Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

422results about How to "Dimensional stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pentane compatible polyester polyols

InactiveUS6359022B1Increase valueImprove flame retardant performanceOther chemical processesPolyesterDolichol

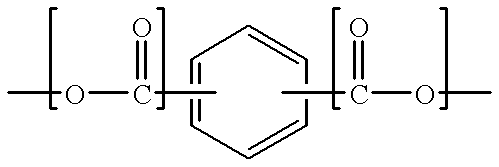

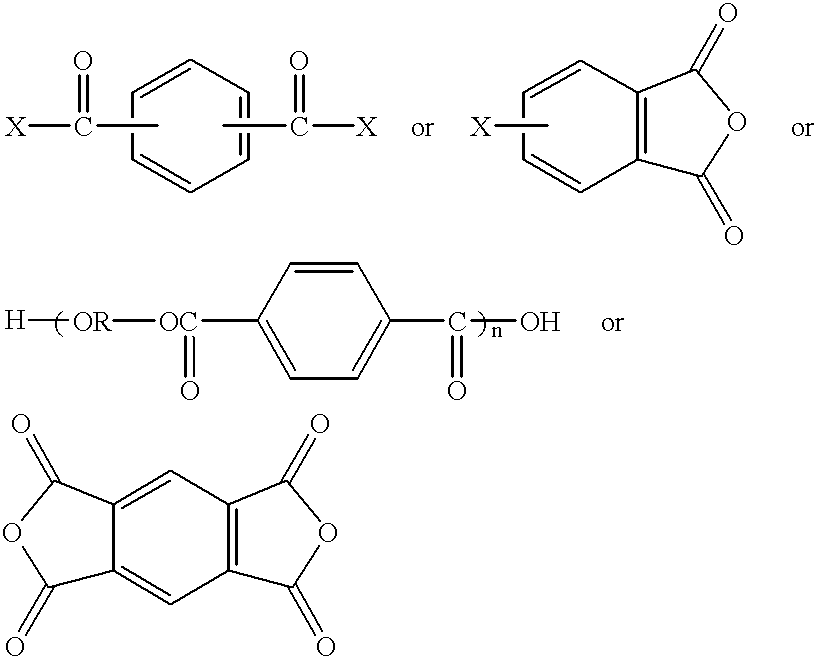

Disclosed are aromatic polyester polyols, polyol based resin blends, and rigid closed-cell polyisocyanate-based foams made using the polyol based resin blends. The resin blends generally comprise:(a) an aromatic polyester polyol reaction product formed by inter-esterification of a phthalic acid based material; a hydroxylated material having a functionality of at least 2; and a hydrophobic material; and(b) a C4-C7 hydrocarbon blowing agent. Also disclosed is a method for preparing rigid closed-cell polyisocyanate-based foams comprising reacting a polyisocyanate and a polyol based resin blend.

Owner:STEPAN COMPANY

Multilayer composite films and articles prepared therefrom

InactiveUS20060165929A1Improve physical propertiesGood physical propertiesBottlesVehicle componentsElectrical and Electronics engineeringComposite film

Owner:PERFORMANCE MATERIALS NA INC

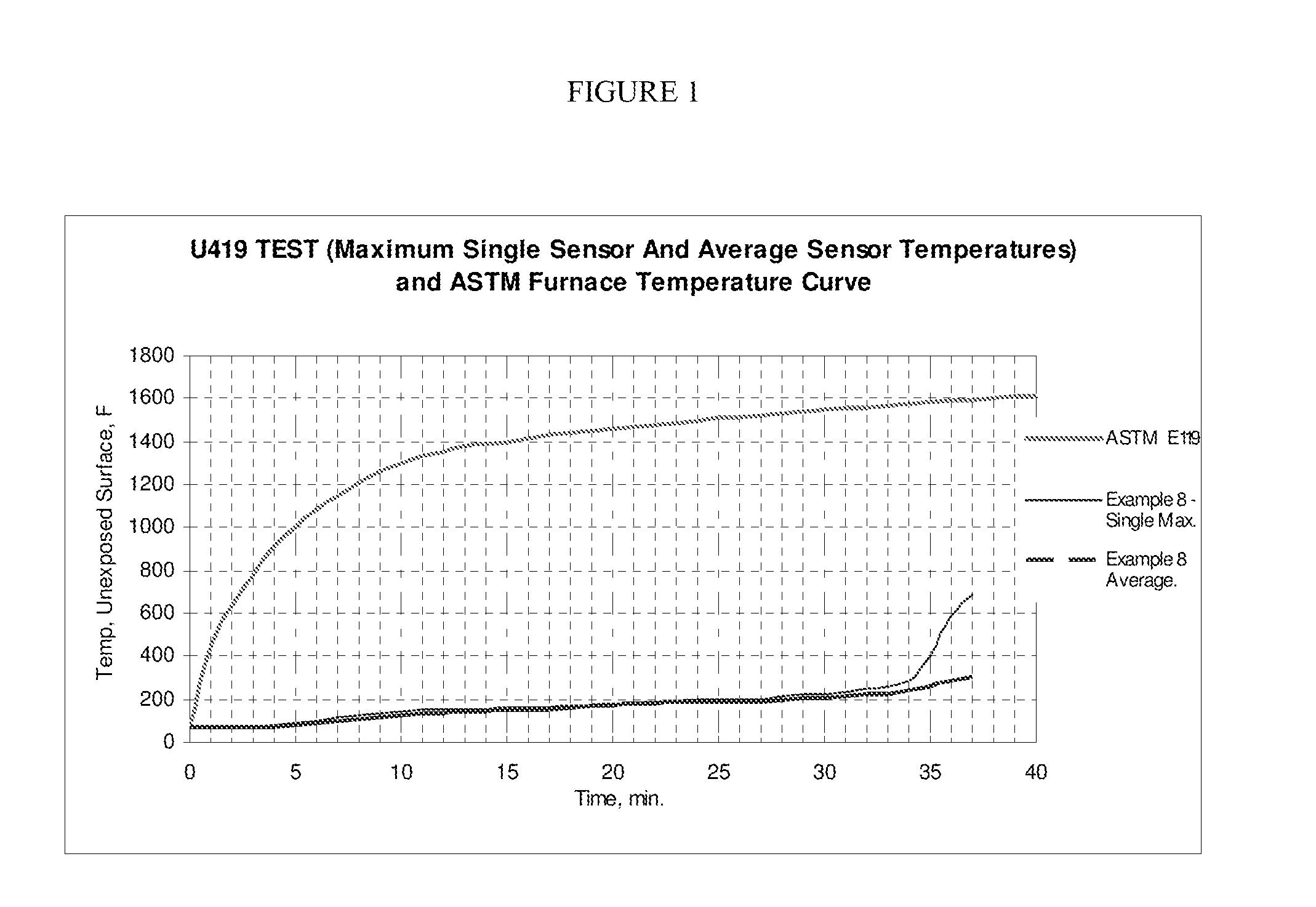

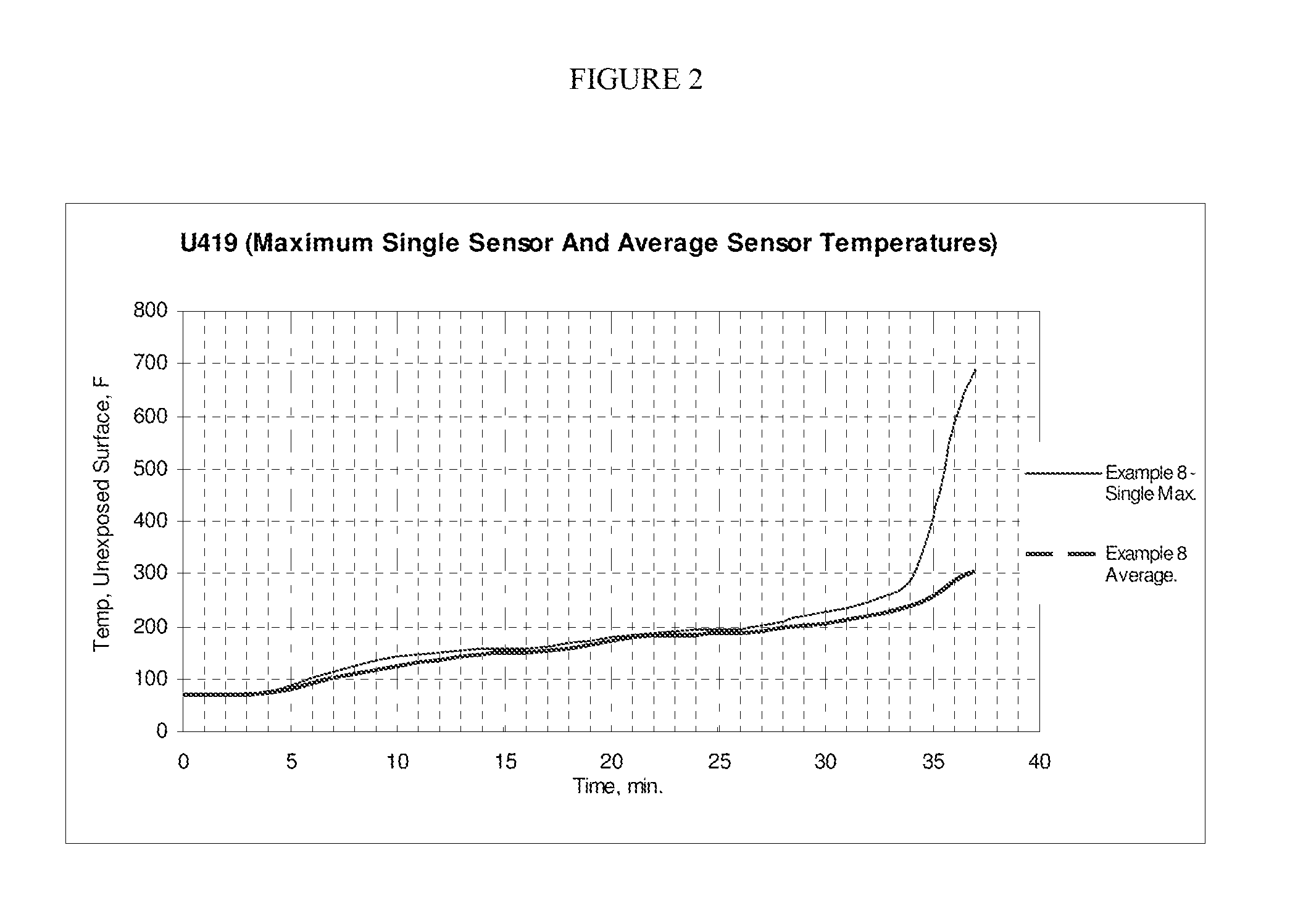

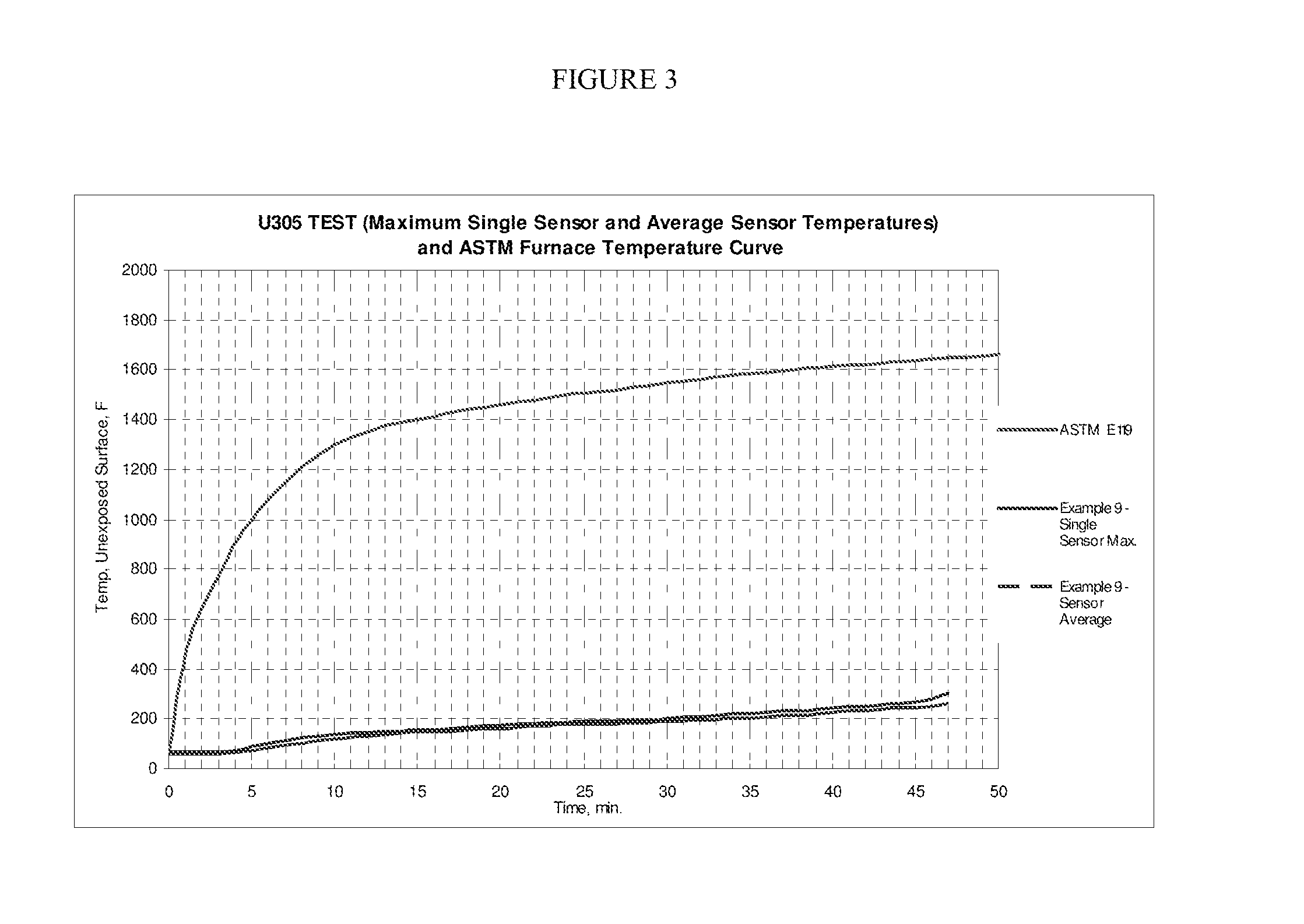

Low Weight and Density Fire-Resistant Gypsum Panel

InactiveUS20110195241A1Small expansionReduce Shrinkage ProblemsSolid waste managementWood layered productsThermal insulationVolumetric Mass Density

An about ⅝ inch to ¾ inch thick low weight, low density gypsum panel with fire resistance capabilities sufficient to provide a Thermal Insulation Index of at least 17.0 minutes which when subjected to U419 test procedures will not fail for at least 30 minutes and, in selected embodiments, also has outstanding water resistance properties.

Owner:UNITED STATES GYPSUM CO

Ostomy appliance with recovery resistant moldable adhesive

InactiveUS20070185464A1Easily moldStable dimensionSurgical adhesivesNon-surgical orthopedic devicesBiomedical engineeringStoma

Owner:CONVATEC TECH INC

Polyurethane foam, process for producing the same, and foam forming composition

InactiveUS6455606B1Improve mechanical propertiesLow compression setPeptide preparation methodsCushioningFoaming agent

A polyurethane foam which is obtained by reacting an addition-polymerizable active hydrogen component comprising a compound having a group containing active hydrogen and an addition-polymerizable functional group or comprising both this compound and a compound containing at least 2.5 groups (on the average) containing active hydrogen and not containing addition-polymerizable functional groups with an organic polyisocyanate in the presence or absence of at least one auxiliary selected from the group consisting of foaming agents and additives to polymerize the addition-polymerizable functional group and simultaneously form a polyurethane, and which has a structure in which the chains formed by the addition polymerization have been cross-linked to the polyurethane chains. The polyurethane foam is useful as a rigid polyurethane foam excellent in hardness, dimensional stability, etc. and usable as a heat insulator, shock-absorbing material, synthetic wood, etc., or is useful as a soft polyurethane foam reduced in compression set and usable as a cushioning material, shock-absorbing material, sound insulating / absorbing material, etc.

