High thermal conductivity composite phase change microcapsule and preparation method thereof

A composite phase transition, high thermal conductivity technology, applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problems of particle agglomeration, complex preparation technology, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

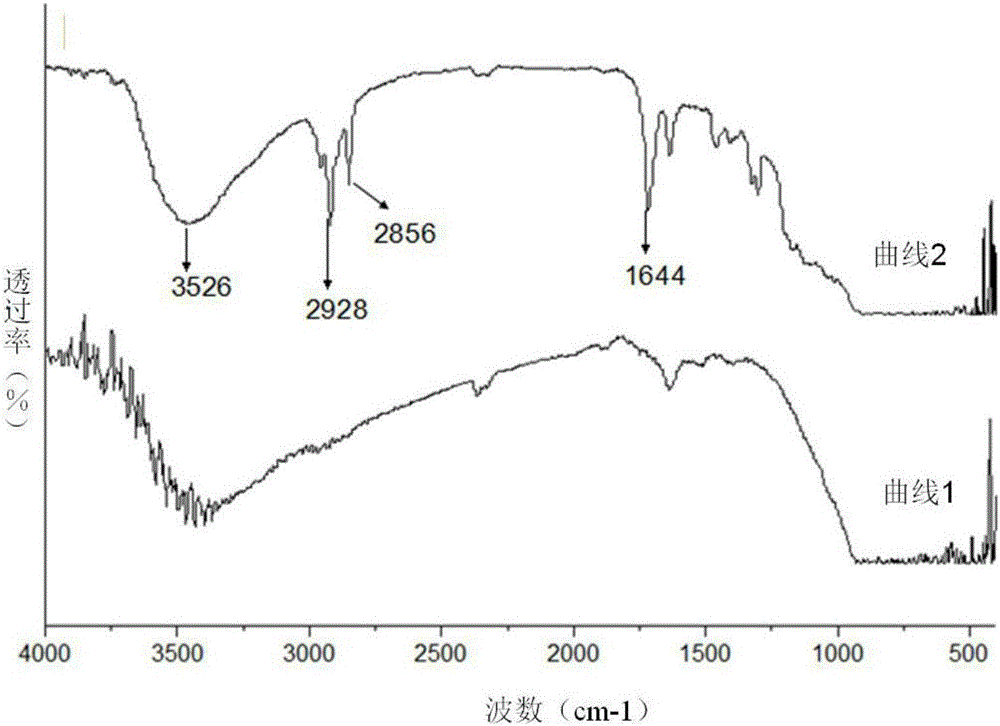

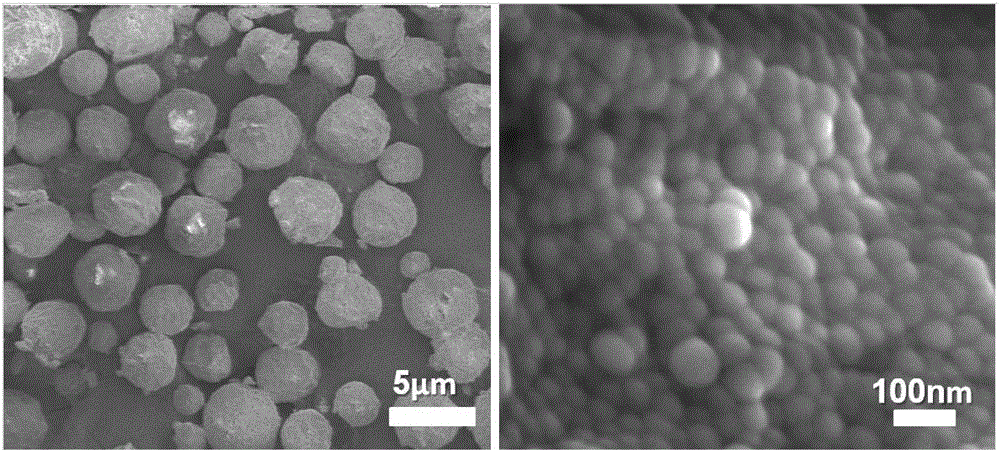

[0024] Embodiment 1: A kind of high thermal conductivity composite phase change microcapsule

[0025] (1) 2g nano-Al 2 o 3 The powder is ultrasonically dispersed in ethanol, and 5% silane coupling agent KH-570 is dissolved in Al 2 o 3 In the dispersion liquid, heat up to 70°C and reflux for more than 8 hours. After centrifugal washing, vacuum drying at 40°C for more than 12 hours to obtain KH-570 modified nano-Al 2 o 3 particles.

