System and method for manufacturing asphalt products with recycled asphalt shingles

a technology of asphalt products and asphalt suspensions, applied in the field of asphalt products, can solve problems such as significant waste, and achieve the effect of reducing the moisture content of the ground shingles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

Production of Processed Asphalt Suspension

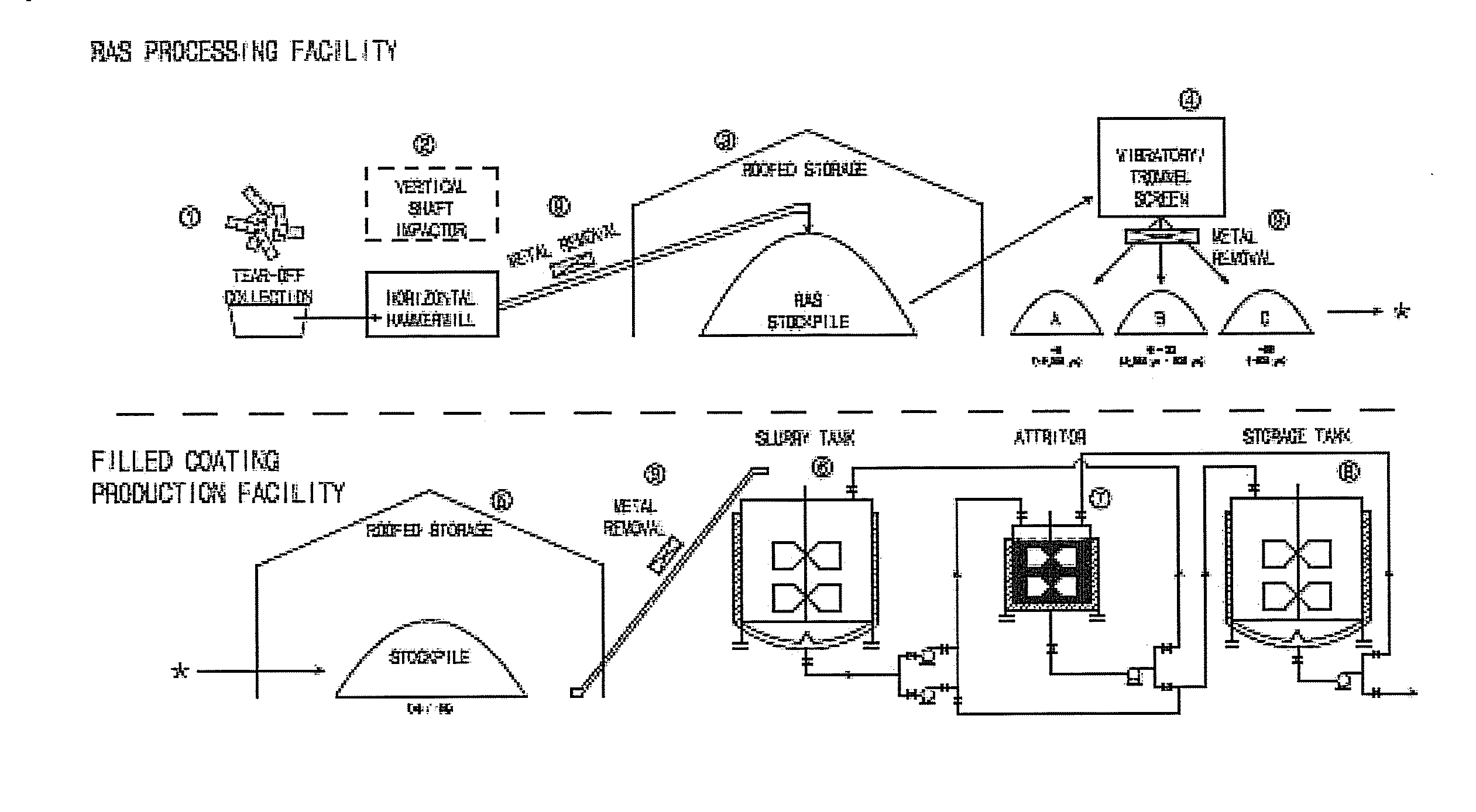

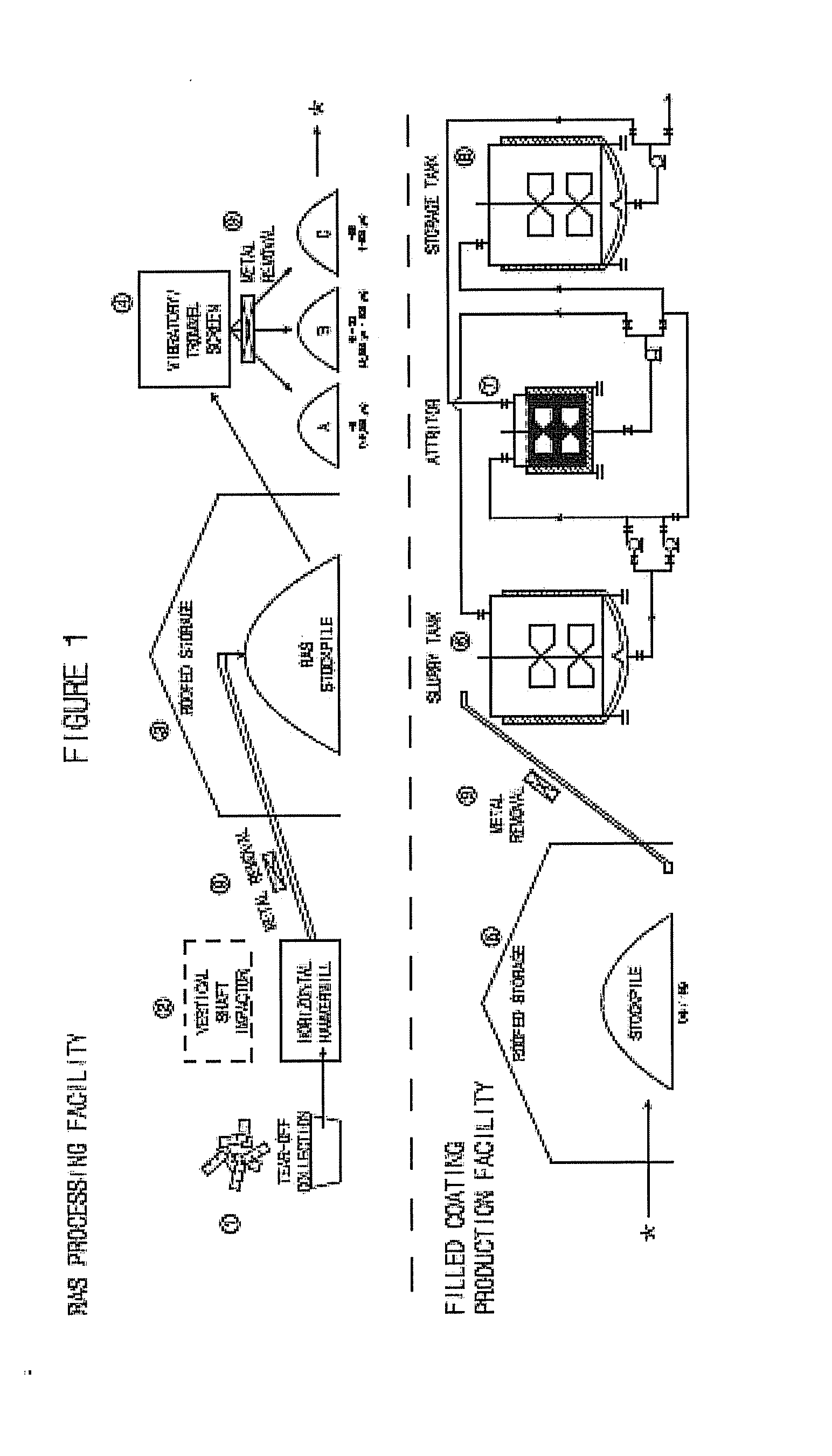

[0036]There are three main components in the production of processed asphalt suspension: processing of the RAS input material (FIG. 1: 1-4, 9), mixing and processing the processed asphalt suspension (FIG. 1: 5-7, 9), and storage of the processed asphalt suspension (FIG. 1: 8). Each component of the process will be described in the following example.

Processing of the Shingle Input Material

[0037]The quality of the shingle input material is critical to the production of the processed asphalt suspension. Quality refers to the amount of debris present, moisture content, and the size of the RAS after grinding and processing.

[0038]Debris is defined as the non-shingle materials present due to the tear off process (nails, flashing, wood, packaging for new shingles, etc.). Debris present during the processing is detrimental to the performance of the pumps, hoses, storage tanks, and mills used during the processing; however, minor amounts of debris, su...

