Polyester resin with high humidity and heat resistance and high irradiance as well as preparation method and application thereof

A polyester resin and irradiance technology, applied in the field of polyester resin, can solve the problems of acid value, viscosity and weather resistance that cannot meet the long-term protection requirements of highway guardrails, high price, poor mechanical properties, etc. The effect of production and wide application, short synthesis time and super weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

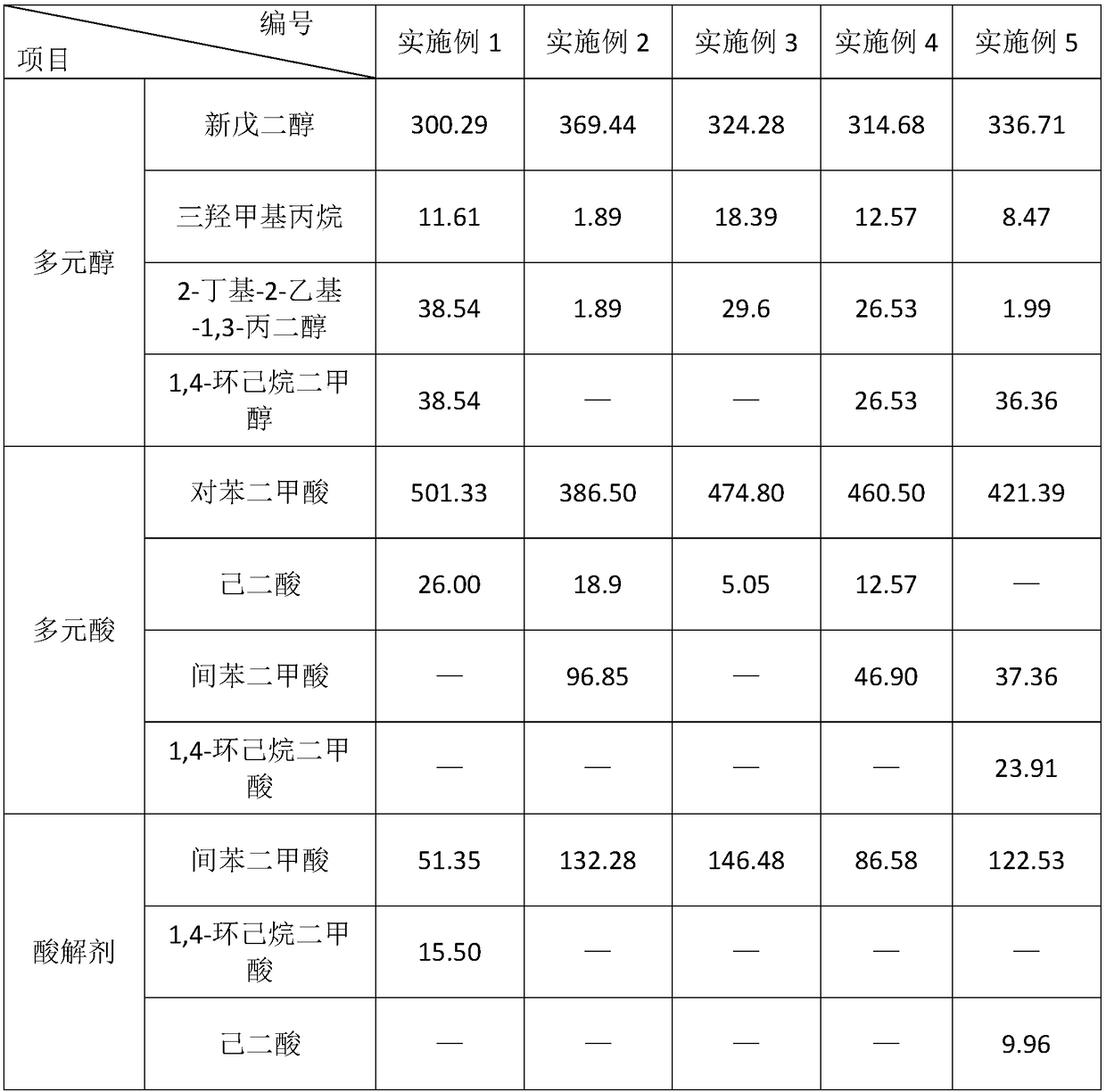

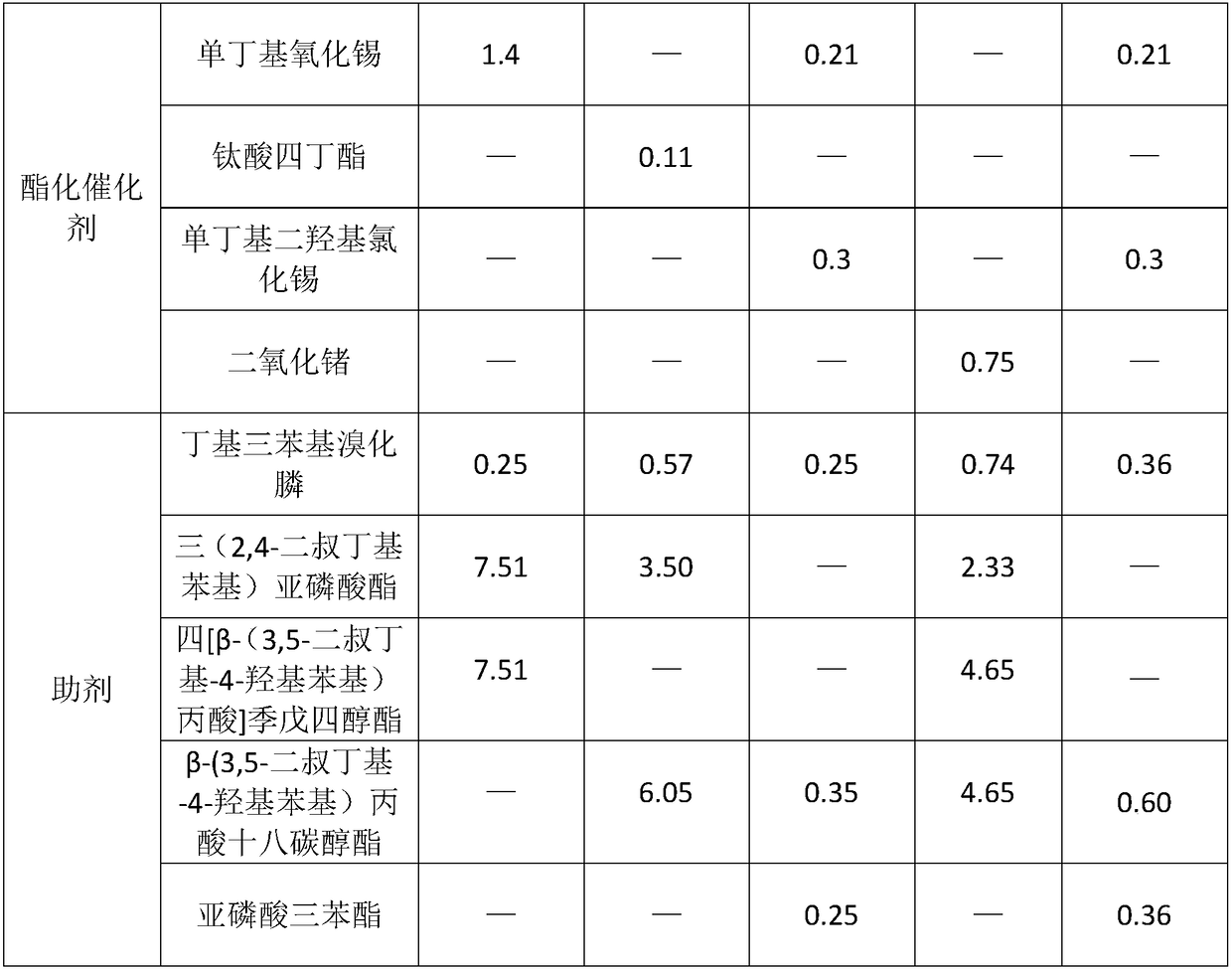

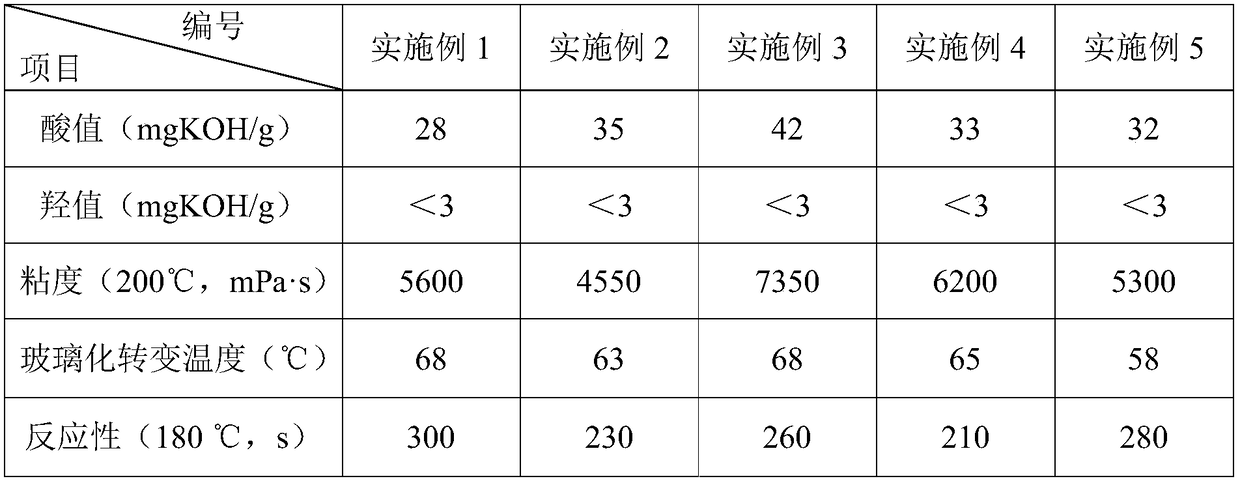

Examples

Embodiment 1

[0051] The preparation steps of embodiment 1 polyester resin:

[0052] 1) Add polyhydric alcohol into the reaction kettle according to the proportion of Example 1 in Table 1, heat up to the melting of the material, then add polyacid and catalyst, and raise the temperature to 180°C within 1h under the protection of nitrogen, and then rise to 180°C within 2h 210°C, keep warm for 1.5h, then continue to heat up to 220°C within 1h, and rise to 250°C within 2h for esterification reaction, the acid value reaches 13-18mgKOH / g, vacuumizes for 2h, the acid value reaches 5-8mgKOH / g, Esterification products are obtained;

