Asphalt tile

A technology for asphalt shingles and asphalt, applied in the field of asphalt shingles, can solve the problems that affect the application of asphalt shingles, the easy aging of petroleum asphalt, and the easy falling off of mineral pellets, and achieve the improvement of fast aging speed, low wax content and excellent adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

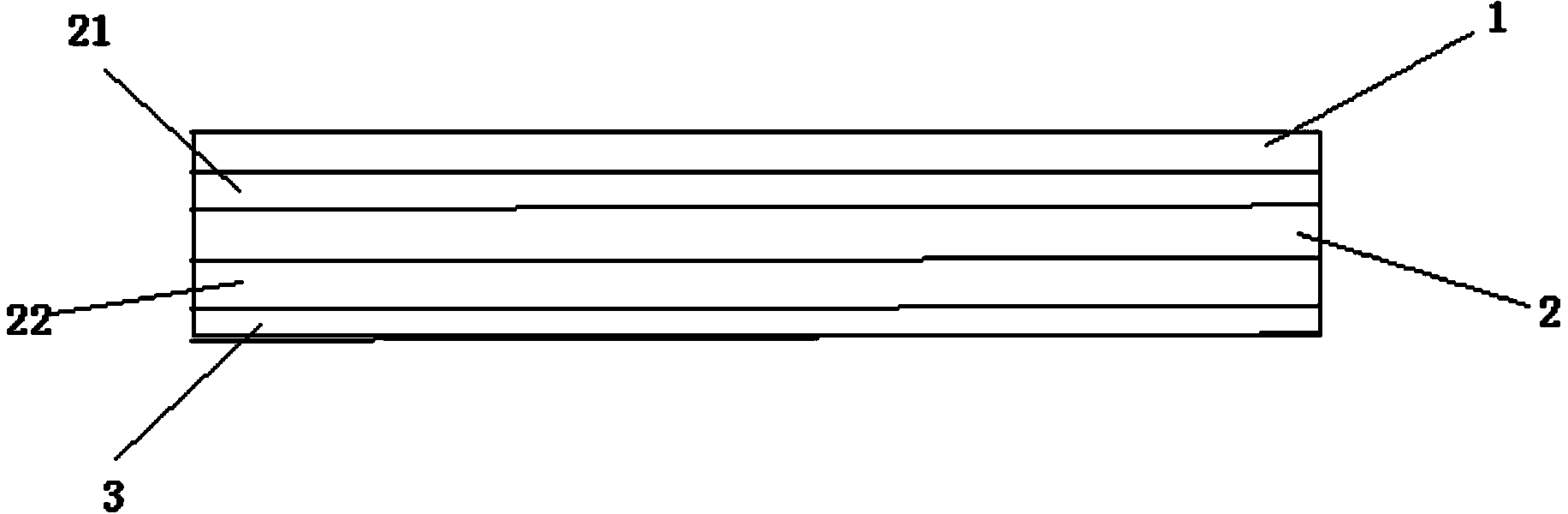

Image

Examples

Embodiment 1

[0024] Prepare modified asphalt by the following method: add 30g of natural lake asphalt to 70g of AH90# petroleum asphalt, heat up to 170°C, add 5g of thermoplastic elastomer SBS4402 and 5g of polypropylene, heat up to 185°C to 195°C, start the colloid Grinding, homogenization time is 2 hours; add 90g montmorillonite, keep the temperature at 180°C ~ 185°C, stir for 1 hour, then add 0.15g of ultraviolet absorber, stir for 0.5h, and then make modified asphalt for asphalt shingles. Then the modified asphalt shingle is prepared by the asphalt shingle forming system.

[0025] The mineral aggregates used are basalt aggregates, the glass fiber felt is alkali-free 300# glass fiber felt, and the isolation material layer is PP isolation film.

Embodiment 2

[0027] Prepare modified asphalt by the following method: add 50g of natural lake asphalt to 50g of AH90# petroleum asphalt, heat up to 170°C, add 4g of thermoplastic elastomer SBS4402 and 4.5g of polypropylene, heat up to 185°C to 195°C, start Colloid grinding, homogenization time is 2 hours; add 60g montmorillonite, keep the temperature at 180℃~185℃, stir for 1 hour, then add 0.08g ultraviolet absorber, stir for 0.5h, and then make modified asphalt for asphalt tiles , and then the modified asphalt shingle is prepared by the asphalt shingle forming system.

[0028] The mineral aggregates used are basalt aggregates, the glass fiber felt is alkali-free 450# glass fiber felt, and the isolation material layer is PET isolation film.

Embodiment 3

[0030] Prepare modified asphalt by the following method: add 70g of natural lake asphalt to 30g of AH90# petroleum asphalt, heat up to 170°C, add 3g of thermoplastic elastomer SBS4402 and 3.5g of polypropylene, heat up to 185°C to 195°C, start Colloid grinding, homogenization time is 2 hours; add 90g of montmorillonite, keep the temperature at 180℃~185℃, stir for 1 hour, then add 0.05g of ultraviolet absorber, stir for 0.5h, and then make modified asphalt for asphalt tiles , and then the modified asphalt shingle is prepared by the asphalt shingle forming system.

[0031] The mineral aggregates used are granite aggregates, the glass fiber felt is alkali-free 3 () (0# glass fiber felt, and the isolation material layer is LDPE isolation film.

[0032] The modified asphalt for asphalt shingles obtained in the above preparation process was first aged in a film oven (TFOT, temperature 163°C, time 5h), and then indoor accelerated ultraviolet aging test (125W high pressure mercury lam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com