Bisphenol A polyether and preparation method thereof

A polyether and bisphenol technology, applied in the field of bisphenol A polyether and its preparation, can solve the problems of short validity period, complicated preparation process and high chromaticity, and achieve the effects of good subsequent application, simple process and low chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of bisphenol A polyether of the present invention is simple in technology, adopts bisphenol A and alkylene oxide to react, after ripening, degassing, adds antioxidant to obtain bisphenol A polyether product, the method of the present invention can obtain hydroxyl Uniform bisphenol A polyether product with low value, low viscosity and low color.

[0045] In a preferred embodiment of the present invention, the mass ratio of bisphenol A to alkylene oxide is 30-50:40-60, preferably 35-45:45-55, more preferably 42:50.

[0046] The use of a specific amount of alkylene oxide helps to improve the reaction efficiency with bisphenol A, reduce by-products, and obtain bisphenol A polyether products with low hydroxyl value, low viscosity and low chroma.

[0047] In a preferred embodiment of the present invention, the vacuum degree of the vacuum reaches above -0.098MPa, preferably above -0.099MPa.

[0048] In a preferred embodiment of the present invention, th...

Embodiment 1

[0082] A preparation method of bisphenol A polyether, comprising:

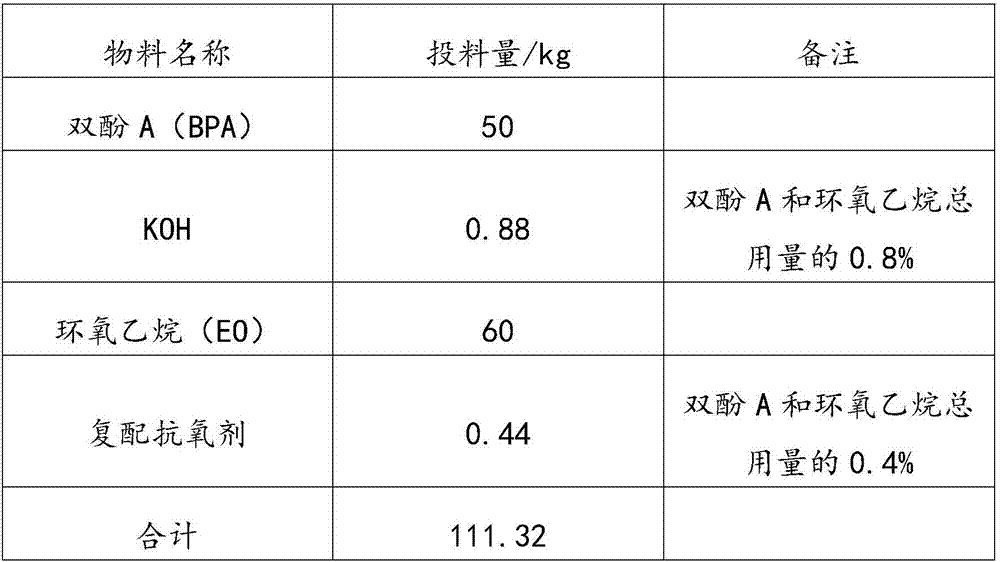

[0083] 1. The dosage of each raw material is shown in Table 1:

[0084] Table 1 Example 1 of the present invention Bisphenol A polyether preparation method each raw material consumption

[0085]

[0086]

[0087] 2. Process flow:

[0088] 1. Check:

[0089] The kettle is clean, the reaction kettle, external circulation pump and all valves and pipelines of the system have no leakage, the vacuum pump is running normally, and the vacuum degree is above -0.098MPa, such as -0.099MPa, the lower the better. There is no pure material produced in the previous batch in the reactor and pipeline.

[0090] 2. Feeding:

[0091] Throw in BPA.

[0092] 3. Add KOH:

[0093] Add KOH according to the amount of feed, which can be pumped or poured directly. After adding KOH, install the blind plate and replace it with negative pressure twice. If the seal of the reactor is good, feed the material under negative pressure...

Embodiment 2

[0104] A preparation method of bisphenol A polyether, comprising:

[0105] 1. The dosage of each raw material is shown in Table 2:

[0106] Table 2 The amount of each raw material used in the preparation method of bisphenol A polyether in Example 2 of the present invention

[0107]

[0108] 2. Process flow:

[0109] 1. Check:

[0110] The kettle is clean, the reaction kettle, external circulation pump and all valves and pipelines of the system have no leakage, the vacuum pump is running normally, and the vacuum degree is above -0.098MPa, such as -0.099MPa, the lower the better. There is no pure material produced in the previous batch in the reactor and pipeline.

[0111] 2. Feeding:

[0112] Throw in BPA.

[0113] 3. Add KOH:

[0114] Add KOH according to the amount of feed, which can be pumped or poured directly. After adding KOH, install the blind plate and replace it with negative pressure twice. If the seal of the reactor is good, feed the material under negative ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com