Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

122 results about "Benzoic anhydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Benzoic anhydride is the organic compound with the formula (C₆H₅CO)₂O. It is acid anhydride of benzoic acid and the simplest symmetrical aromatic acid anhydride. It is a white solid.

Benzoic anhydride catalyst and preparation method thereof

ActiveCN101422727AImprove performanceImprove working environmentOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsChemical industryGas phase

The invention relates to a catalyst that is used in the catalytic oxidation reaction between raw materials of ortho-xylene and / or naphthalin and gas phase that contains molecular oxygen for producing phthalic anhydride, as well as a preparation method of the catalyst. The catalyst comprises an inert imperforated carrier material and a catalytic active substance layer that is coated on the carrier and contains vanadic oxide, diantimony trioxide, titanium dioxide and a cementing agent, etc. In a preparation process of the catalyst, serum is firstly prepared, viscosity of the catalytic active substance serum is controlled, the carrier is heated, the serum is sprayed onto the carrier in a barrate, and the carrier is dried by hot wind. The catalyst is used for the field of chemical industry.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined polyether and composition for preparing polyurethane rigid foam and application method thereof

InactiveCN102079804AWide operating temperature rangeSolve the problem of not being able to foamPolyesterPolyol

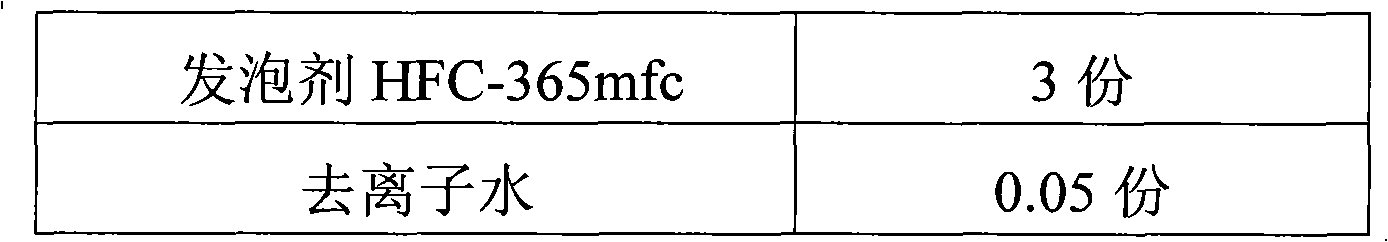

The invention discloses a combined polyether for preparing polyurethane rigid foam and an application method thereof. The combined polyether comprises polyether polyol DS400, benzoic anhydride polyester polyol, foam stabilizer, polyurethane synthetic catalyst, foaming agent and water. The invention also discloses a composition for preparing polyurethane rigid foam, which comprises the combined polyether for preparing polyurethane rigid foam and isocyanate, wherein the mass ratio of the combined polyether to the isocyanate is 1:1-1:1.2. The invention overcomes the defects that the combined polyether can not meet the requirements for low-temperature construction in the prior art, the construction temperature is high, the prepared polyurethane foam has poor dimensional stability and the like, and provides a combined polyether for preparing polyurethane rigid foam and an application method thereof. The combined polyether can be used for construction in the low-temperature environment, andthe prepared polyurethane rigid foam has high dimensional stability.

Owner:SHANGHAI DONGDA POLYURETHANE

Interpenetrating polymer network anticorrosion paint and production method thereof

InactiveCN101492588AShorten drying timeHigh surface hardnessAnti-corrosive paintsEpoxy resin coatingsEpoxyBenzoic anhydride

Owner:衡阳市化工研究所

Soybean oil modified alkyd as well as preparation method and application thereof in coating

The invention discloses soybean oil modified alkyd which is prepared from the following raw materials in parts by weight: 180-250 parts of soybean oil, 180-280 parts of benzoic acid, 230-260 parts of benzoic anhydride, 130-150 parts of pentaerythritol, 15-20 parts of trimethylolpropane, 30-50 parts of diglycol, 20-30 parts of reflux dimethylbenzene, 260-280 parts of diluted dimethylbenzene, 1.5-3.0 parts of color-reducing antioxidant and 0.1-0.2 part of catalyst. The invention has the advantages that the alcoholysis temperature can be decreased, and the alcoholysis reaction time can be shortened, thereby the heat efficiency loss of a heat supply system is reduced, the utilization ratio of heat energy is improved, the fuel oil consumption is reduced, the production efficiency is improved, coating films with different characteristics can be formed, and the soybean oil modified alkyd has quite excellent use characteristic and quite wide application fields.

