High-hydroxyl-value polyester resin for extinction type powder coating and preparation method and application thereof

A polyester resin, powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of easy agglomeration of finished powder coatings, affecting downstream applications, affecting the cost and downstream application potential of matte powder coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

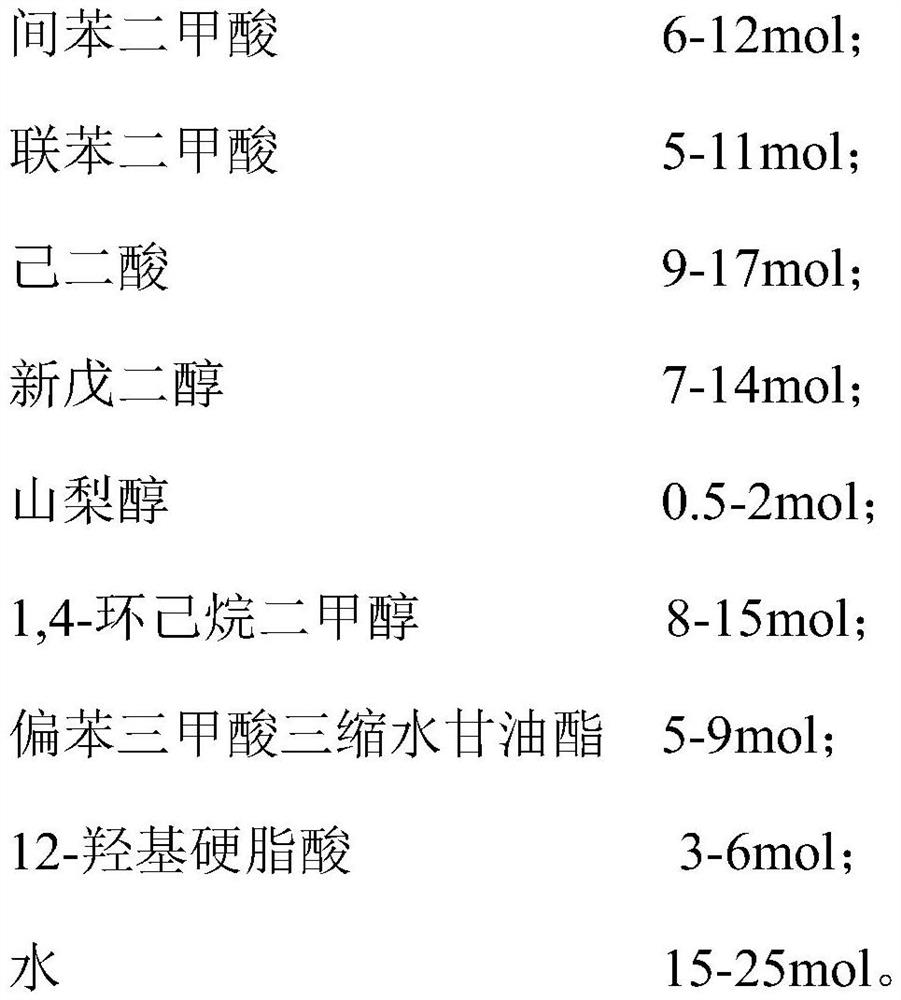

[0028]The extinction powder coating of the extinction powder coating is a high-hydroxyl resolved polyester resin which includes a component comprising a molar number:

[0029]

[0030]Silitone oxide whose amount is 0.08 mol% of the total mole amount of the preparation raw material;

[0031]Antioxidant 1010 has a total amount of 0.1 mol% of the preparative raw material.

[0032]The preparation method of the extinctable polyester resin of the extinction type powder coating, including the steps of:

[0033](1) The napultanediol and sorbitol of the acquisition are mixed, and the melt is heated at 130 ° C, and the formulation amount is added to the mixed material. Dicic acid, and catalyst, in the protective atmosphere, gradually warmed to 210 ° C under protective atmosphere to 210 ° C for insulation reaction, and the acid value is lowered to 122 mgKOH / g;

[0034](2) Continue to add the amount of 1,4-cyclohexane dimethanol to be mixed, gradually warp the polymerization at 6 ° C / h to 225 ° C, and the ac...

