Method for processing barometric pressure, normal-temperature plasma modification on carbon nano-tube surface

A technology of plasma and carbon nanotubes, applied in the direction of dyeing physical treatment, fibrous fillers, etc., to achieve the effects of high degree of automation, strong process controllability, and improved bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

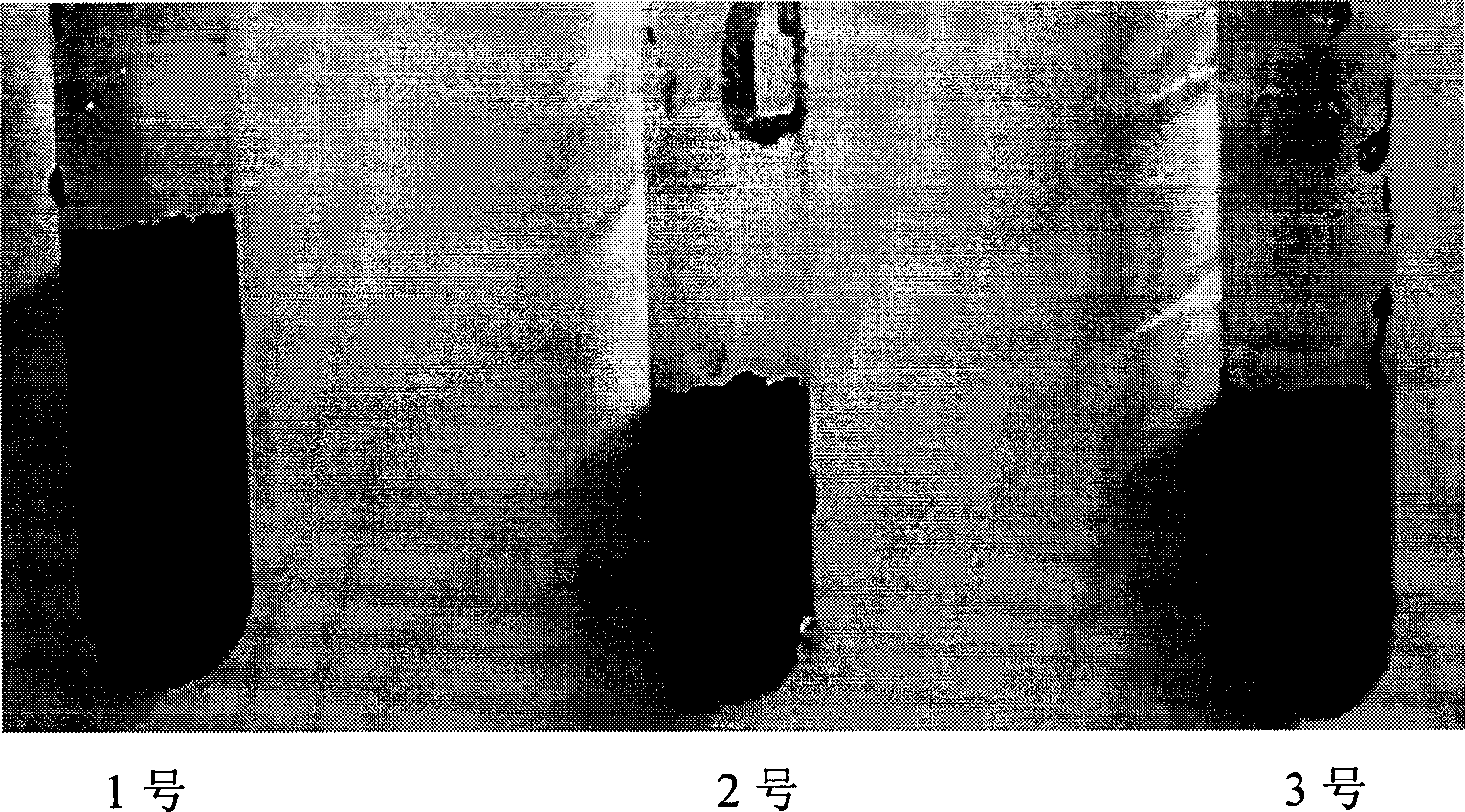

[0034] Take a certain amount of commercial carbon nanotubes and put them on the special transfer device of the plasma processing equipment. Schematic such as image 3 (or a channel for adding a plasma nozzle), the container or carrier is placed within a specific distance of 2 cm below the nozzle of the normal pressure and normal temperature plasma spray device (the design of the nozzle part of the channel is based on specific requirements), and the thickness of the nanopowder laying Lay it according to the thickness of 5 mm. Under the premise of turning on the normal pressure and room temperature plasma, the container or carrier moves at a specific speed. Realize that the carbon nanotubes can be processed in a helium plasma atmosphere with a power of 40 watts and 5 seconds. The transmission electron micrograph of the sample is shown in figure 1 . The hydrosol (0.5 / 1000 nanometer powder / water) that is formed by this sample left standstill 24 hours comparative experiment photo...

Embodiment 2

[0036] Take a certain amount of commercial carbon nanotubes and put them on the special transfer device of the plasma processing equipment. Schematic such as image 3 (or a channel for adding a plasma nozzle), the container or carrier is placed within a specific distance of 2 cm below the nozzle of the normal pressure and normal temperature plasma spray device (the design of the nozzle part of the channel is based on specific requirements), and the thickness of the nanopowder laying Lay it according to the thickness of 2-9 mm. Under the premise of turning on the plasma at normal pressure and room temperature, the container or carrier moves at a specific speed. Realize that carbon nanotubes can be processed in an oxygen plasma atmosphere with a power of 40 watts and 5 seconds. . The transmission electron micrograph of the sample is shown in figure 1 . The hydrosol (0.5 / 1000 nanometer powder / water) that is formed by this sample left standstill 24 hours comparative experiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com