Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Good resistance to stress cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

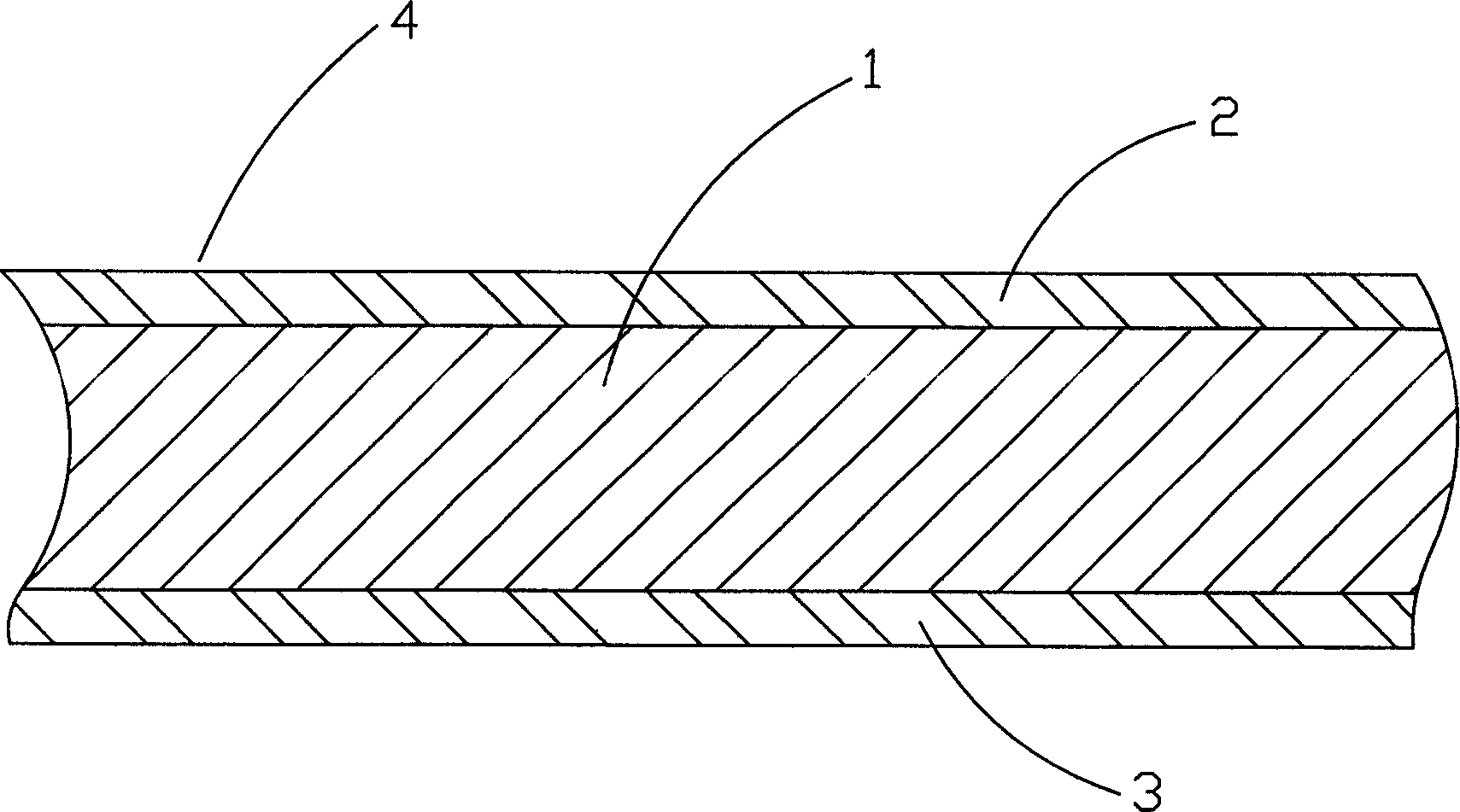

Uniaxially-tensioned high speed printing matt PE film and production technology thereof

ActiveCN107351474AGood processing performanceGood resistance to stress crackingSynthetic resin layered productsDomestic containersEngineeringHigh stiffness

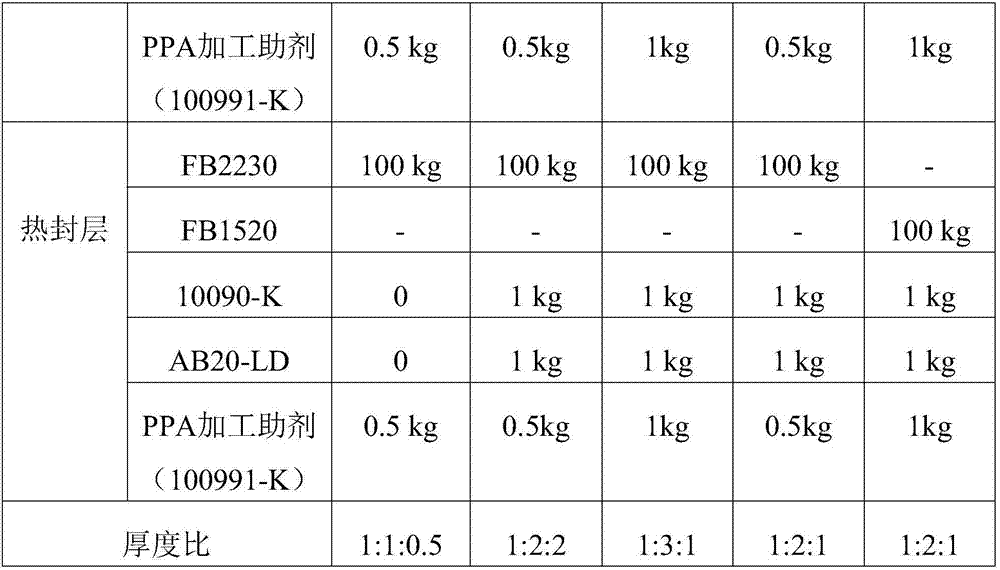

The invention discloses a uniaxially-tensioned high speed printing matt PE film and a production technology thereof. The matt PE film comprises a corona layer, a middle layer and a heat sealing layer, and the corona layer, the middle layer and the heat sealing layer respectively independently comprise blown film grade bimodal metallocene polyethylene. The uniaxially-tensioned high speed printing matt PE film has the advantages of guaranteeing of high haze, low crystallization point and high stiffness, and can meet the demands of high speed printing.

Owner:永新股份(黄山)包装有限公司

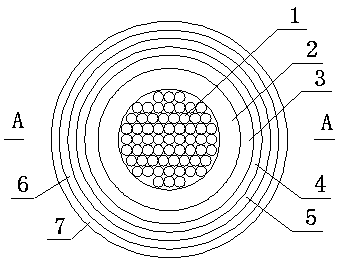

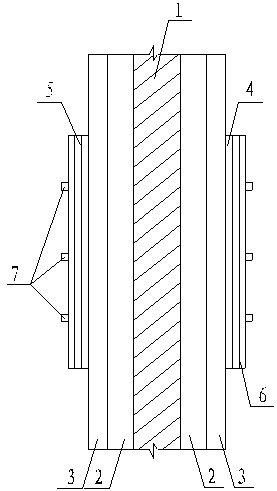

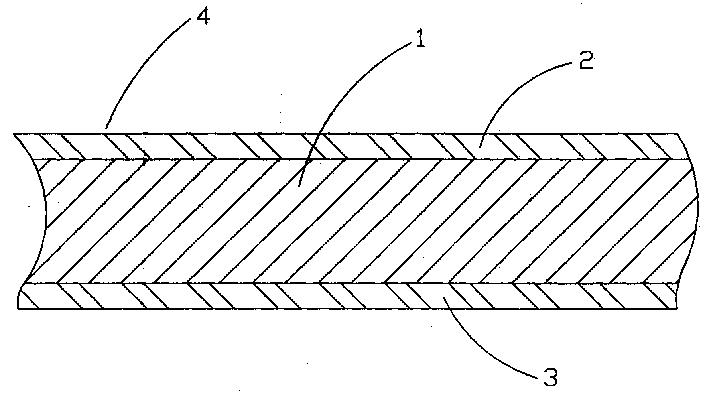

Polyethylene cable duct

ActiveCN102617914AHigh tensile strengthNo brittle crackingCable installations in underground tubesPolymer scienceCrack resistance

The invention discloses a polyethylene cable duct. The polyethylene cable duct is characterized by being prepared from a modified polyethylene material; and the modified polyethylene material consists of the following components by weight: 100 parts of base material, 1 to 5 parts of ethylene propylene diene monomer resin, 0.1 to 1 part of polytetrafluoroethylene, 0.1 to 1 part of calcium stearate, 0.1 to 1 part of polyethylene wax and 0.01 to 0.1 part of pigment, wherein the base material consists of 85 to 95 weight percent of high-density polyethylene and 5 to 15 weight percent of ultra-high molecular weight polyethylene. The polyethylene cable duct has the following excellent performance: (1) high tensile strength; (2) high impact strength: the polyethylene cable duct has excellent low-temperature impact resistance and extremely low brittleness temperature and can be safely used at the temperature of between 20 DEG C below zero and 60 DEG C; (3) high abrasion resistance; (4) high toughness, flexibility and shock resistance; (5) high stress cracking resistance and low notch sensitivity; (6) corrosion resistance and long service life; and (7) simplicity in cable threading.

Owner:GUANGDONG SANLING PLASTIC PIPE MATERIAL

Polyphenyl ether resin alloy material, and preparation method and application thereof