Owner:SANYO CHEM IND LTD

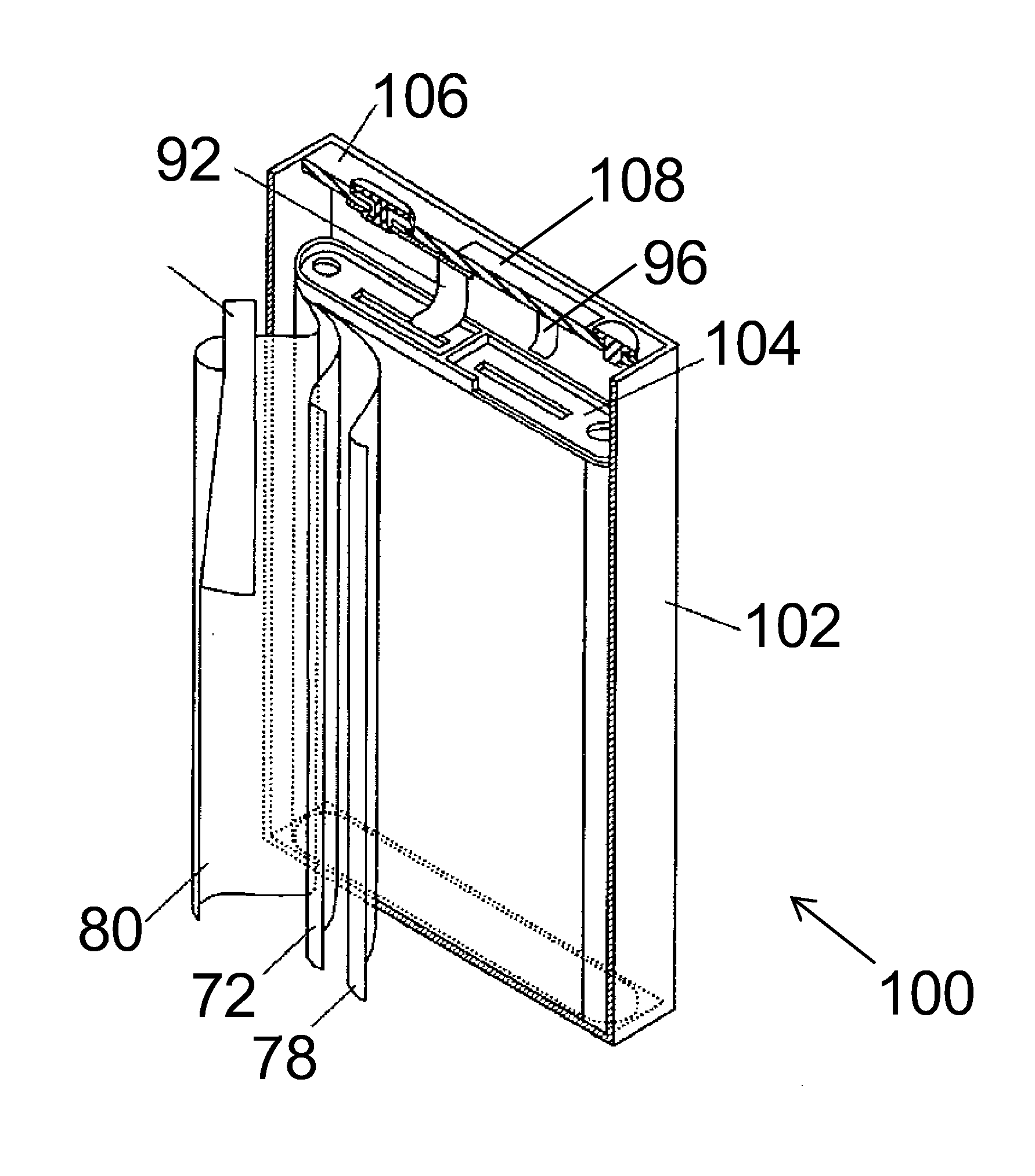

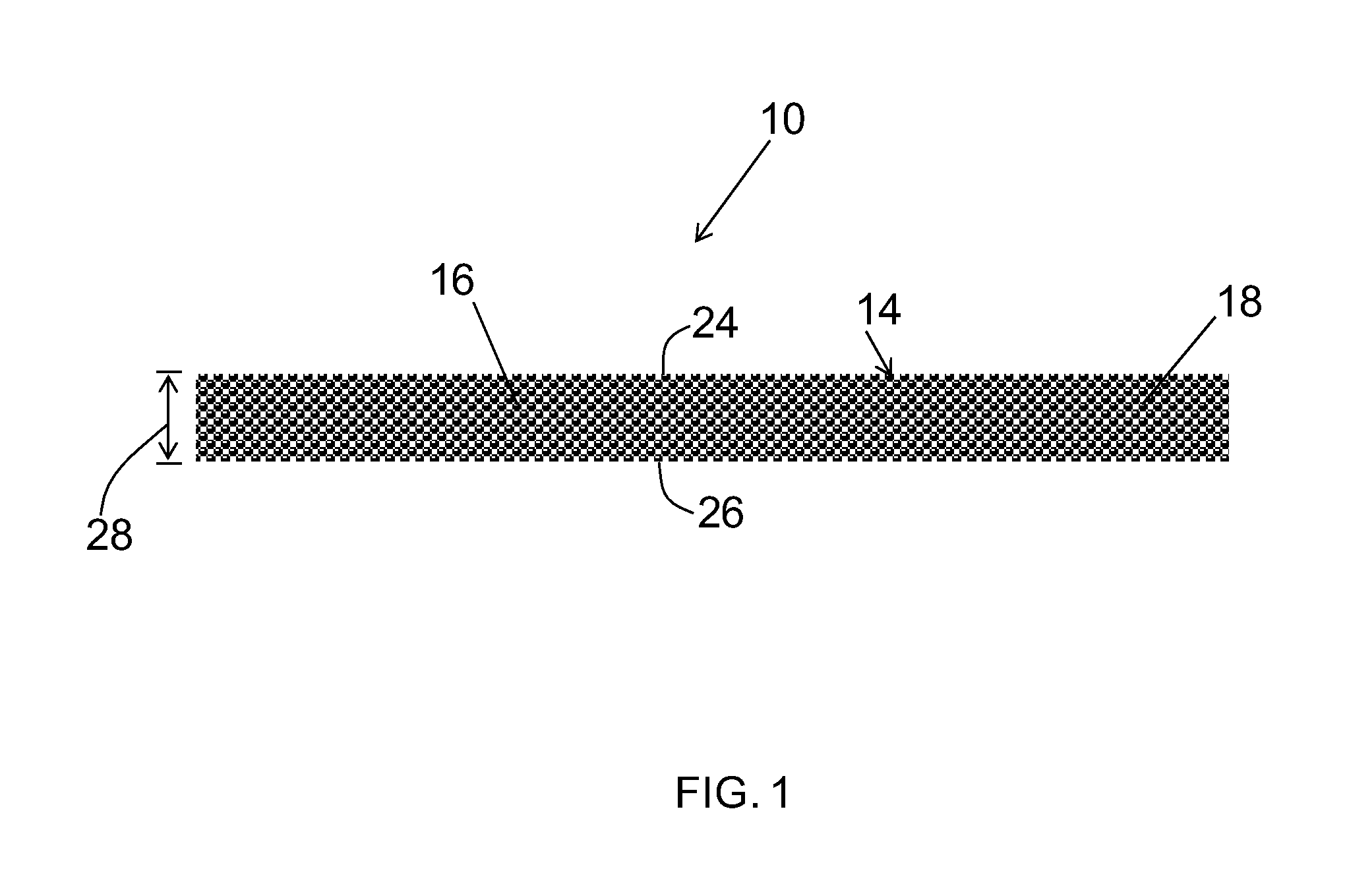

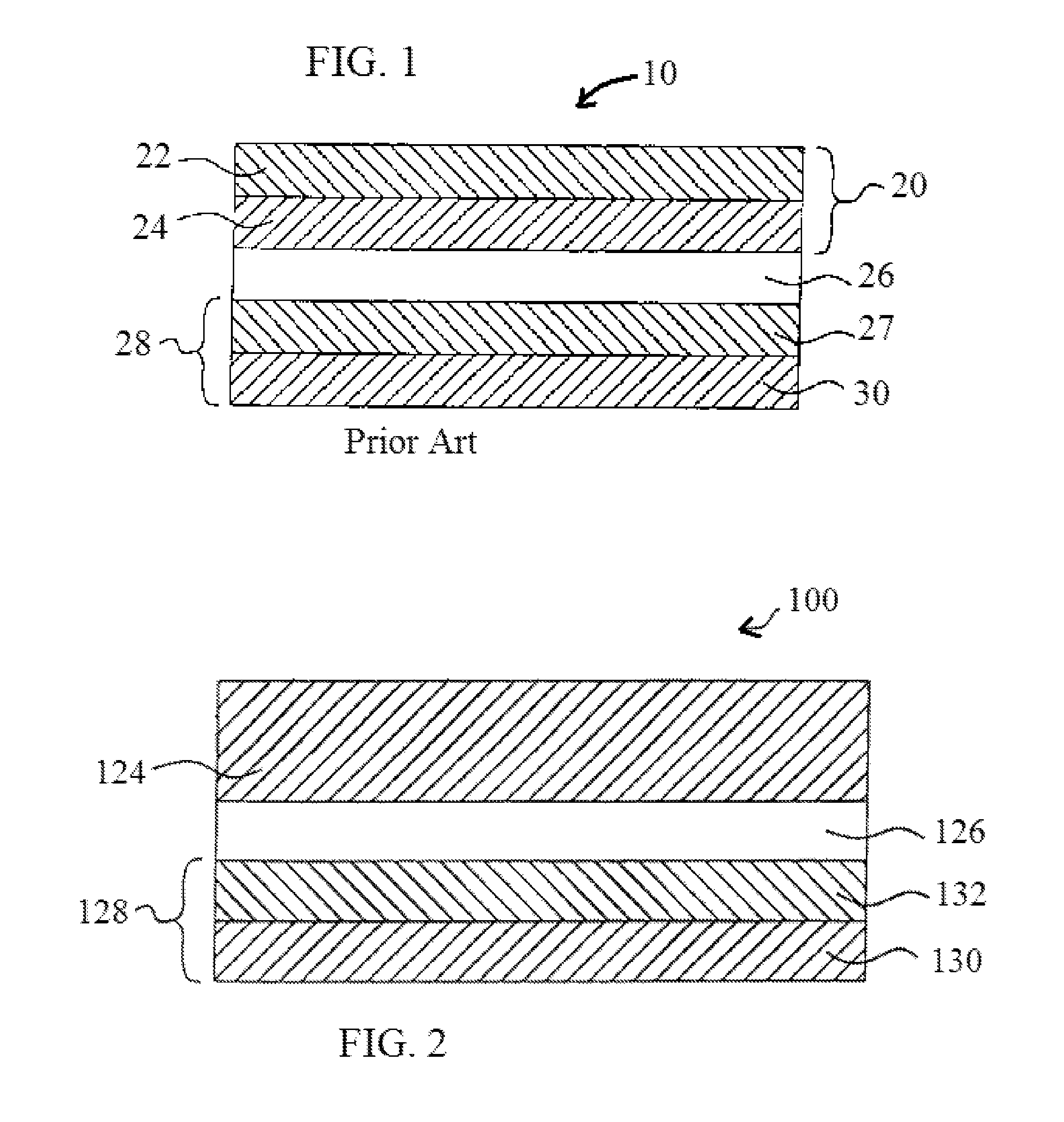

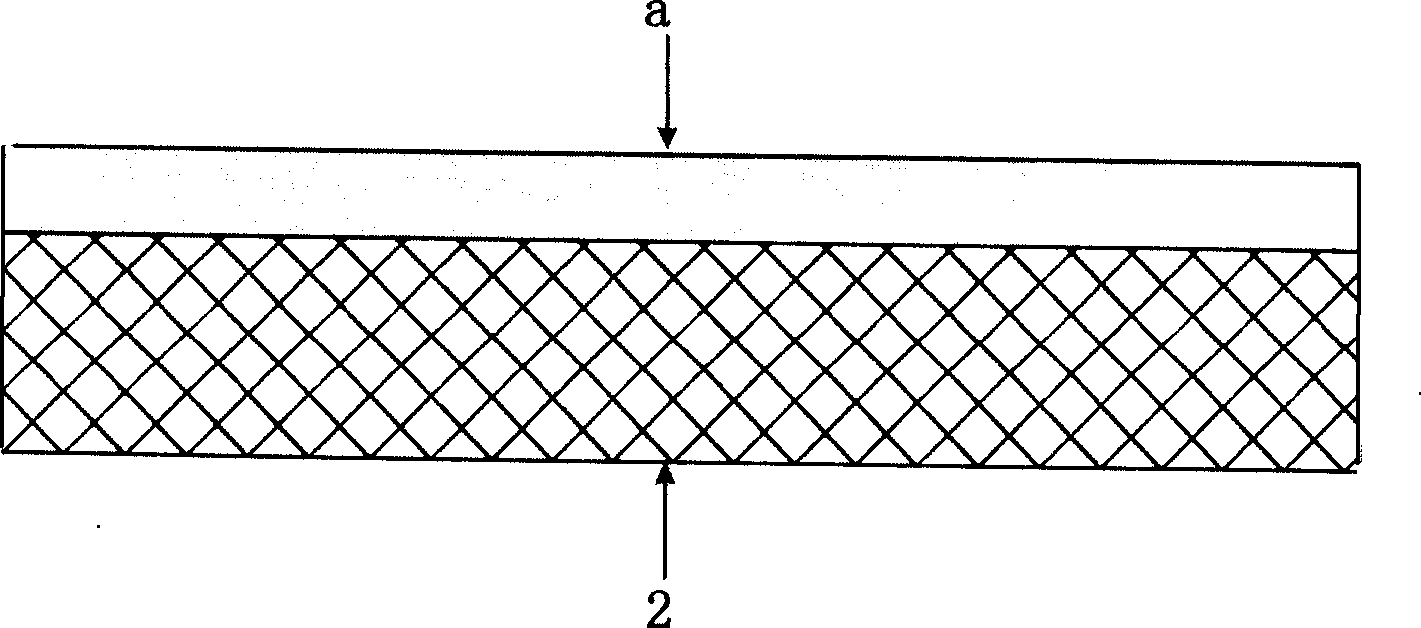

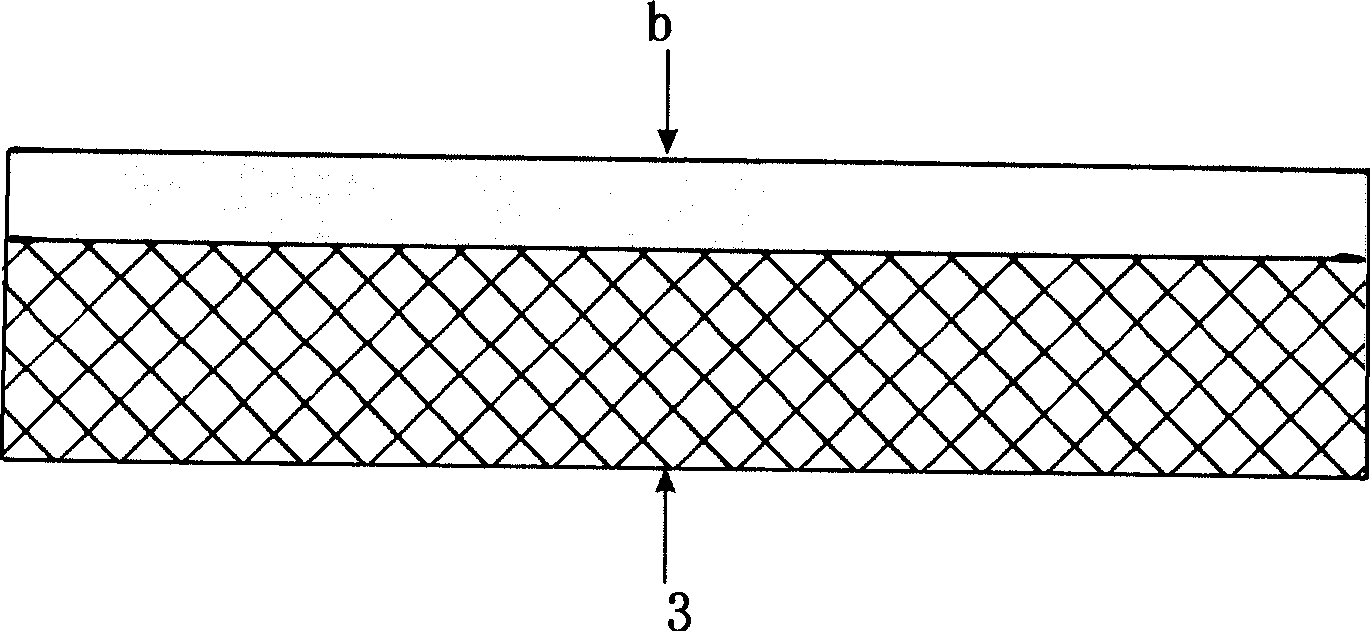

Freestanding, heat resistant microporous film for use in energy storage devices

ActiveUS20120145468A1Low thermal shrinkageHigh level of loadingPrimary cell to battery groupingAuxillary drivesCross-linked polyethyleneMelting Point Temperature

