Three lager coextrusion foamed board and its use and preparation method

A three-layer co-extrusion and foam board technology, which is applied in the field of plastic boards, can solve problems such as the weight of composite boards, and achieve the effects of improving surface physical rigidity, reducing weight, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

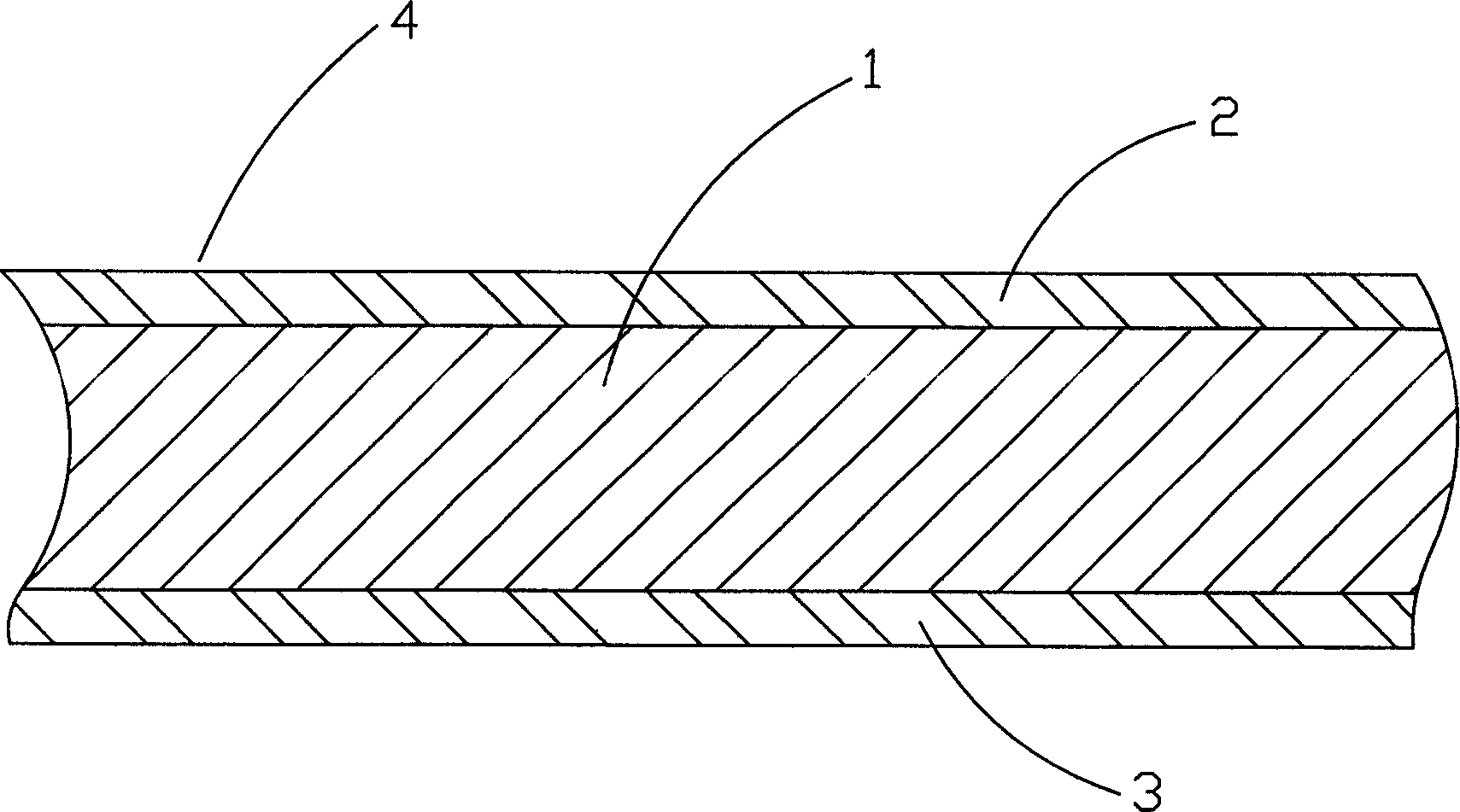

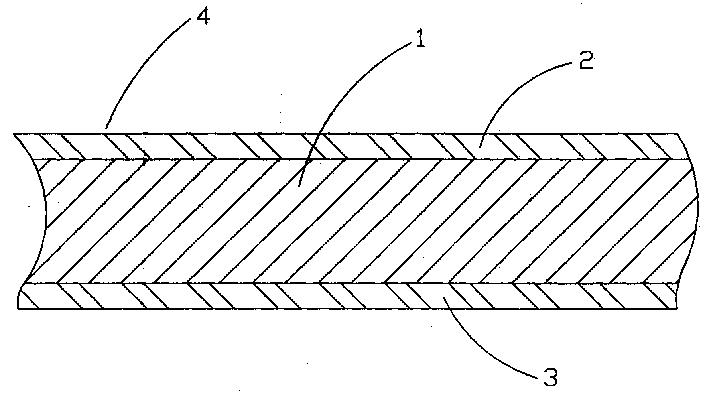

[0017] See attached figure 1 As shown, the three-layer co-extruded foam board (4) is characterized in that it includes a high-foaming plastic layer (1), and the two surfaces of the high-foaming plastic layer (1) are respectively covered with hard plastic layers (2, 3) .

[0018] The thickness of the highly foamed plastic layer (1) is greater than the respective thicknesses of the hard plastic layers (2, 3).

[0019] The high-foaming plastic layer (1) and the hard plastic layer (2, 3) can be made of thermoplastic materials respectively.

[0020] The thermoplastic material is polypropylene, polyethylene, polystyrene, ethylene vinyl acetate, polyvinyl chloride, ABS or nylon material.

[0021] In the preparation method of the above-mentioned three-layer co-extruded foamed board, the high-foamed plastic layer (1) is made by physical foaming method, and carbon dioxide or propane or butane gas is used as a foaming agent, and directly injected into an extruder to make a density 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com