Owner:CARPOLY CHEM GRP

Disinfectant for improving hydrogen peroxide bactericidal activity

InactiveCN101053330AImprove the bactericidal effectBroad spectrumBiocideDisinfectantsGlutaric anhydrideBenzoic acid

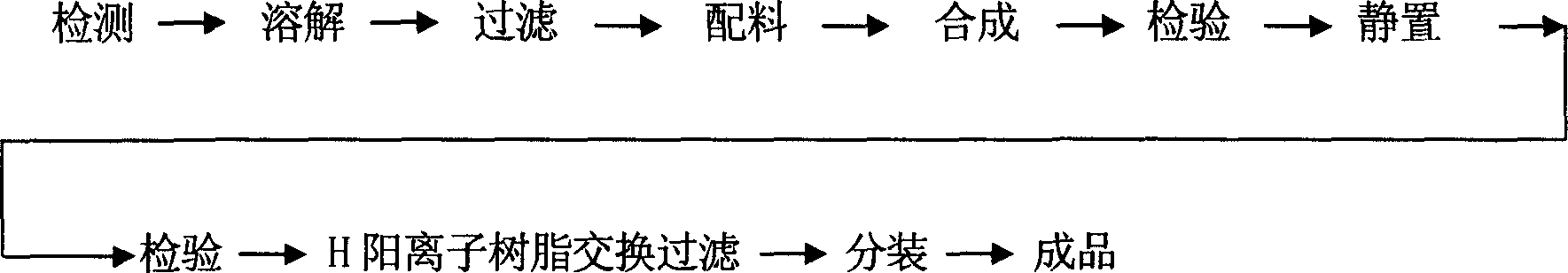

A disinfectant with hydrogen peroxide bactericidal activity is composed of A, B, C and D component. If the solute is metered by 100%, its weight account proportion of mixed solution A:B:C:D=5-100:1-50:1-100:1-1000 obtained through hydrogen cation resin exchanged and filtered, wherein A is hydrogen peroxide; B is form one or more of glutaric anhydride, adipic anhydride, succinic anhydride, acetic anhydride, propionic anhydride, benzoic anhydride and phthalic anhydride; C is from one or more of sulfuric acid, phosphoric acid, salicylic acid, tartaric acid, citric acid, dipicolinic acid, sorbic acid, acetic acid, glutaric acid, oxalic acid, succinic acid, acetic acid, propionic acid, benzoic acid, and phthalic acid; D is from one or more of ethanol, ethylene glycol, isopropanol, glycerol, and polyvinyl alcohol. It is a good stability, strong bactericidal, fungicidal spectrum-efficient disinfectant.

Owner:西藏大昭圣泉实业有限公司

Antiseptics for improving hydrogen peroxide sterilizing activity and preparing process thereof

InactiveCN1552211AHigh bactericidal activityIncrease free radical concentrationBiocideAnimal repellantsGlutaric anhydrideButanedioic acid

A disinfectant able to increase the bactericiding activity of hydrogen peroxide is prepared from the aqueous solution of hydrogen peroxide, the activating agent chosen from the complex of metallic ion (Fe, Cu, Ag or Mg), the anhydride of acetic acid, propionic acid, butanedioic acid, etc and the stabilizer chosen from organic acid and inorganic acid through proportional mixing, and controlling pH=0.5-4 and temp to be lower than 100 deg.C. Its advantages are high bactericiding power, broad spectrum and high stability.

