Polyphenyl ether resin alloy material, and preparation method and application thereof

A polyphenylene ether resin and alloy material technology, applied in the field of polyphenylene ether resin alloy materials, can solve problems such as stress cracking, poor oil resistance, and high fluidity, and achieve the effects of poor fluidity, low cost, and high fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

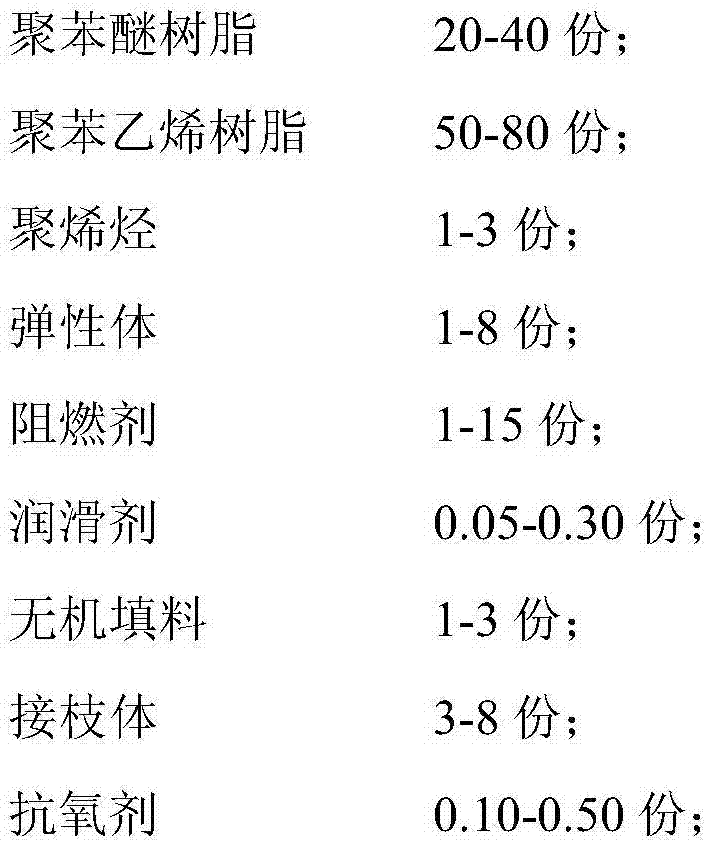

Method used

Image

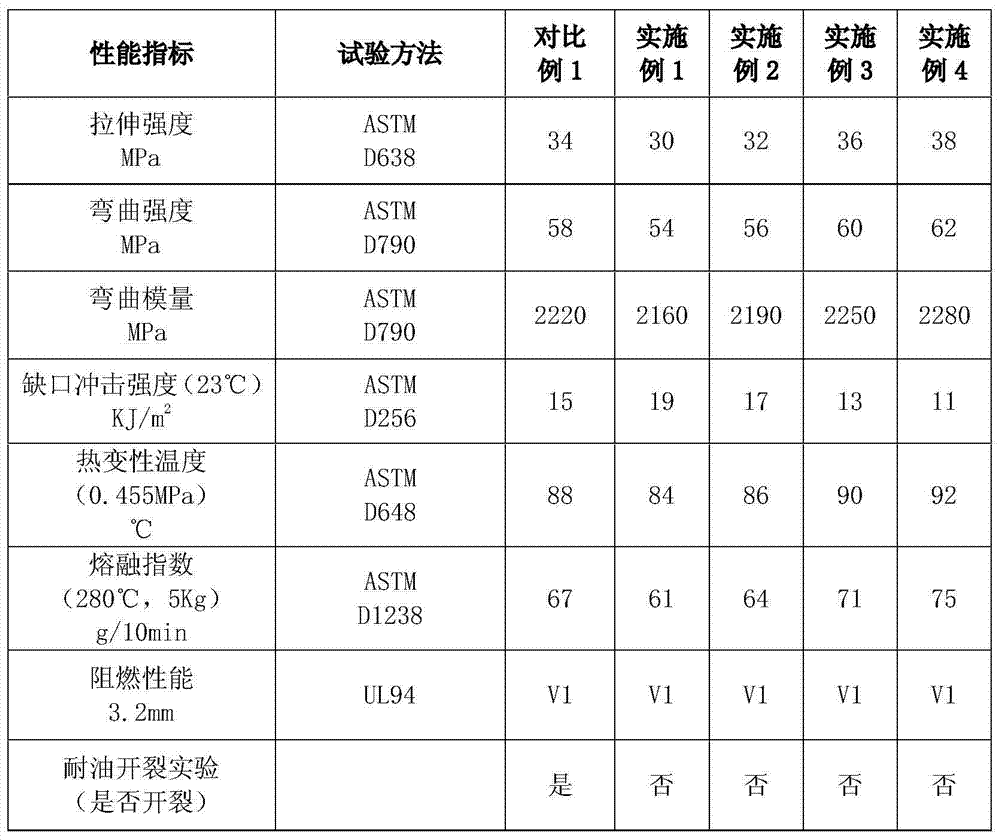

Examples

Embodiment 1

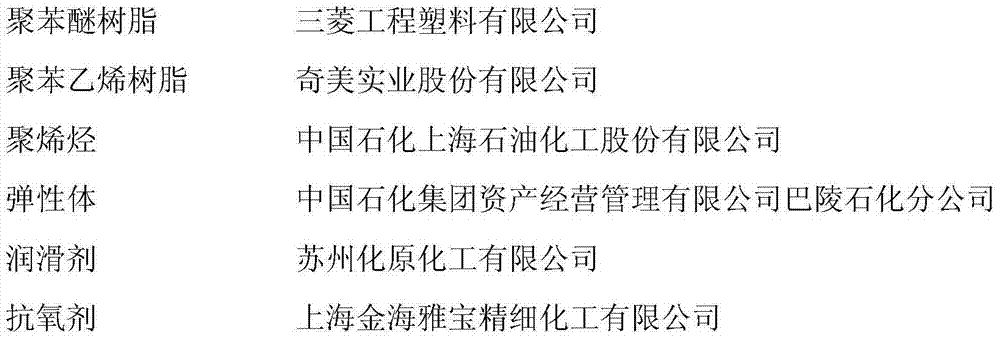

[0027] The raw materials and dosages used in this example are shown in Table 1, where:

[0028] Polyphenylene ether resin: a polymer selected from 2,6-dimethylphenol with an intrinsic viscosity of 0.4dl / g;

[0029] Polystyrene resin: composed of polystyrene and high-impact polystyrene in a weight ratio of 1:3;

[0030] Polyolefin: It is composed of polypropylene, ethylene propylene copolymer and polybutene in a weight ratio of 3:1:1;

[0031] Elastomer: It is composed of styrene butadiene rubber, hydrogenated styrene butadiene rubber, polyacrylate rubber, 1,2 polybutadiene elastomer in a weight ratio of 4:4:1:1;

[0032] Flame retardant: It is composed of phosphorus flame retardant and nitrogen flame retardant in a weight ratio of 3:1, wherein the phosphorus flame retardant is a phosphate flame retardant, and the nitrogen flame retardant is melamine;

[0033] Lubricant: It is composed of calcium stearate, zinc stearate and stearic acid in a weight ratio of 1:1:1;

[0034] Inorganic filler...

Embodiment 2

[0040] The raw materials and dosages used in this embodiment are shown in Table 1. The raw materials other than polyphenylene ether resin, polystyrene resin, and graft are the same as those in Embodiment 1.

