Flame-retardant ASA material dedicated for new-energy vehicle battery case and preparation method thereof

A technology for new energy vehicles and battery casings, applied in the field of polymer materials, can solve problems such as material cracking and residual stress, and achieve high production efficiency, excellent low-temperature toughness, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

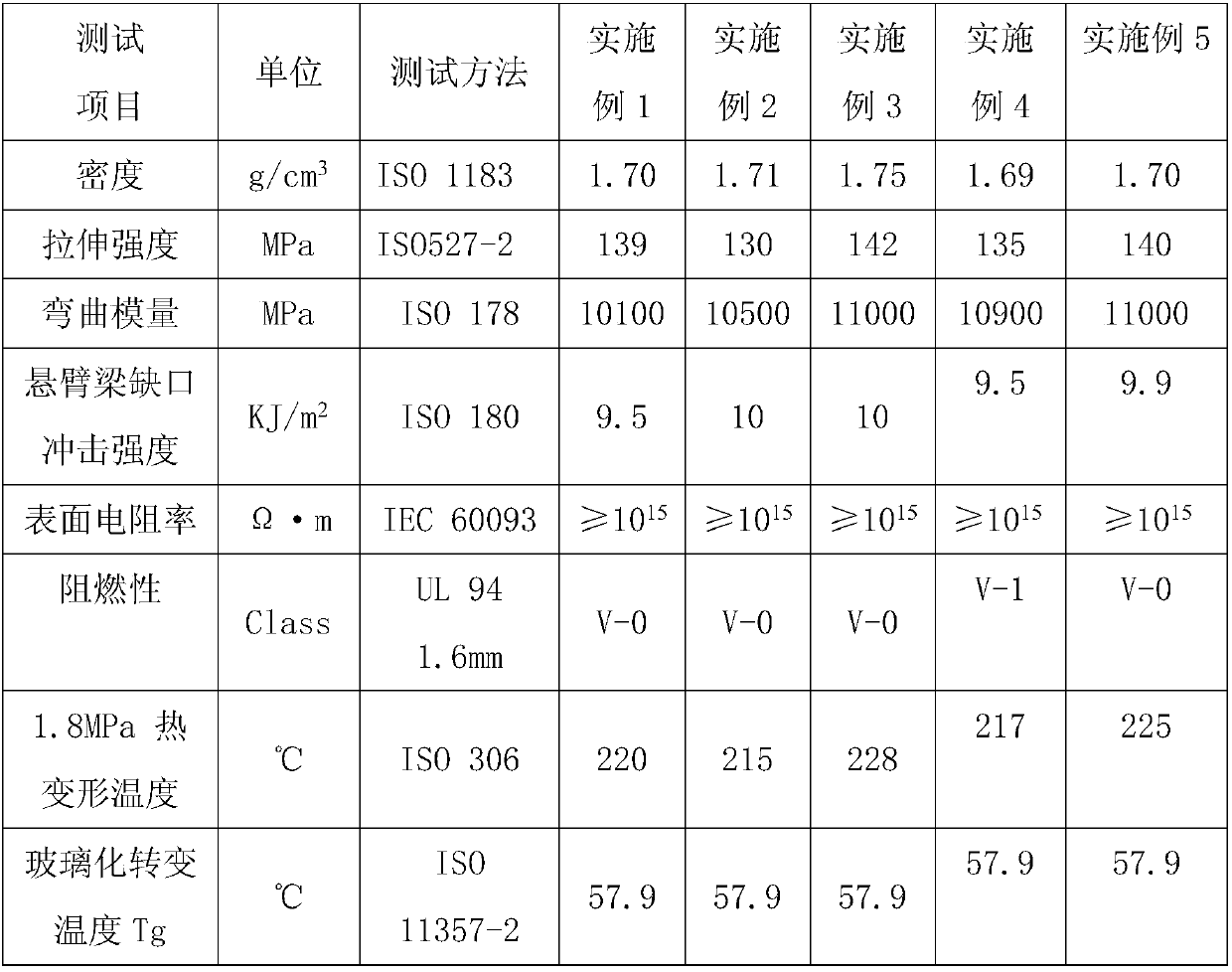

Examples

Embodiment 1

[0024] In this embodiment, the special flame-retardant ASA material for the new energy vehicle battery casing is made of the following raw materials in parts by weight: 40 parts of ASA resin, 30 parts of polymethyl methacrylate, 20 parts of polycarbonate, 10 parts of polyhexafluoroethylene, glass 10 parts of microbeads, 3 parts of anti-stress cracking agent, 2 parts of flame retardant, 2 parts of toughening agent, 1 part of compatibilizer, 1 part of silicone, 2 parts of tetraisopropyl titanate, 1 part of tricresyl phosphate ;

[0025] Among them, the flame retardant is sodium antimonate, potassium perfluorobutane sulfonate, bisphenol A bis(diphenyl phosphate), and brominated flame retardant in a weight ratio of 1:1:1:2. , the brominated flame retardant is decabromodiphenylethane;

[0026] ASA resin is a graft copolymer composed of acrylate-styrene-acrylonitrile, wherein the quality of acrylate accounts for 60% of the graft copolymer; the compatibilizer is styrene-maleic anhyd...

Embodiment 2

[0033] In this embodiment, the special flame-retardant ASA material for the new energy automobile battery casing is made of the following raw materials in parts by weight: 75 parts of ASA resin, 50 parts of polymethyl methacrylate, 30 parts of polycarbonate, 18 parts of polyhexafluoroethylene, glass 16 parts of microbeads, 8 parts of anti-stress cracking agent, 6 parts of flame retardant, 6 parts of toughening agent, 4 parts of compatibilizer, 3 parts of silicone, 5 parts of tetraisopropyl titanate, 3 parts of tricresyl phosphate ;

[0034] Among them, the flame retardant is sodium antimonate, potassium perfluorobutane sulfonate, bisphenol A bis(diphenyl phosphate), and brominated flame retardant in a weight ratio of 1:1:1:2. , the brominated flame retardant is brominated polystyrene;

[0035] ASA resin is a graft copolymer composed of acrylate-styrene-acrylonitrile, wherein the quality of acrylate accounts for 70% of the graft copolymer; the compatibilizer is styrene-acrylon...

Embodiment 3

[0042] In this embodiment, the special flame-retardant ASA material for the new energy vehicle battery casing is made of the following raw materials in parts by weight: 57 parts of ASA resin, 40 parts of polymethyl methacrylate, 25 parts of polycarbonate, 14 parts of polyhexafluoroethylene, glass 13 parts of microbeads, 5.5 parts of anti-stress cracking agent, 4 parts of flame retardant, 4 parts of toughening agent, 2.5 parts of compatibilizer, 2 parts of silicone, 3.5 parts of tetraisopropyl titanate, 2 parts of tricresyl phosphate ;

[0043] Among them, the flame retardant is sodium antimonate, potassium perfluorobutane sulfonate, bisphenol A bis(diphenyl phosphate), and brominated flame retardant in a weight ratio of 1:1:1:2. , the brominated flame retardant is brominated epoxy resin;

[0044] ASA resin is a graft copolymer composed of acrylate-styrene-acrylonitrile, wherein the quality of acrylate accounts for 65% of the graft copolymer; the compatibilizer is styrene-male...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com