Uniaxially-tensioned high speed printing matt PE film and production technology thereof

A high-speed printing and unidirectional stretching technology, which is applied in the packaging field, can solve the problems that the size of the printing unit cannot be guaranteed, the surface printing effect cannot be guaranteed, and the PE matting film is not common, so as to improve printing adaptability, high stiffness, mechanical high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

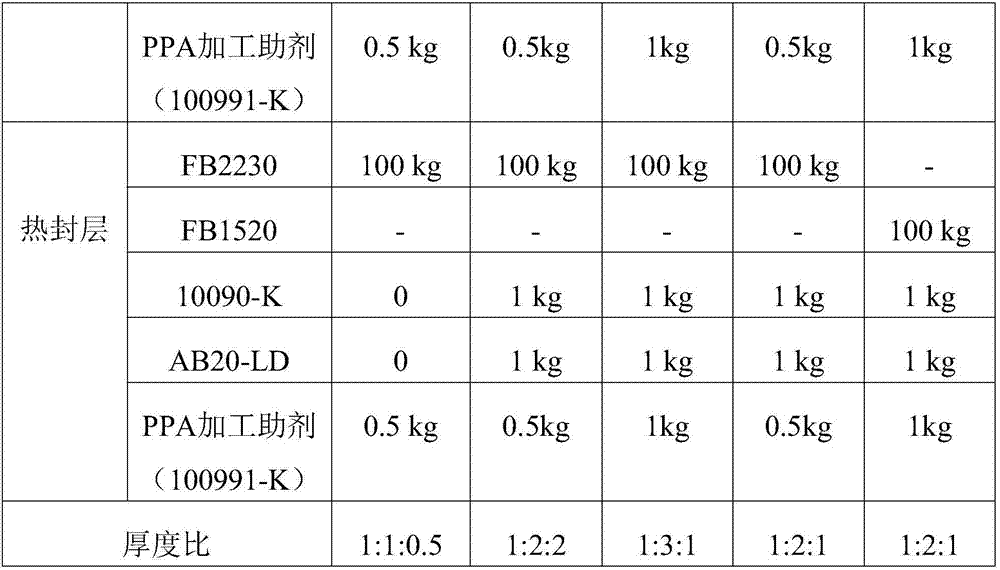

[0042] The raw material composition and formula of the matte PE film of Examples 1-5 are shown in Table 1.

[0043] FB2230 and FB1520 are blown film grade bimodal metallocene PE from Borouge. 10090-K is a slippery agent with color matching. AB-20LD is the opening agent of Beijing Allen.

[0044] Table 1

[0045]

[0046]

[0047] Wherein the thickness ratio is the thickness ratio of the corona layer, the intermediate layer and the heat-sealing layer.

[0048] figure 1 It is a flow chart of the production process of the matte PE film of the present invention. The matte PE film of the present invention is made of PE particles through a film blowing process and then stretched by MDO to finally obtain a matte PE film.

[0049] The present invention can adopt on-line corona treatment, and both sides can be treated according to requirements, and the surface tension value of the finished product is greater than 38dyn.

[0050] The specific production process is as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com