[0041] In this example, polyphenylene ether resin: a polymer of 2,6-dimethylphenol, a copolymer of 2,6-dimethylphenol and 2,3,6-trimethylphenol in a weight ratio of 2: 1 composition of the mixture, its intrinsic viscosity is 0.5dl / g;

[0042] In this example, polystyrene resin: selected from polystyrene;

[0043] In this example, the graft: styrene-butadiene rubber as the base material, and the graft is a mixture of acetic anhydride, succinic anhydride, and benzoic anhydride in a weight ratio of 3:1:1

[0044] In this example, the preparation method of the polyphenylene ether resin alloy material is the same as in Example 1, and will not be repeated here.

Embodiment 3

[0046] The raw materials and dosages used in this embodiment are shown in Table 1. The raw materials other than polyolefin, elastomer, and antioxidant are the same as in Embodiment 1.

[0047] In this example, polyolefin: selected from polyethylene;

[0048] In this example, elastomer: a mixture of hydrogenated styrene butadiene rubber and binary ethylene propylene rubber in a weight ratio of 1:1;

[0049] In this example, antioxidant: It is composed of main antioxidant and auxiliary antioxidant in a weight ratio of 3:1, among which, the main antioxidant is 3,5-di-tert-butyl-4-hydroxyphenylpropionic acid Stearyl alcohol ester, 2,2-methylene bis(4-methyl-6-tert-butylphenol) is a mixture of 1:1 by weight, and the auxiliary antioxidant is bis(2,4-di-tert-butyl (Phenyl) pentaerythritol diphosphate and bis(octadecyl) pentaerythritol diphosphate in a weight ratio of 1:1;

[0050] In this example, the preparation method of the polyphenylene ether resin alloy material is the same as in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com