Porous ceramic for electronic cigarette, atomizing core containing porous ceramic and preparation method of atomizing core

A technology for porous ceramics and electronic cigarettes, applied in the field of electronic cigarettes, can solve the problems of high cost, low efficiency, unstable performance, etc., and achieve the effects of stable molding size, low production cost, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

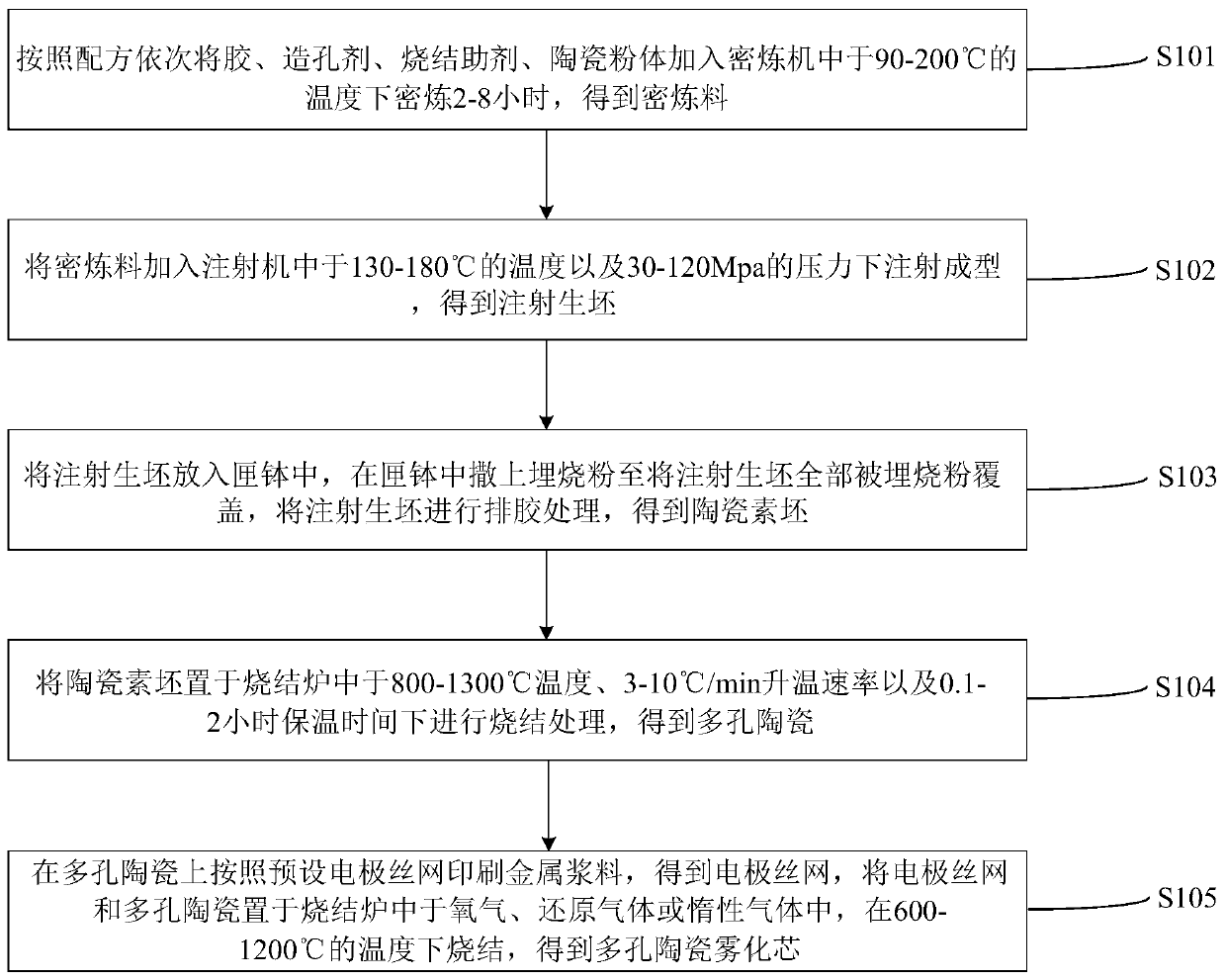

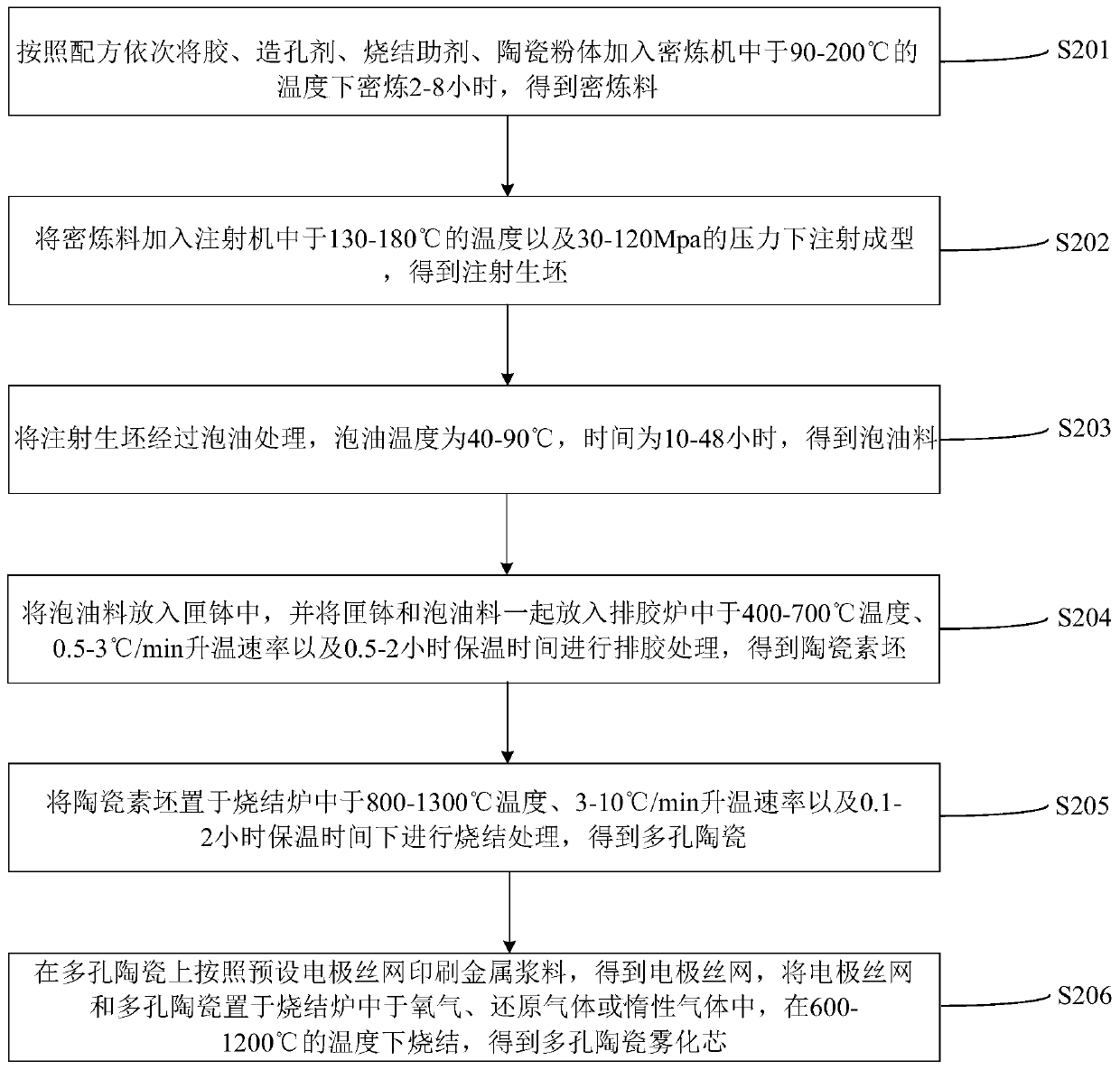

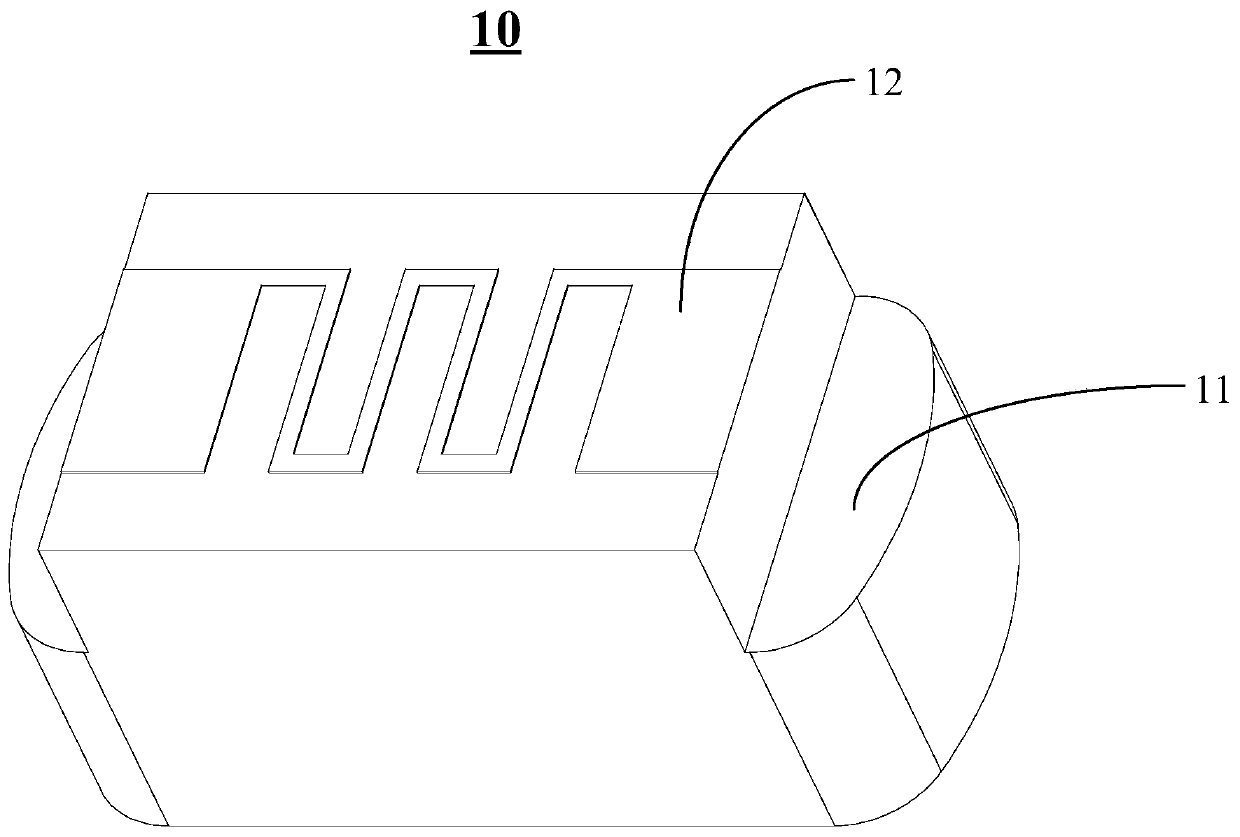

[0037] The embodiment of the present invention discloses a method for preparing an atomizing core. The atomizing core includes the above-mentioned porous ceramics for electronic cigarettes. Please refer to figure 1 , figure 1 It is a schematic flow chart of the preparation method of the porous ceramics for electronic cigarettes according to the first embodiment of the present invention, the preparation method includes:

[0038] Step S101: add glue, pore forming agent, sintering aid, and ceramic powder into the internal mixer in sequence according to the formula, and banbury at a temperature of 90-200° C. for 2-8 hours to obtain a banbury.