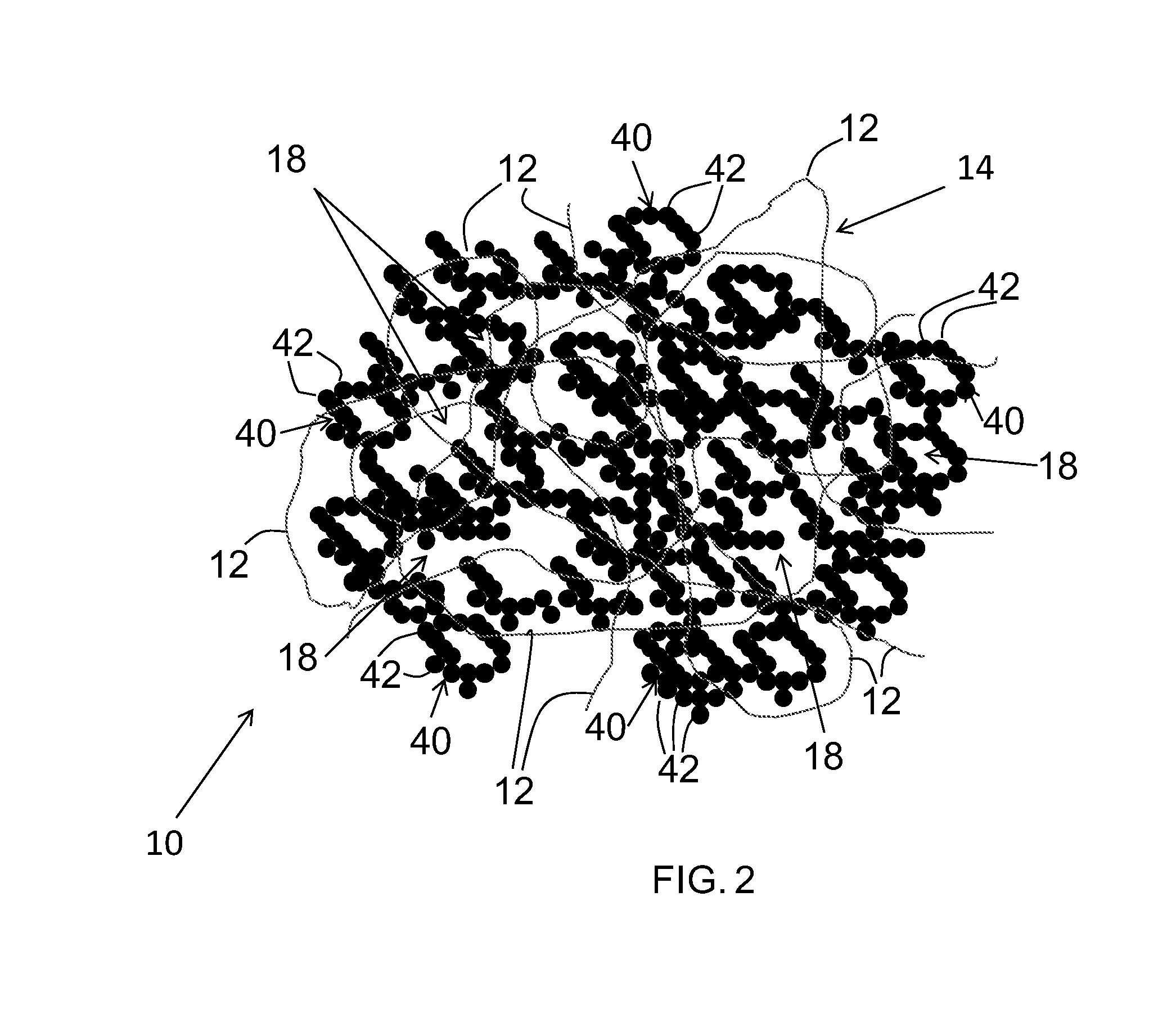

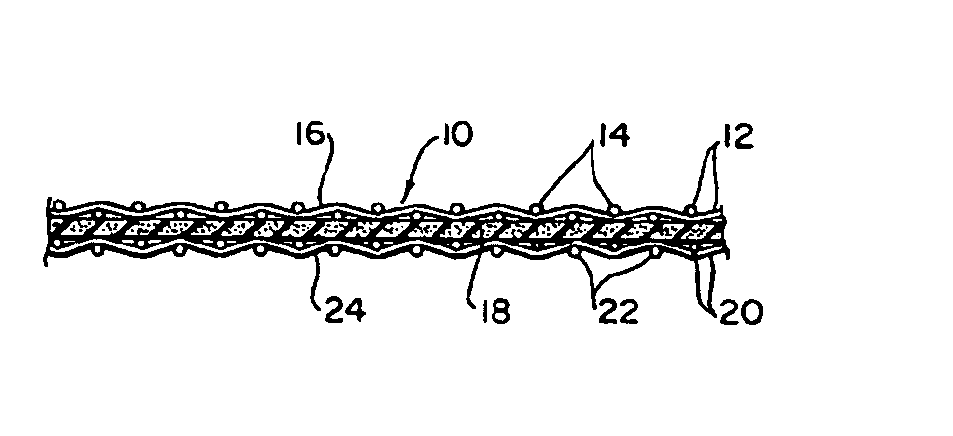

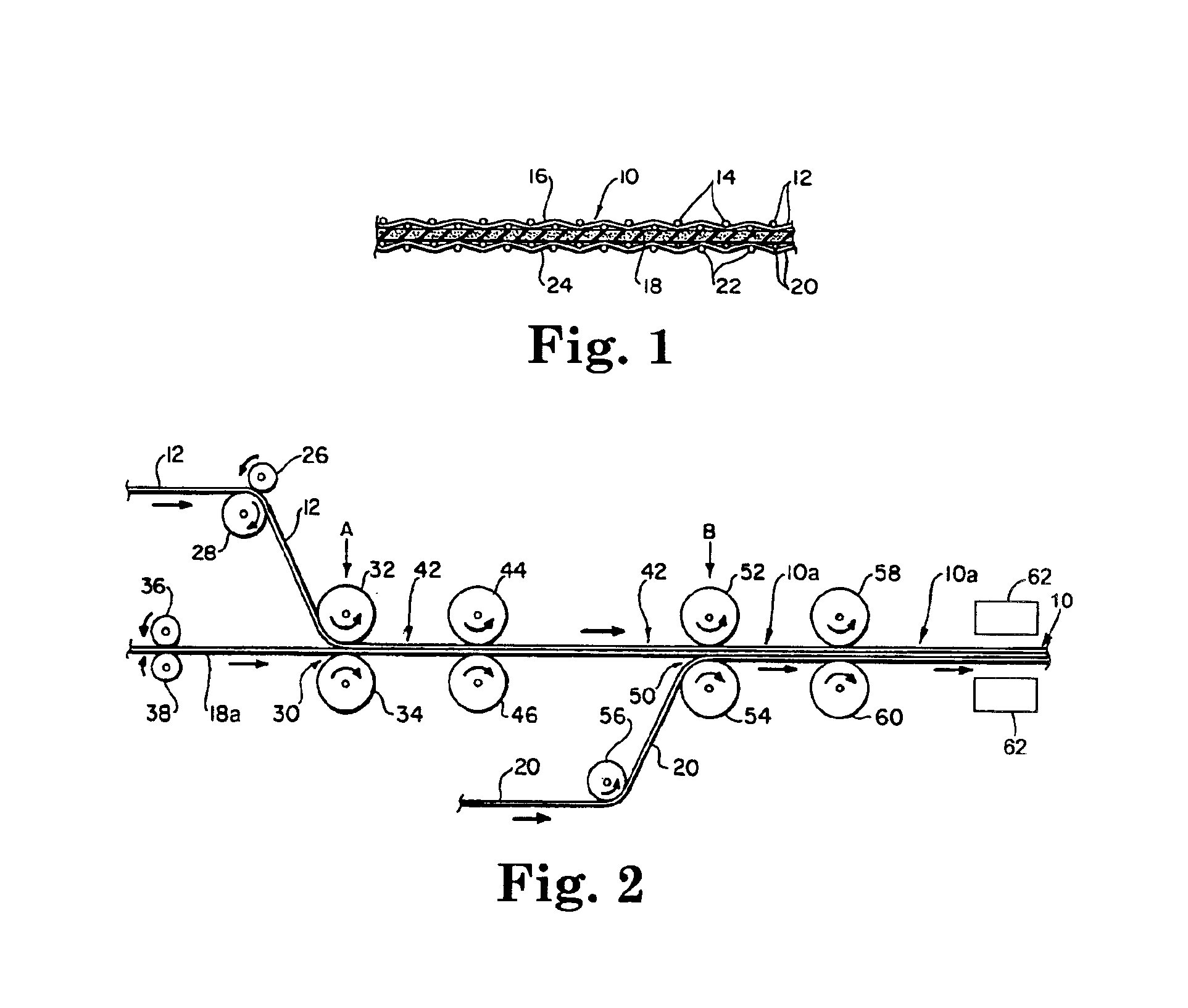

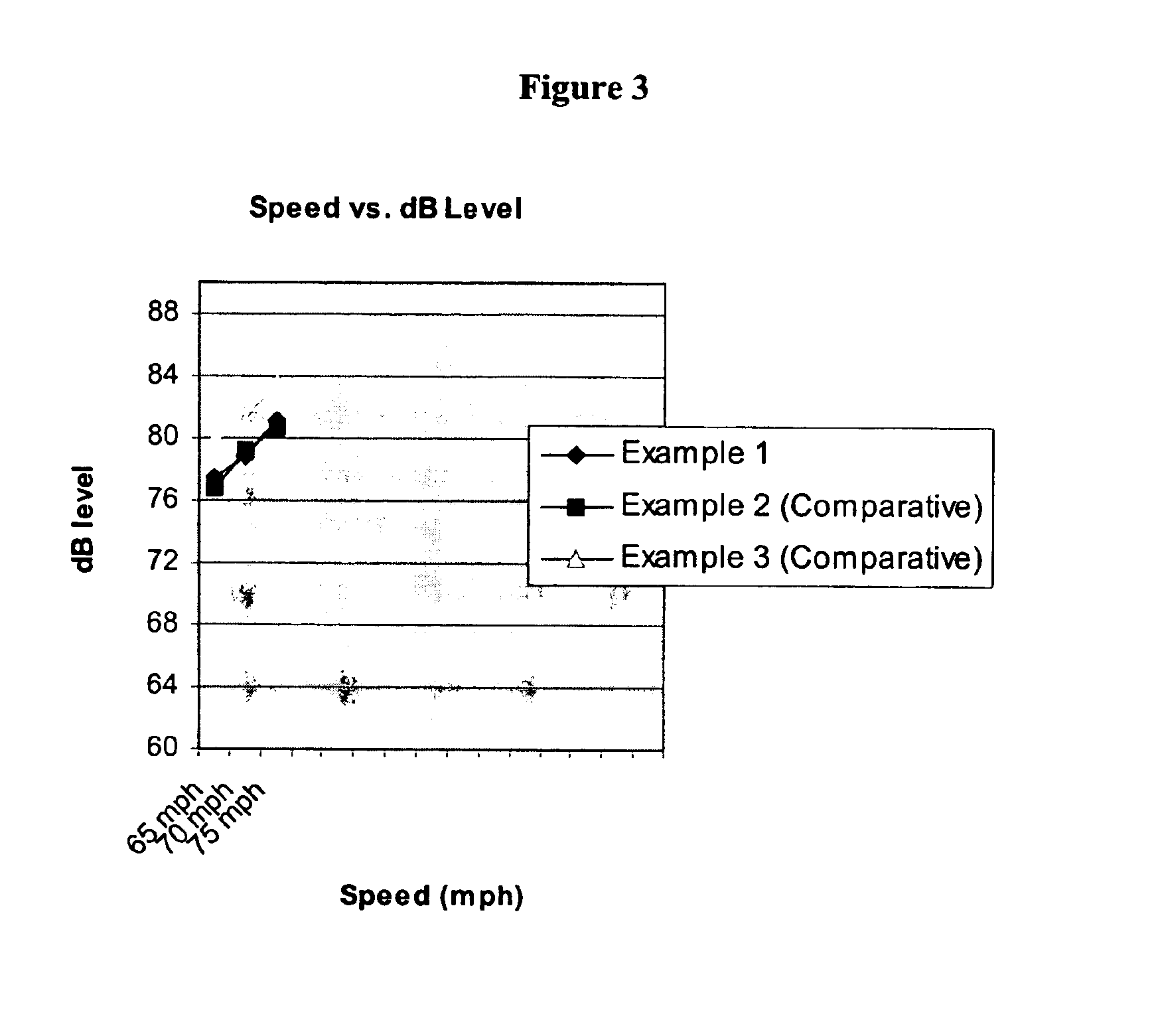

Preferred embodiments of a freestanding, heat resistant microporous polymer film (10) constructed for use in an energy storage device (70, 100) implements one or more of the following approaches to exhibit excellent high temperature mechanical and dimensional stability: incorporation into a porous polyolefin film of sufficiently high loading levels of inorganic or ceramic filler material (16) to maintain porosity (18) and achieve low thermal shrinkage; use of crosslinkable polyethylene to contribute to crosslinking the polymer matrix (14) in a highly inorganic material-filled polyolefin film; and heat treating or annealing of biaxially oriented, highly inorganic material-filled polyolefin film above the melting point temperature of the polymer matrix to reduce residual stress while maintaining high porosity. The freestanding, heat resistant microporous polymer film embodiments exhibit extremely low resistance, as evidenced by MacMullin numbers of less than 4.5.

Owner:AMTEK RES INT

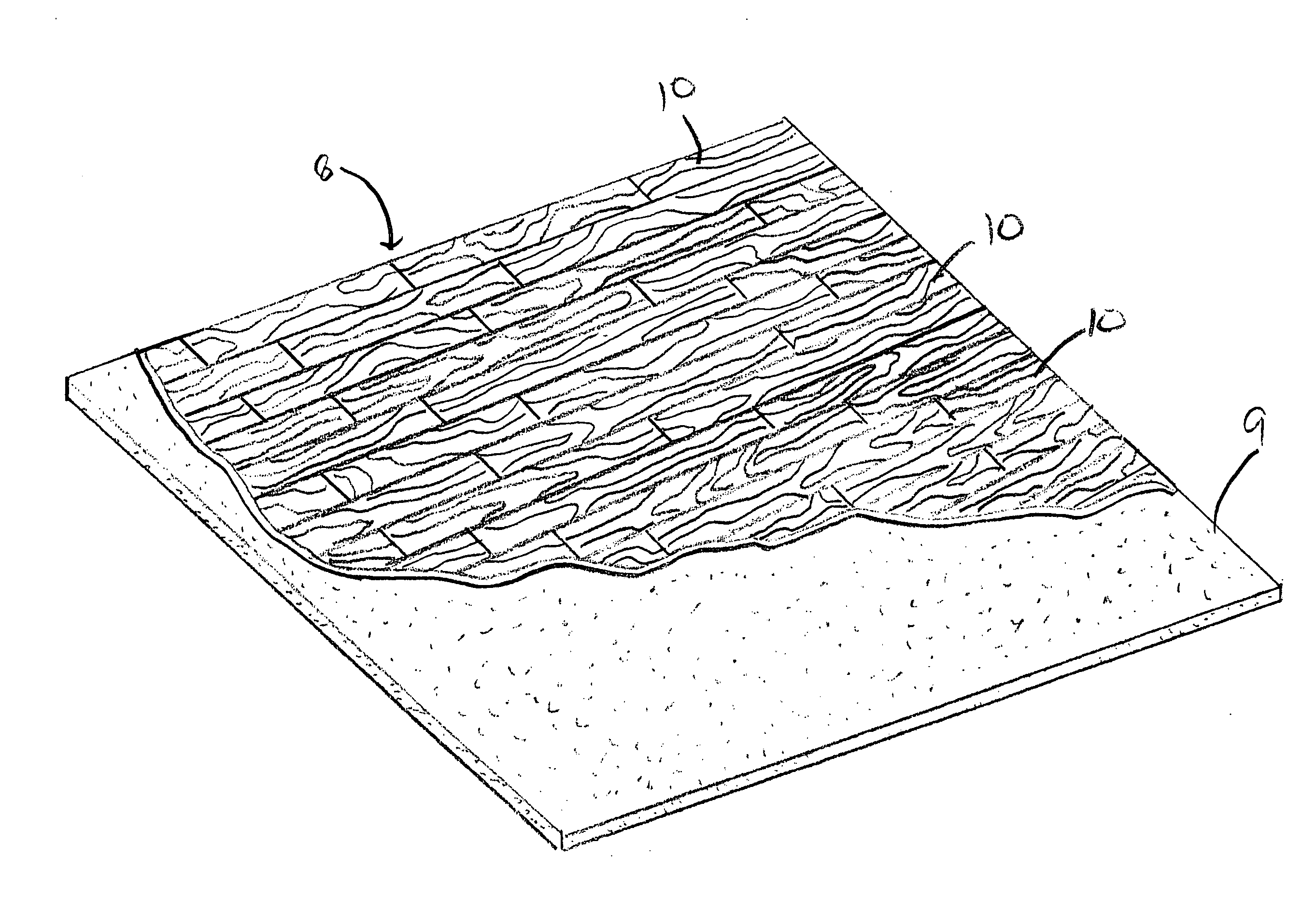

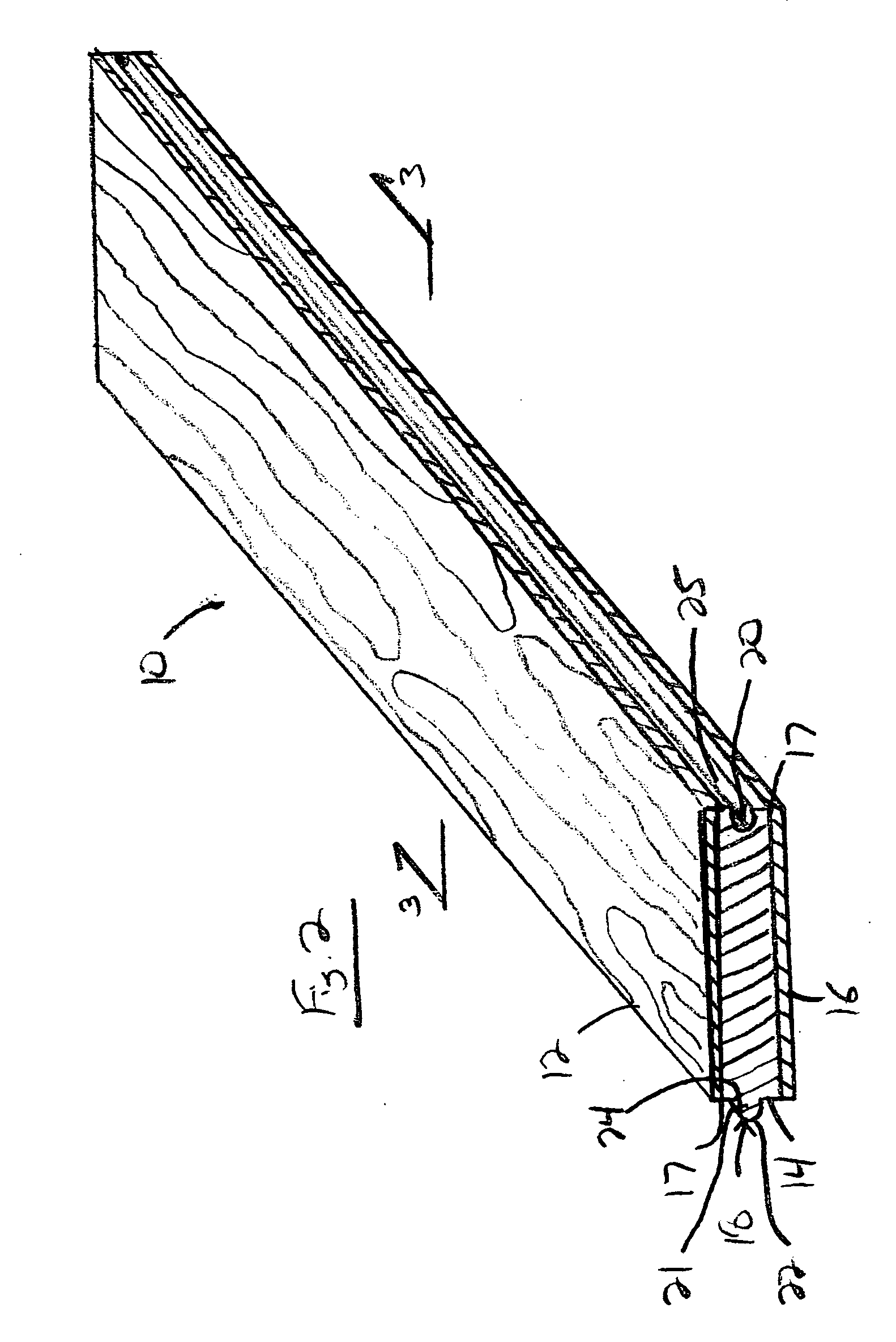

Hardwood flooring board

InactiveUS20060070325A1Maintain hardwood appearanceGood dimensional stabilityConstructions elementsWood layered productsAdhesiveEngineering

