Phosphogypsum-based imitated granite structure building material and preparation method thereof

A technology for imitating granite and building materials, applied in sustainable waste treatment, solid waste management, climate sustainability, etc. The effect of simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Formula: phosphogypsum 400kg, electrolytic yellow phosphorus slag 300kg, quicklime 20kg.

[0041] Preparation:

[0042] (1) Ingredients: take phosphogypsum and unslaked lime according to the mass ratio of 20:1 and neutralize them for 1 minute, put them in the mixer and stir for 40 seconds, then turn on the mixer, add electrolytic yellow phosphorus slag and continue to stir for 60 seconds to obtain the mixed material, then After the mixed material is dried to free water ≤ 1%, put it into a ball mill and grind it for 30 minutes until the specific surface area is 260m 2 / kg;

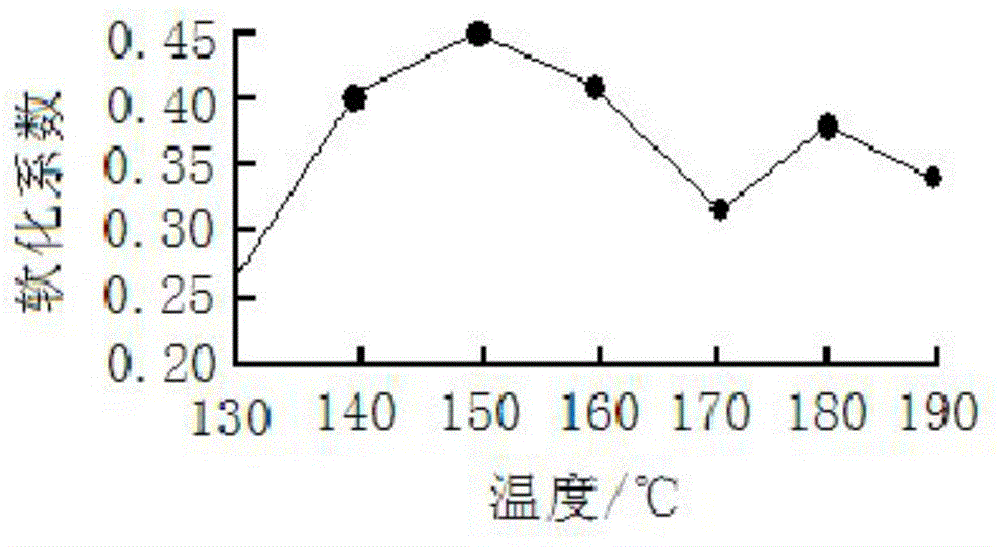

[0043] (2) Aging: aging the mixed material after ball milling in step (1) after calcining at a temperature of 140° C. for 3 hours, and the aging time is 24 hours;

[0044] (3) Forming: put the aged material into the vibration forming machine, and vibrate and form according to the required shape;

[0045] (4) Autoclaving curing: autoclaving the vibration-molded material with a heating rate of 20°C...

Embodiment 2

[0051] Formula: 500kg of phosphogypsum, 350kg of electrolytic yellow phosphorus slag, 25kg of quicklime, 125kg of colored sand, and 250kg of silicon-acrylic emulsion.

[0052] Preparation:

[0053] (1) Ingredients: take phosphogypsum and unslaked lime according to the mass ratio of 20:1 and neutralize them for 1 minute, put them in the mixer and stir for 40 seconds, then turn on the mixer, add electrolytic yellow phosphorus slag and continue to stir for 60 seconds to obtain the mixed material, then After the mixed material is dried to free water ≤ 1%, put it into a ball mill and grind it for 30 minutes until the specific surface area is 260m 2 / kg;

[0054] (2) Aging: aging the mixed material after ball milling in step (1) after calcining at a temperature of 145° C. for 3 hours, and the aging time is 25 hours;

[0055] (3) Forming: put the aged material into the vibration forming machine, and vibrate and form according to the required shape;

[0056] (4) Autoclaving curing...

Embodiment 3

[0062] Formula: 800kg of phosphogypsum, 500kg of electrolytic yellow phosphorus slag, and 40kg of quicklime.

[0063] Preparation:

[0064] (1) Ingredients: take phosphogypsum and unslaked lime according to the mass ratio of 20:1 and neutralize them for 1 minute, put them in the mixer and stir for 40 seconds, then turn on the mixer, add electrolytic yellow phosphorus slag and continue to stir for 60 seconds to obtain the mixed material, then After the mixed material is dried to free water ≤ 1%, put it into a ball mill and grind it for 30 minutes until the specific surface area is 260m 2 / kg;

[0065] (2) Aging: aging the mixed material after ball milling in step (1) after calcining at a temperature of 150° C. for 3 hours, and the aging time is 26 hours;

[0066] (3) Forming: put the aged material into the vibration forming machine, and vibrate and form according to the required shape;

[0067] (4) Autoclave curing: Autoclave curing of the vibration-molded material with a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com