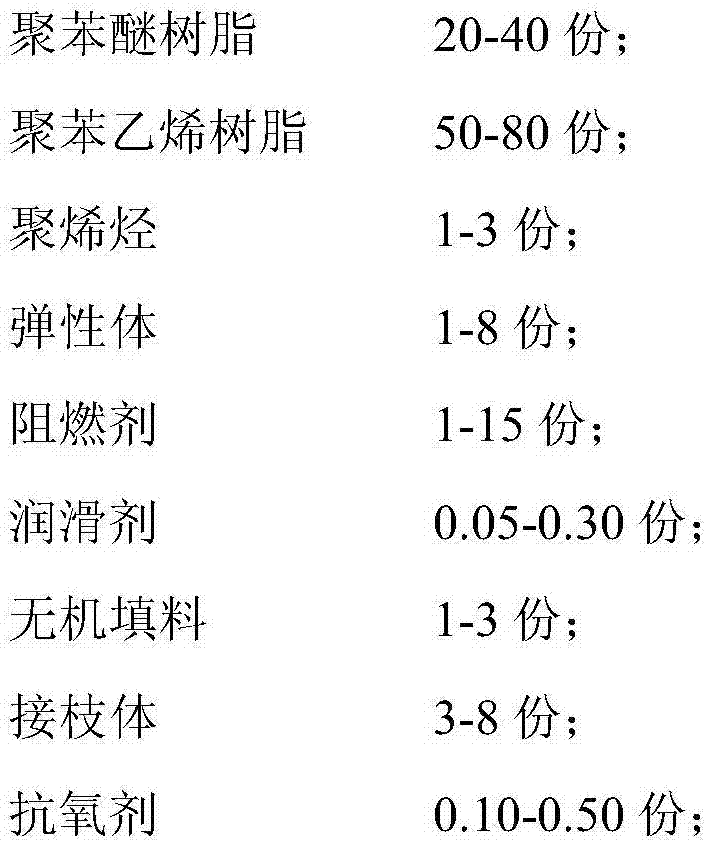

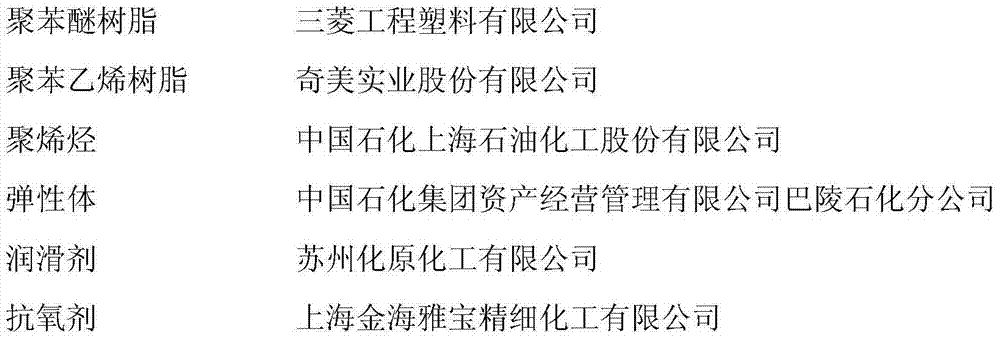

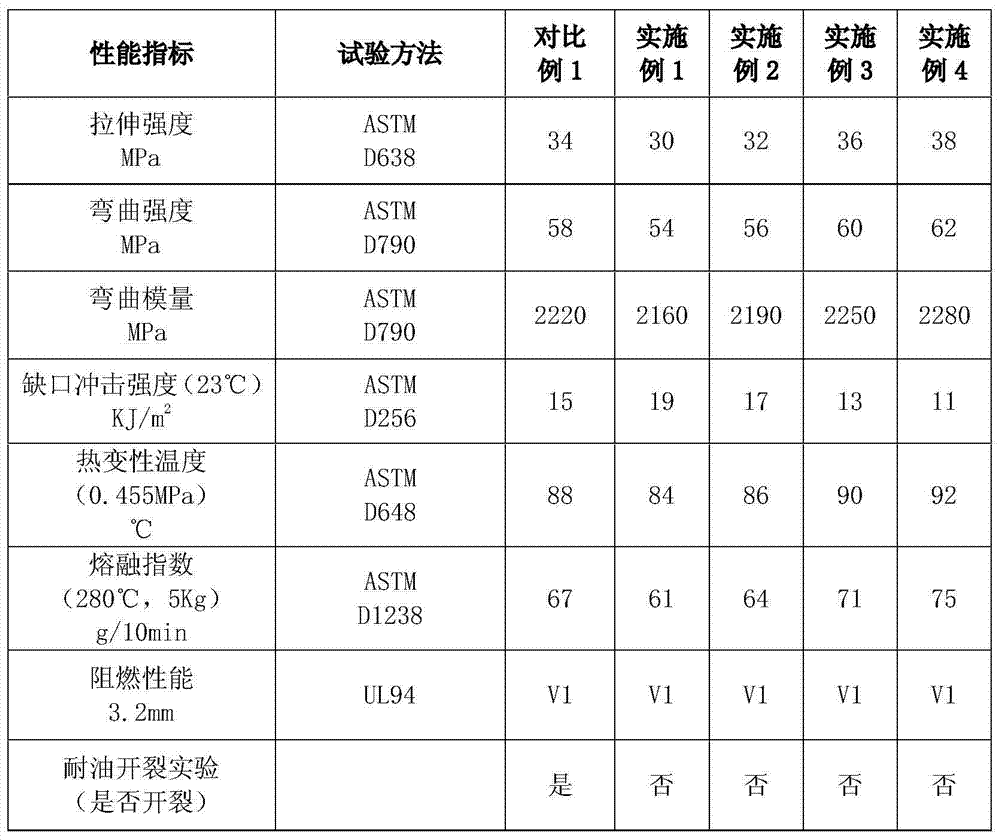

The invention belongs to the field of high-polymer alloy materials, and particularly relates to a polyphenyl ether resin alloy material used for processing automobile spare tire covers and a preparation method of the polyphenyl ether resin alloy material. The polyphenyl ether resin alloy material is prepared by, by weight, 20-40 parts of polyphenyl ether resin, 50-80 parts of polystyrene resin, 1-3 parts of polyolefin, 1-8 parts of elastomer, 1-15 parts of flame retardant, 0.05-0.30 part of lubricant, 1-3 parts of inorganic filler, 3-8 parts of grafting bodies, and 0.10-0.50 part of antioxidant. By adjusting formula composition and selecting proper process and extruding conditions, the problem about mobility of the polyphenyl ether resin alloy material is solved. The polyphenyl ether resin alloy material has high mobility and no stress cracking after spraying, is capable of sufficiently meeting operating requirements of the application field of automobile parts and quite applicable to raw materials for automobile spare tire covers.

