PC/PET (polycarbonate/polyethylene terephthalate) alloy material and preparation method thereof

A technology of polyethylene terephthalate and polyethylene terephthalate, which is applied in the field of polycarbonate/polyethylene terephthalate alloy materials and their preparation, can solve the problem of not adding ABS components Classification problems, to achieve the effect of improving stress cracking resistance, high toughness, and excellent comprehensive performance

Active Publication Date: 2015-04-29

CGN JUNER NEW MATERIALS +1

View PDF8 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The patent also does not involve material shrinkage and spray coating problems, and no AB

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

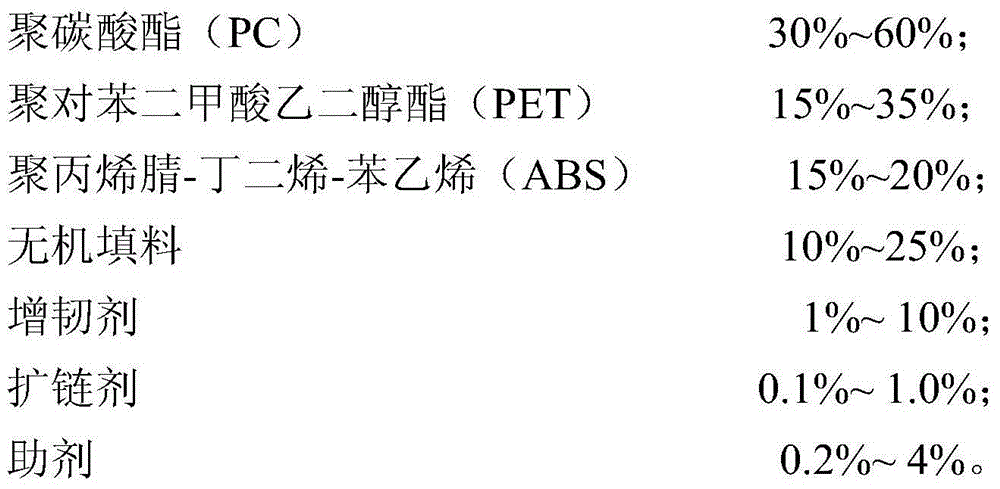

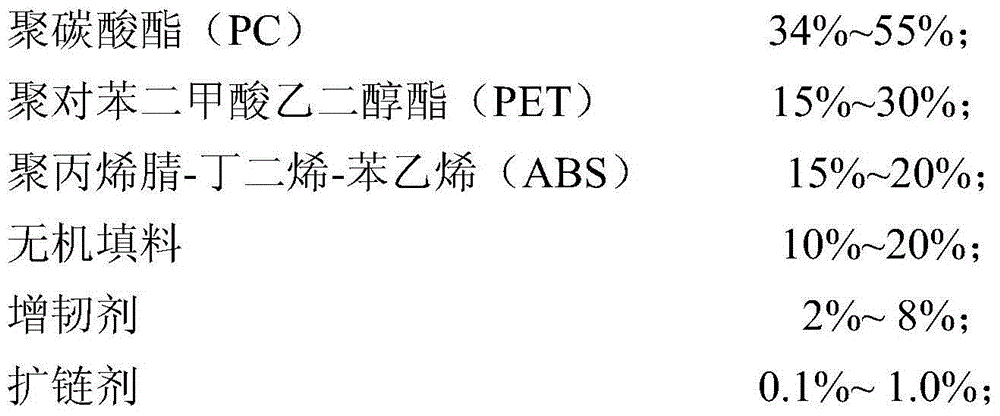

The invention discloses a PC/PET (polycarbonate/polyethylene terephthalate) alloy material which has low shrinkage and is easy to coat. The PC/PET alloy material comprises components in percentage by weight as follows: 30%-60% of PC, 15%-35% of PET, 15%-20% of acrylonitrile-butadiene-styrene, 10%-25% of inorganic filler, 1%-10% of a toughening agent, 0.1%-1% of a chain extender and 0.2%-4% of an assistant. According to the PC/PET alloy material, specific quantities of the components are combined to produce ideal synergistic effect, so that the alloy material not only has excellent comprehensive mechanical property, but also has ultra-low shrinkage rate, a product does not require polishing processing, primer coating can be directly avoided, and the coating cost is saved. The invention discloses a preparation method of the PC/PET alloy material. According to the preparation method, the preparation can be realized by adopting conventional equipment, namely a double-screw extruder, and through control of feeding position and temperature, the preparation is simple and easy to control.

Description

technical field [0001] The invention relates to the field of polycarbonate / polyethylene terephthalate alloy materials, in particular to a polycarbonate / polyethylene terephthalate alloy material with low shrinkage and easy coating and a preparation method thereof. Background technique [0002] Polycarbonate / polyethylene terephthalate (PC / PET) alloy not only retains the processing fluidity and solvent resistance of PET, but also has the dimensional stability and high toughness of PC. It has been widely used in decoration and other fields. In the PC / PET alloy, as the PET content increases, the shrinkage rate increases and the solvent resistance improves. In practical industrial applications, especially for thick-walled products that need to be sprayed, such as car door handles, rearview mirror shells, and central control panels, it is required that the formed products should not have shrink prints, be easy to paint, have good paint adhesion, and ensure that the finished produc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L69/00C08L67/02C08L55/02C08L51/04C08L23/08C08L25/08C08K13/04C08K3/34C08K7/10C08K5/134C08K5/526C08K5/103C08J3/22B29C47/92B29C48/92

CPCB29C48/92B29C2948/92704C08J3/226C08J2369/00C08J2467/02C08L69/00C08L2205/035C08L67/02C08L55/02C08L51/04C08K13/04C08K3/34C08K7/10C08K5/1345C08K5/526C08K5/103

Inventor 黄瑞杰肖红伟姜小龙

Owner CGN JUNER NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com