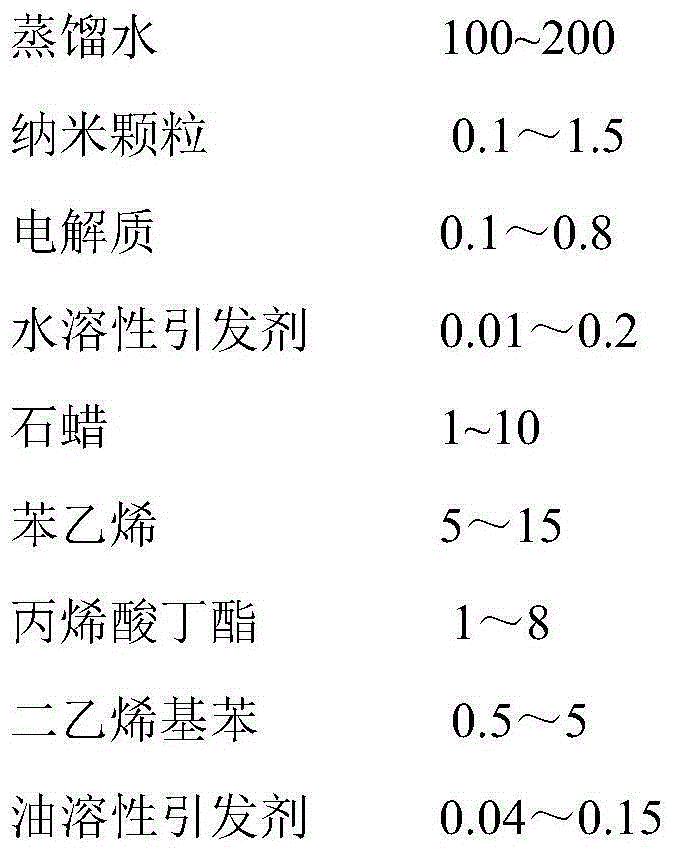

[0026] (2) 0.4g modified Al 2 o 3 Ultrasonic dispersion of nanoparticles in 100g of distilled water, adding an appropriate amount of water-soluble initiator ammonium persulfate 0.05g and a small amount of CaCl 2 0.3g; 5g 52°C paraffin wax is heated to 60°C and mixed with 2g styrene, 1.5g butyl acrylate, 0.5g divinylbenzene solution, and 0.04g azobisisobutyronitrile is dissolved in the monomer solution to form a compound Oil phase: After mixing the water phase and the oil phase, emulsify at a high speed of 10,000r / min for 5 minutes to form a...

Embodiment 2

[0027] Embodiment 2: A kind of high thermal conductivity composite phase change microcapsule

[0028] (1) 2g nano-Al 2 o 3 The powder is ultrasonically dispersed in ethanol, and 5% silane coupling agent KH-570 is dissolved in Al 2 o 3 In the dispersion liquid, heat up to 70°C and reflux for more than 8 hours. After centrifugal washing, vacuum drying at 40°C for more than 12 hours to obtain KH-570 modified nano-Al 2 o 3 particles.

[0029] (2) 0.75g modified Al 2 o 3Ultrasonic dispersion of nanoparticles in 100g of distilled water, adding an appropriate amount of water-soluble initiator ammonium persulfate 0.05g and a small amount of CaCl 2 0.2g; heat 7.5g of 52℃ paraffin wax to 60℃ and mix with 4.5g of styrene, 1.5g of butyl acrylate and 1.5g of divinylbenzene solution, and dissolve 0.15g of azobisisobutyronitrile in the monomer solution A composite oil phase is formed; the water phase and the oil phase are mixed and emulsified at a high speed of 10,000 r / min to form ...

Embodiment 3

[0030] Embodiment 3: A kind of high thermal conductivity composite phase change microcapsule

[0031] (1) 2g nano-Al 2 o 3 The powder is ultrasonically dispersed in ethanol, and 5% silane coupling agent KH-570 is dissolved in Al 2 o 3 In the dispersion liquid, heat up to 70°C and reflux for more than 8 hours. After centrifugal washing, vacuum drying at 40°C for more than 12 hours to obtain KH-570 modified nano-Al 2 o 3 particles.

[0032] (2) 0.2g modified Al 2 o 3 Nanoparticles are ultrasonically dispersed in 100g distilled water, and an appropriate amount of water-soluble initiator ammonium persulfate 0.01g and a small amount of CaCl are added 2 0.1g; 5g of 52°C paraffin wax is heated to 60°C and mixed with 4.5g of styrene, 1.5g of butyl acrylate, and 1.5g of divinylbenzene solution, and 0.075g of azobisisobutyronitrile is dissolved in the monomer solution to form Composite oil phase: After mixing the water phase and the oil phase, emulsify at a high speed of 10,000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com