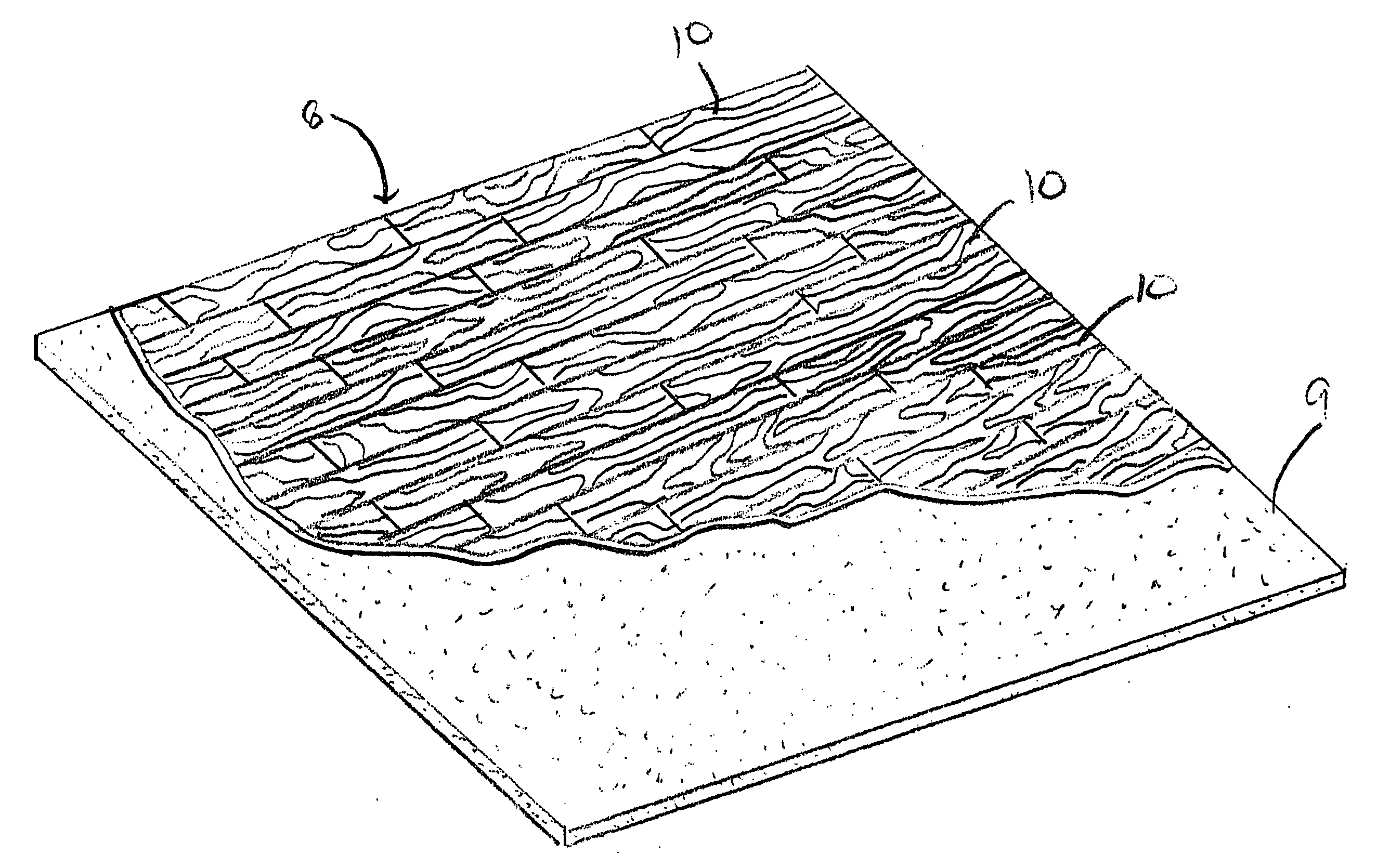

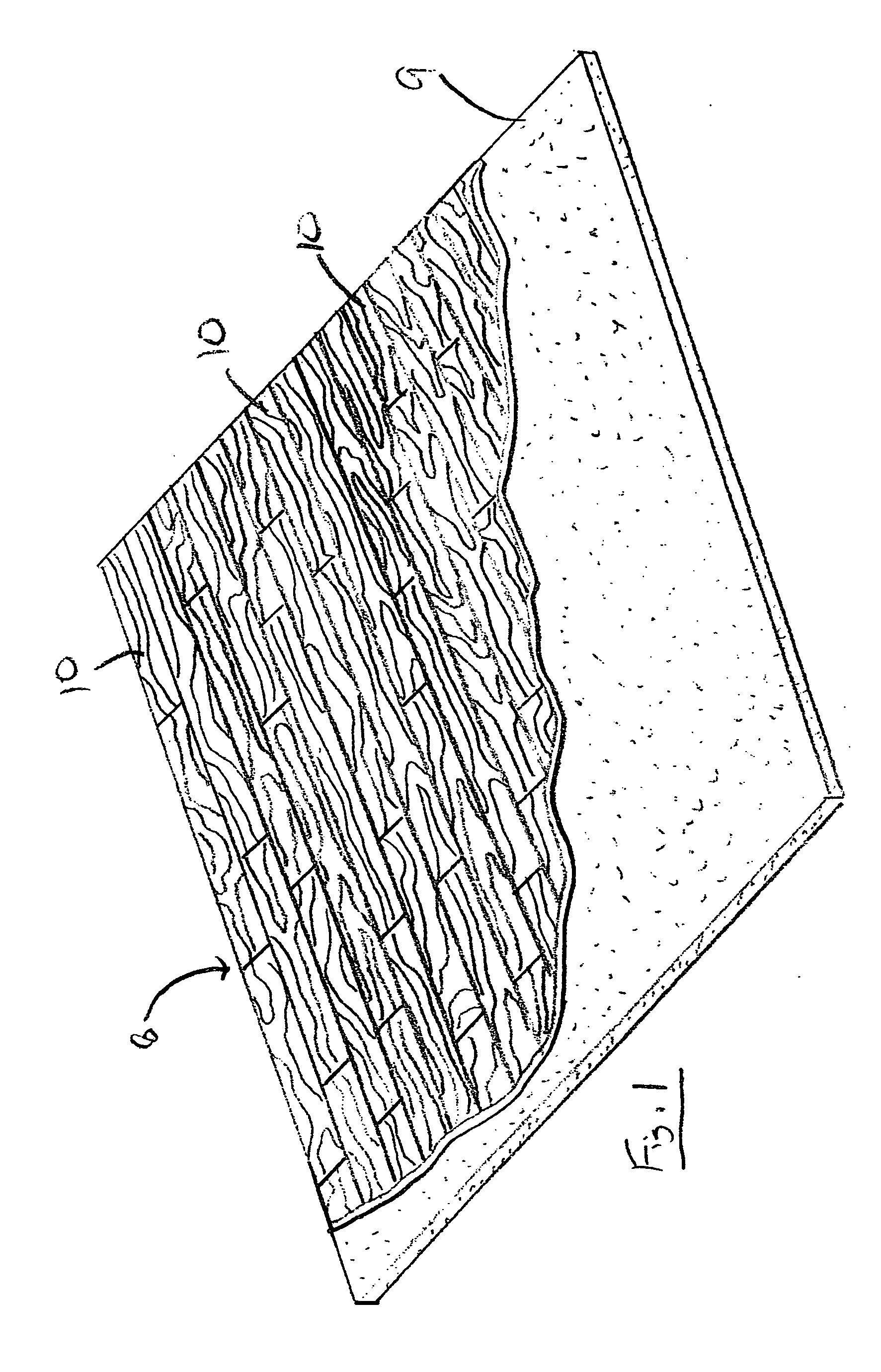

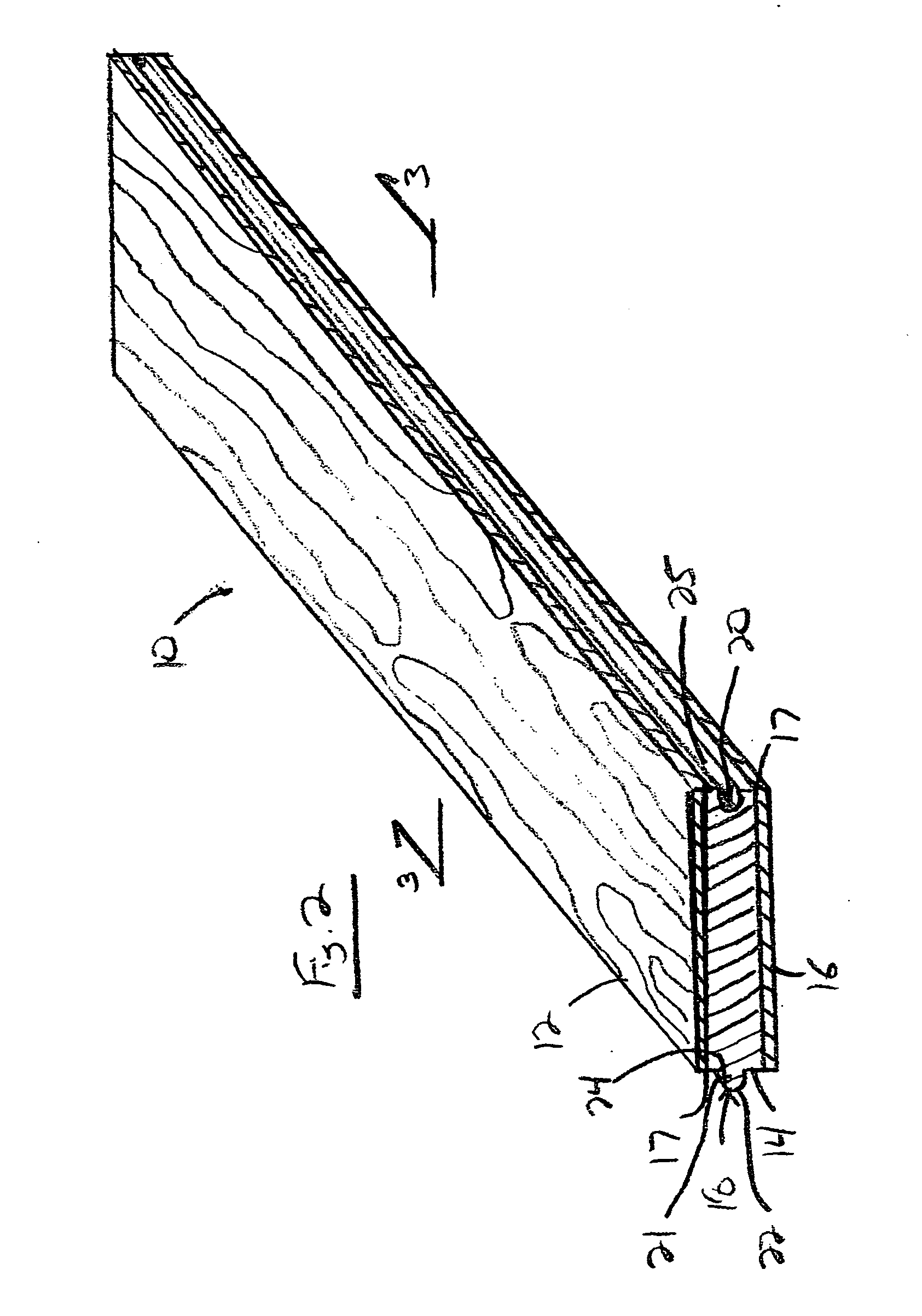

The present invention is a hardwood flooring board including a middle layer formed from a non-hardwood flooring material and a hardwood material upper layer which is secured to an upper surface of the middle layer that is thick enough to include decorative designs. The middle layer forms between 45% and 75% of the overall material of the board and enables the board to be manufactured to be more dimensionally stable, i.e., wider and longer, than conventional hardwood flooring boards such that the boards can be more uniformly constructed. Also the use of the non-hardwood material in the middle layer greatly increases the dimensional stability and long term performance of the flooring boards, while providing a genuine hardwood appearance to the floor. The board also includes a lower layer that can be formed from either a hardwood material or a non-hardwood material to function as a base for the board. The upper layer is secured to the middle layer by an adhesive that is urged into the openings or cracks in the upper layer during the assembly of the board to prevent the cracks from spreading through the upper layer when the boards are in use.

Owner:FLOORING SPECTRUM +1

Glass reinforced nylon blend with improved knitline strength

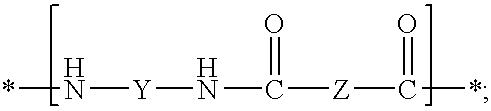

The present invention provides a polymer alloy including from about 40% to about 75% by weight of at least one polyamide, from about 10% to about 50% by weight polypropylene, from about 0.01% to about 1.0% by weight of at least one block copolymer including a vinyl aromatic monomer and a conjugated diene, and also includes an unsaturated dicarboxylic reagent, from about 0.1% to about 5.0% by weight of at least one block copolymer or terpolymer, wherein the terpolymer may have an unsaturated dicarboxylic reagent grafted thereto, from about 0.01% to about 7.5% of a compatibilizing agent, and from about 5% to about 50% by weight of a filler. The alloy of the present invention exhibits improved knitline strength and improved drop impact results compared with prior art fiberglass-reinforced nylon blends.

Owner:LYONDELLBASELL ADVANCED POLYMERS INC

Ink-jet recording material comprising pigment layers

InactiveUS6502935B1Shorten drying timeImprove image qualityDuplicating/marking methodsCoatingsPigmentChemistry

Owner:FELIX SCHOELLER JR FOTO & SPEZIALPAPIERE

Synthetic two-piece induction seal products

ActiveUS7850033B2Efficient and cost-effectiveSafe and cleanCapsClosure using stoppersWaxSynthetic materials

A two-piece induction seal for use in creating clean, safe, and secure inner seals on containers having a monolayer plastic formed from synthetic fibers with stable pore dimensions for fluid permeability while retaining dimensional stability for compression. An inductive innerseal membrane is provided having a first side and a second side thereof, with an adhesive layer at the first side of the membrane. The second side of the membrane is detachably bound to the synthetic material with a wax layer. The synthetic material is further suitable for absorbing substantially all of said wax layer when said wax layer is in liquid form.