Owner:江苏沃特新材料科技有限公司

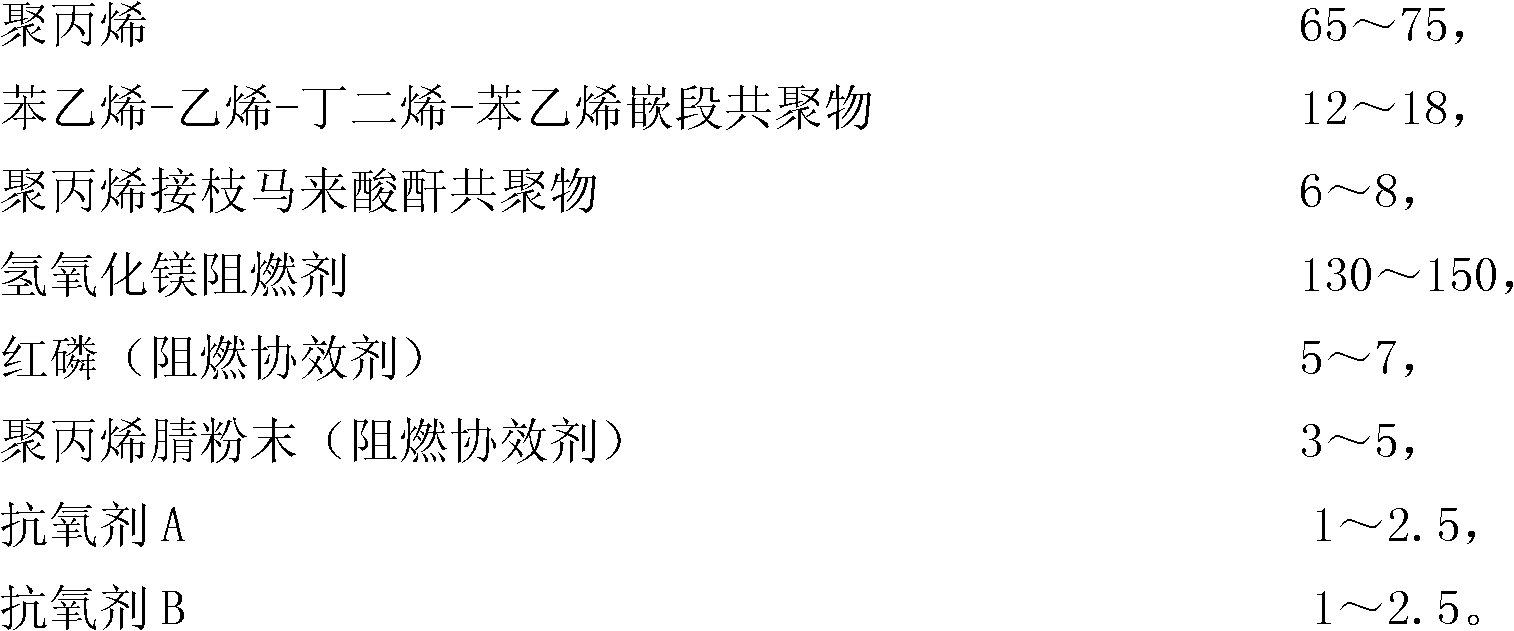

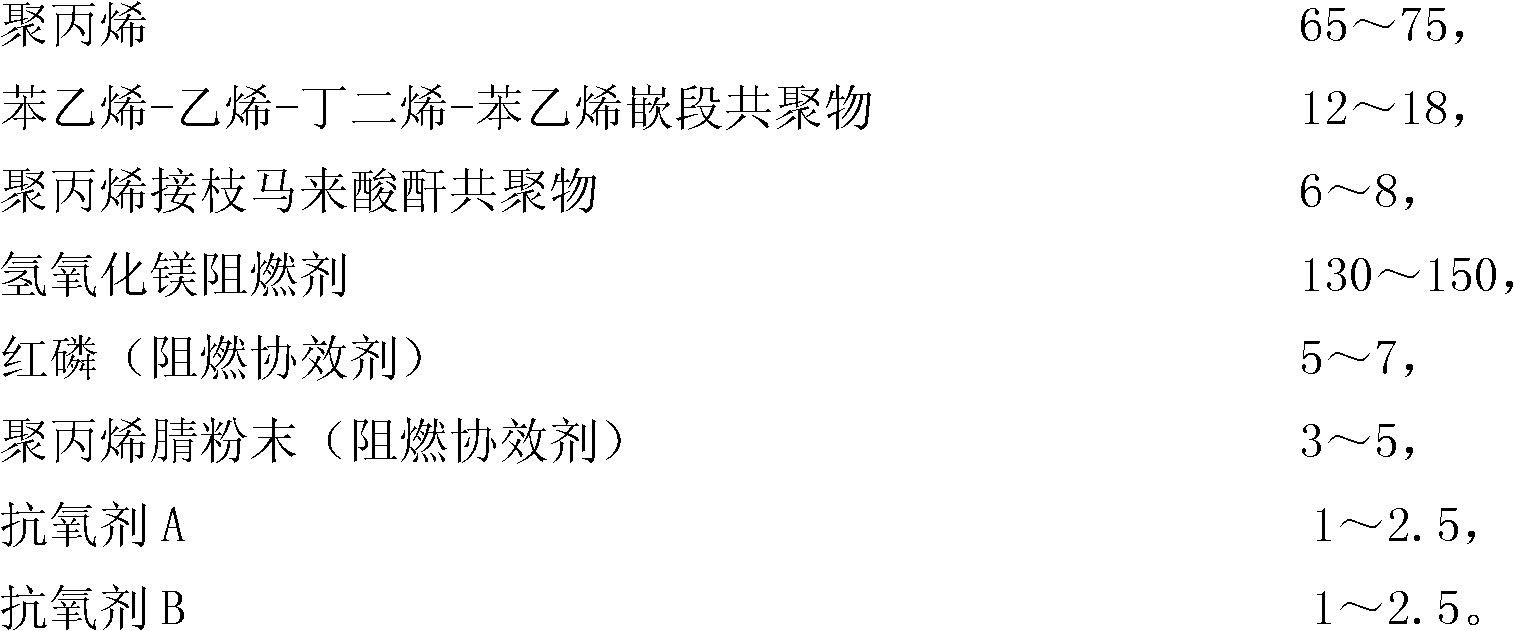

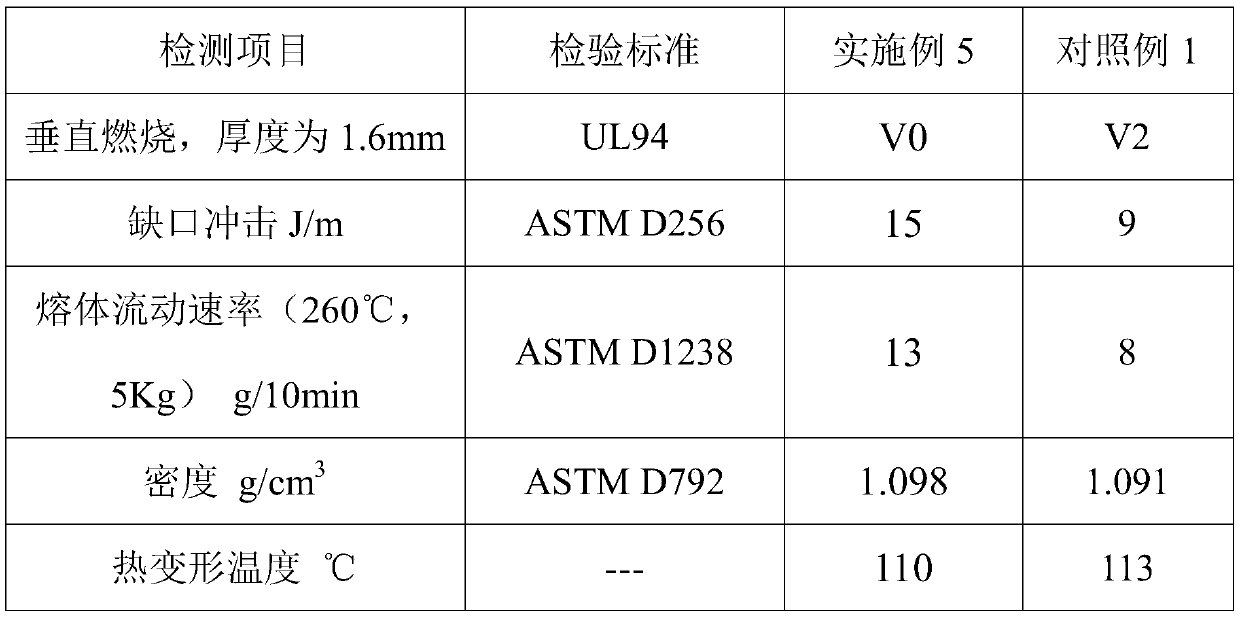

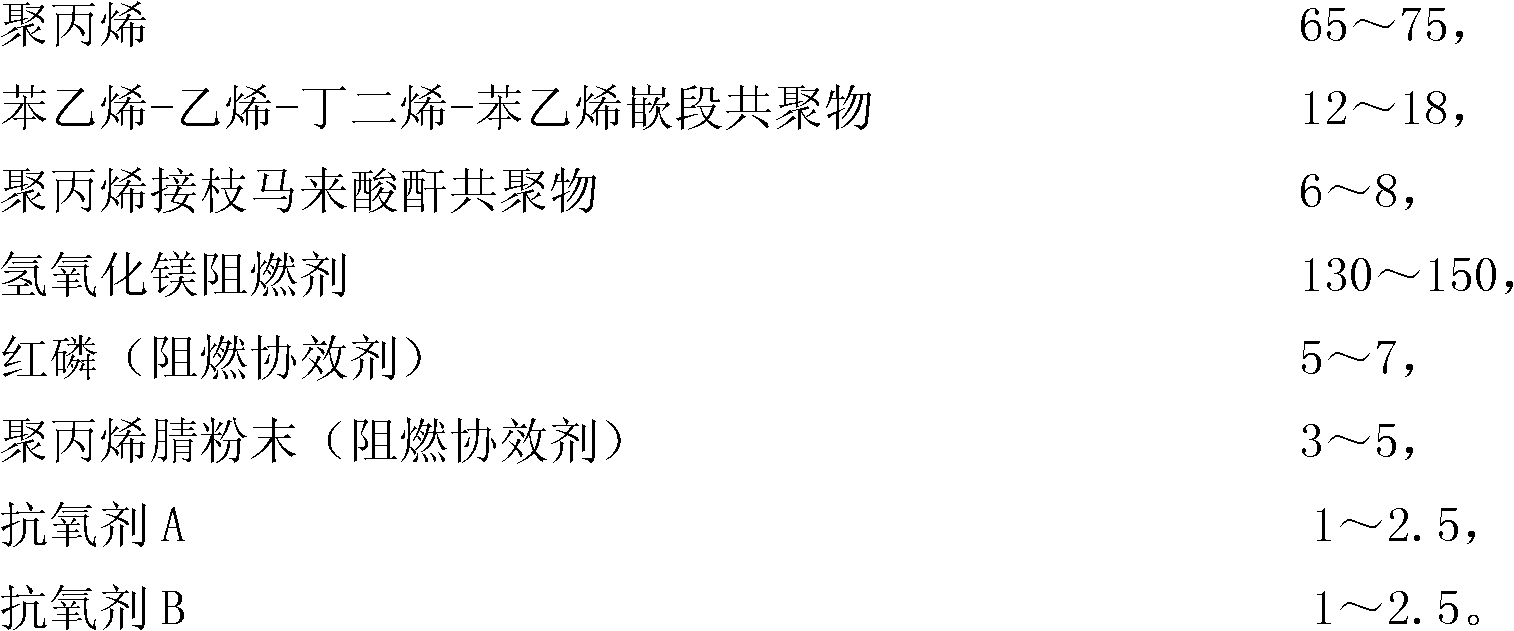

Low-smoke halogen-free flame-retarding polypropylene cable material and preparation method thereof

The invention belongs to the field of cable materials, in particular to a low-smoke halogen-free flame-retarding polypropylene cable material and a preparation method thereof. The low-smoke halogen-free flame-retarding polypropylene cable material is characterized by being prepared from the following raw materials in part by weight: 65 to 75 parts of polypropylene, 12 to 18 parts of styrene-ethylene / butadiene-styrene block copolymer, 6 to 8 parts of polypropylene grafted maleic anhydride copolymer, 130 to 150 parts of magnesium hydroxide fire retardant, 5 to 7 parts of red phosphorus, 3 to 5 parts of polyacrylonitrile powder, 1 to 2.5 parts of antioxygen A and 1 to 2.5 parts of antioxygen B. The low-smoke halogen-free flame-retarding polypropylene cable material obtained by the method hasthe characteristics of high machining performance, high temperature resistance and high stress cracking resistance.

Owner:WUHAN TEXTILE UNIV

Material for producing injection molding oil tank and manufacturing method thereof

InactiveCN102617910AOvercome stressOvercoming oil resistanceLow-density polyethyleneLinear low-density polyethylene

The invention discloses a material for producing an injection molding oil tank and a manufacturing method thereof. A material comprises the following raw materials in parts by weight: 48-68 parts of linear low-density polyethylene resin, 12-32 parts of high-density polyethylene resin, 5-15 parts of polypropylene resin, 5-15 parts of a saturated ethylene-octene copolymer, 0.1-0.2 part of a nucleating agent, 0.4-0.6 part of an antioxidant, 0.3-0.7 part of a lubricating agent and 0.1-0.5 part of carbon black. Due to the adoption of the material for the injection molding oil tank, the problems of air tightness, oil resistance, stress cracking resistance, cold resistance and the like are solved.

Owner:重庆嘉良塑胶制品有限责任公司

Stress-cracking-resistant halogen-free flame-retardant TPE (thermoplastic elastomer)

InactiveCN105670200AReduced risk of environmental stress crackingReasonable formulaElastomerCrack resistance

The invention provides a stress-cracking-resistant halogen-free flame-retardant TPE (thermoplastic elastomer). The stress-cracking-resistant halogen-free flame-retardant TPE comprises, by weight, 15-50 parts of SEBS (styrene-ethylene-butene-styrene) rubber resin, 20-30 parts of softening plasticizers, 15-40 parts of flame retardants, 10-20 parts of polyphenyl ether resin, 0.1-10 parts of char forming resin, 5-15 parts of polypropylene resin and 2-5 parts of polyethylene resin. The stress-cracking-resistant halogen-free flame-retardant TPE has the advantages that partial polyphenyl ether resin is replaced by the char forming resin, accordingly, risks of environmental stress cracking of formed products can be greatly reduced, the halogen-free flame-retardant TPE formed products with merits of zero halogen, good flame-retardant property, excellent stress cracking resistance, easiness in processing and the like can be quickly manufactured by the aid of a method, and can be widely applied to high-grade earphone cables and other cable products such as data cables, technological steps are simple, and the stress-cracking-resistant halogen-free flame-retardant TPE is easy to implement and high in productivity.

Owner:SHENZHEN PUTEMEI RUBBER & PLASTIC RAW MATERIAL

Polymer composition, process for producing the polymer composition, and molded articles for automobile exterior trim

The partially cross-linked polymer composition of the present invention is obtainable by dynamically heat-treating: 95 to 50 % by weight of a resin (A) comprising an ethylene copolymer containing 5 to 48 % by weight of units derived from at least one monomer selected from vinyl acetate, (meth)acrylic acid, (meth)acrylate ester, glycidyl (meth)acrylate and carbon monoxide, and 5 to 50 % by weight of a resin (B) having a melt viscosity (JAI 7-1991) at 180oC of over 10,000 mPa.s and comprising a two or more-component propylene copolymer containing 0.1 to 20 % by mol of units derived from a-olefins other than propylene, or a blend of the two or more-component propylene copolymer and a propylene homopolymer in the presence of an organic peroxide (C) in an amount of from 0.001 to 4 parts by weight based on 100 parts by weight of the total amount of the resins (A) and (B). The invention can provide the polymer compositions having excellent fluidity and productivity, which allow to produce molded articles with heat resistance, adhesion with paint, tensile strength, flexibility, stress crack resistance, and RF weldability, such as molded articles for automobile exterior trim, and can provide the process for producing the polymer compositions.

