Whisker reinforcement-based self-leveling cement mortar and application thereof

A kind of cement mortar and self-leveling technology, applied in the field of self-leveling cement mortar, can solve the problems of poor surface strength, unstable performance, surface micro-cracks, etc. Salt corrosion, good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

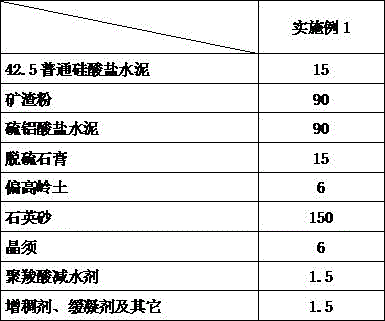

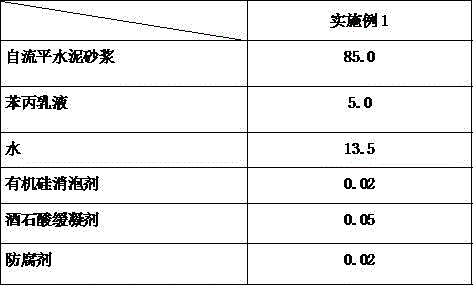

[0078] 1. The raw material ratio of self-leveling cement mortar is shown in Table 1

[0079] Table 1 Self-leveling cement mortar formula table Unit: kg

[0080]

[0081] Among them, the whiskers are composed of 60% gypsum whiskers and 40% calcium carbonate whiskers (weight ratio), which are added separately to facilitate uniform stirring.

[0082] According to the formula of self-leveling cement mortar in Example 1 corresponding to Table 1, ordinary Portland cement, slag powder, special cement, gypsum, metakaolin, water reducing agent and whisker powder were weighed according to the weight ratio and the above-mentioned sieved raw materials and quartz sand.

[0083] Stir the weighed ordinary Portland cement, slag powder, sulphoaluminate cement, gypsum, metakaolin and whisker crystal seeds; then add quartz sand for stirring, and release it from the discharge port after 10-20 minutes About half of the powder, re-add the powder from the feed port and continue stirring for abo...

Embodiment 2

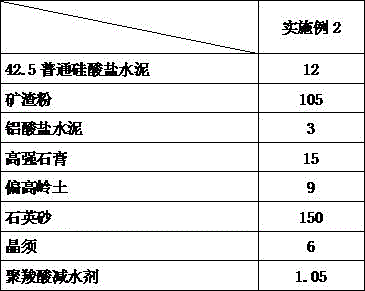

[0091] Table 3 Self-leveling cement mortar formula table Unit: kg

[0092]

[0093] Among them, the whiskers are 60% gypsum whiskers and 40% ettringite whiskers. The cost of the two is relatively low, but they should be added separately to facilitate uniform mixing.

[0094] Table 4 Formulation of retarded emulsion Unit: kg

[0095]

[0096] According to the formula corresponding to Table 3, adopt the method of Example 1 to prepare self-leveling cement mortar; according to the formula corresponding to Table 4, adopt the method of Example 1 to prepare retarded emulsion.

[0097] Weigh 85 kg of self-leveling cement mortar and all the retarded emulsions prepared above, and use the method in Example 1 to prepare a self-leveling floor.

[0098] The method provided by JC / T 985-2005 "Cement-based self-leveling mortar for ground" is used for detection. The 28-day flexural strength of the wear-resistant floor prepared in this example is >12.5MPa. The 28-day compressive strength...

Embodiment 3

[0100] Table 5 Self-leveling cement mortar formula table Unit: kg

[0101]

[0102] Among them, the whiskers are 40% gypsum whiskers, 20% ettringite whiskers, 20% calcium carbonate whiskers and 20% magnesium oxide whiskers (weight ratio), and the cost of magnesium oxide whiskers is relatively high, but the performance Increase can improve the tensile strength and crack resistance of the floor mortar after the emulsion content is reduced. The above-mentioned whiskers should be added separately to facilitate uniform mixing.

[0103] Table 6 Formulation of retarded emulsion Unit: kg

[0104]

[0105] According to the formula corresponding to Table 5, adopt the method of Example 1 to prepare self-leveling cement mortar; according to the formula corresponding to Table 6, adopt the method of Example 1 to prepare retarded emulsion.

[0106] 85 kg of the self-leveling cement mortar prepared above and all the slow-setting emulsions prepared above were used to prepare a wear-resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com