example 2

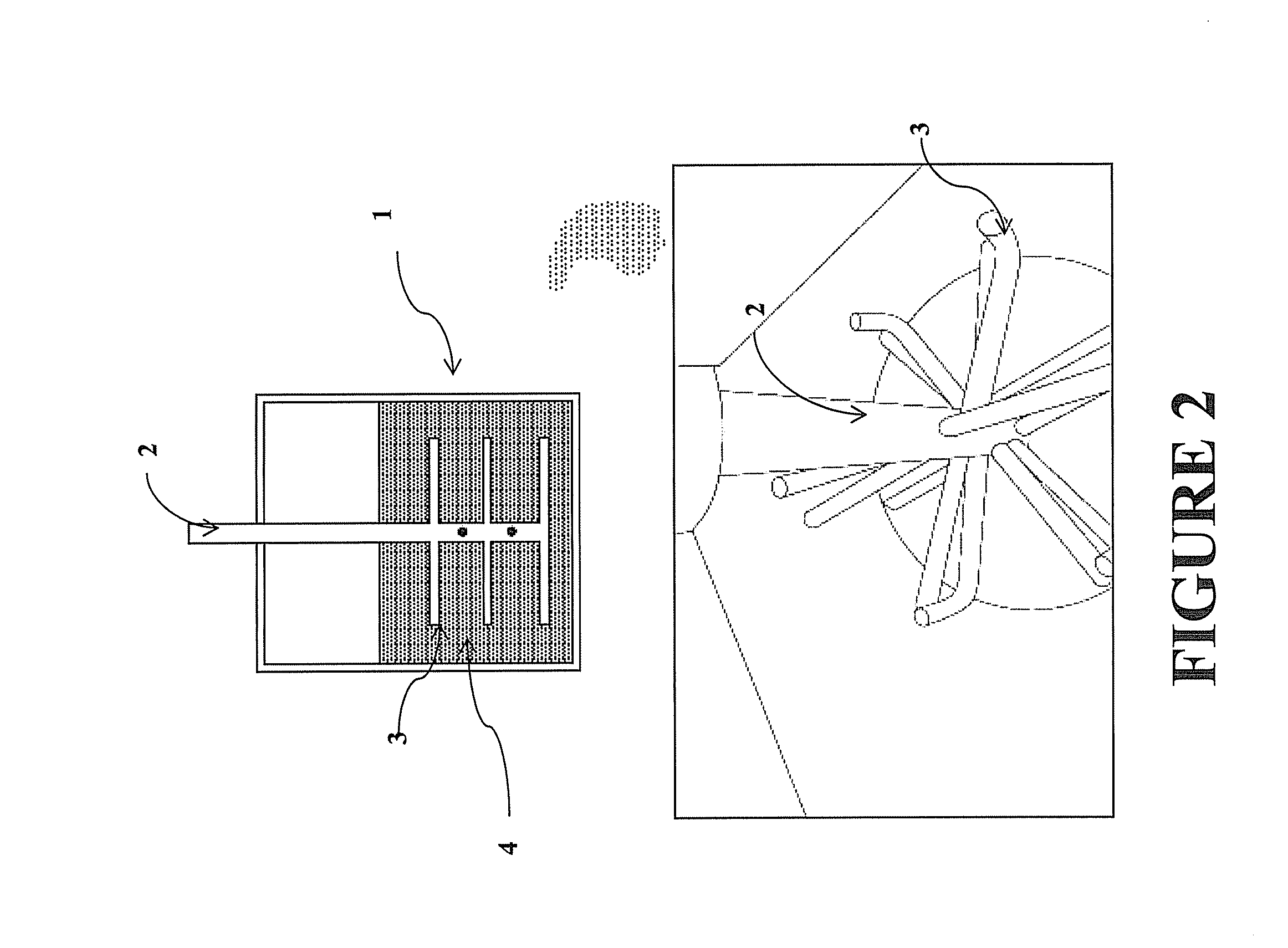

[0051]In the following examples, processed asphalt suspension compositions were prepared according to the following method. The RAS was mixed with virgin asphalt in a wetting tank and then transferred to a 400 liter jacketed attritor. The grinding media used in the attritor were 1 cm chrome steel ball bearings. The system was preheated to approximately 175° C. prior to adding the asphalt / RAS mixture. A nitrogen blanket was introduced to prevent oxidation during attriting. The mixing bar was rotated at about 100-150 rpm. The grinding media and the asphalt additive mixture were then mixed for about 5-12 minutes. During this process the grinding media provides shearing and impact forces, which reduce the asphalt additive particle size.

[0052]The processed asphalt suspension produced by the present invention is particularly useful for preparing roofing products. As mentioned above, such roofing products may include, but are not limited to, hot roofing adhesive, modified shingle adhesives...

example 4

Hot Mix Asphalt Paving Applications

[0065]The processed asphalt suspension as described in this present invention can additionally be used to create hot mix asphalt (HMA) pavements. The RAS can be mixed into virgin asphalt at levels between 5 and 65% of the total mixture. In one exemplary embodiment, the processed asphalt suspension contains 50% PG 58-28 with vacuum tower bottoms and 50% RAS. The properties of the processed asphalt suspension are shown in Table 5.

TABLE 550% PG 58-28 with vacuum tower bottomsDescription50% RASSoftening Point, ° F.135.524 hours Separation Test, ° F.0.548 hours Separation Test, ° F.225° C. Penetration42Solubility in TCE, % Soluble81.49Brookfield Rotational Viscosity @300° F., PaS0.469Brookfield Rotational Viscosity @325° F., PaS0.275Brookfield Rotational Viscosity @350° F., PaS0.150Original Binder DSR, G* / sin (delta), 76° C., Kpa0.96Original Binder DSR Fail Temp, ° C.75.6Original Binder DSR Phase Angle @76° C. 86.7RTFO Mass Loss, %−0.321RTFO Binder DSR,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com