Owner:MITSUI LTD

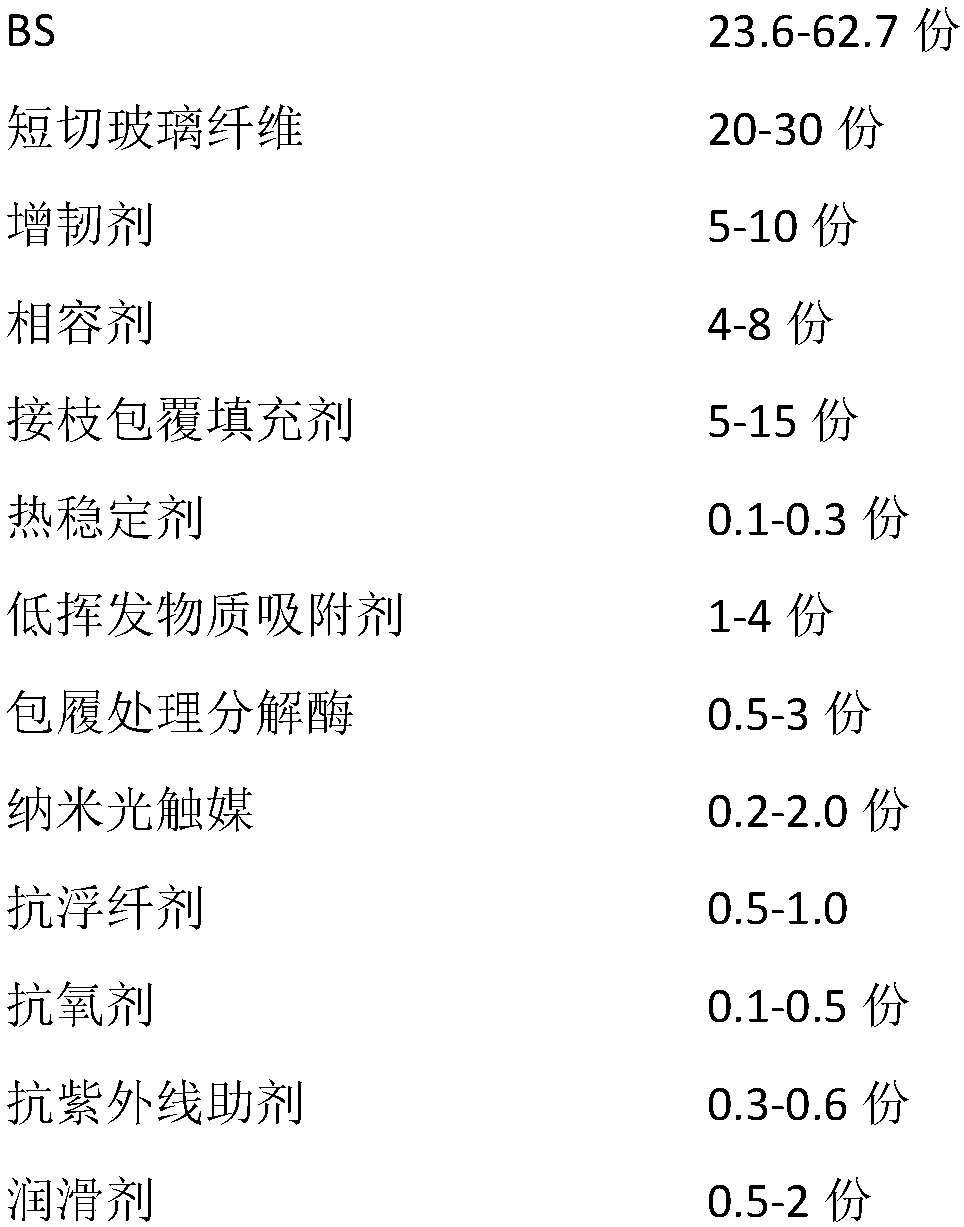

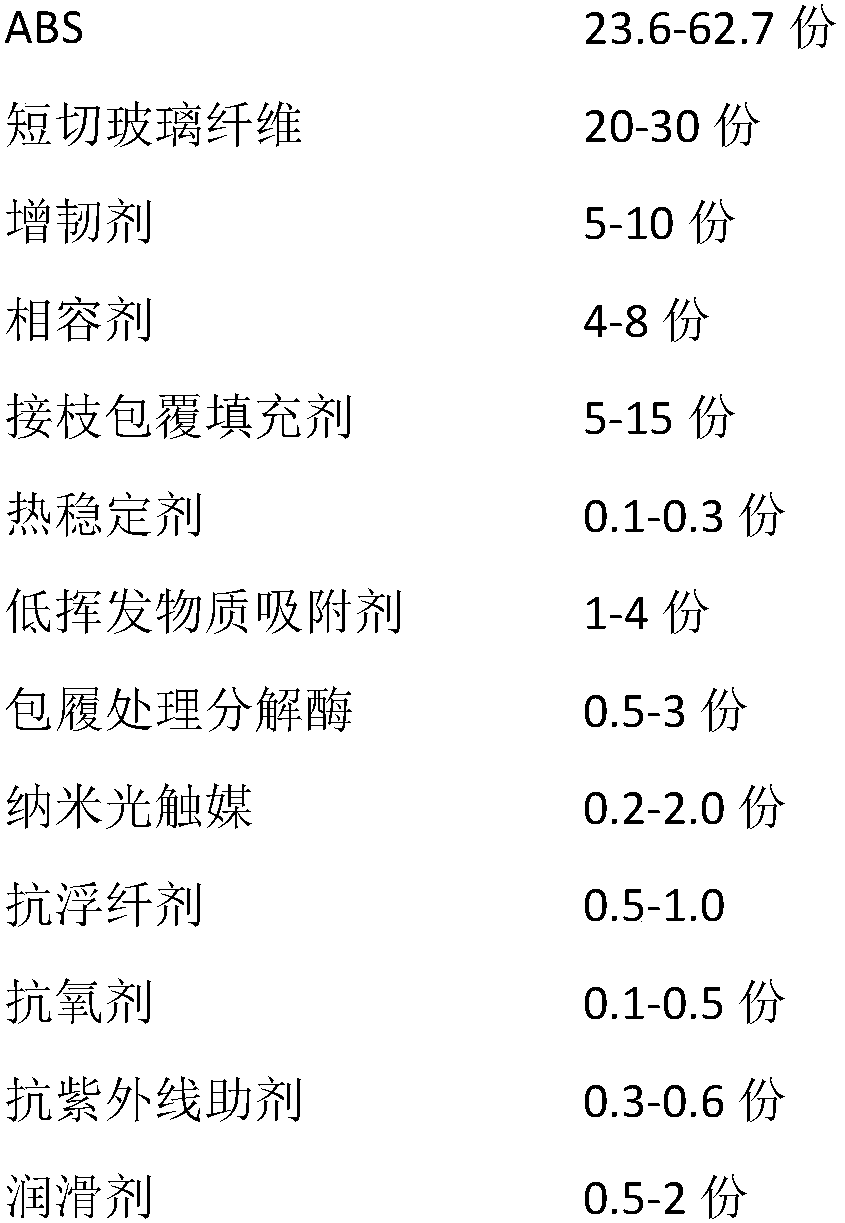

Low-odor sterilization reinforced ABS (acrylonitrile butadiene styrene) automobile rearview mirror frame material and method for preparing same

The invention discloses a low-odor sterilization reinforced ABS (acrylonitrile butadiene styrene) automobile rearview mirror frame material and a method for preparing the same. The low-odor sterilization reinforced ABS automobile rearview mirror frame material comprises, by weight, ABS, chopped glass fibers, toughening agents, compatilizers, grafting and coating fillers, heat stabilizers, low-volatility matter adsorbents, coating treatment clastic enzymes, nano-photocatalysts, antioxidants, anti-ultraviolet absorbents, anti-floating cellosolve and lubricants. The low-odor sterilization reinforced ABS automobile rearview mirror frame material and the method have the advantages that the low-volatility matter adsorbents are extremely high in adsorption capacity, and low-volatility harmful gasgenerated by components formed from composite materials can be effectively prevented from being outwardly diffused; generated trace low-volatility harmful gas can be decomposed by the coating treatment clastic enzymes and the nano-photocatalysts to obtain carbon dioxide and water which are harmless, and the low-odor sterilization reinforced ABS automobile rearview mirror frame material is excellent in physical and mechanical property, heat aging resistance and weather resistance and low in odor and TVOC (total volatile organic compound) content, is stress-crack-resistant, corrosion-resistant,shock-resistant and scratch-resistant and can be used for producing automobile rearview mirror frames.

Owner:DONGGUAN JISU PLASTIC TECH

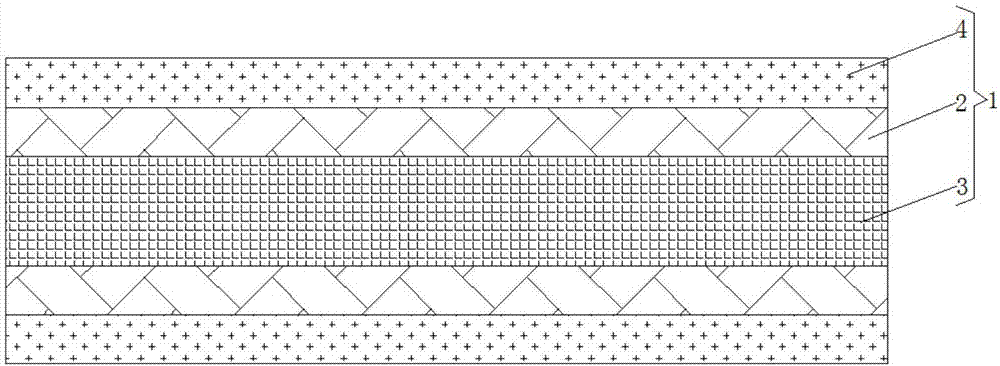

A composite geomembrane

InactiveCN104476883AStrong chemical resistanceImprove stabilitySynthetic resin layered productsConstructions elementsLow-density polyethyleneLinear low-density polyethylene

A composite geomembrane is provided. The composite geomembrane comprises a non-woven fabric layer, a geotechnical cloth layer and an impermeable membrane layer. The impermeable membrane layer comprises a first impermeable layer, a second impermeable layer and a third impermeable layer. The first impermeable layer, the second impermeable layer and the third impermeable layer are combined in order. The impermeable membrane layer is prepared from 30-80 parts by weight of high density polyethylene and 40-60 parts by weight of linear high density polyethylene. The impermeable membrane layer also comprises following auxiliary materials by weight: 0.05-0.4 part of an antioxidant, 0.1-0.6 part of an ultraviolet-light-resistant absorbent, 0.1-0.3 part of an anti-ageing agent, 0.05-0.5 part of carbon black, 0.1-0.5 part by weight of a fire retardant, and the like. The composite geomembrane has high impermeability, chemical stability and penetration resistance, effectively prevents permeation of harmful chemical compounds, and has good stretching flexibility and resistance to stress cracking. In addition, addition of the auxiliary materials improves safety performance of the composite geomembrane and largely prolongs the service lifetime of the composite geomembrane.

Owner:NANYANG FENGHUI PLASTIC

Novel flame-retardant cable material and preparation method thereof

InactiveCN107236185AImprove performanceGood physical propertiesPlastic/resin/waxes insulatorsAntioxidantPolyvinyl chloride

The invention discloses a novel flame-retardant cable material. The cable material is prepared from raw materials in parts by weight as follows: 15-35 parts of polyvinyl chloride, 3-8 parts of an ethylene-octylene copolymer, 13-18 parts of ethylene-vinyl acetate, 18-33 parts of high impact polypropylene, 7-18 parts of nitrile rubber, 1-2 parts of stearic acid, 12-23 parts of filler, 1.5-3.3 parts of a heat stabilizer, 0.7-1.2 parts of an antioxidant, 1-2 parts of an antibacterial agent, 4-8 parts of a plasticizer, 3-5 parts of a compatilizer and 1-3 parts of a flame retardant. The novel flame-retardant cable material has excellent performance, good physical performance, wide temperature adaptation range, high-temperature resistance, good flame-retardant performance, antibacterial and anti-corrosion capacity and long service life.

Owner:HEFEI DAHU ELECTRIC WIRE & CABLE TECH CO LTD

Repairing method of large-section low-voltage single-core flexible cable

InactiveCN107732803AImprove insulation performanceImprove thermal deformationApparatus for repairing insulation/armouring cablesInsulation layerLow voltage

The invention relates to a repairing method of a large-section low-voltage single-core flexible cable and belongs to the electric construction technical field. According to the method, an adhesive ofwhich the chemical compositions are identical with the chemical compositions of the insulation layer of a cable is attached to the damaged portion of the cable when the insulation layer does not falloff yet; when the insulation layer falls off, a gap is trimmed, and is filled with a rubber sheet of which the thickness and material are identical with the thickness and material of the insulation layer, the gap is adhered with an adhesive of which the chemical compositions are identical with the chemical compositions of the insulation layer; a high-voltage waterproof insulation rubber self-adhesive tape which can withstand 1.5 times of the rated voltage of the cable to be repaired is adopted to wrap the damaged portion in a semi-overlapped manner; an electrical insulation adhesive tape can withstand 1.5 times of the rated voltage of the cable to be repaired is adopted to wrap the damaged portion within the range of the high-voltage waterproof insulation rubber self-adhesive tape in a semi-overlapped manner; and a cross-linked polyethylene hard jacket with a thickness more than 2mm is adopted to wrap a damaged wrapping range, and is tightened by nylon cable ties. The method can realize fast construction speed; the materials adopted by the method are light; quality can be ensured, and safety is within a controllable range; and the method is easy to popularize and apply.

