Minimum inflation low heat silicate cement

A portland cement and micro-expansion technology, applied in cement production, sustainable waste treatment, solid waste management, etc., can solve the problems of high heat of hydration, easy cracking, etc., achieve long-term strength stability, low water demand, and later The effect of high strength increase rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

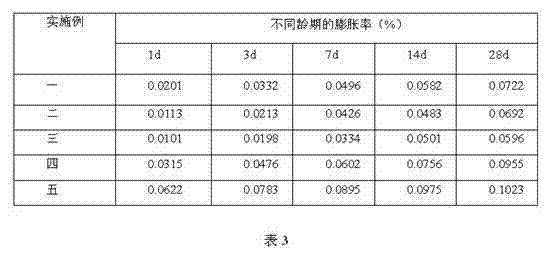

Examples

Embodiment 1

[0033] Calcinate the magnesite at 800°C for 60 minutes, and after natural cooling, grind it through a 0.125 μm sieve, and grind the steel slag to a specific surface area of 300m 2 / kg, according to the following ratio:

[0034] Low heat portland cement clinker 85%

[0035] Gypsum 5%

[0036] Lightly burnt MgO 2%

[0037] Steel slag 6%

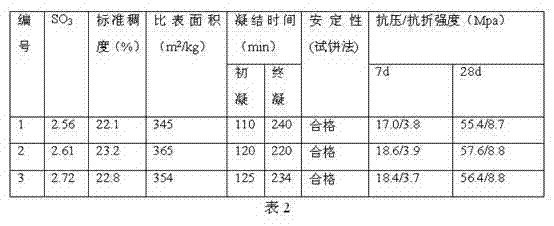

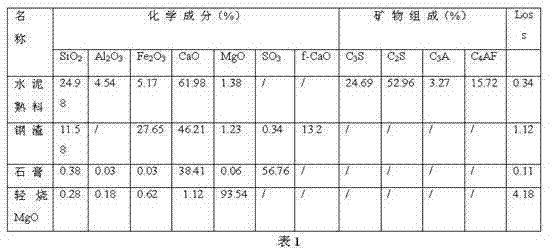

[0038] Grind after mixing, so that the fineness is less than 12%, and it is prepared into micro-expansion low-heat Portland cement. The chemical composition and mineral composition of the prepared micro-expansion low-heat Portland cement are shown in Table 1.

[0039]

[0040]

Embodiment 2

[0042] Calcinate the magnesite at 850°C for 60 minutes, and after natural cooling, grind it through a 0.125 μm sieve, and grind the steel slag to a specific surface area of 390m 2 / kg, according to the proportion of low-heat Portland cement clinker 85%, gypsum 5%, light-burned MgO2%, steel slag 6%. Grind after mixing, so that the fineness is less than 12%, and it is prepared into micro-expansion low-heat Portland cement.

Embodiment 3

[0044] Calcinate the magnesite at 950°C for 60min, cool it naturally and grind it through a 0.125μm sieve, and grind the steel slag to a specific surface area of 420m 2 / kg, according to the following ratio:

[0045] Low heat portland cement clinker 85%

[0046] Gypsum 5%

[0047] Lightly burnt MgO 2%

[0048] Steel slag 6%

[0049] Grind after mixing, so that the fineness is less than 12%, and it is prepared into micro-expansion low-heat Portland cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com