected with the concrete base, and the problem of asphalt shingle damage caused by the quality problems of the waterproof base can be solved very well; the self-healing function of the self-adhesion rolls can be utilized so that an integrated waterproof layer formed by the self-adhesion rolls and the asphalt shingles can be formed, and the waterproof problem of the sloping roof is solved well. The construction method is reasonable in step and easy to operate.

Owner:北京金港建设股份有限公司 +1

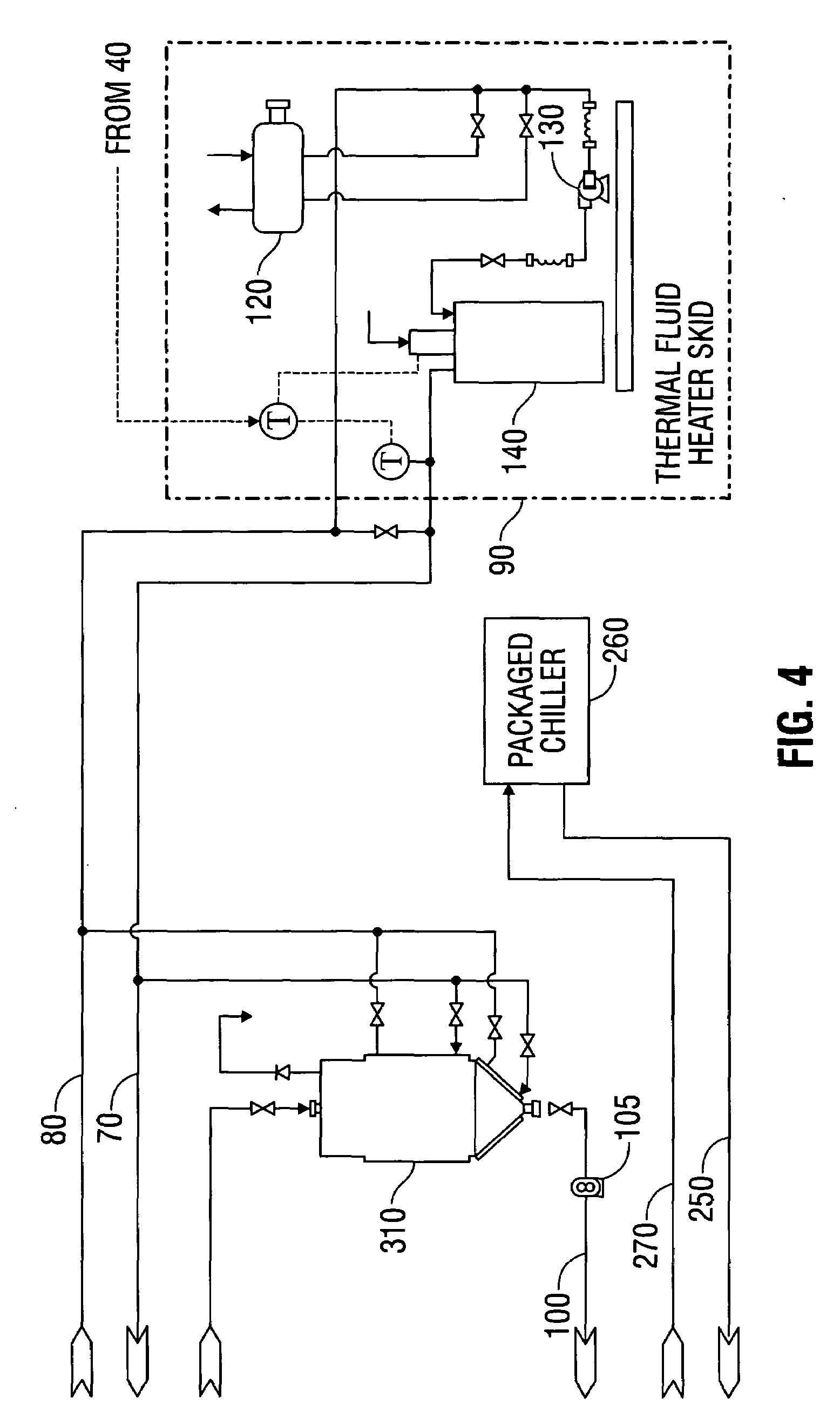

Asphalt production plant with pre-dryer assist

ActiveUS20170145642A1Emission controlThermally efficientDrying solid materials with heatTransportation and packagingAsphalt shingleProcess engineering

A combination of components for use in making asphalt concrete from a mixture of virgin aggregate material with recycled asphalt products and / or recycled asphalt shingles encompasses a direct dryer for heating virgin aggregate material; a pre-dryer for heating recycled asphalt product and / or recycled asphalt shingles, said pre-dryer using warm exhaust gas from said direct dryer to heat the recycled asphalt product and / or recycled asphalt shingles; and means for conveying warm exhaust gas from said direct dryer to said pre-dryer.

Owner:ASTEC INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com