Owner:SINOHYDRO BUREAU 14 CO LTD

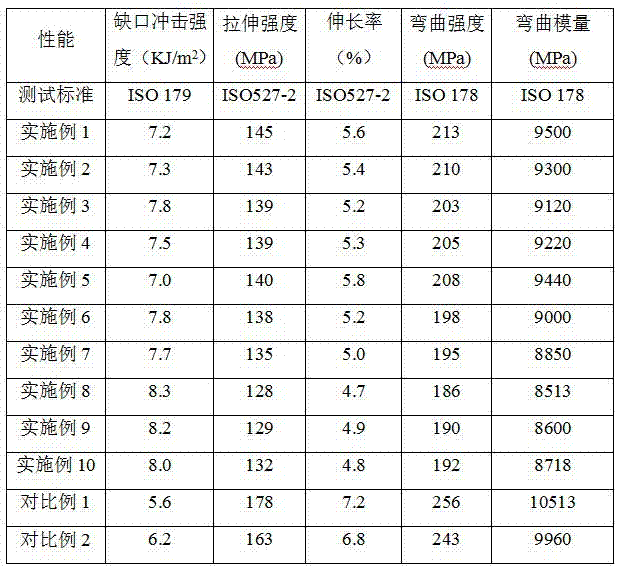

PA6/PC/ PBT ternary alloy material and preparation method thereof

ActiveCN107365494AImprove toughnessGood dimensional stabilityPolytetramethylene terephthalateCrack resistance

The invention relates to the technical field of polymer materials, in particular to a PA6 / PC / PBT ternary alloy material and a preparation method of the PA6 / PC / PBT ternary alloy material. The ternary alloy material comprises the following raw materials in parts by weight: 20 to 80 parts of PA6 resin, 10 to 70 parts of PC, 10 to 30 parts of polybutylene terephthalate, 5 to 30 parts of glass fibers, 2 to 15 parts of compatibilizers, 0.1 to 1 part of an antioxidant and 0.1 to 1 part of a lubricant. The PA6 / PC / PBT ternary alloy material disclosed by the invention has high performances of toughness, dimensional stability, corrosion resistance, stress cracking resistance, oil resistance, mechanical strength and the like, and is high in molding performance, excellent in processability, low in cost and high in use value, and the preparation method is simple, convenient to operate and control, stable in quality, high in production efficiency, low in production cost and suitable for large-scale industrial production.

Owner:广东壹豪新材料科技股份有限公司

Flame-retardant ASA material dedicated for new-energy vehicle battery case and preparation method thereof

InactiveCN108676309AImprove mechanical propertiesImprove flame retardant performanceAnti stressCrack resistance

The invention provides a flame-retardant ASA material dedicated for a new-energy vehicle battery case and a preparation method thereof and relates to the technical field of high molecular materials. The flame-retardant ASA material dedicated for the new-energy vehicle battery case disclosed by the invention is prepared from the following raw materials of ASA resin, polymethyl methacrylate, polycarbonate, polyhexafluoroethylene, glass bead, an anti-stress cracking agent, a flame retardant, a toughening agent, a compatilizer, silicone, tetraisopropyl titanate and tricresyl phosphate. The flame-retardant ASA material dedicated for the new-energy vehicle battery case disclosed by the invention has the characteristics of a good mechanical property, good flame resistance, good solvent resistance, good stress cracking resistance and the like; the material achieves environmental friendliness and reliability; furthermore, the material has the advantages of excellent low temperature toughness, ageing resistance, weather resistance and chemical resistance and is suitable for low temperature occasions and battery case occasions with higher solvent resistance; a product can be energetically popularized in actual production.

Owner:WUHU CHUANGKE NEW MATERIAL TECH CO LTD

Non-asphalt-based reaction type pre-paving macromolecular self-adhesion adhesive film waterproof coiled material

InactiveCN107267083AAvoid pollutionAvoid Fire HazardsFilm/foil adhesivesPolymer scienceCrack resistance

The invention discloses a non-asphalt-based reactive pre-paved polymer self-adhesive film waterproof coiled material, which includes a waterproof coiled material body, and the waterproof coiled material body includes a resin polymer sheet, a polymer waterproof base layer and a self-adhesive membrane. Adhesive outer layer, the outer surface of the polymer waterproof base layer is fixedly connected with the resinous polymer sheet, and the outer surface of the resinous polymer sheet is fixedly connected with the self-adhesive outer layer. The non-asphalt-based reactive pre-paved polymer self-adhesive film waterproof membrane has super bonding performance, the peel strength is 2-3 times that of ordinary self-adhesive membranes, high tear resistance, waterproof and impermeable It has strong performance and hydrolysis resistance, and has a skin-like waterproof effect, which is conducive to popularization and use. It has excellent toughness, strong elasticity, stress crack resistance, softness, and high toughness. Poor, low tear strength, poor waterproof and impermeable performance and hydrolysis resistance, which is not conducive to popularization and use.

Owner:淮安市大有塑纤有限公司

Insulating heat-conducting cable material and preparation method thereof

InactiveCN108727670AHigh thermal conductivityImprove insulation performancePlastic/resin/waxes insulatorsHeat-exchange elementsHeat conductingFire retardant

The invention discloses an insulating heat-conducting cable material. The insulating heat-conducting cable material is prepared from, by weight, 20-30 parts of high-density polyethylene, 10-20 parts of graphene modified polypropylene, 15-25 parts of ethylene-vinyl acetate copolymer, 7-11 parts of arabic gum, 3-6 parts of montmorillonoid, 4-8 parts of light calcium carbonate, 3-7 parts of glass fibers, 2-4 parts of polyethylene wax, 1-3 parts of calcium stearate, 6-9 parts of a flame retardant, 2-5 parts of a plasticizer and 2-4 parts of a reinforcing agent. The insulating heat-conducting cablematerial has advantages of high heat conductivity, great insulating performance, high tensile strength, high toughness and convenience in processing.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

Production method of steaming-grade CPP film

The invention discloses a production method of a steaming-grade CPP film. The method comprises the following steps: (a) manufacturing a corona layer by weighing 19 to 21 parts of ternary polypropylene randon copolymer, manufacturing a core layer by weighing 59 to 61 parts of homo-polypropylene, manufacturing a heat seal layer by weighing 19 to 20 parts of ternary co-polypropylene, 0.5 to 0.64 part of a slipping agent and 0.08 to 0.22 part of anti-electrostatic agent, and mixing all raw materials for 3 minutes in a high-speed mixing machine; (b) plastically extruding the uniformly mixed materials at the temperature of 245 DEG C; (c) adhering a melt onto a cold roller by virtue of a high-pressure air knife, chilling the melt in a water bath at the temperature of 23 to 27 DEG C to form a cast sheet; (d) forming, and carrying out the thickness measurement feedback by utilizing an infrared system; (e) carrying out the corona spark treatment on the surface of the corona layer, enabling the corona tension to be 44 to 50 mN / m, and coiling the cast sheet at a speed of 60 to 70 m / min; (f) curing the cast sheet for 48 hours at the temperature of 27 to 28 DEG C. The product molded in the method is light in weight, resistant to impact, high in smoothness and clarity, resistant to abrasion, good in stress fracture resistance and excellent in chemical stability, insulation property and low-temperature heat seal property.

Owner:ANHUI SONGTAI PACKAGING MATERIALS

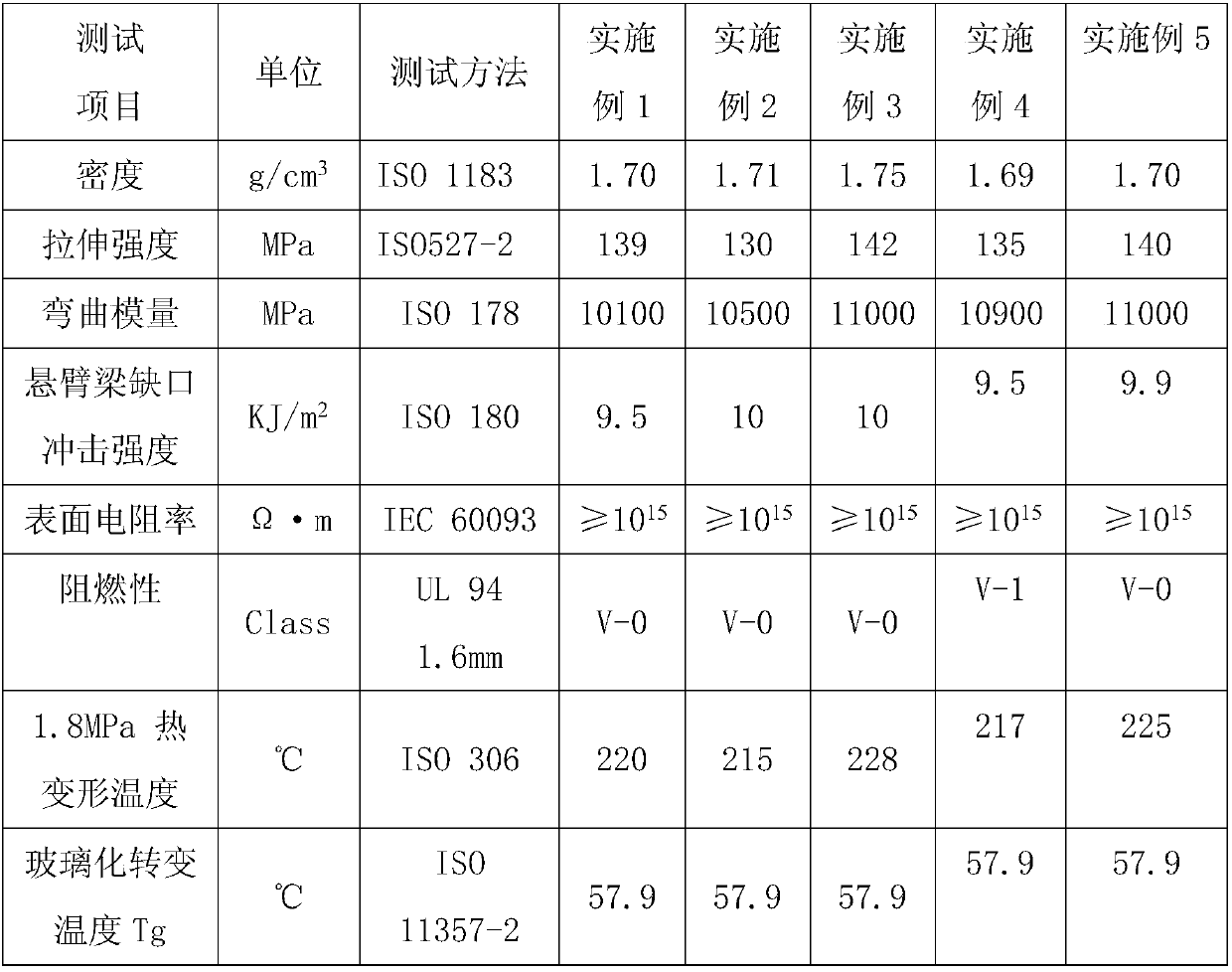

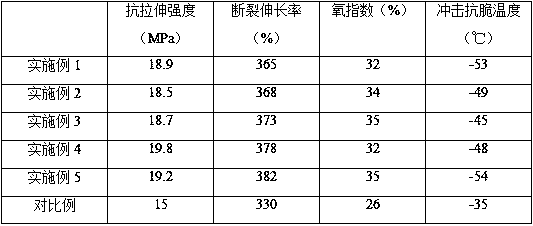

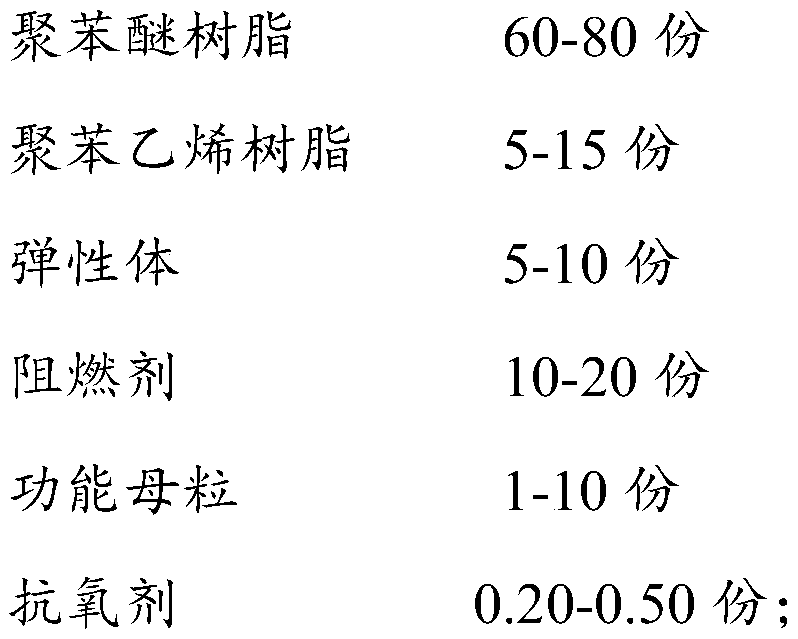

Polyphenyl ether resin alloy material, preparation method thereof and refrigeration compressor

InactiveCN105504767AExcellent stress crack resistance and low temperature impact strengthGood resistance to stress crackingPositive displacement pump componentsPositive-displacement liquid enginesWork performanceFire retardant

The invention discloses a polyphenyl ether resin alloy material, a preparation method thereof and a refrigeration compressor. The polyphenyl ether resin alloy material is prepared from, by weight, 60-80 parts of polyphenyl ether resin, 5-15 parts of polystyrene resin, 5-10 parts of an elastomer, 10-20 parts of fire retardant, 1-10 parts of functional masterbatch and 0.20-0.50 part of antioxygen. The polyphenyl ether resin alloy material has excellent stress cracking resistance, low-temperature impact strength and a flame retardant property, the preparation method is simple in process, and production cost is effectively lowered. A shell of the refrigeration compressor contains the polyphenyl ether resin alloy material, so that the refrigeration compressor is stable in work performance, resistant to low temperature and safe.