Owner:SELIG SEALING PROD INC

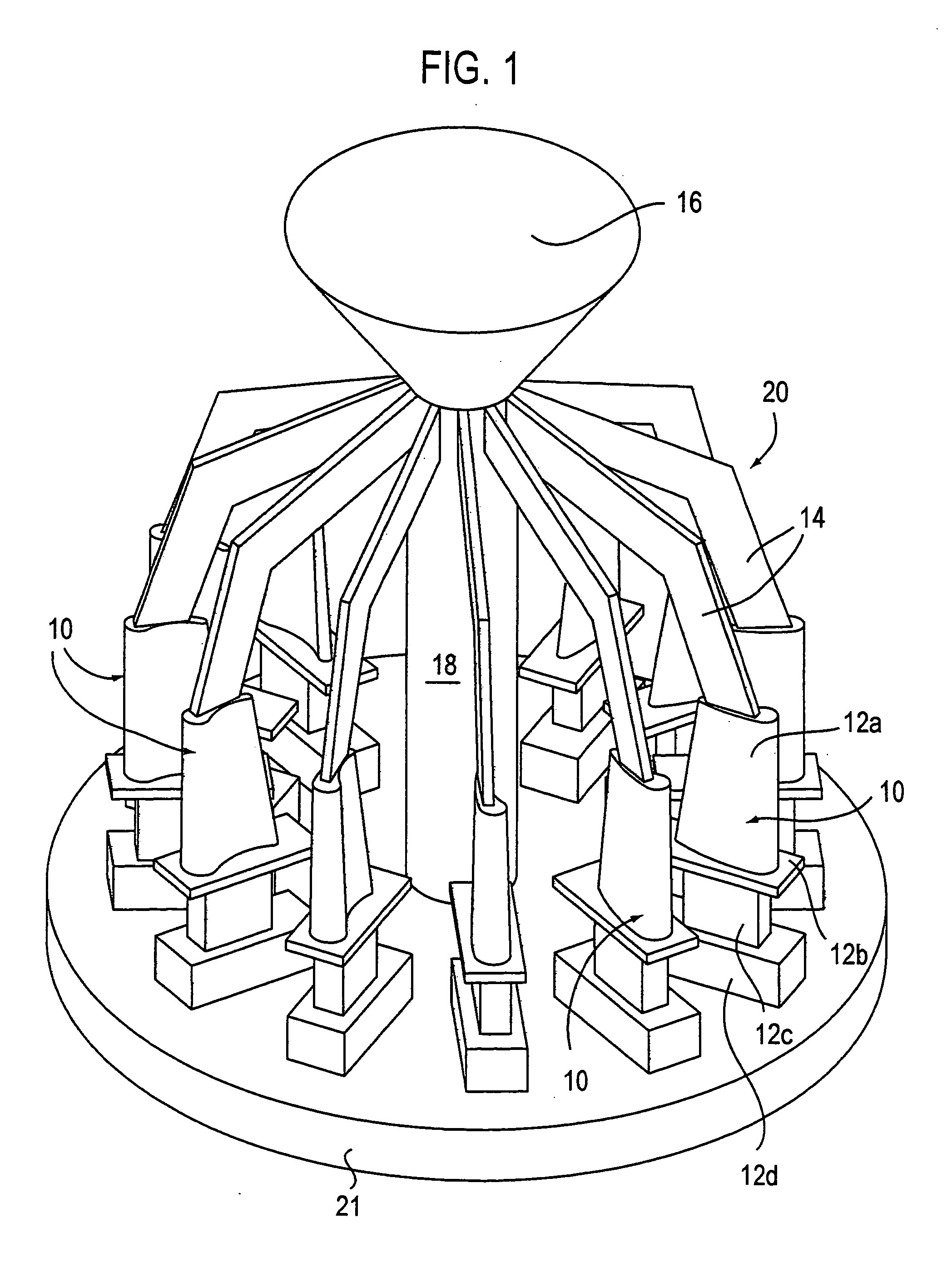

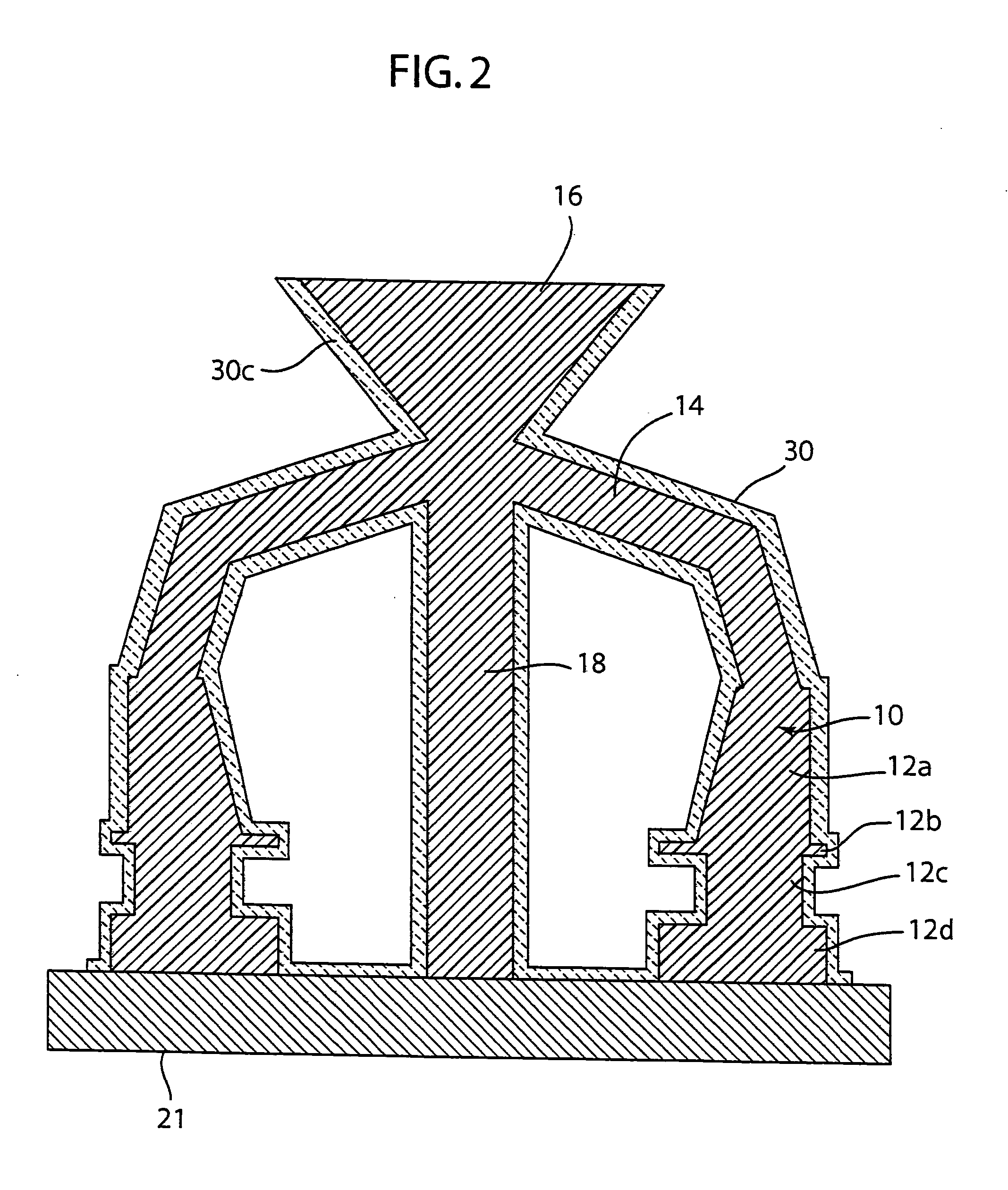

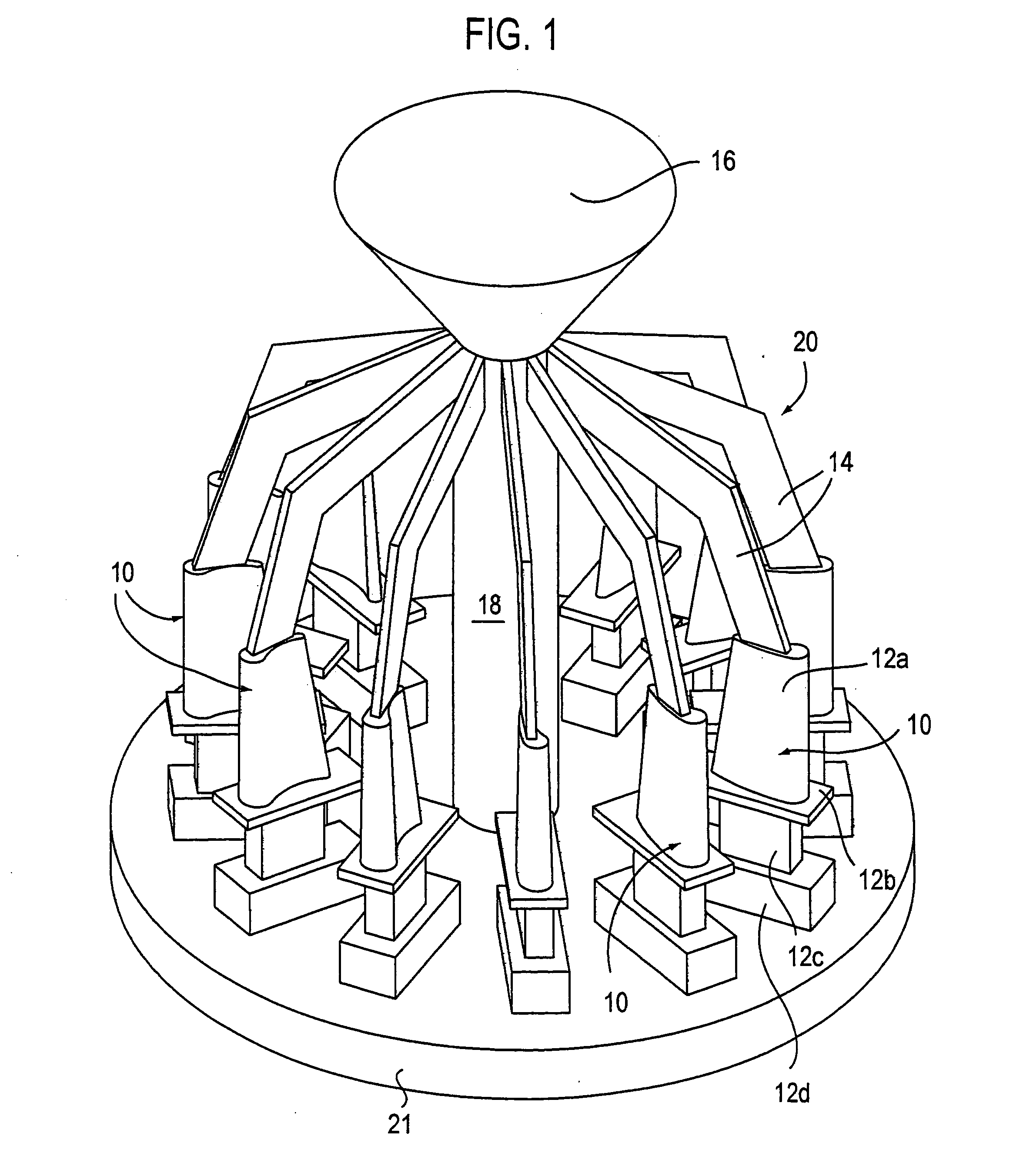

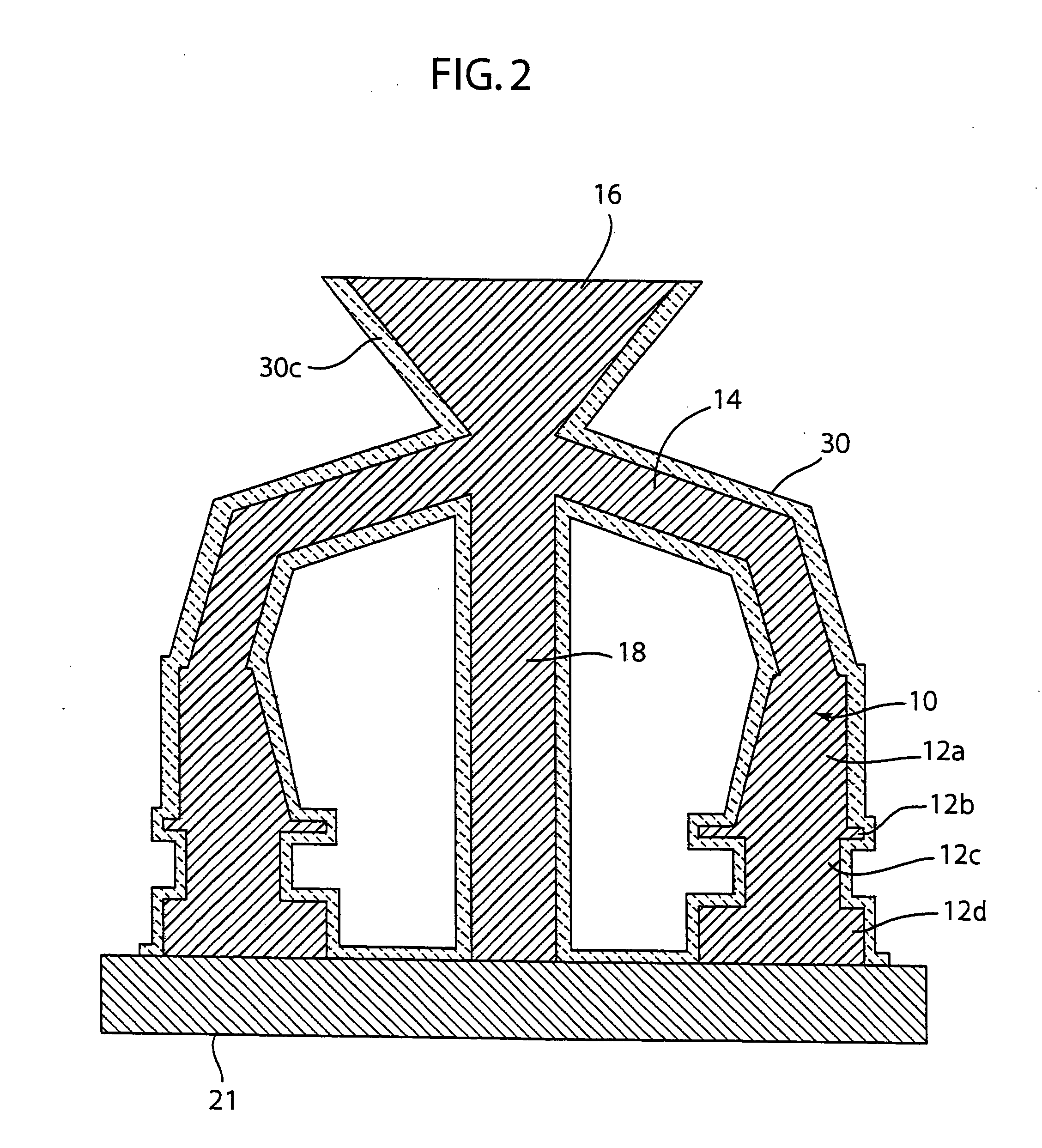

Fugitive pattern for casting

InactiveUS20060052499A1Improved pattern mechanical propertyFast and low costFilm/foil adhesivesFoundry mouldsPolymer scienceInvestment casting

A fugitive pattern for making a shell mold for investment casting a metal or alloy comprises a substantially random interpolymer and a low molecular weight polymer in proportions to provide a fugitive pattern having a combination of properties suitable for use in making the shell molds.

Owner:HOWMET CORPORATION

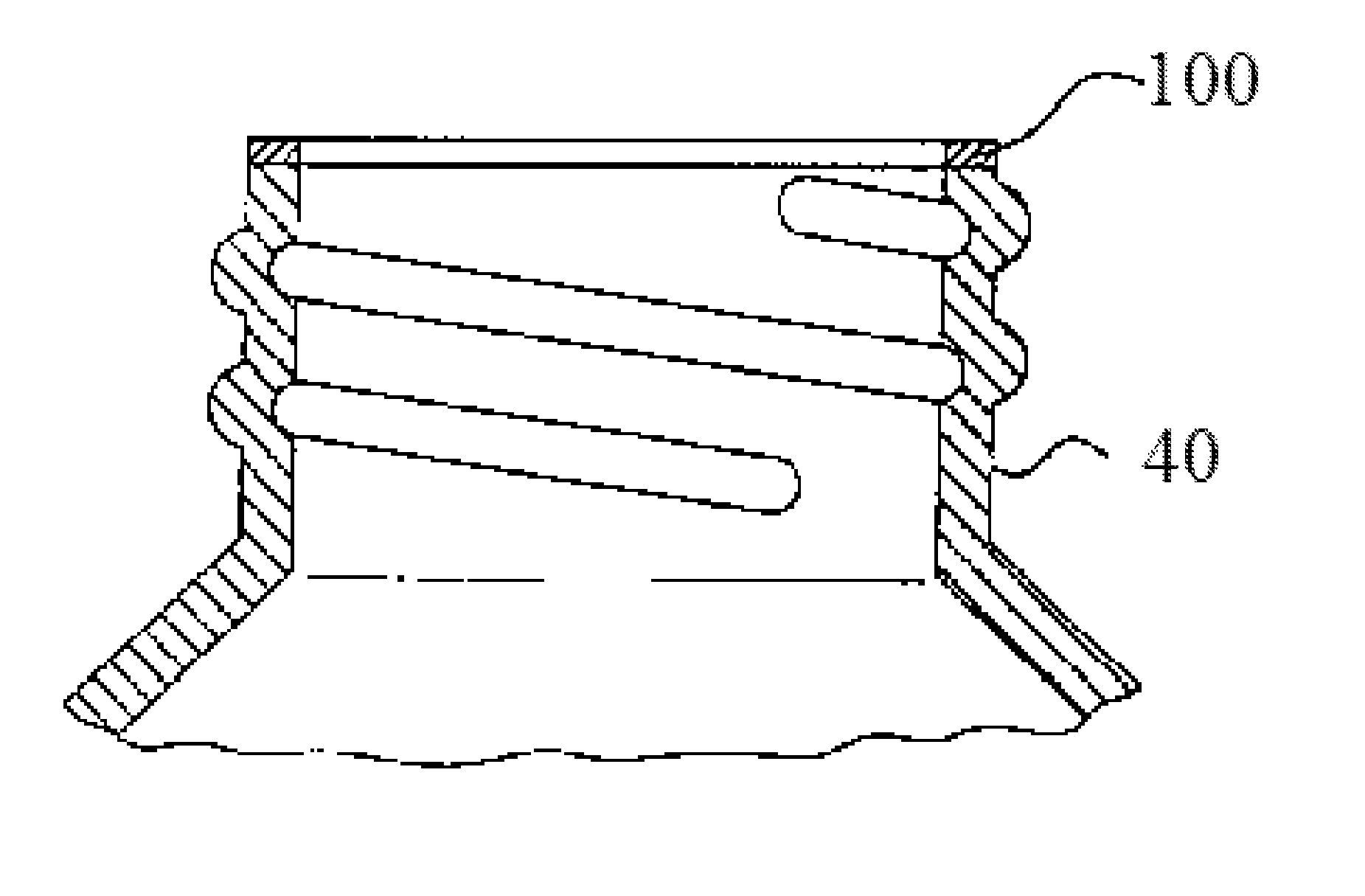

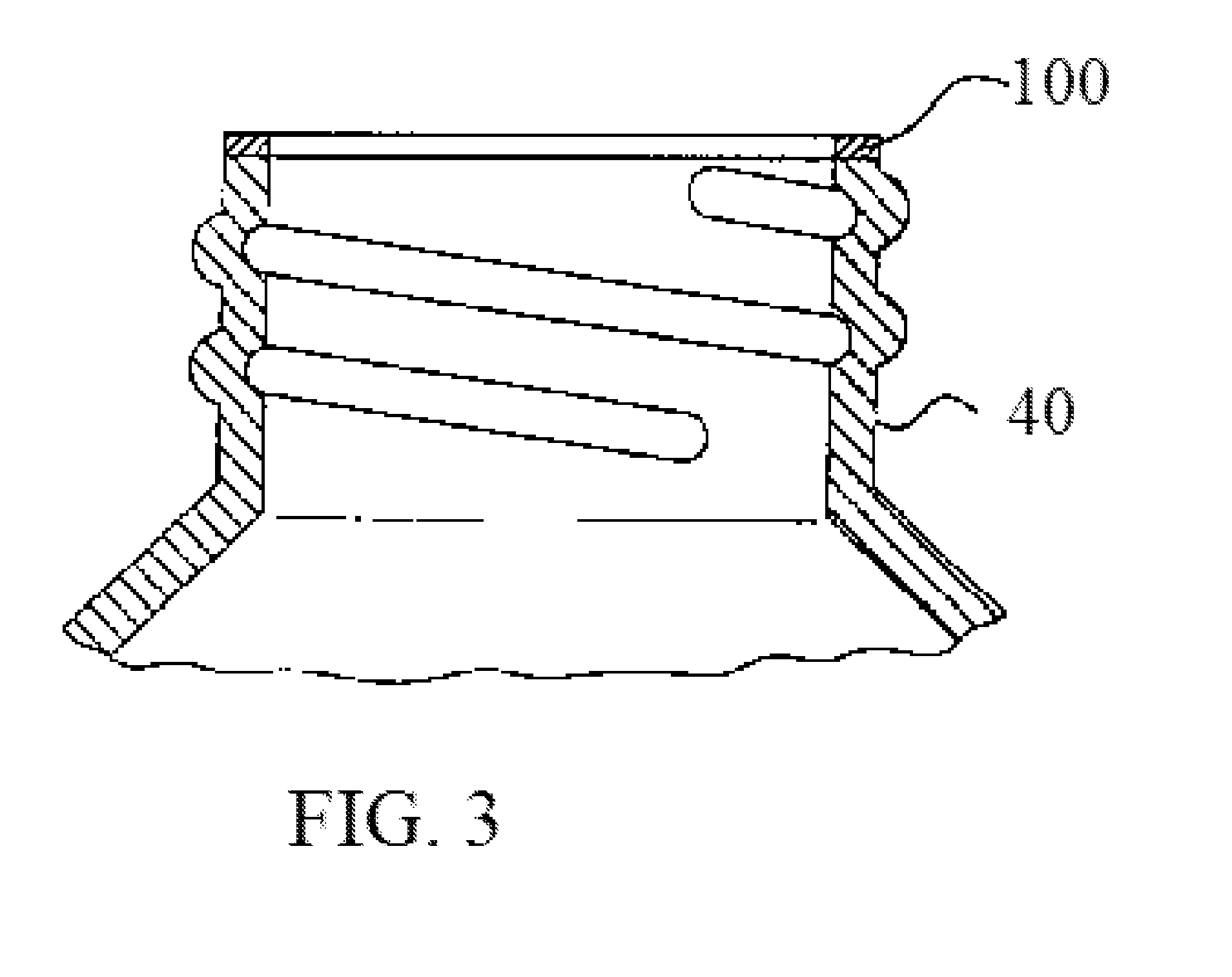

Core component having sealed frame and membrane electrode prepared thereby

ActiveCN101393989AStable supportDimensional stabilitySolid electrolyte fuel cellsSealing/support meansPhysical chemistryCore component

The invention relates to a core component with a sealed frame and a membrane electrode prepared by using the core component. A method for preparing the membrane electrode of the core component with the sealed frame is characterized in that a sealed frame material coated with a sticky glue layer on one surface thereof at the normal temperature is adopted, and a strengthened underlay is attached to the other surface thereof. The sealed frame is overlapped on two surfaces of an ion exchange membrane under the condition that one surface of the ion exchange film is supported. Then, an active area of the ion exchange membrane is coated with a catalyst, and the core component (CCM) with the sealed frame is prepared, and then carries out the hot pressing with a gas diffusion layer with a micropore layer and a gas diffusion layer (GDL), so as to prepare the membrane electrode (MEA).

Owner:武汉理工新能源有限公司

Polyurethane foam, process for producing the same, and foam forming composition

InactiveUS20020052425A1Improve mechanical propertiesLow compression setPeptide preparation methodsCushioningHydrogen

A polyurethane foam which is obtained by reacting an addition-polymerizable active hydrogen component comprising a compound having a group containing active hydrogen and an addition-polymerizable functional group or comprising both this compound and a compound containing at least 2.5 groups (on the average) containing active hydrogen and not containing addition-polymerizable functional groups with an organic polyisocyanate in the presence or absence of at least one auxiliary selected from the group consisting of foaming agents and additives to polymerize the addition-polymerizable functional group and simultaneously form a polyurethane, and which has a structure in which the chains formed by the addition polymerization have been cross-linked to the polyurethane chains. The polyurethane foam is useful as a rigid polyurethane foam excellent in hardness, dimensional stability, etc. and usable as a heat insulator, shock-absorbing material, synthetic wood, etc., or is useful as a soft polyurethane foam reduced in compression set and usable as a cushioning material, shock-absorbing material, sound insulating / absorbing material, etc.

Owner:SANYO CHEM IND LTD

Polyamide composition

InactiveUS6887930B2Low water absorptionOvercome lack of heat resistanceCarboxylic acidTerephthalic acid

A polyamide composition comprising 50 to 90 parts by weight of (A) semiaromatic polyamides having dicarboxylic acid units containing 60 to 100 mole % of terephthalic acid units and diamine units containing 60 to 100 mole %, in total, of 1,9-nonanediamine units and / or 2-methyl-1,8-octanediamine units, and 50 to 10 parts by weight of (B) aliphatic polyamides in which the average of total carbon atoms of dicarboxylic acid units and diamine units per one amide group is 7 to 12; having excellent moldability, toughness, light-weightness, hot water and steam resistance, heat resistance, mechanical characteristics, low water absorption, chemical resistance and melt stability; and are applicable for molding at low temperature with a conventional steam-heating or a conventional hot-water-heating type mold to give molded articles having sufficient heat resistance, rigidity at high temperature and dimensional stability.

Owner:KURARAY CO LTD

Fugitive pattern for casting

InactiveUS20060063870A1Fast and low costSuitable surface qualityFilm/foil adhesivesFoundry mouldsPolymer scienceInvestment casting

A fugitive pattern for making a shell mold for investment casting a metal or alloy comprises a substantially random interpolymer and a low molecular weight polymer in proportions to provide a fugitive pattern having a combination of properties suitable for use in making the shell molds.