Embodiment 2

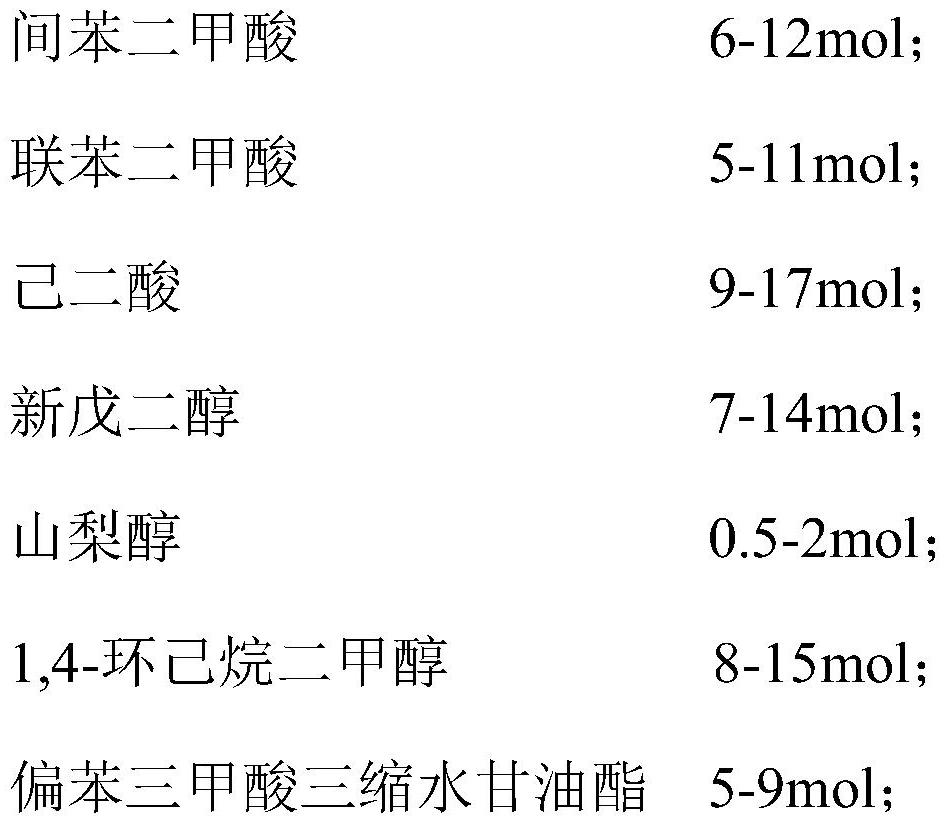

[0039]The extinction powder coating of the extinction powder coating is a high-hydroxyl resolved polyester resin which includes a component comprising a molar number:

[0040]

[0041]

[0042]Silitrous oxide whose amount is 0.2 mol% of the total mole of the preparation raw material;

[0043]Antioxidant 1010 has a total amount of 0.2 mol% of the preparation raw material.

[0044]The preparation method of the extinctable polyester resin of the extinction type powder coating, including the steps of:

[0045](1) The napultanediol and sorbitol of the acquisition are mixed, and the melt is heated below 130 ° C, and then the formulation amount is added to the mixed material, and the complexeniphenylene terephthalic acid, Adipic acid, and catalyst, in the protective atmosphere, gradually warmed to 205 ° C for thermal insulation at 10 ° C / h, and the acid value is lowered to 130 mgKOH / g;

[0046](2) Continue to add the amount of 1,4-cyclohexane dimethanol mixing, gradually warming up to 220 ° C at 8 ° C / h,...

Embodiment 3

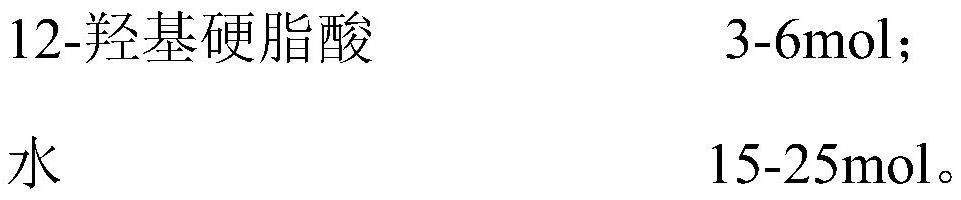

[0051]The extinction powder coating of the extinction powder coating is a high-hydroxyl resolved polyester resin which includes a component comprising a molar number:

[0052]

[0053]Silitone oxide, which is used for the preparation of total molar amounts of total molar;

[0054]Antioxidant 1010 has a total amount of a total mole of a total mole of a total mole of the preparation raw material.

[0055]The preparation method of the extinctable polyester resin of the extinction type powder coating, including the steps of:

[0056](1) The napultanediol and sorbitol of the acquisition are mixed, and the melt is heated below 130 ° C, and then the formulation amount is added to the mixed material, and the complexeniphenylene terephthalic acid, Adipic acid, and catalyst, in the protective atmosphere, gradually warmed to 200 ° C under protective atmosphere, and the acid value is lowered to stop the reaction when the acid value is lowered to 148 mgKOH / g;

[0057](2) Continue to add the amount of 1,4-cycloh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com