Owner:江苏沃特新材料科技有限公司

High-temperature resistant halogen-free flame-retardant cable material and preparation method thereof

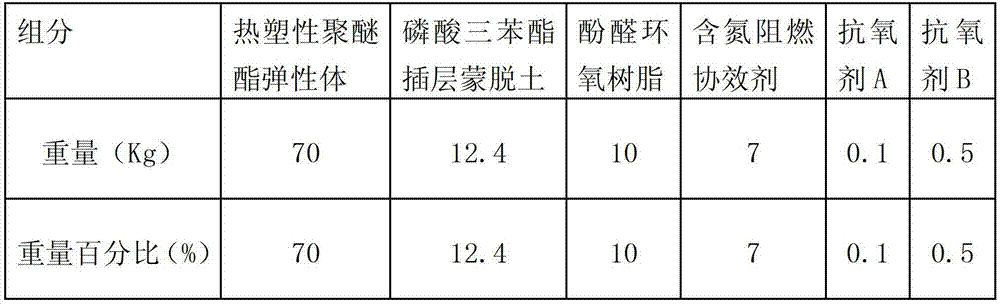

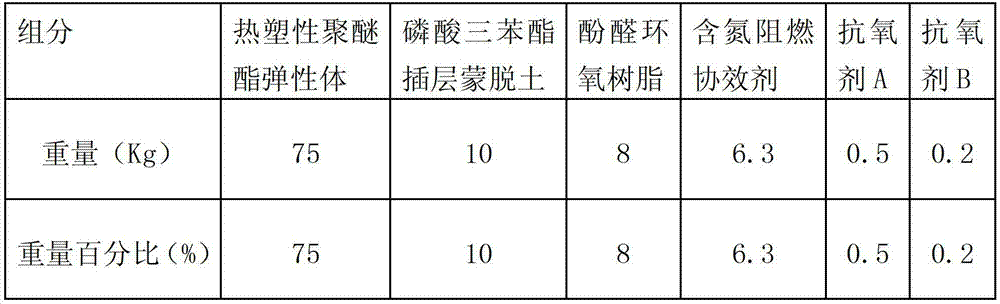

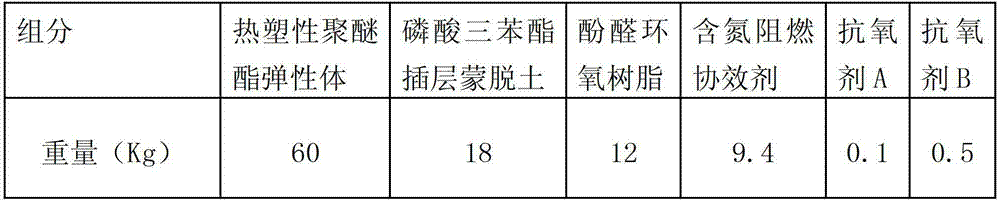

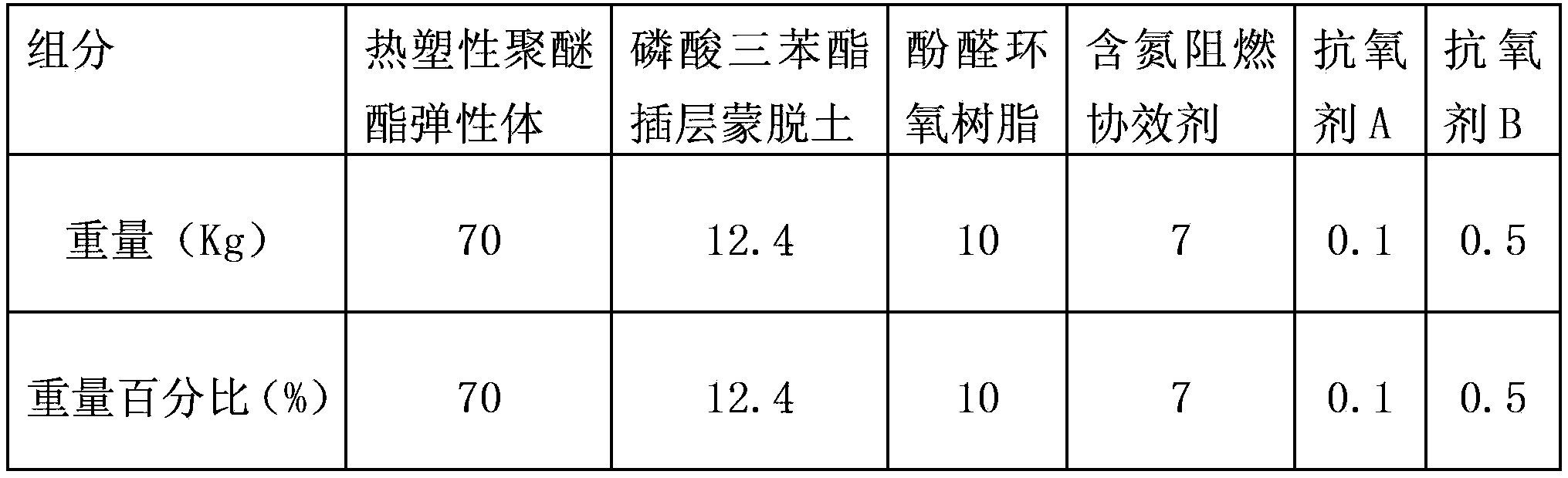

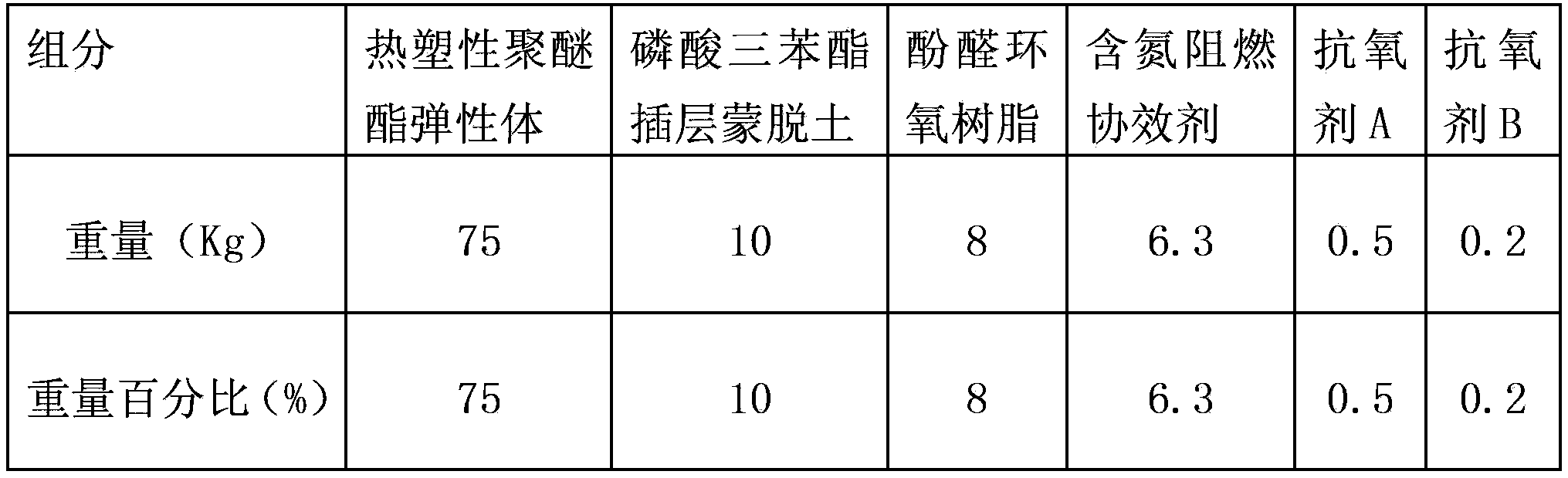

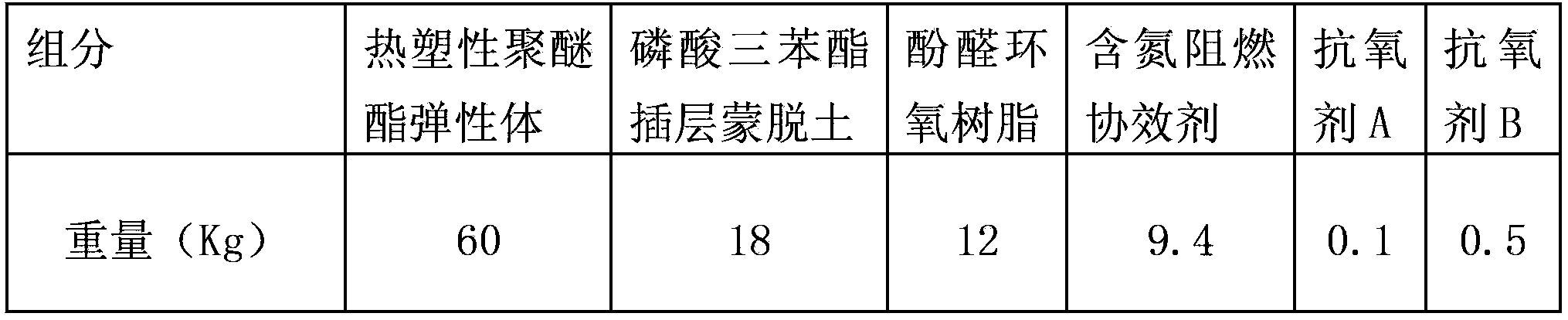

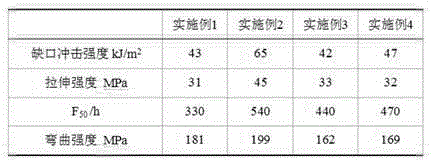

ActiveCN103205089AMolten dripping does not occurEffective against drippingPlastic/resin/waxes insulatorsInsulated cablesElastomerEpoxy

The invention discloses a high-temperature resistant halogen-free flame-retardant cable material and a preparation method thereof. The cable material comprises the following components by weight percent: 60% to 80% of thermoplastic polyether ester elastomer, 10% to 20% of triphenyl phosphate intercalated montmorillonite, 6% to 15% of novolac epoxy resin, 3% to 15% of nitrogen-containing flame-retardant synergist, 0.1% to 0.5% of antioxidant A and 0.1% to 0.5% of antioxidant B, wherein the antioxidant A is selected from double (2,4-two tertiary butyl phenyl) pentaerythritol phosphate, 4-{3-(3,5-two tertiary butyl-4-hydroxyl phenyl) propionic acid} ntaerythritol alcohol ester or Beta (3,5-two tertiary butyl-4 hydroxyl phenyl) octadecyl propionate; and the antioxidant B is selected from (2,4,6-three tertiary butyl phenyl-2-butyl-2-ethyl)-1,3-propylene glycol phosphite ester, 2,2'-ethylidene double (4,6-two tertiary butyl phenyl) fluoro phosphite ester or 2(2,4-2 pair isopropyl phenyl) pentaerythritol double phosphite ester. The cable material disclosed by the invention is good in mechanical and processing performance, strong in stress cracking resistance and high in high-temperature resisting level.