Owner:HOWMET CORPORATION

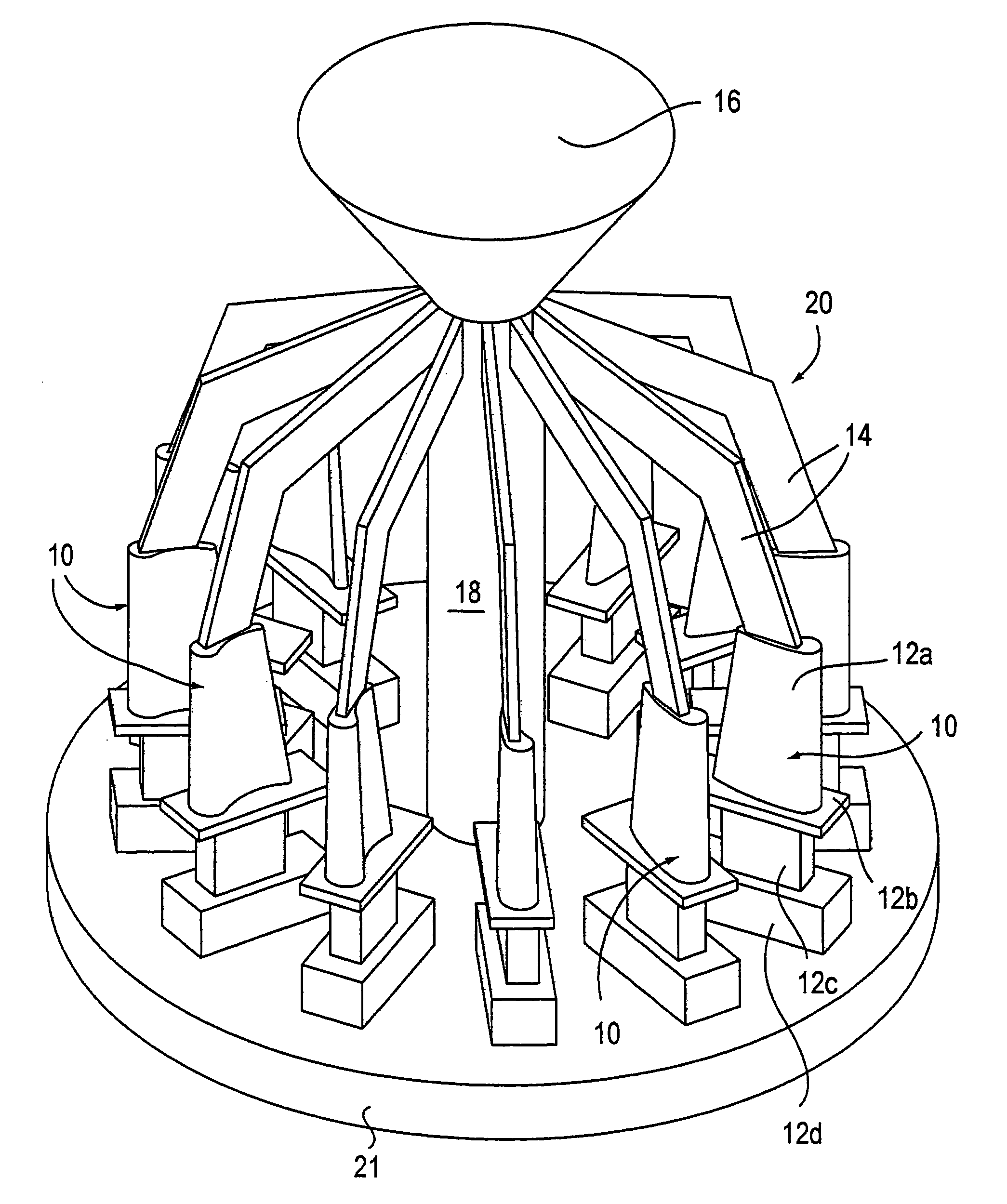

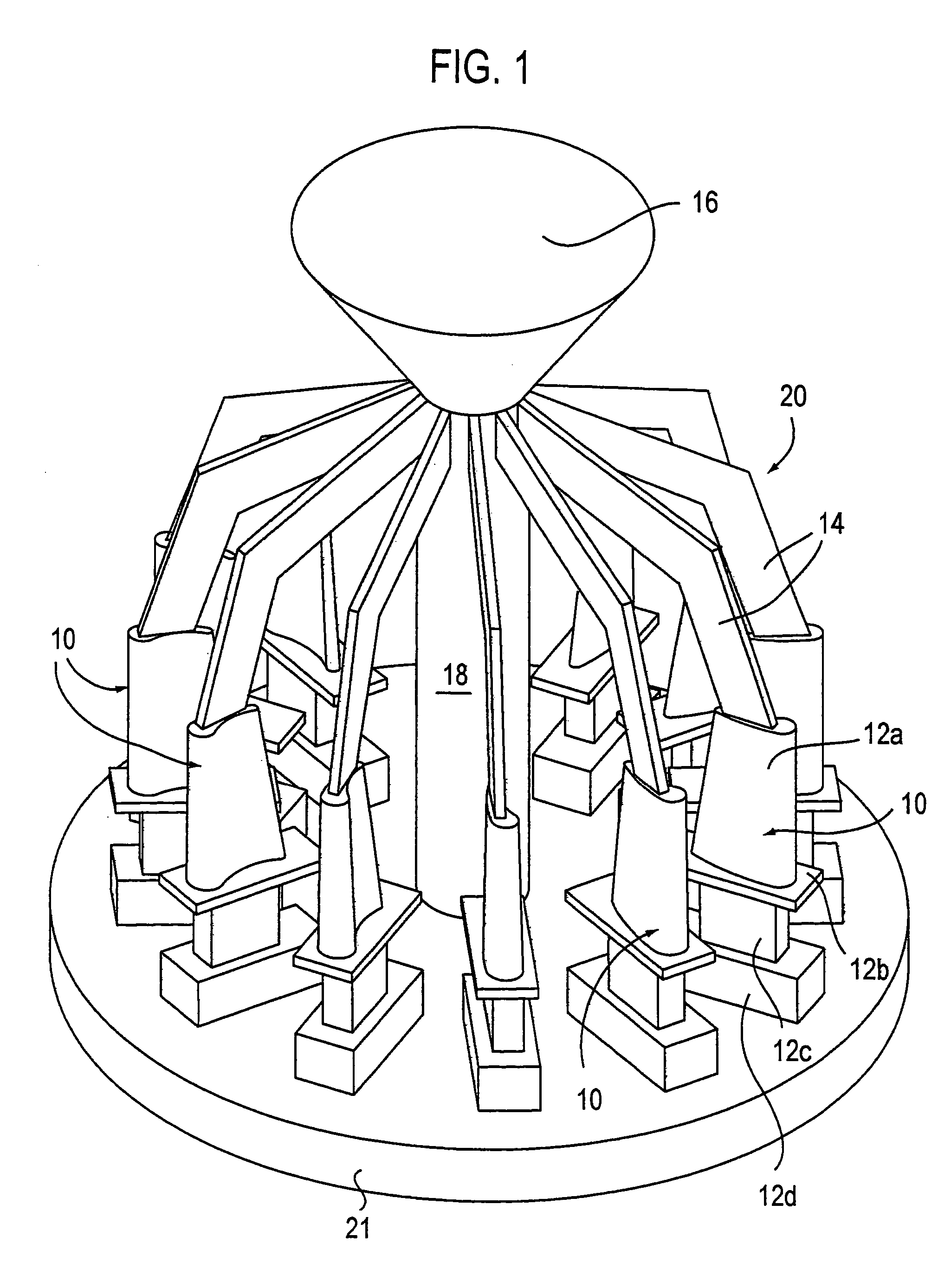

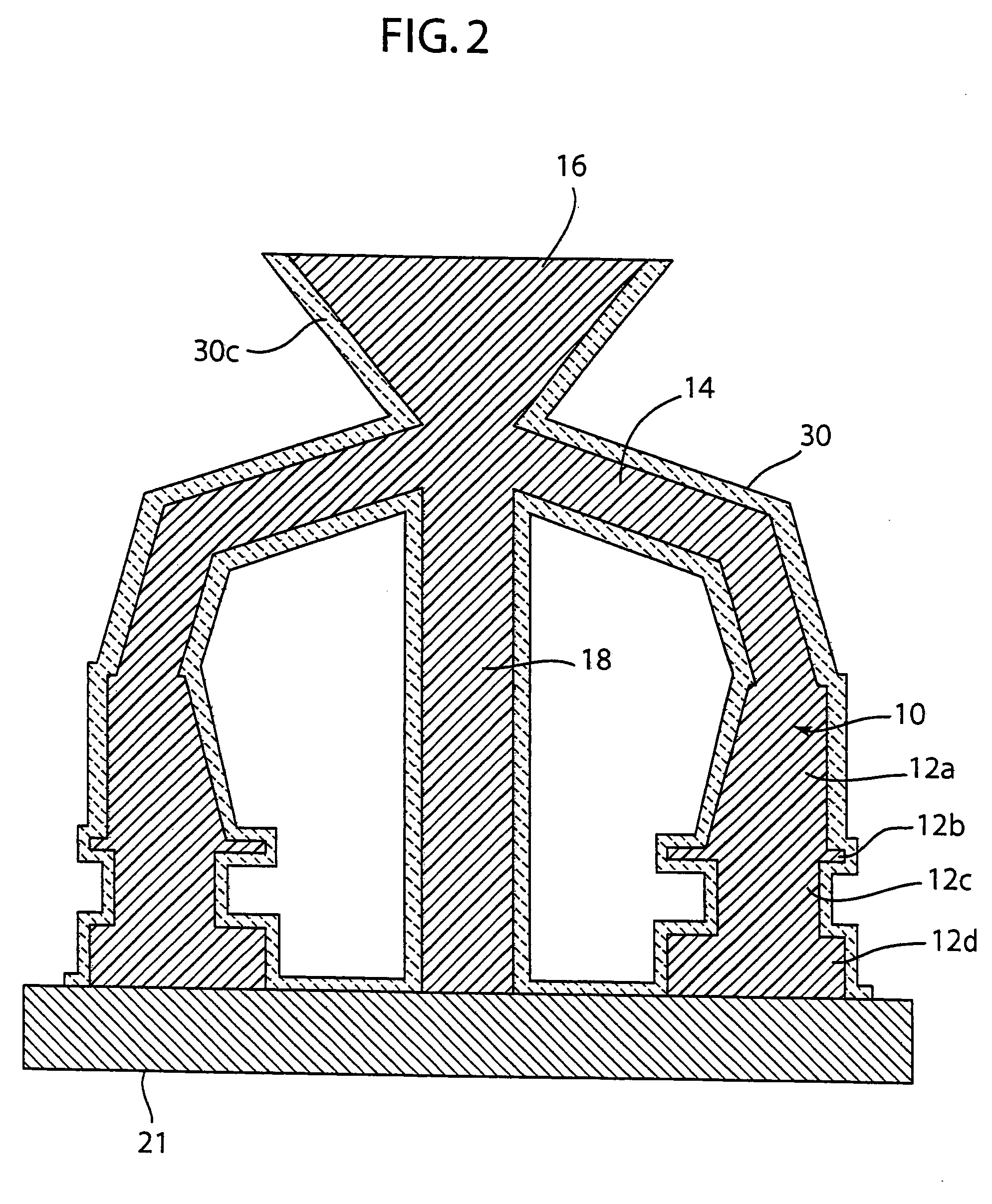

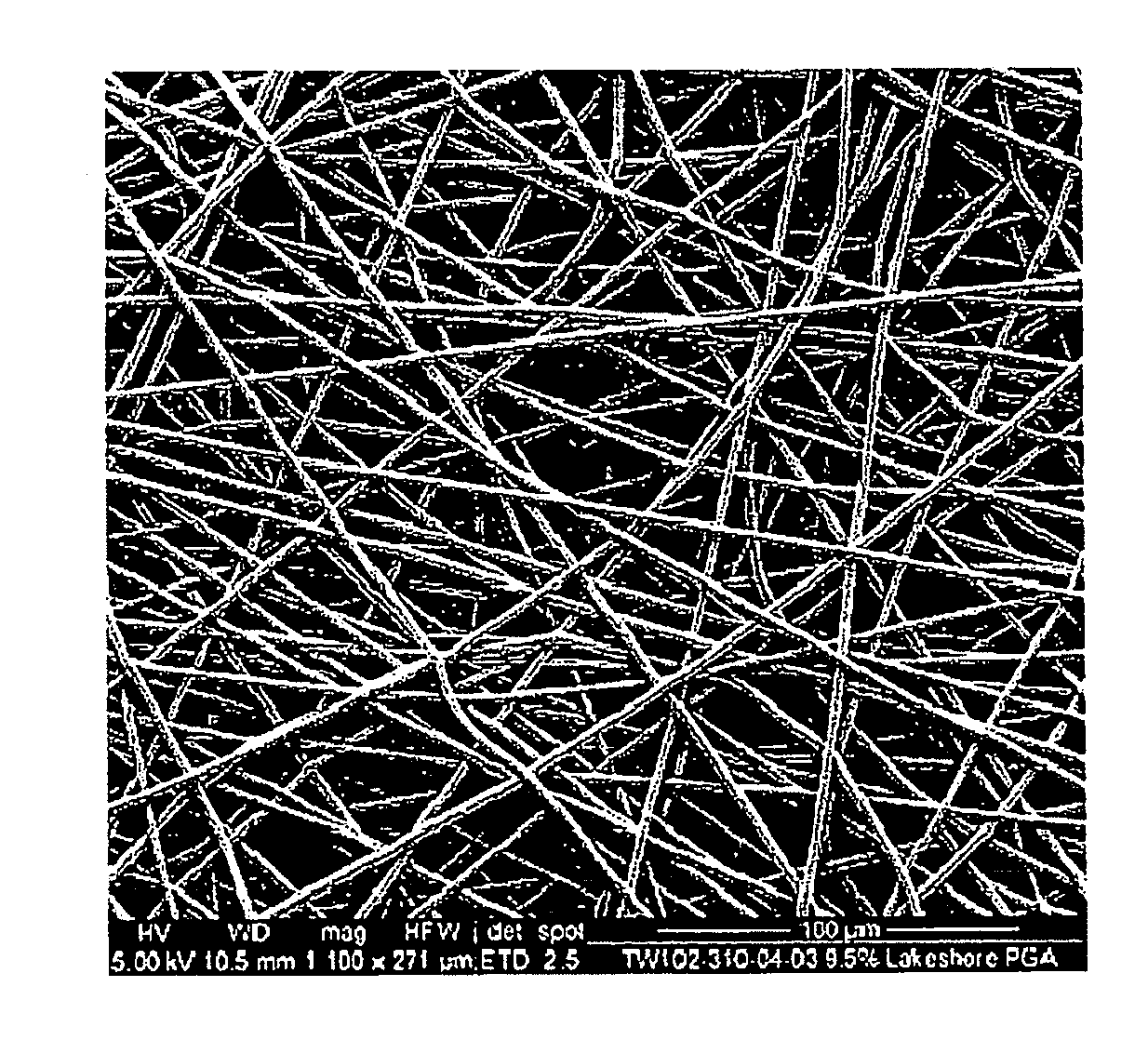

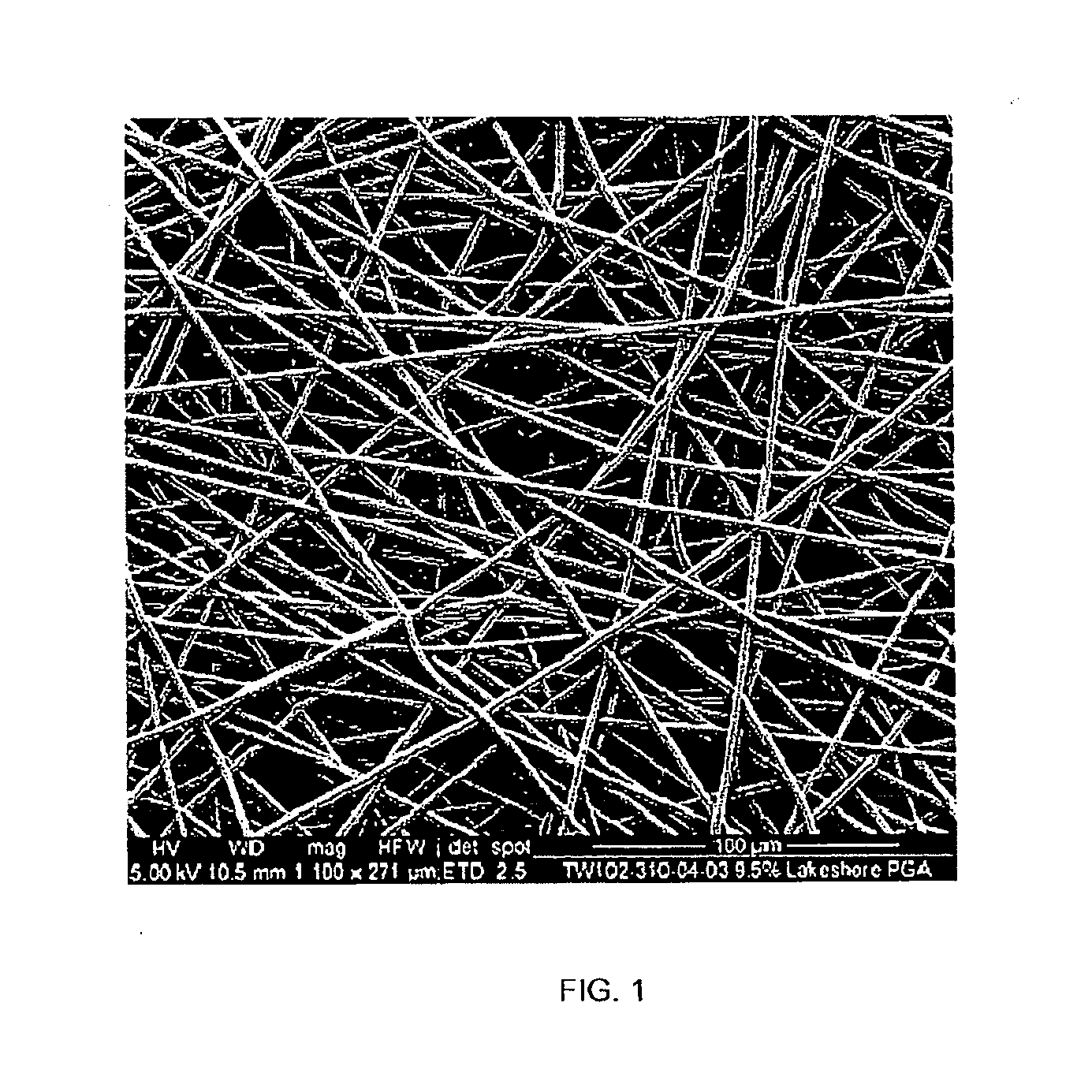

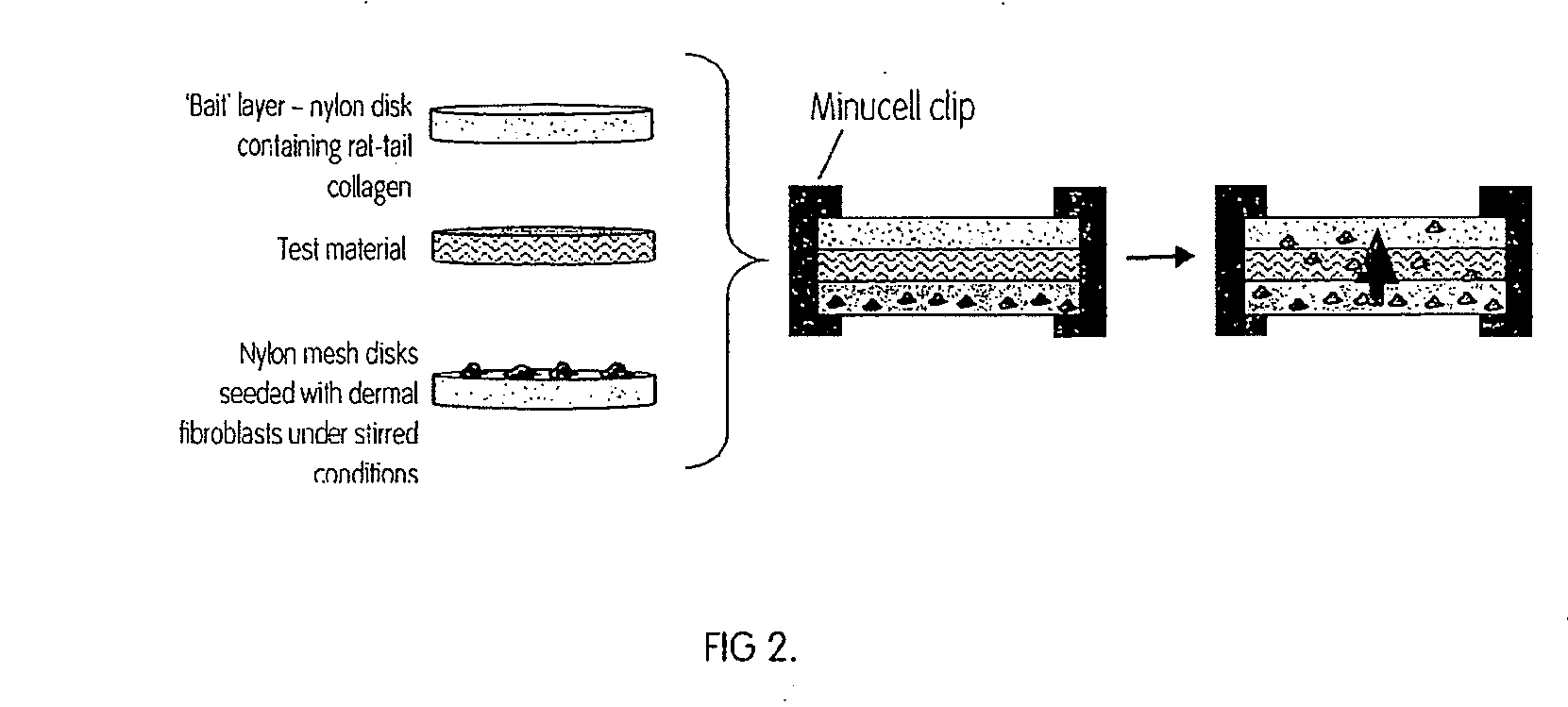

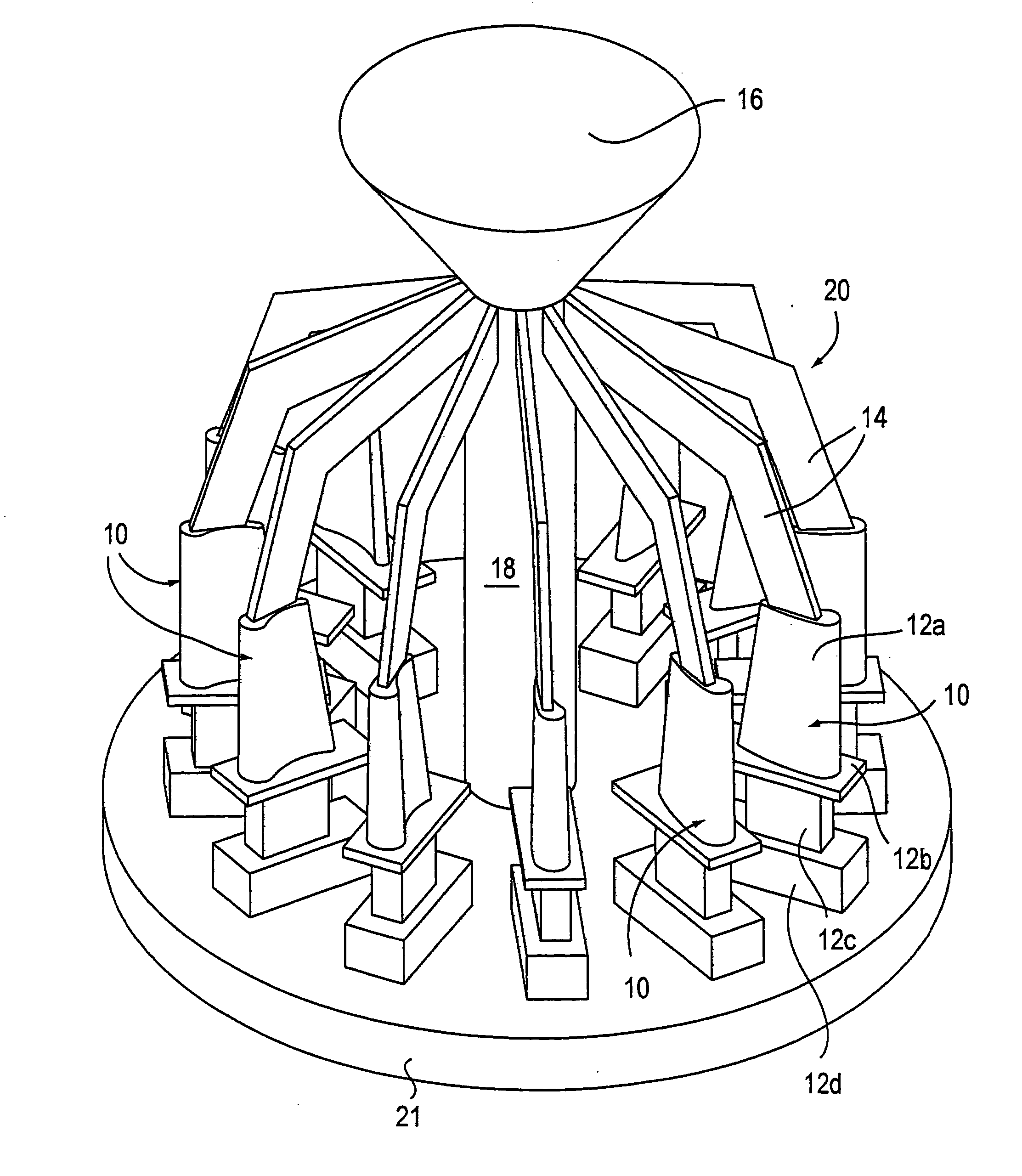

Scaffold

ActiveUS20100297208A1Fast seedingDimensional stabilityBiocideElectric discharge heatingFiberSource material

The present invention relates to scaffolds which can be used as medical devices for guided tissue regeneration and repair, in particular the invention is directed to a scaffold comprising fibres having a mean fibre diameter of between from about 1.2 to 4.0 microns, wherein the fibres comprise a glycolide. The invention further relates to the use of the scaffolds for the selective capture of cell populations for a cell source material.

Owner:SMITH & NEPHEW INC

Fugitive pattern for casting

InactiveUS20060063869A1Fast and low costSuitable surface qualityFilm/foil adhesivesFoundry mouldsPolymer scienceInvestment casting

A fugitive pattern for making a shell mold for investment casting a metal or alloy comprises a substantially random interpolymer and a low molecular weight polymer in proportions to provide a fugitive pattern having a combination of properties suitable for use in making the shell molds.

Owner:HOWMET CORPORATION

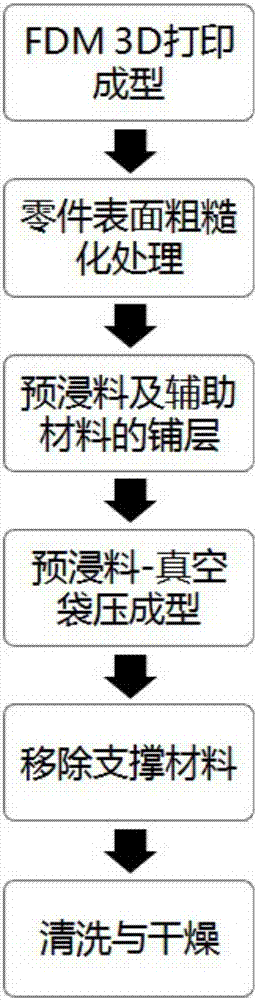

3D printing assisted forming method for fiber reinforced composite material

ActiveCN107187020AImprove surface roughnessIncrease mechanical bite forceAdditive manufacturing apparatus3D object support structuresFiber-reinforced compositeInvestment material

Provided is a 3D printing assisted forming method for a fiber reinforced composite material. An FDM 3D printing forming method and a continuous fiber composite material forming method are combined, a prepreg coating and an assisting material are laid on the surface of a part in a prepreg-vacuum bag molding composite material forming mode with an FDM 3D formed part as a forming mold, curing of prepreg is completed under a certain degree of temperature and pressure, and a supporting material is removed, cleaned and dried. By integrating the advantages of the flexibility and high precision of FDM 3D printing forming and the advantages of low weight and high strength of the composite material, the defects that FDM 3D printing forming is low in strength while the composite material is can not be separated from the mold easily are overcome, and the fiber reinforced composite material of a complex structure can be formed and manufactured into parts.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Hardwood flooring board

InactiveUS20050268571A1Maintain hardwood appearanceGood dimensional stabilityWallsFlooringHardwoodEngineering

The present invention is a hardwood flooring board including a middle layer formed from a non-hardwood flooring material and a hardwood material upper layer which is secured to an upper surface of the middle layer. The middle layer forms between 45% and 75% of the overall material of the board and enables the board to be manufactured to be more dimensionally stable, i.e., wider and longer, than conventional hardwood flooring boards. Also the use of the non-hardwood material in the middle layer greatly increases the dimensional stability and long term performance of the flooring boards, while providing a genuine hardwood appearance to the floor. The board also includes a lower layer that can be formed from either a hardwood material or a non-hardwood material to function as a base for the board.

