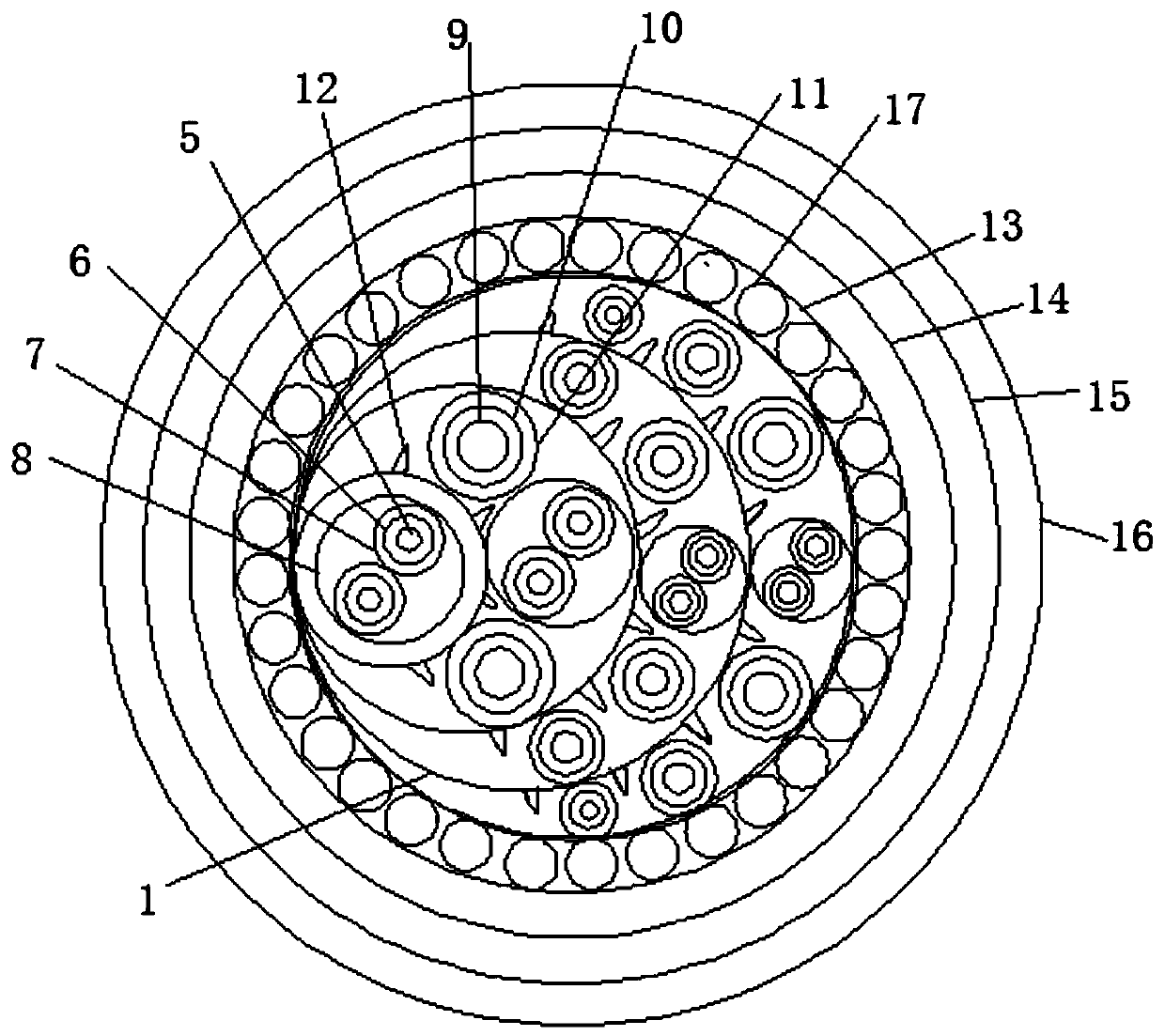

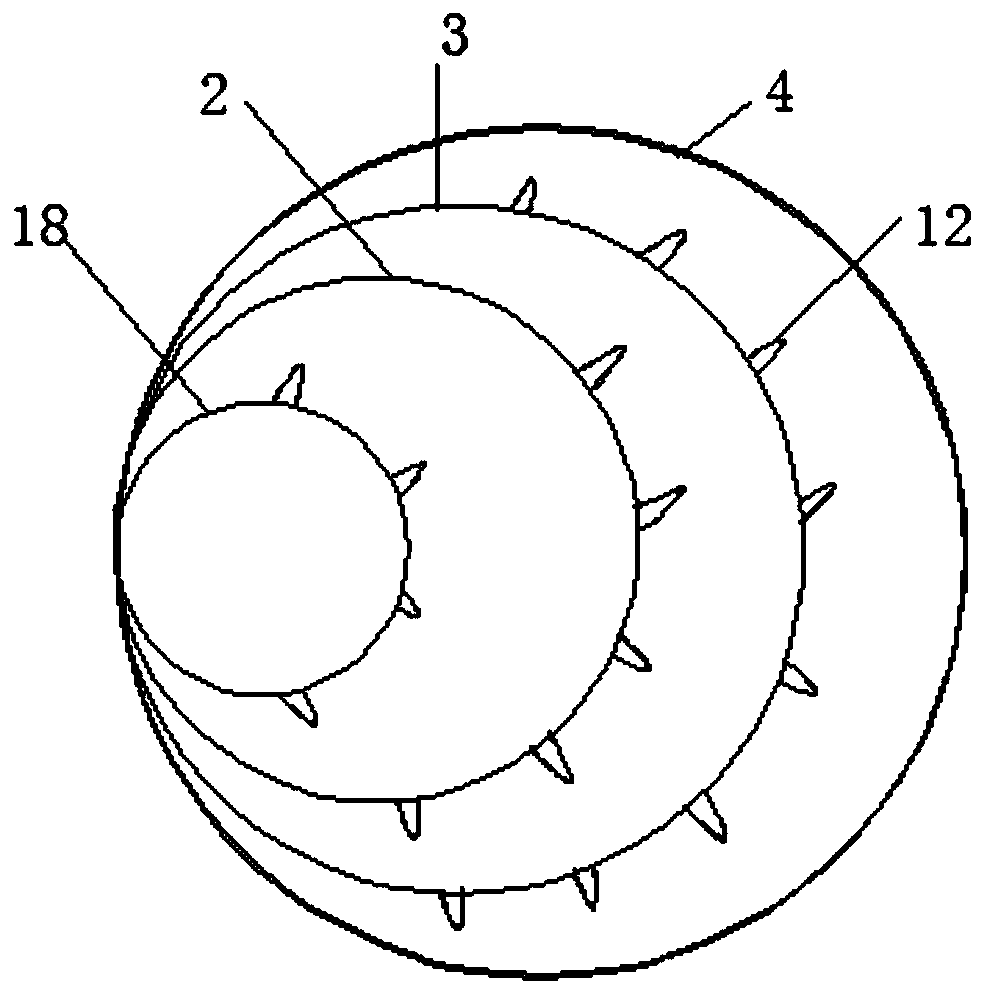

Waterproof fireproof control cable

A technology for controlling cables, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of complex fireproof cable technology, decreased cable insulation performance, poor cable bending performance, etc., to achieve compact and stable internal structure of the cable, good insulation effect, Good toughness and impact strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of described ethylene-propylene rubber elastic rod, comprises the following steps:

[0027] (1) Take 8-hydroxyquinoline, add it to 13 times of its weight in toluene, stir evenly, add propylene oxide, send it into a constant temperature water bath at 50°C, add nano-carbon powder, keep stirring for 1 hour, and distill off Toluene, to get activated carbon powder;

[0028] (2) Get 6-hydroxyl-2-naphthoic acid, add it to 20 times of its weight in deionized water, stir evenly to obtain acid solution;

[0029] (3) Take diethylenetriamine, add it to 10 times its weight in absolute ethanol, stir evenly, add ethylene-propylene rubber powder, raise the temperature to 55°C, add anti-aging agent RD, keep stirring for 20 minutes, and distill off the ethanol , added to the above acid solution, raising the temperature to 70°C, insulated and stirred for 1 hour, suction filtered, washed the filter cake with water, sent to an oven, and dried to obtain modified rubbe...

Embodiment 2

[0032] Described ethylene-propylene rubber elastic rod is made up of the raw material of following parts by weight:

[0033] Ethylene-propylene rubber powder 130, 6-hydroxy-2-naphthoic acid 5, zinc cyanurate 2, 8-hydroxyquinoline 1, diethylenetriamine 6, antioxidant RD2, propylene oxide 9, nano-carbon powder 13, sulfur 1 .

[0034] The preparation method of described ethylene-propylene rubber elastic rod, comprises the following steps:

[0035] (1) Take 8-hydroxyquinoline, add it to 20 times its weight in toluene, stir evenly, add propylene oxide, send it into a constant temperature water bath at 55°C, add nano-carbon powder, keep stirring for 2 hours, and distill off Toluene, to get activated carbon powder;

[0036] (2) Get 6-hydroxy-2-naphthoic acid, add it to 30 times of its weight in deionized water, stir evenly to obtain acid solution;

[0037] (3) Take diethylenetriamine, add it to 17 times its weight in absolute ethanol, stir evenly, add ethylene-propylene rubber pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com