Owner:江苏迈新新材料有限公司

Three lager coextrusion foamed board and its use and preparation method

An extruded three-layer foam plate used as the casing of container or insulating plate is composed of a high-foamed plastic layer as sandwich layer, and two hard plastic layers are surface layers. Said sandwich layer is prepared by physical foaming, that is, the CO2, propane, or butane gas is directly pumped into extruder.

Owner:张瑞洋

Fresh air pretreatment terrestrial heat exchange system

ActiveCN105737308AReduce indoor pollution sourcesEnsure efficient operationOther heat production devicesGeothermal energy generationVentilation tubeEngineering

The invention relates to a fresh air pretreatment terrestrial heat exchange system. The fresh air pretreatment terrestrial heat exchange system comprises an outdoor fresh air taking part, a terrestrial heat exchange part and an indoor fresh air treatment part, wherein the outdoor fresh air taking part, the terrestrial heat exchange part and the indoor fresh air treatment part are communicated through ventilation pipelines. The fresh air pretreatment terrestrial heat exchange system is characterized in that the outdoor fresh air taking part is arranged on the ground, the outdoor fresh air taking part comprises a fresh air port, a coarse-efficiency filter device, a medium-efficiency filter device, an electrostatic dust collector and a solid dehumidification device which are arranged in sequence from top to bottom and are communicated; the terrestrial heat exchange part comprises buried pipes, temperature measuring points which are formed on the buried pipes, pneumatic cleaning device reserved openings and flow measuring points; the indoor fresh air treatment part comprises a fresh air unit, a drain pipe, a fresh air valve, a plenum chamber and a fresh air pipeline.

Owner:山东省建筑工程质量检验检测中心有限公司 +1

Flame retardant polyphenylene ether material

The invention discloses a flame retardant polyphenylene ether material, which comprises the following raw materials by weight: 60-80 parts of polyphenylene ether, 26-34 parts of impact resistant polystyrene, 0.4-0.6 part of an antioxidant, 0.4-0.6 part of an anti-dripping agent PTEE, 0.8-1.2 parts of a cross-linking agent, 1.5-2 parts of a lubricant, 2.8-3.7 parts of a compatilizer, 5- 7 parts ofan elastomer and 25-30 parts of a flame retardant. Specifically, the flame retardant is bisphenol A bis(diphenyl phosphate) and polyphenylmethylsiloxane. Through the interaction of all the substances,the flame retardant polyphenylene ether material provided by the invention has good flame retardance, stress cracking resistance, melt fluidity and processability.

Owner:合肥邦联新材料有限责任公司

Low-smoke halogen-free flame-retarding polypropylene cable material and preparation method thereof

The invention belongs to the field of cable materials, in particular to a low-smoke halogen-free flame-retarding polypropylene cable material and a preparation method thereof. The low-smoke halogen-free flame-retarding polypropylene cable material is characterized by being prepared from the following raw materials in part by weight: 65 to 75 parts of polypropylene, 12 to 18 parts of styrene-ethylene / butadiene-styrene block copolymer, 6 to 8 parts of polypropylene grafted maleic anhydride copolymer, 130 to 150 parts of magnesium hydroxide fire retardant, 5 to 7 parts of red phosphorus, 3 to 5 parts of polyacrylonitrile powder, 1 to 2.5 parts of antioxygen A and 1 to 2.5 parts of antioxygen B. The low-smoke halogen-free flame-retarding polypropylene cable material obtained by the method hasthe characteristics of high machining performance, high temperature resistance and high stress cracking resistance.