Owner:SHAW INDS GROUP

Isocyanate-based polymer foams with nano-scale materials

Isocyante-based polymer foams containing functionalized nano-scale materials in which the functional groups are OH, NH2, COOH or NCO groups. The incorporation of such functionalized nano-scale materials into the isocyanate-based polymer foams provides foams with improved properties such as insulation values, mechanical properties and flame retardancy performance properties, including but not limited to k-factor and dimensional stability.

Owner:HONEYWELL INT INC

Soft cover for vehicles and process for making

InactiveUS6871898B2Good and good noise controlHeavy weightEngine sealsLayered productsPliabilityAgricultural engineering

A soft cover for a vehicle is provided comprising a foam composite having a water resistant top layer, a flexible foam layer, and a protective bottom layer. The composite is flexible, dimensionally stable and tear resistant. Methods of manufacture and of use of the soft cover are also provided.

Owner:OMNOVA SOLUTIONS INC

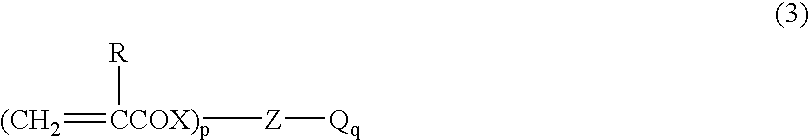

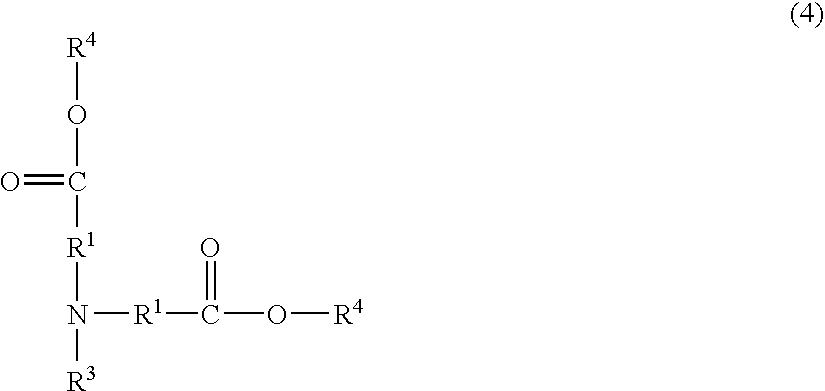

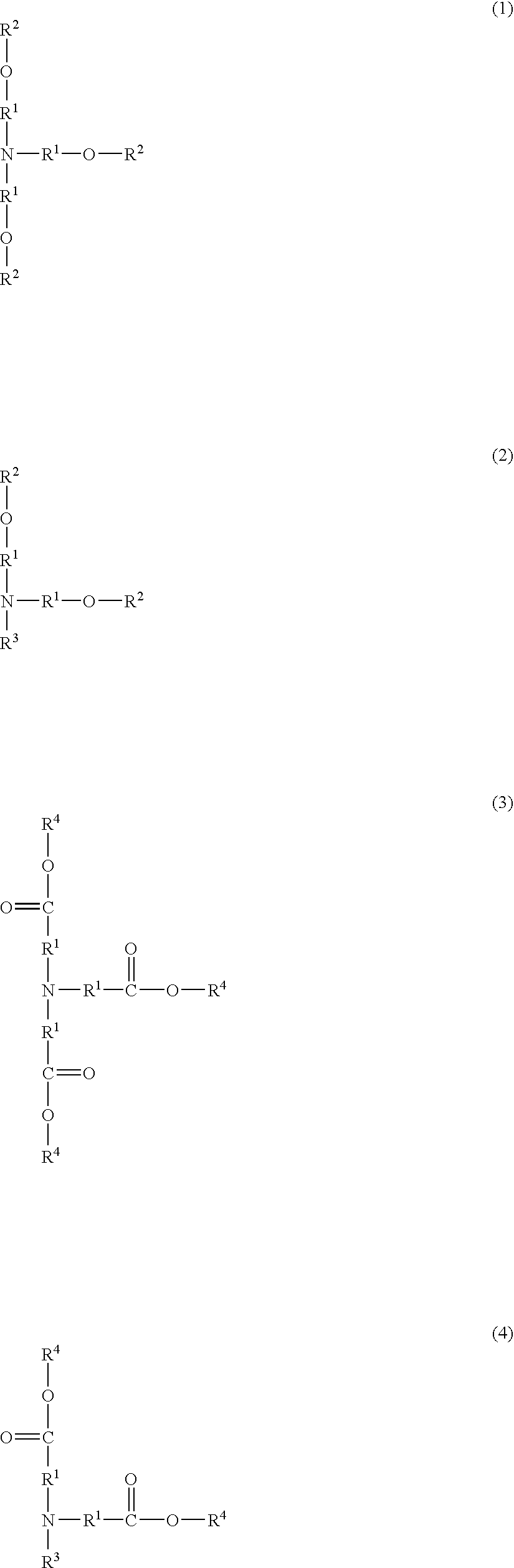

Resist composition

InactiveUS6916593B2Small sizeReduce film thicknessRadiation applicationsDiazo compound compositionsResistChemical compound

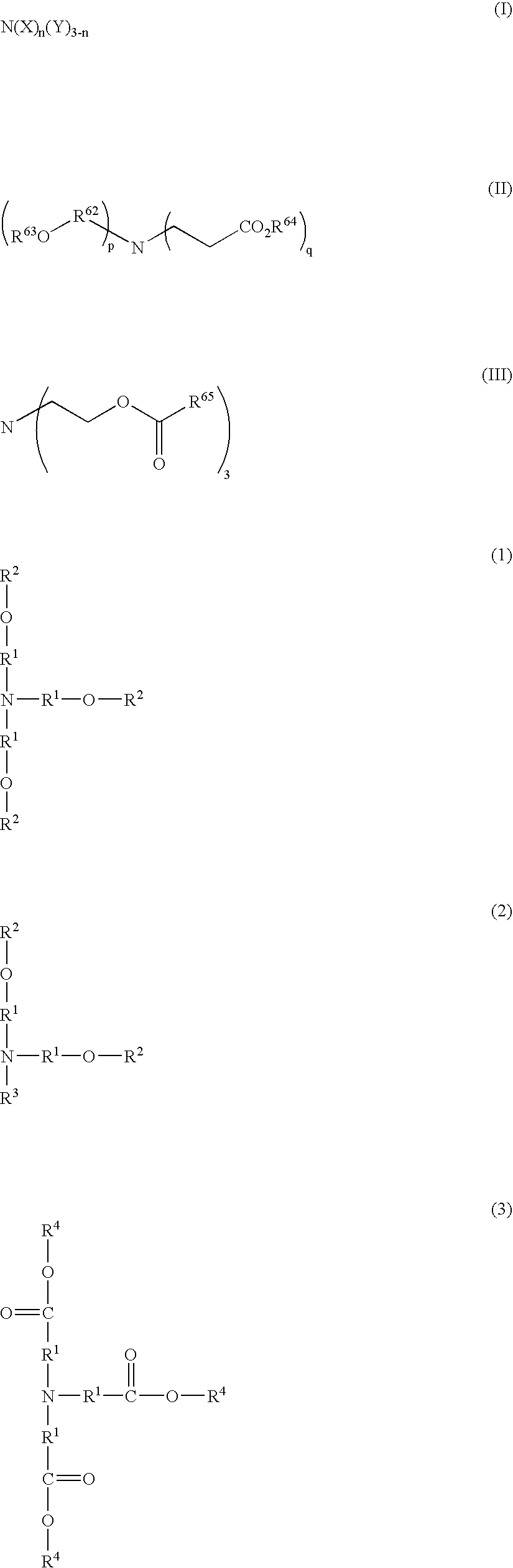

Although use of a nitrogen-containing compound as a basic compound component of a resist composition makes it possible to ease the T-top problem at an acid dissociation constant pKa falling within a range of 2 to 6, it is accompanied with the problem that the reaction, that is, acid diffusion upon use of a highly-reactive acid-labile group cannot be controlled. In order to overcome this problem, one or more basic compounds selected from those represented by the following formulas (I) to (III) and (1) to (4) are employed.

Owner:SHIN ETSU CHEM IND CO LTD

Method of manufacturing a release liner

InactiveUS20060228480A1High mechanical strengthEasy to tearLamination ancillary operationsFilm/foil adhesivesEngineeringMechanical engineering

The present invention relates to a method of manufacturing a release liner to be temporarily adhered to the surface of an adhesive. A single-layer or multi-layer film is obtained by impressing a plastic base liner substrate. At least one surface of the base liner substrate is coated with a release agent to form a tearable release liner. There is no fibrous debris along the edges when the release liner is torn apart.

Owner:LIN DAVID

Polypropylene-based resin composition and molded article thereof

A polypropylene-based resin composition of drastically improved dimensional stability realized by incorporating a polypropylene resin of specific structure with an inorganic filler of specific particle size, carbon fibers of specific fiber diameter and length, and, as required, an ethylene- and / or styrene-based elastomer. Another polypropylene-based resin composition of well-balanced properties of rigidity, heat-resistance, impact resistance and lightness even essentially in the absence of inorganic filler, realized by compositing a propylene / ethylene block copolymer of specific structure and well-balanced mechanical properties with an ethylene- and / or styrene-based elastomer, and carbon fibers of specific structure.

