Mineral oil based magnetorheological fluid for high power transmission and preparation method thereof

An oil-based magnetic, high-power technology, used in the petroleum industry, lubricating compositions, additives, etc., can solve the problems affecting the application of construction machinery, small shear yield stress, poor settlement stability, etc., to improve settlement stability and shear stability. Shear yield stress, prevent particle settling, reduce settling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

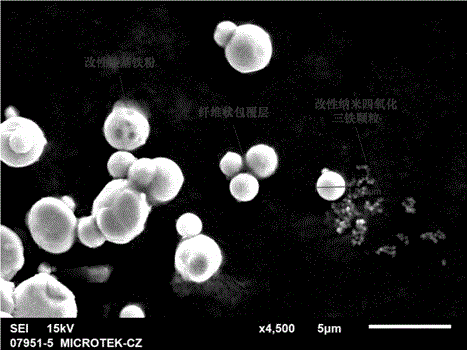

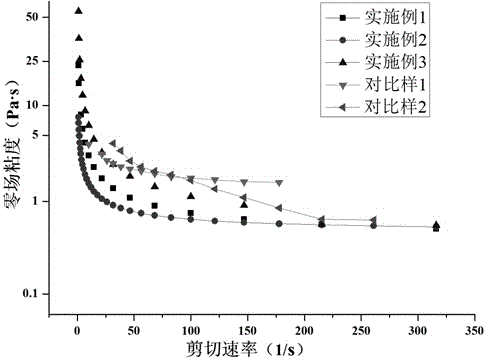

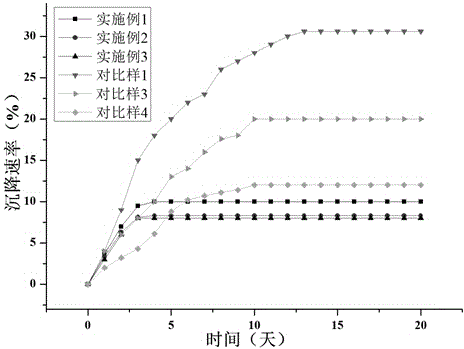

[0055] Prepare a mineral oil-based magnetorheological fluid for high-power transmission with a volume fraction of 20%, that is, the mass fraction of magnetic particles is 67%, and the preparation steps are:

[0056] (1 Disperse 200g of carbonyl iron powder particles after acidification and activation treatment into a three-necked bottle filled with electroless plating solution (reaction solution containing cobalt element), pass in nitrogen gas, keep ventilation during the reaction process, and heat in a water bath at 65°C Stir uniformly under the conditions for 2 hours. After the stirring is completed, the mixture is separated and washed, and vacuum-dried under low pressure to obtain cobalt-coated carbonyl iron powder particles;

[0057] (2 put a certain quality of FeC1 3 ·6H 2 O and FeCl 2 4H 2 O mixed to ensure Fe in the mixture 2+ with Fe 3+ The ratio is 1:1.5, take 150 ml Place in a four-necked flask, and stir at high speed under the condition of heating in a water b...

Embodiment 2

[0062] Prepare a mineral oil-based magnetorheological fluid for high-power transmission with a volume fraction of 25%, that is, the mass fraction of magnetic particles is 75%, and the preparation steps are:

[0063] (1 will be 305 g Carbonyl iron powder particles are acidified and activated and dispersed into a three-neck bottle filled with electroless plating solution (reaction solution containing cobalt element), and nitrogen gas is introduced to keep ventilation during the reaction process, and the water bath is heated at 70°C and stirred evenly 2 h ; After the stirring is finished, the mixture is separated and washed, and vacuum-dried under low pressure to obtain cobalt-coated carbonyl iron powder particles;

[0064] (2 obtain the modified nanometer Fe according to the step in embodiment 1 3 o 4 particles;

[0065] (3 Add a certain proportion of additives, specifically 2.6 g HT-610, 1.4 g diatomaceous earth, 2.3 g organic bentonite, 1.8 g Benzoic acid, 1.6 g of si...

Embodiment 3

[0069] Prepare a mineral oil-based magnetorheological fluid for high-power transmission with a volume fraction of 30%, that is, the mass fraction of magnetic particles is 80%, and the preparation steps are:

[0070] (1 will be 400 g Carbonyl iron powder particles are acidified and activated and dispersed into a three-neck bottle filled with electroless plating solution (reaction solution containing cobalt element), and nitrogen gas is introduced to keep ventilation during the reaction process, and the water bath is heated at 70°C and stirred evenly 2 h ; After the stirring is finished, the mixture is separated and washed, and vacuum-dried under low pressure to obtain cobalt-coated carbonyl iron powder particles;

[0071] (2 obtain the modified nanometer Fe according to the step in embodiment 1 3 o 4 particles;

[0072] (3 Add a certain proportion of additives, specifically 3.5 g HT-610, 2.2 g diatomaceous earth, 3 g organic bentonite, 1.8 g of benzoic acid, 2 g of sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com