Heat-resisting waterproof wallpaper and production method thereof

A waterproof wall and heat-resistant technology, which can be used in textiles, papermaking, coatings, construction, etc., and can solve the problems of poor heat-resistant and waterproof performance of wallpaper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

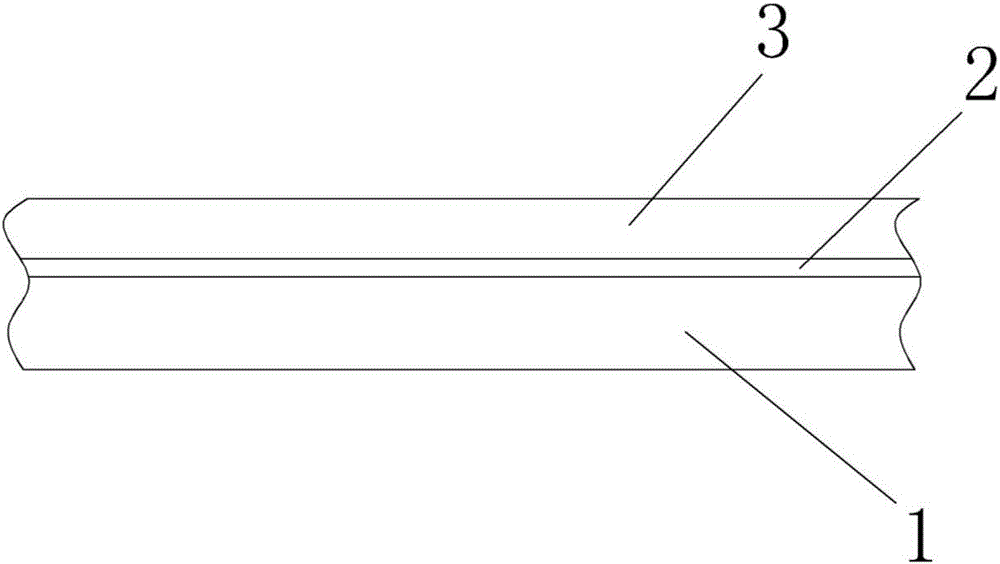

[0025] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a heat-resistant and waterproof wallpaper proposed by the present invention.

[0026] refer to figure 1 , a heat-resistant waterproof wallpaper proposed by the present invention, comprising a substrate layer 1, a waterproof layer 2 and a heat-resistant layer 3, the outer periphery of the substrate layer 1 is coated with a waterproof layer 2, and the waterproof layer 2 is far away from the substrate layer 1 The outer periphery of is coated with a heat-resistant layer 3, wherein:

[0027] The substrate layer 1 is wood pulp paper;

[0028] The raw materials of waterproof layer 2 include by weight: 30 parts of water-based saturated polyester resin, 9 parts of hexamethoxymethylmelamine resin, 4.5 parts of water-based pure acrylic resin, 3 parts of methyl etherified amino resin, silicone modified epoxy resin 3.5 parts, 2.5 parts of silicone modified alkyd resin, 3.5 parts of aluminum powder, 2 par...

Embodiment 2

[0031] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a heat-resistant and waterproof wallpaper proposed by the present invention.

[0032] refer to figure 1 , a heat-resistant waterproof wallpaper proposed by the present invention, comprising a substrate layer 1, a waterproof layer 2 and a heat-resistant layer 3, the outer periphery of the substrate layer 1 is coated with a waterproof layer 2, and the waterproof layer 2 is far away from the substrate layer 1 The outer periphery of is coated with a heat-resistant layer 3, wherein:

[0033] The substrate layer 1 is non-woven paper;

[0034] The raw materials of the waterproof layer 2 include by weight: 25 parts of water-based saturated polyester resin, 15 parts of hexamethoxymethylmelamine resin, 3 parts of water-based pure acrylic resin, 5 parts of methyl etherified amino resin, silicone modified epoxy resin 2 parts, 4 parts of silicone modified alkyd resin, 2 parts of aluminum powder, 3 parts ...

Embodiment 3

[0041] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a heat-resistant and waterproof wallpaper proposed by the present invention.

[0042] refer to figure 1 , a heat-resistant waterproof wallpaper proposed by the present invention, comprising a substrate layer 1, a waterproof layer 2 and a heat-resistant layer 3, the outer periphery of the substrate layer 1 is coated with a waterproof layer 2, and the waterproof layer 2 is far away from the substrate layer 1 The outer periphery of is coated with a heat-resistant layer 3, wherein:

[0043] The substrate layer 1 is cloth;

[0044] The raw materials of the waterproof layer 2 include by weight: 35 parts of water-based saturated polyester resin, 3 parts of hexamethoxymethylmelamine resin, 6 parts of water-based pure acrylic resin, 1 part of methyl etherified amino resin, silicone modified epoxy resin 5 parts, 1 part of silicone modified alkyd resin, 5 parts of aluminum powder, 1 part of aluminum si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com