Owner:JAPAN POLYPROPYLENE CORP

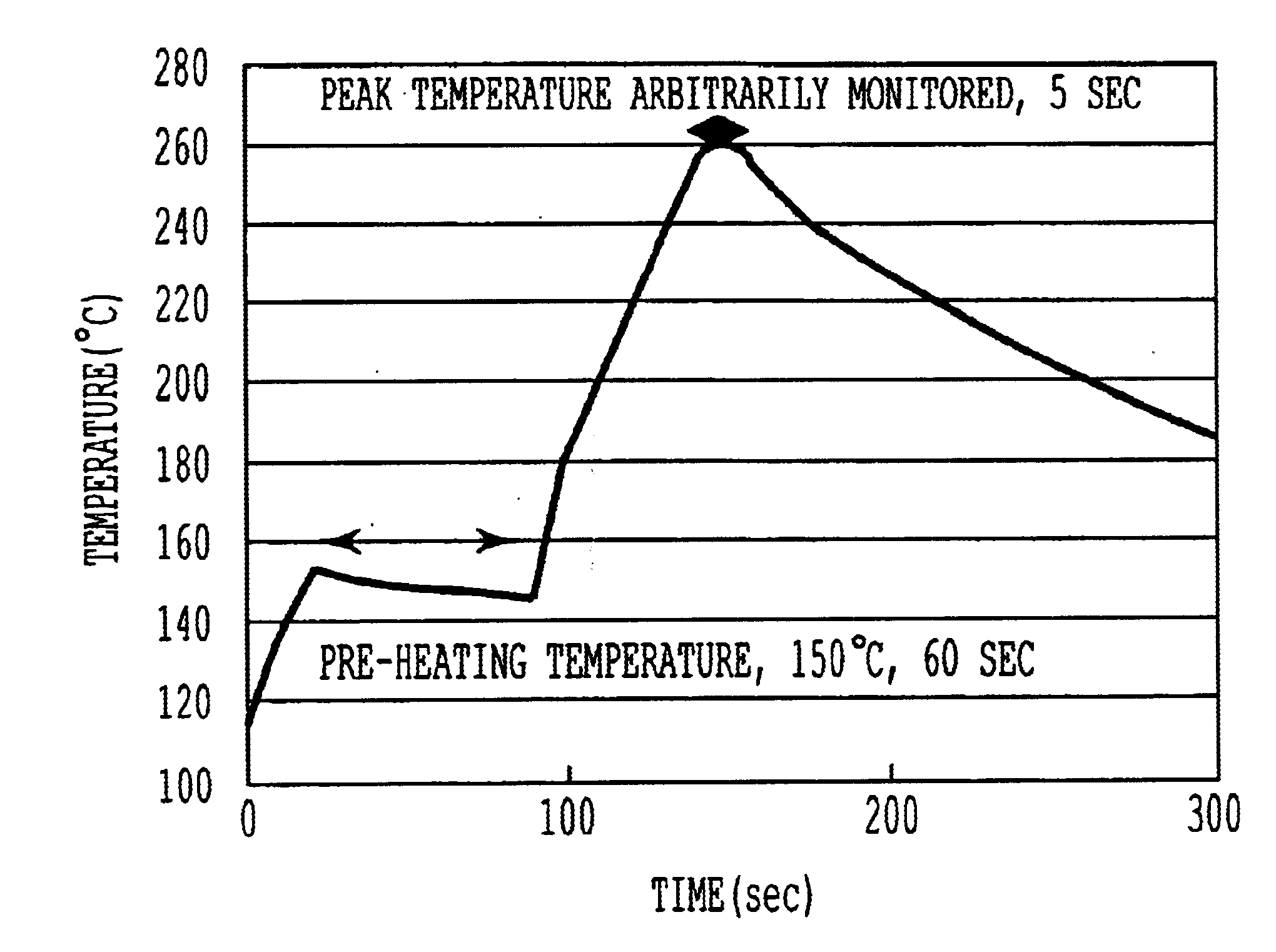

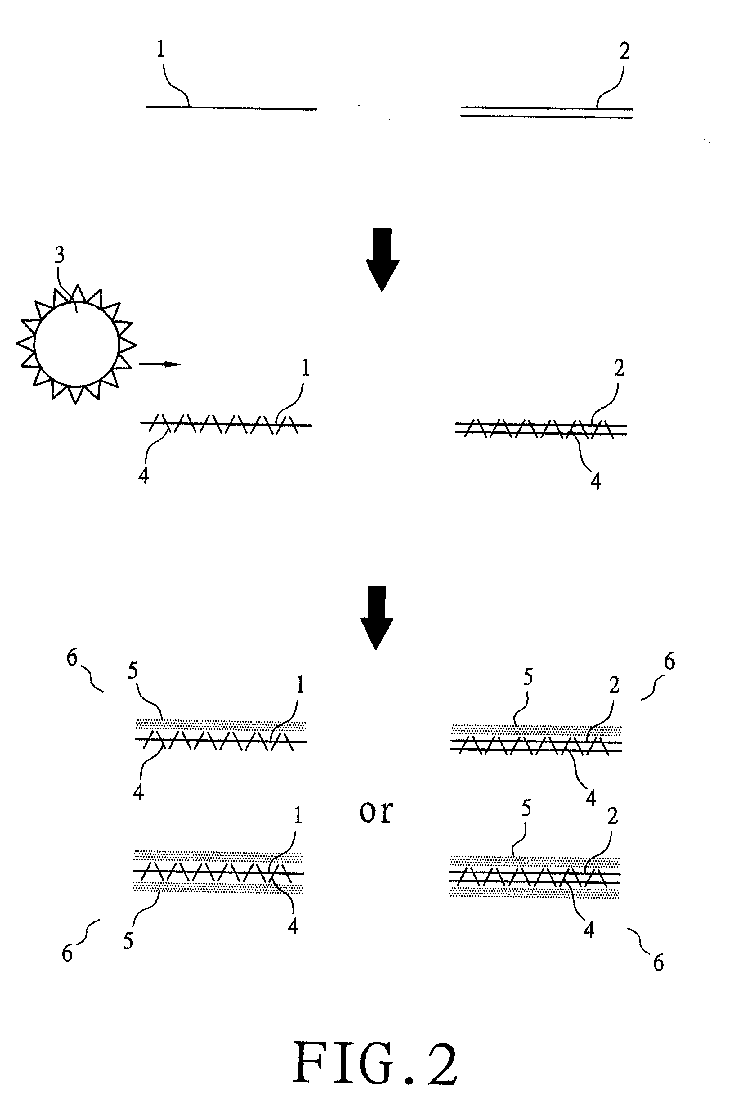

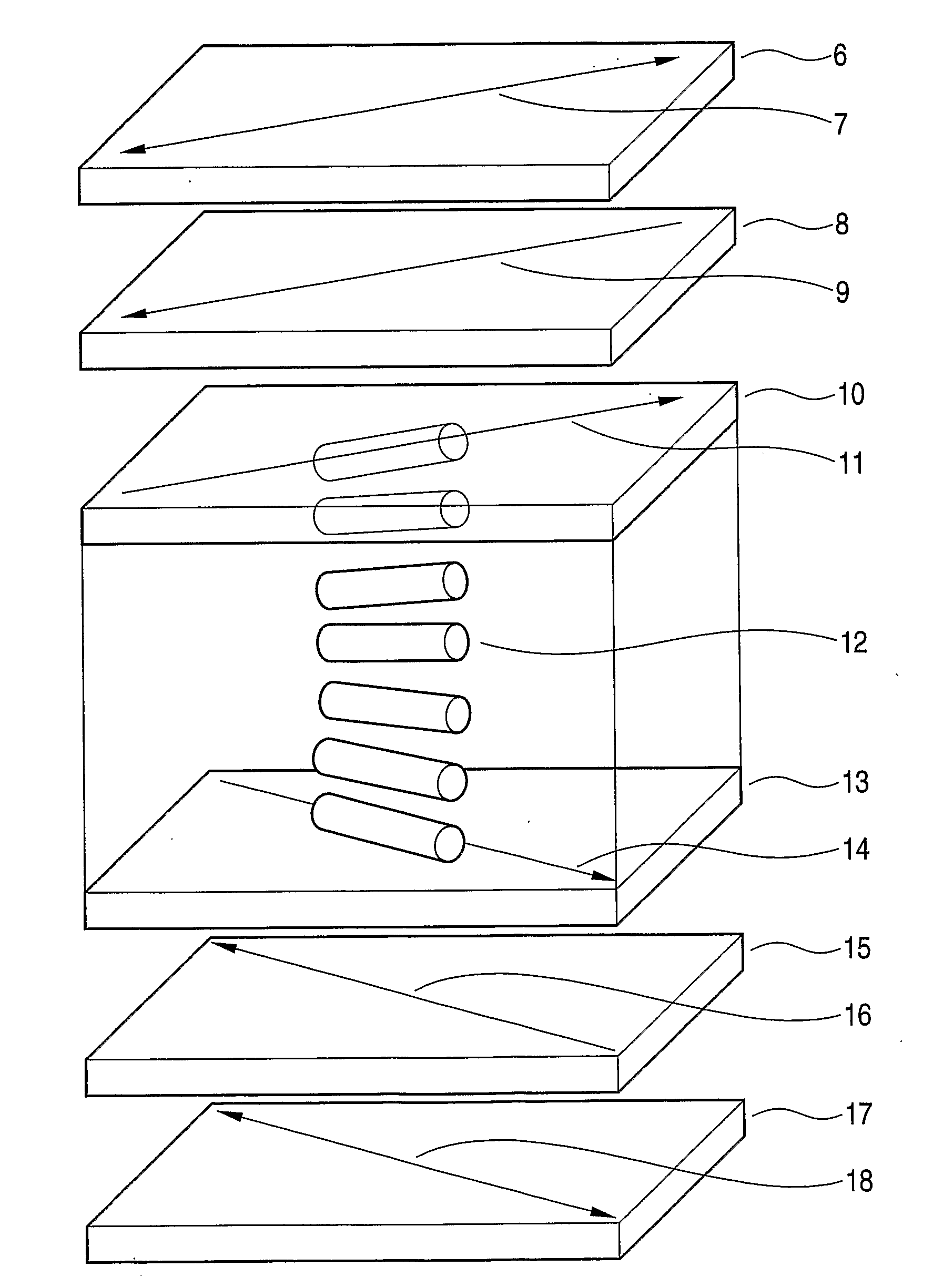

Cellulose Acylate Film, Method for Producing Cellulose Acylate Film, Polarizing Plate and Liquid Crystal Display Device

InactiveUS20090021671A1Stable in retardationDimensional stabilityLiquid crystal compositionsCellulosic plastic layered productsVitrificationCellulose

A method for producing a cellulose acylate film containing an additive comprising an aliphatic compound, the method contains a process of thermal shrinkage treatment at an atmospheric temperature higher than the glass transition temperature (Tg) in the state where at least one of the transverse direction and the machine direction of the film is free, and a cellulose acylate film obtained by the above method.

Owner:FUJIFILM CORP

Elastic fiber fabric and preparation method thereof

The invention relates to an elastic fiber fabric, in particular to an elastic fiber fabric and a preparation method thereof. Warps and wefts are respectively 150D or75D PTS elastic yarns. The elastic fiber fabric is prepared through the steps of winding, twisting, sectional warping, healding, weaving, blank inspection, unrolling and flattening, pre-shrinking treatment, presetting, dyeing, reduction clearing and finishing. The elastic fiber fabric and a preparation method thereof have the advantages as follows: the structure is simple, the chemical fiber differentiation is promoted, the added value is increased, the preparation steps are scientific and reasonable and conform to the basic state policy of energy conservation and emission reduction, and the fabric feels like nylon, has a bright and pure color, is far lower than spandex in price and is a preferred garment material.

Owner:杭州宏海纺织有限公司 +1

Nanoparticle and preparation method thereof

InactiveCN101708162AGood biocompatibilityDimensional stabilityPharmaceutical non-active ingredientsGranular deliveryLactideHalf-life

The invention relates to a nanoparticle and a preparation method thereof. Poly(lactide-glycolide acid) (PLGA) is in the center to serve as a core, phospholipid surrounds the surface of the PLGA core in monolayer and distearoyl phosphatidylethanolamine-polyethyleneglycol-carboxyl (DSPE-PEG-COOH) penetrates the monolayer phospholipid to serve as the shell. The phospholipid, the DSPE-PEG-COOH and the PLGA have good biocompatibility, can entrap hydrophobic drugs and control the drugs to release slowly in the human bodies. The phospholipid surrounds the surface of the PLGA, thus ensuring that the particle can avoid immune system recognition so that the circulating half life of the particle is lengthened. The PEG shell ensures the particle to have spatial stability, static stability, long circulation and other characteristics and to be not easily agglomerated. Meanwhile, carboxyl is easily crosslinked with such ligands as antibodies, peptide, probes and the like, thus ensuring the particle to have targeting characteristic. The preparation method of the nanoparticle is simple, convenient practical and is easy to operate and popularize.

Owner:SHENZHEN INST OF ADVANCED TECH

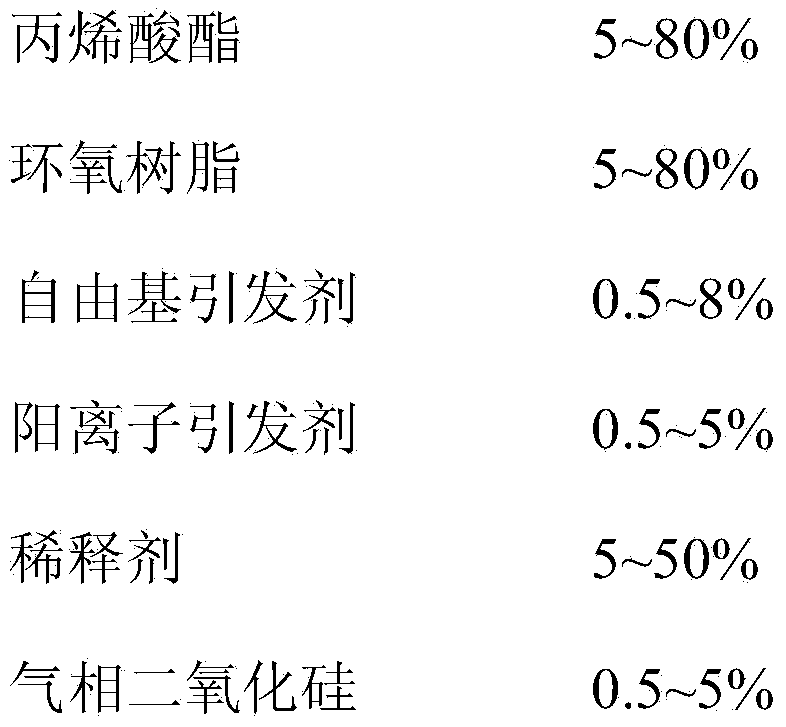

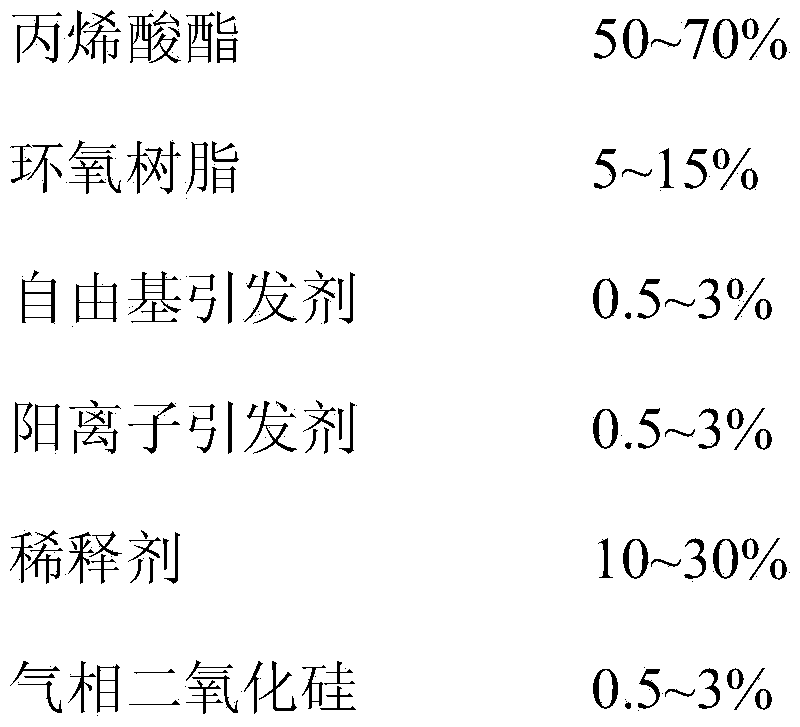

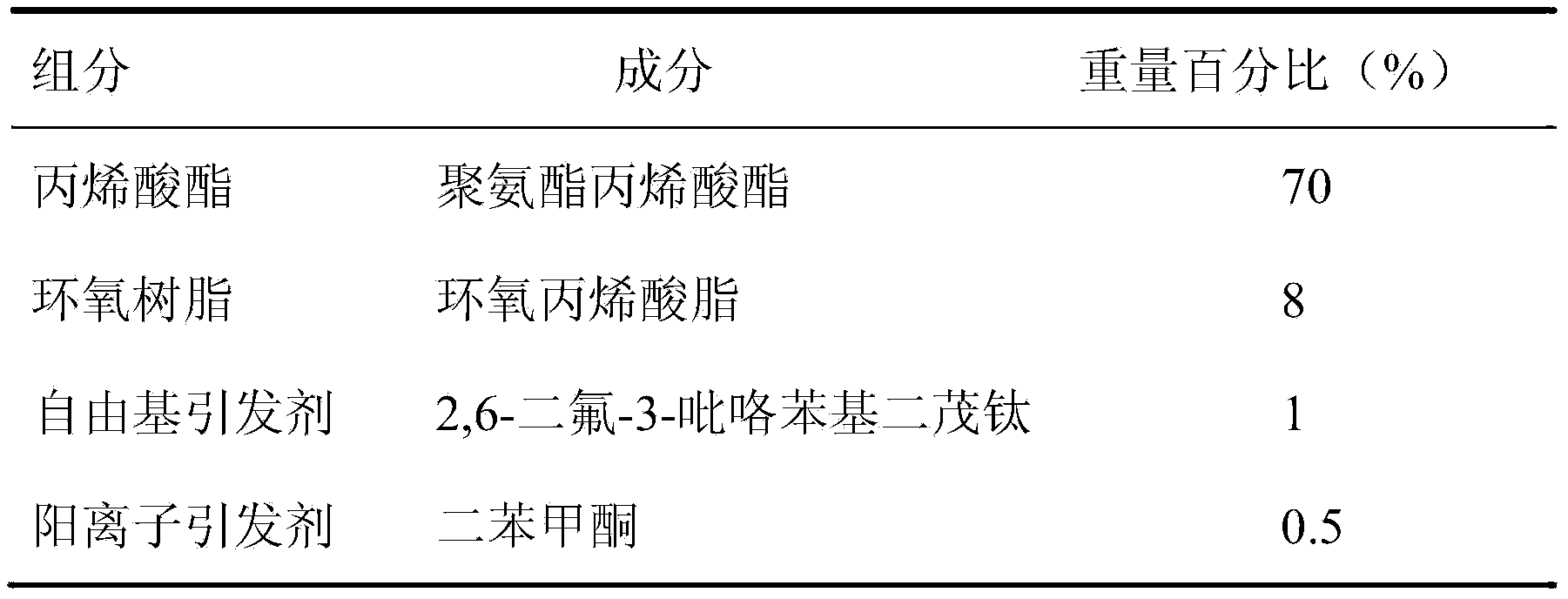

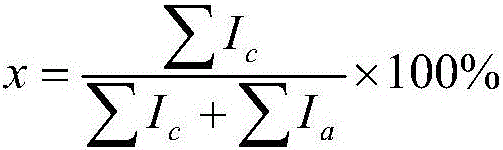

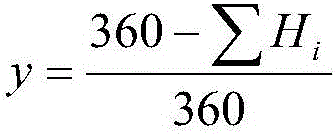

Photosensitive resin and preparation method thereof

The invention belongs to the field of novel 3D printing materials and in particular belongs to the field of photosensitive resin. The photosensitive resin is prepared from the following components in percentage by weight: 5-80% of acrylic ester, 5-80% of epoxy resin, 0.5-8% of a radical initiator, 0.5-5% of a cationic initiator, 5-50% of a diluent and 0.5-5% of gas phase silicon dioxide. Flexural modulus and tensile modulus of the photosensitive resin reach over 2000Mpa; the photosensitive resin is high in capability of resisting bending deformation stress in an elastic limit, high in strength, low in possibility of deforming and high in mechanical strength; the service life is greatly prolonged; the volume shrinkage rate is about 1.0%; the ultralow volume shrinkage rate is achieved; the industrial use requirement can be met.

Owner:NANJING BAICHUAN XINGYUAN LASER TECH

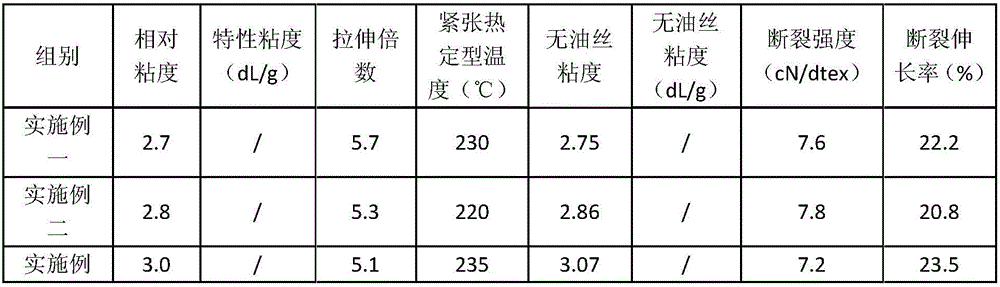

Polyamide 5X medium-tenacity yarn and preparation method thereof

ActiveCN106835329AHigh strengthLow elongationArtificial filament heat treatmentMelt spinning methodsDiaminePolyamide

The invention provides polyamide 5X medium-tenacity yarn and a preparation method thereof. Production raw materials of the polyamide 5X medium-tenacity yarn at least include 1,5-pentamethylene diamine and dicarboxylic acid or polyamide 5X obtained by polymerizing 1,5-pentamethylene diamine and dicarboxylic acid serving as monomers; the breaking strength of the polyamide 5X medium-tenacity yarn is 6.0-8.0 cN / dtex. The preparation method comprises the steps as follows: (1) 1,5-pentamethylene diamine and dicarboxylic acid are polymerized to form polyamide 5X melt; or polyamide 5X resin is heated to be in a molten state to form the polyamide 5X melt; (5) the polyamide 5X melt is spun to form primary yarn; (3) the primary yarn is treated to form the polyamide 5X medium-tenacity yarn. The polyamide 5X medium-tenacity yarn has the characteristics of high strength, low elongation, low heat shrink performance and the like; besides, the polyamide 5X medium-tenacity yarn also has the advantages of good wear resistance, good alkali resistance, size stability and the like, so that the polyamide 5X medium-tenacity yarn can be widely applied to the fields of sewing threads, safety belts, ropes, fishing nets, filter cloth and the like.

Owner:CATHAY R&D CENT CO LTD +2

Cross blend material based on polycarbonate and its prepn. method

InactiveCN1415661AImprove heat resistanceImproved boiling water aging resistanceHeat resistanceEngineering plastic

A polycarbonate-base mixture suitable for the engineering plastics in wet or hot water environment is prepared through mixing polyethene with maleic acid anhydride modified polyolefine or ionic polymer, kneading, granulating, mixing with polycarbonate and acrylonitrile-butadiene-styrene copolymer, and extruding out. Its advantages are high mechanical performance, size stability and refractory nature, and high antiageing nature in boiling water.

Owner:上海天原集团胜德塑料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com