Owner:WUHAN TEXTILE UNIV

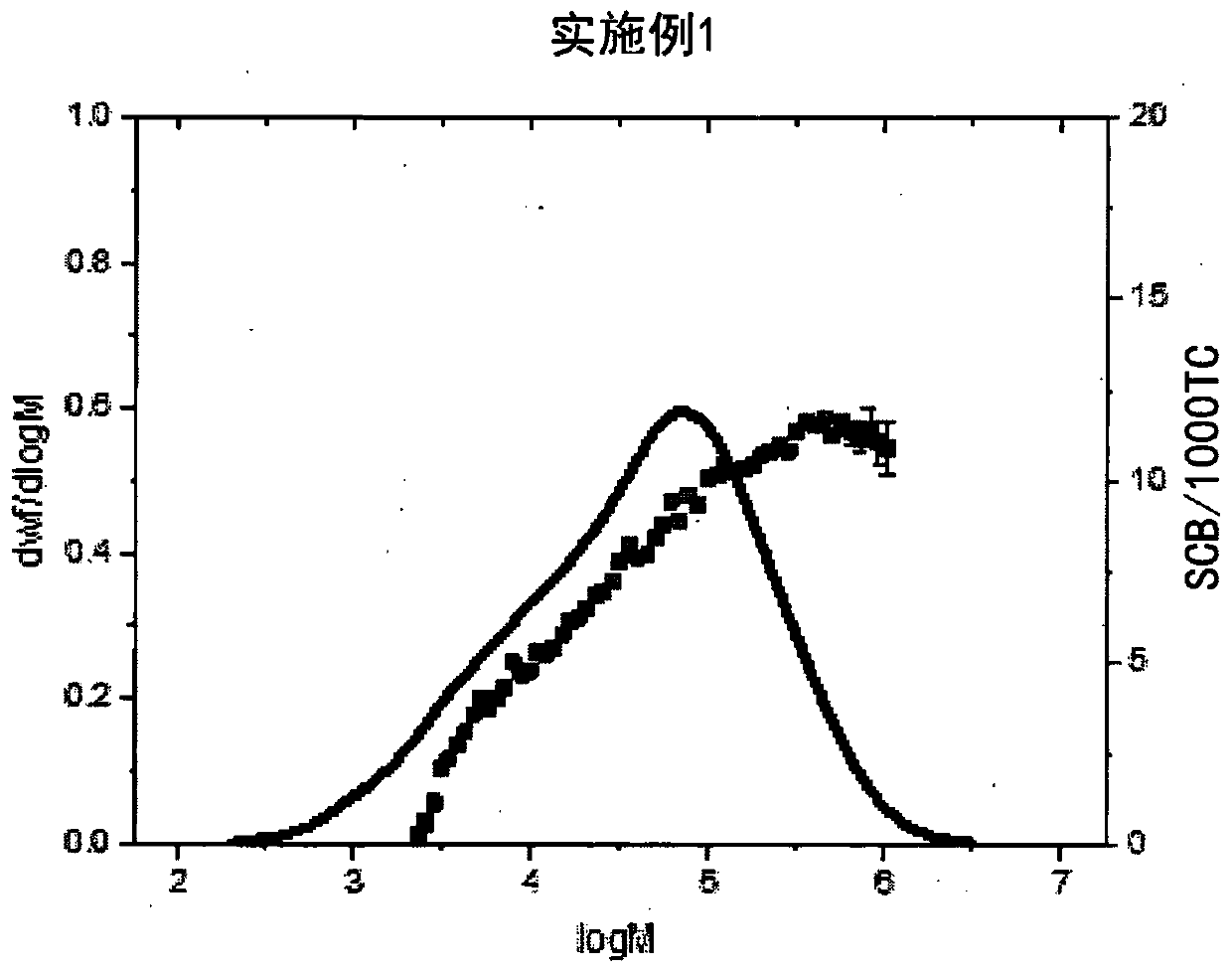

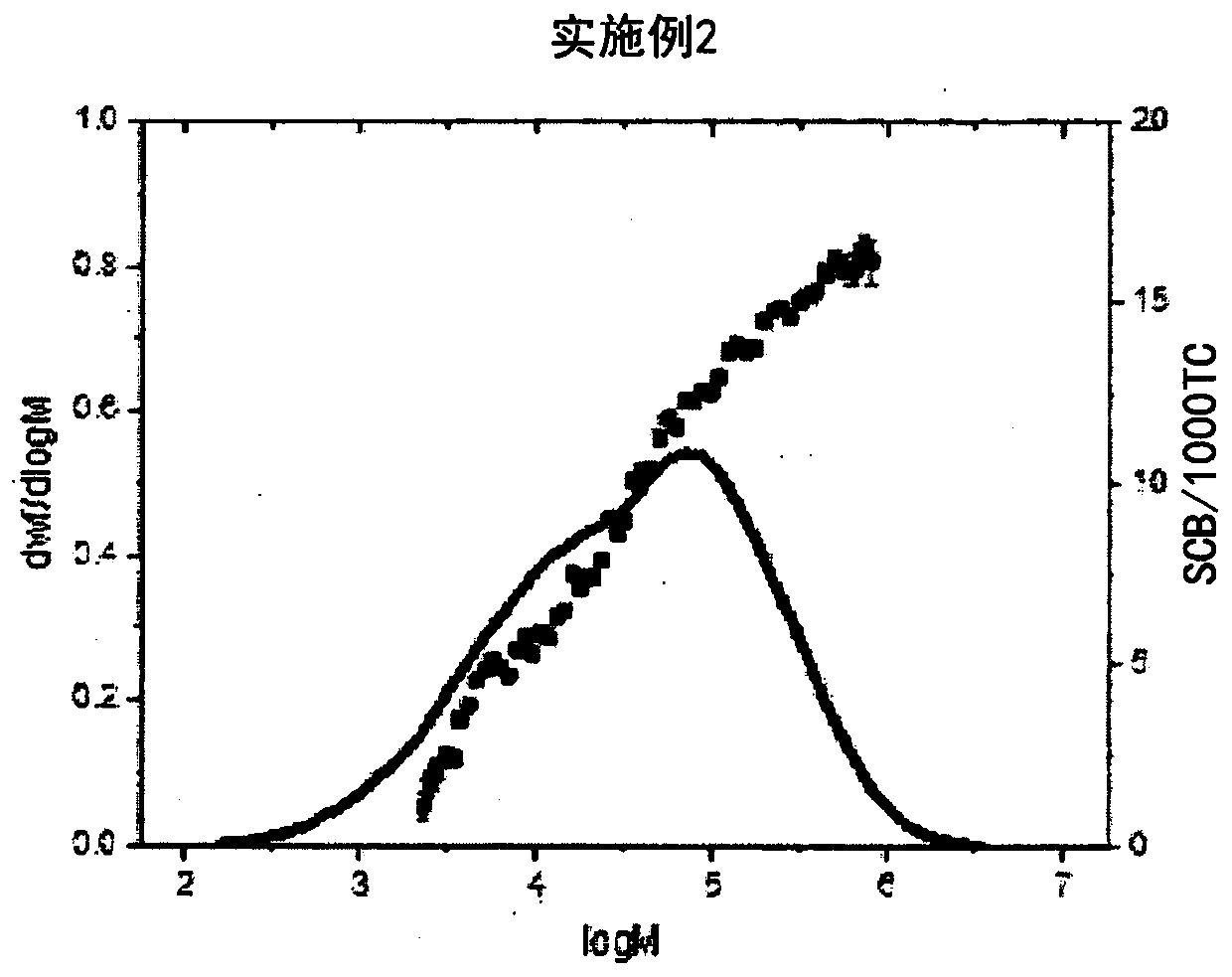

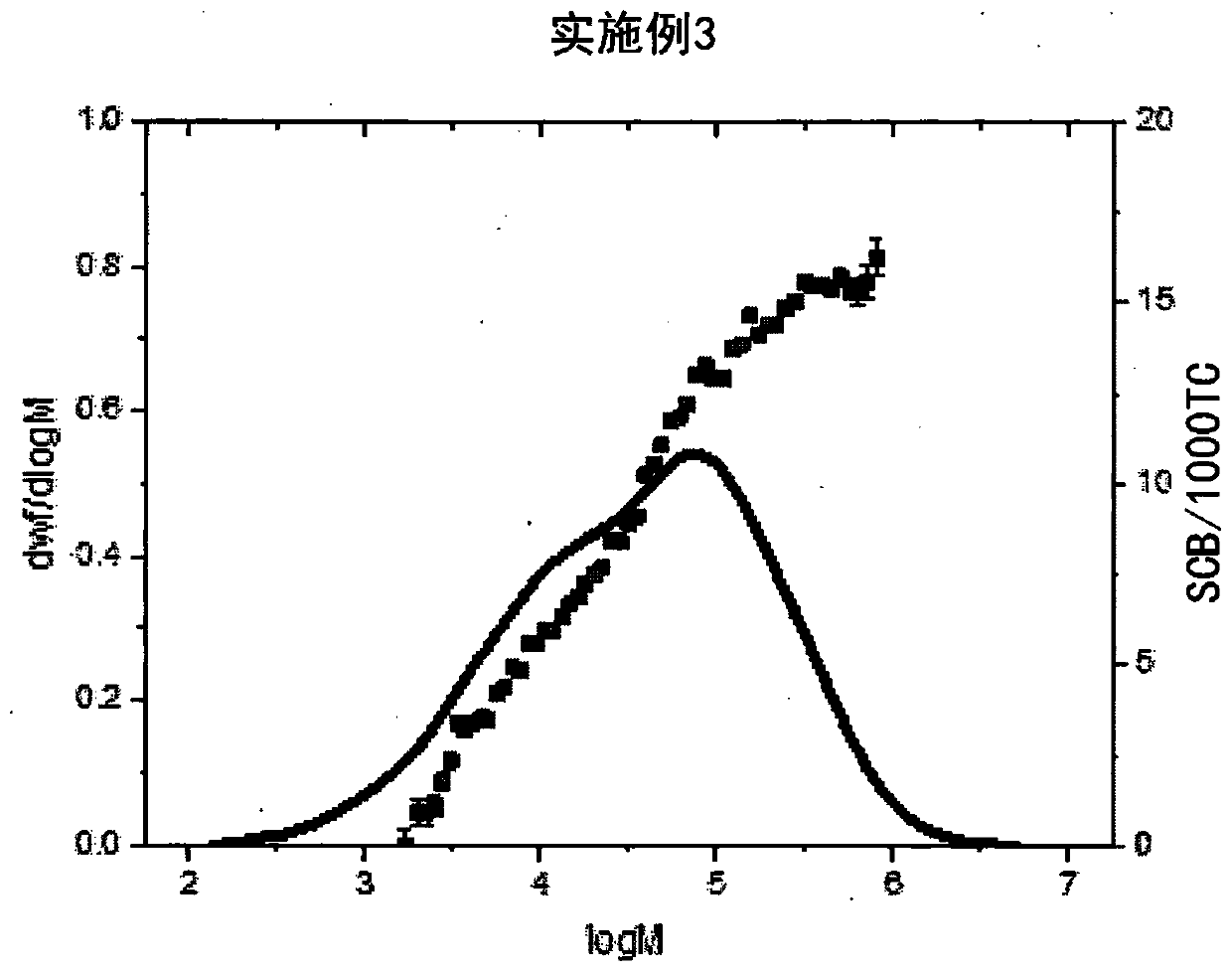

Ethylene/1-butene copolymer having excellent processability

The present invention relates to an ethylene / 1-butene copolymer having excellent processability and stress cracking resistance. The ethylene / 1-butene copolymer according to the present invention can be applied to a high pressure resistance heating tube, a PE-RT pipe, or a large-diameter pipe, and the like.

Owner:LG CHEM LTD

Anti-UV LED lampshade and preparation method thereof

The invention discloses an anti-UV LED lampshade. The LED lampshade is prepared from raw materials in pars by weight as follows: 70-80 parts of PP, 20-30 parts of PMMA, 3-5 parts of a coupling agent,2-3 parts of a flame retardant, 2-3 parts of an anti-UV agent, 1-2 parts of an antioxidant and 3-5 parts of a filling agent, wherein the anti-UV agent is prepared from 70-80 parts by weight of a benzotriazole UV absorbent, 20-30 parts by weight of phenyl salicylate, 15-25 parts by weight of zinc borate, 5-10 parts by weight of zinc oxide, 4-10 parts by weight of magnesium hydrate and 5-10 parts byweight of cerium oxide. According to the anti-UV LED lampshade, a main body of the LED lampshade is produced by combination of PP and PMMA, meanwhile, with adoption of the coupling agent, the flame retardant, the anti-UV agent, the antioxidant and the filling agent, dispersing performance of the LED lampshade can be obviously improved, light transmittance and haze are obviously improved, and mechanical property and surface hardness are remarkably improved.

Owner:NINGBO QICHI ILLUMINATION LAMP

Cutting-resistant glove processing technology

InactiveCN110644243ASimple processing technologyImprove cut resistanceWeft knittingGlovesPolyesterYarn

The invention provides a cutting-resistant glove processing technology, and relates to the field of labor protection gloves. The cutting-resistant glove processing technology includes the steps: glovecore preparation; glove core coating. Inner yarns and outer yarns are interwoven to form a glove core, polyethylene fibers with super-high relative molecule weight and bamboo-carbon modified polyester fibers wrap carbon fibers to form the outer yarns, and polyethylene fibers with super-high relative molecule weight and nylon fibers spirally wrap polyurethane filaments to form the inner yarns. A coating method of the glove core particularly includes the step: coating a composite material outside the woven glove core. The cutting-resistant glove processing technology is simple, large-scale automation production can be achieved, a processed cutting-resistant glove has excellent cutting resistance, comfortable and portable to wear and long in service life, hand flexibility is good, and replacing frequency is reduced.

Owner:徐州华通手套有限公司

Polyurethane copolymerization transparent nylon and preparation method thereof

The invention belongs to the field of polymers, and particularly relates to a polyurethane copolymerization transparent nylon and a preparation method thereof. The preparation method for the polyurethane copolymerization transparent nylon comprises the following steps: (1) dissolving bisphenol A, diamine, alkali and organic quaternary ammonium salt in water to obtain an aqueous solution A; dissolving aromatic benzenedicarbonyl chloride in an organic solvent to obtain an oil solution B; (2) under a stirring condition, adding the oil solution B into the aqueous solution A, and reacting at a temperature of 10-30 DEG C for 0.5-3 h to obtain a reaction product which contains the polyurethane copolymerization transparent nylon. The polyurethane copolymerization transparent nylon prepared by themethod provided by the invention has the advantages of high transparency, relatively high glass transition temperature Tg, low water absorption, high modulus, good product heat resistance, good stresscracking resistance, good solvent resistance and excellent self lubrication performance and friction coefficient, and can meet varied requirements of different fields on required polymer product performance.

Owner:ZHONGLUN PLASTIC IND FUJIAN

High-temperature resistant halogen-free flame-retardant cable material and preparation method thereof

ActiveCN103205089BMolten dripping does not occurEffective against drippingPlastic/resin/waxes insulatorsInsulated cablesElastomerEpoxy

The invention discloses a high-temperature resistant halogen-free flame-retardant cable material and a preparation method thereof. The cable material comprises the following components by weight percent: 60% to 80% of thermoplastic polyether ester elastomer, 10% to 20% of triphenyl phosphate intercalated montmorillonite, 6% to 15% of novolac epoxy resin, 3% to 15% of nitrogen-containing flame-retardant synergist, 0.1% to 0.5% of antioxidant A and 0.1% to 0.5% of antioxidant B, wherein the antioxidant A is selected from double (2,4-two tertiary butyl phenyl) pentaerythritol phosphate, 4-{3-(3,5-two tertiary butyl-4-hydroxyl phenyl) propionic acid} ntaerythritol alcohol ester or Beta (3,5-two tertiary butyl-4 hydroxyl phenyl) octadecyl propionate; and the antioxidant B is selected from (2,4,6-three tertiary butyl phenyl-2-butyl-2-ethyl)-1,3-propylene glycol phosphite ester, 2,2'-ethylidene double (4,6-two tertiary butyl phenyl) fluoro phosphite ester or 2(2,4-2 pair isopropyl phenyl) pentaerythritol double phosphite ester. The cable material disclosed by the invention is good in mechanical and processing performance, strong in stress cracking resistance and high in high-temperature resisting level.

Owner:江苏迈新新材料有限公司

Calcium sulfate whisker modified high density polyethylene composite material and preparation method thereof

ActiveCN102241846BHigh strengthImprove toughnessLow-density polyethyleneLinear low-density polyethylene

The invention relates to a calcium sulfate whisker modified high density polyethylene composite material and a preparation method thereof. The calcium sulfate whisker modified high density polyethylene composite material is prepared from the following raw materials: 100 parts by weight of high density polyethylene, 10-40 parts by weight of calcium sulfate whiskers, 10-20 parts by weight of linearlow density polyethylene, 10-20 parts by weight of chlorinated polyethylene, 0.1-0.3 parts by weight of an antioxidant 1010, 1-4 parts by weight of a lubricant Hst, and 1-3 parts by weight of a titanate coupling agent. The preparation method of the composite material comprises the following steps: 1, adding the calcium sulfate whiskers and the titanate coupling agent into a high speed mixer to mix for 5-12 min; 2, mixing other raw materials with modified calcium sulfate whiskers in the high speed mixer for 5-10 min; and 3, carrying out extrusion granulation on a mixture obtained in step 2 by a twin screw. The calcium sulfate whisker modified high density polyethylene composite material of the present invention which has the advantages of high strength, good toughness and good stress cracking resistance is especially suitable for various places needing high strength materials.

Owner:XIANGFU NEW BUILDING MATERIAL HUNAN

Polycarbonate-polyamide alloy plastic for automobile parts, and preparation method thereof

The invention relates to the field of automobile part materials, and discloses a polycarbonate-polyamide alloy plastic for automobile parts, and a preparation method thereof. The preparation method comprises the following steps: (1) mixing a PC / PA mixed resin, a compatilizer, microporous aluminum fibers, an antioxidant and a heat stabilizer for the first time, and grinding to obtain a fibrous compatilizer; and (2) carrying out secondary mixing on the fibrous compatilizer and a PC / PA mixed resin, and carrying out melt blending extrusion to obtain the PC / PA alloy material. According to the invention, aluminum fibers are endowed with compatibility through primary mixing and grinding, then the compatibility of the aluminum fibers is enhanced during secondary mixing to enhance the compatible compounding of the PC / PA alloy material, and the microporous aluminum fibers are well dispersed in the alloy material, so that the polycarbonate-polyamide alloy plastic has excellent oil resistance andstress cracking resistance and is suitable for being processed into various automobile parts.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Environmental-friendly polyethylene plastic

The invention relates to environmental-friendly polyethylene plastic which comprises the following components in parts by weight: 80-100 parts of polyethylene plastic, 13-25 parts of sulfo-dipropionic acid silicone grease, 15-25 parts of degrading agent, 10-15 parts of acrylate copolymer, 1-5 parts of coupling agent, 2-6 parts of zinc stearate and 1-4 parts of antioxidant. By adding the starch degrading agent into the polyethylene plastic, the polyethylene plastic can be degraded and recycled after waste treatment, so that not only is the resource saved, but also the environment is protected, and the modern environmental-friendly idea is met.

Owner:裴秀琴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com