Granite-imitation wall body material and preparation method thereof

A wall material and granite imitation technology, applied in the field of building materials, can solve the problem of phosphogypsum piled up like mountains, and achieve the effects of low production cost, wide source of raw materials, and enhanced comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] raw material:

[0040] Phosphogypsum 50kg, fiber 1kg, cement 6kg, yellow phosphorus slag 20kg and quicklime 2kg.

[0041] Preparation:

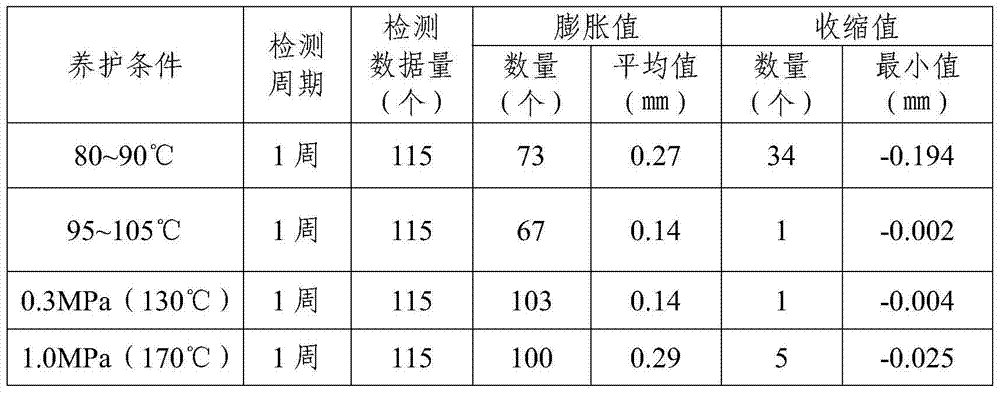

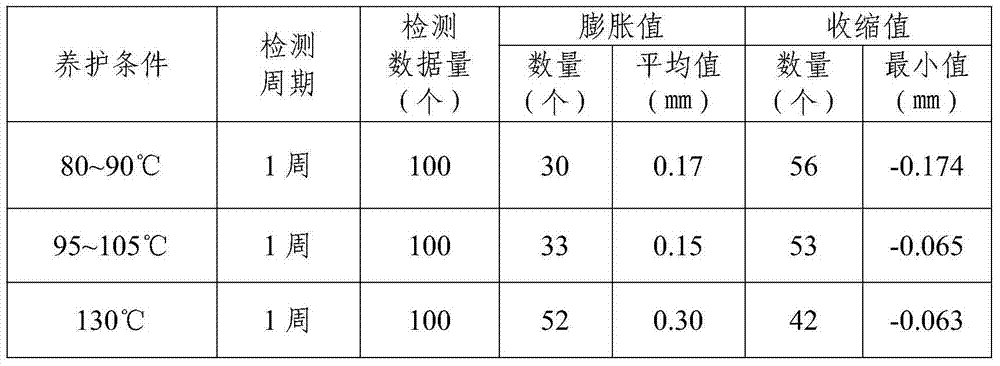

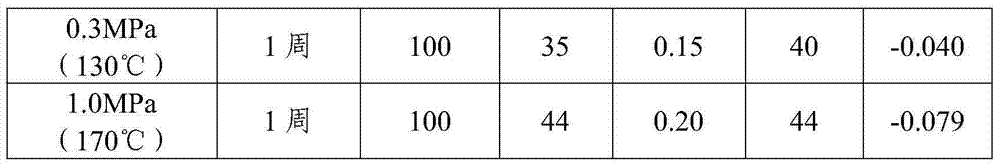

[0042] Put yellow phosphorus slag, cement, fiber, quicklime and phosphogypsum into the mixer, stir and react for 10 hours at a temperature of 80°C and a stirring speed of 3000r / min, then grind it into a fine powder of 80 meshes, and add the mixture to the obtained mixed material After the water with 12% weight of the material is stirred evenly, it is poured into the mold, and the formed phosphogypsum substrate is sent to a curing room with a temperature of 128°C and a pressure of 0.3MPa for 12 hours; After drying to a moisture content of 4%, the surface of the substrate is repaired and sanded to a flatness of 2mm, and the surface of the substrate is coated with polyester oil paint white paint with a thickness of 0.5mm. Dry it for 18 hours, and then spray the granite topcoat with a thickness of 2mm. After the granite topcoat is natura...

Embodiment 2

[0045] raw material:

[0046] Phosphogypsum 80kg, fiber 2kg, cement 16kg, yellow phosphorus slag 30kg and quicklime 10kg.

[0047] Preparation:

[0048] Put yellow phosphorus slag, cement, fiber, quicklime and phosphogypsum into the mixer, stir and react for 8 hours at a temperature of 90°C and a stirring speed of 3500r / min, then grind it into a 100-mesh fine powder, and add the obtained mixed material to the mixed material After the water with 16% weight is stirred evenly, it is poured into the mold, and the formed phosphogypsum substrate is sent to a curing room with a temperature of 132°C and a pressure of 0.3MPa for 12 hours; After drying to a moisture content of 6%, the surface of the substrate is repaired and sanded until its flatness is less than 2mm, and the surface of the substrate is coated with polyester oil paint white paint with a thickness of 1mm, and dried at a temperature of 60°C Treat for 15 hours, and then spray the granite topcoat with a thickness of 1mm. ...

Embodiment 3

[0051] raw material:

[0052] Phosphogypsum 60kg, fiber 1.2kg, cement 10kg, yellow phosphorus slag 22kg and quicklime 4kg.

[0053] Preparation:

[0054] Put yellow phosphorus slag, cement, fiber, quicklime and phosphogypsum into the mixer, stir and react for 9 hours at a temperature of 82°C and a stirring speed of 3100r / min, then grind it into a fine powder of 80 meshes, and add the obtained mixed material to the mixed material After mixing 13% water by weight evenly, pour it into the mold, send the formed phosphogypsum substrate into a curing room with a temperature of 129°C and a pressure of 0.3MPa for 15 hours, and wait for the phosphogypsum substrate to cool at room temperature. After drying to a moisture content of 5%, the surface of the substrate is repaired and sanded until its flatness is less than 2mm, and the surface of the substrate is coated with polyester oil paint white paint with a thickness of 0.9mm, at a temperature of 52°C Dry for 16 hours, and then spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com