[0053] 2) Under the protection of nitrogen, add an acidolysis agent to the esterification product and carry out acidolysis reaction at 245°C for 3 hours to obtain an acidolysis product with an acid value of 35-40 mgKOH / g;

[0054] 3) The acid hydrolysis product was subjected to polycondensation reaction at a vacuum degree of -0.095MPa for 2 hours, the acid value reache...

Embodiment 2

[0055] The preparation steps of embodiment 2 polyester resins:

[0056] 1) Add polyhydric alcohol into the reaction kettle according to the proportion of Example 2 in Table 1, heat up to the melting of the material, then add polyacid and catalyst, and raise the temperature to 180°C within 1h under the protection of nitrogen, and then rise to 180°C within 2h 210°C, keep warm for 1.5h, then continue to heat up to 220°C within 1h, and within 2h to 245°C for esterification reaction for 7h, the acid value reaches 7-9mgKOH / g, vacuumizes for 2h, the acid value reaches 1-3mgKOH / g , to obtain esterification products;

[0057] 2) Under the protection of nitrogen, add an acidolysis agent to the esterification product and carry out acidolysis reaction at 235°C for 4 hours to obtain an acidolysis product with an acid value of 41-46 mgKOH / g;

[0058] 3) The acid hydrolysis product was subjected to polycondensation reaction at a vacuum degree of -0.092MPa for 3 hours, the acid value reached...

Embodiment 3

[0059] The preparation steps of embodiment 3 polyester resins:

[0060] Step 1) is with the step 1) of embodiment 2, and difference is to add by the raw material of embodiment 3 and proportioning;

[0061] 2) Under the protection of nitrogen, add an acidolysis agent to the esterification product and carry out acidolysis reaction at 235°C for 4 hours to obtain an acidolysis product with an acid value of 50-55 mgKOH / g;

[0062] 3) The acid hydrolysis product was subjected to polycondensation reaction at a vacuum degree of -0.089MPa for 4 hours, the acid value reached 40-45mgKOH / g, the hydroxyl value was less than 3mgKOH / g, the melt viscosity at 200°C was 6500-7500mPa.s, and the temperature was lowered to 180- At 210°C, add additives and stir to disperse evenly to obtain polyester resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com