Preparation method of halogen-free flame retardant and application of halogen-free flame retardant to rigid polyurethane foam

A technology of rigid polyurethane and flame retardant, applied in the field of materials, can solve the problems of poor compatibility between halogen-free flame retardant and polyurethane foam matrix, flammability of rigid polyurethane foam, deterioration of mechanical properties of rigid polyurethane foam, etc. Improved mechanical properties, good compatibility and low hydroxyl value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

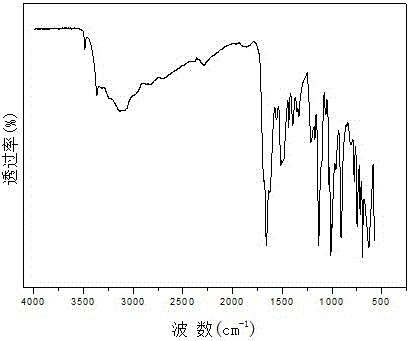

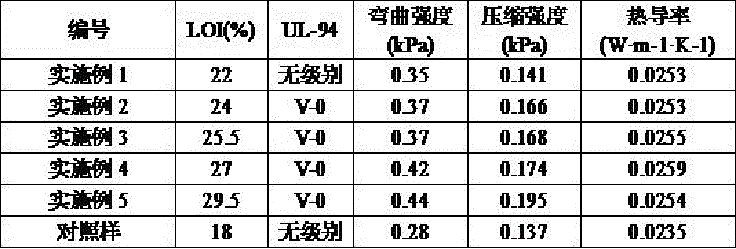

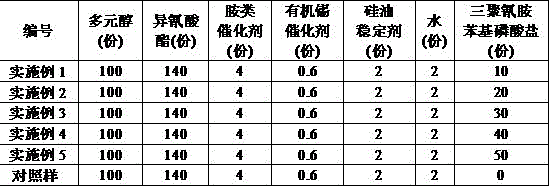

[0018] Add 12.6g of melamine, 15.8g of phenylphosphoric acid, and 270ml of water into an Erlenmeyer flask, raise the temperature to 70°C and keep stirring, react for 5h, filter the product, wash with water, and dry to obtain melamine phenylphosphate. Infrared spectrum of melamine phenyl phosphate, see figure 1 .

[0019] First mix 100 parts of polyether polyol and 10 parts of melamine phenyl phosphate evenly, then add 4 parts of amine catalyst, 0.6 part of organotin catalyst, 2 parts of water and 2 parts of silicone oil foam stabilizer, mix well, and then quickly add 140 parts of polymethylene polyphenyl polyisocyanate, stirred evenly at high speed, poured into the mold for foaming, after the foam was formed, the foam was taken out and placed in an oven at 60°C for 24 hours to obtain the halogen-free flame retardant hard Polyurethane foam.

Embodiment 2

[0021] Add 12.6g of melamine, 15.8g of phenylphosphoric acid, and 300ml of water into an Erlenmeyer flask, raise the temperature to 95°C and keep stirring, react for 3h, filter the product, wash with water, and dry to obtain melamine phenylphosphate.

[0022] First mix 100 parts of polyether polyol and 20 parts of melamine phenyl phosphate evenly, then add 4 parts of amine catalyst, 0.6 part of organotin catalyst, 2 parts of water and 2 parts of silicone oil foam stabilizer, mix well, and then quickly add 140 parts of polymethylene polyphenyl polyisocyanate, stirred evenly at high speed, poured into the mold for foaming, after the foam was formed, the foam was taken out and placed in an oven at 60°C for 24 hours to obtain the halogen-free flame retardant hard Polyurethane foam.

Embodiment 3

[0024] Add 12.6g of melamine, 15.8g of phenylphosphoric acid, and 400ml of water into an Erlenmeyer flask, raise the temperature to 80°C and keep stirring, react for 4h, filter the product, wash with water, and dry to obtain melamine phenylphosphate.

[0025] First mix 100 parts of polyether polyol and 30 parts of melamine phenyl phosphate evenly, then add 4 parts of amine catalyst, 0.6 part of organotin catalyst, 2 parts of water and 2 parts of silicone oil foam stabilizer, mix well, and then quickly add 140 parts of polymethylene polyphenyl polyisocyanate, stirred evenly at high speed, poured into the mold for foaming, after the foam was formed, the foam was taken out and placed in an oven at 60°C for 24 hours to obtain the halogen-free flame retardant hard Polyurethane foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com