[0039] In step S101, the glue is first added in order, and after the glue is completely melted, the pore-forming agent and the sintering aid are slowly added, so that the sintering aid and the pore-forming agent are mixed evenly before adding the ceramic powder. In this embodiment, According to this order of addition, the banburying effici...

Embodiment 1

[0064] Weigh 30% of diatomite, 30% of quartz sand, 10% of polystyrene microspheres, 5% of glass powder, and 25% of glue according to the mass percentage. The softening temperature of the glass powder is 950-1200 ℃, the particle diameter of polystyrene microspheres is 100 μm, glue comprises the following components according to mass percentage: 40% PE, 30% PP, 3% PE wax, 25% paraffin wax, 2% of stearic acid.

[0065] S1: Add glue, polystyrene microspheres, glass powder, diatomaceous earth and quartz sand to the internal mixer in sequence according to the formula, and banbury at 180°C for 3 hours to obtain the banbury.

[0066] Step S2: Put the banburying material into the injection machine and perform injection molding under the temperature of 180-130° C. and the pressure of 30-120 MPa. The injection time is 3 seconds to obtain the injection green body.

[0067] Step S3: Put the injected green body into the sagger, sprinkle the buried burning powder on the sagger until the inj...

Embodiment 2

[0071] Weigh 19% of diatomite, 38% of corundum sand, 15% of carbon powder, 8% of glass powder, and 20% of glue according to the mass percentage. The softening temperature of the glass powder is 950-1200°C. The particle size of the powder is 50 μm, and the glue includes the following components in terms of mass percentage: 33% PE, 32% PP, 2% PE wax, 30% paraffin wax, 3% oleic acid.

[0072] S1: Add glue, carbon powder, glass powder, diatomaceous earth and corundum sand into the internal mixer in sequence according to the formula, and banbury at 180°C for 3 hours to obtain the banbury.

[0073] Step S2: Put the banburying material into the injection machine and perform injection molding under the temperature of 180-130° C. and the pressure of 30-120 MPa. The injection time is 3 seconds to obtain the injection green body.

[0074] Step S3: Put the injected green body into the sagger, sprinkle the buried burning powder on the sagger until the injected green body is completely cove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com