Owner:西藏大昭圣泉实业有限公司

Method for preparing phthalide by benzoic anhydride liquid phase hydrogenation with gold-base catalyst

InactiveCN101302209AImprove hydrogenation activityGood choiceOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsActive componentBenzoic anhydride

The invention discloses a method for preparing phthalide through phthalic anhydride liquid phase hydrogenation under the action of au-base catalyst. The gold-base catalyst used in the preparation method takes SiO2, ZnO, La2O3, CeO2, TiO2, ZrO2 or Fe2O3 as a carrier and takes gold as an active component, and the loading of gold is between 0.05 and 20 percent. As the gold-base catalyst used in the preparation method has excellent hydrogenation activity and selectivity under mild catalytic reaction conditions, the conversion rate of phthalic anhydride can be more than 95 percent, and the selectivity of phthalide can be more than 93 percent, thereby the single pass yield of the target product phthalide is high. Moreover, the gold-base catalyst is very good in performance stability, and more particularly, the gold-base catalyst after metal oxide modification can still maintain the selectivity over 92 percent even through the activity of the gold-base catalyst declines slightly after repeated recycling use. In addition, the gold-base catalyst provided is simple to prepare and does not pollute the environment. Therefore, the preparation method has significant advantages.

Owner:ZHEJIANG UNIV OF TECH

Process for catalytic synthesis of phthalide from phthalic anhydride

InactiveCN1884272AHigh activityImprove stabilityCatalyst carriersOrganic chemistryNickel catalystBenzoic anhydride

The invention relates to a method for synthesizing phthalide catalyzed by benzoic anhydride in liquid phase, especially relates to method with loading nickel catalyst. Said method employs phthalide as reacting solvent, prepares phthalide through selective hydrogenation with benzoic anhydride under catalysis of loading nickel catalyst; the ratio by weight between said benzoic anhydride and phthalide is 1: 0.1-10, the reacting temperature is 130-200 Deg. C, reacting pressure is 1.0-5.0 Mpa; said loading nickel catalyst is catalyst with nickel loaded on SiO2, diatom earth, activated char, TiO2, ZrO2, TiO2-SiO2, TiO2-Al2O3 or TiO2-ZrO2, and the loading amount of nickel is 5-50 wt.%. The invention is characterized by high activity and stability of used loading nickel catalyst, no pollution of process, direct usage of phthalide as solvent, low cost for post treatment, and simple process.

Owner:ZHEJIANG UNIV OF TECH

Clean production method for dioctyl phthalate

InactiveCN1884249AReasonable useEmission reductionOrganic compound preparationCarboxylic acid esters preparationWater vaporOctanol

The invention discloses a cleaning manufacturing method of phthalic acid dioctyl, which is characterized by the following: setting esterification and dealcoholization within one equipment; adopting benzoic anhydride and octanol as raw material at 1:2-3 weight percentage; utilizing titanic hydroxide four propyl ester as catalyst; setting addictive quantity at 0.0015%-0.005% in the total material; generating coarse ester in the autoclave under normal pressure; controlling reacting final temperature at 220-240 deg.c; flashing octanol through residual heat in the autoclave; dehydrating excess 60-80% octanol in the esterifying reaction; collecting sedimenting water after condensing; cooling temperature in the autoclave at 170-190 deg.c; inputting water at this temperature; distilling steam in the autoclave; removing residual octanol.

Owner:TIANJIN TIANRONG CHEM

Method for improving thermal stability of dibutyl/diisobutyl phthalate

ActiveCN102219688AImproves intrinsic thermal stabilityImprove thermal stabilityOrganic compound preparationCarboxylic acid esters preparationOrganic synthesisPolyvinyl chloride

The invention provides a method for r improving thermal stability of dibutyl / diisobutyl phthalate, and belongs to the technical fields of fine organic synthesis and application and machine shaping of macromolecular new materials. The method which improves the intrinsic thermal stability of plasticizers of dibutyl phthalate and diisobutyl phthalate by an inorganic carbonate heat treatment is characterized in that: protonic acid, such as sulfuric acid, is adopted to serve as an esterifying catalyst, coarse ester is thermally decomposed by anhydrous solid carbonates in a reaction system prepared through esterifying synthesis of benzoic anhydrides and n-butyl alcohol or isobutyl alcohol, the catalyst and byproducts generated in the reaction process are effectively removed, coloring byproducts in the esterifying reaction system can be effectively removed, the effect of improving the product stability is achieved, and the requirement on thermal treatment of polyvinyl chloride (PVC) products is met; compared with the conventional production methods, the method has the advantages that: process wastewater is reduced by two-thirds, the production period is shortened, and the aims of energy conservation and emission reduction are fulfilled.

Owner:JIANGNAN UNIV +1

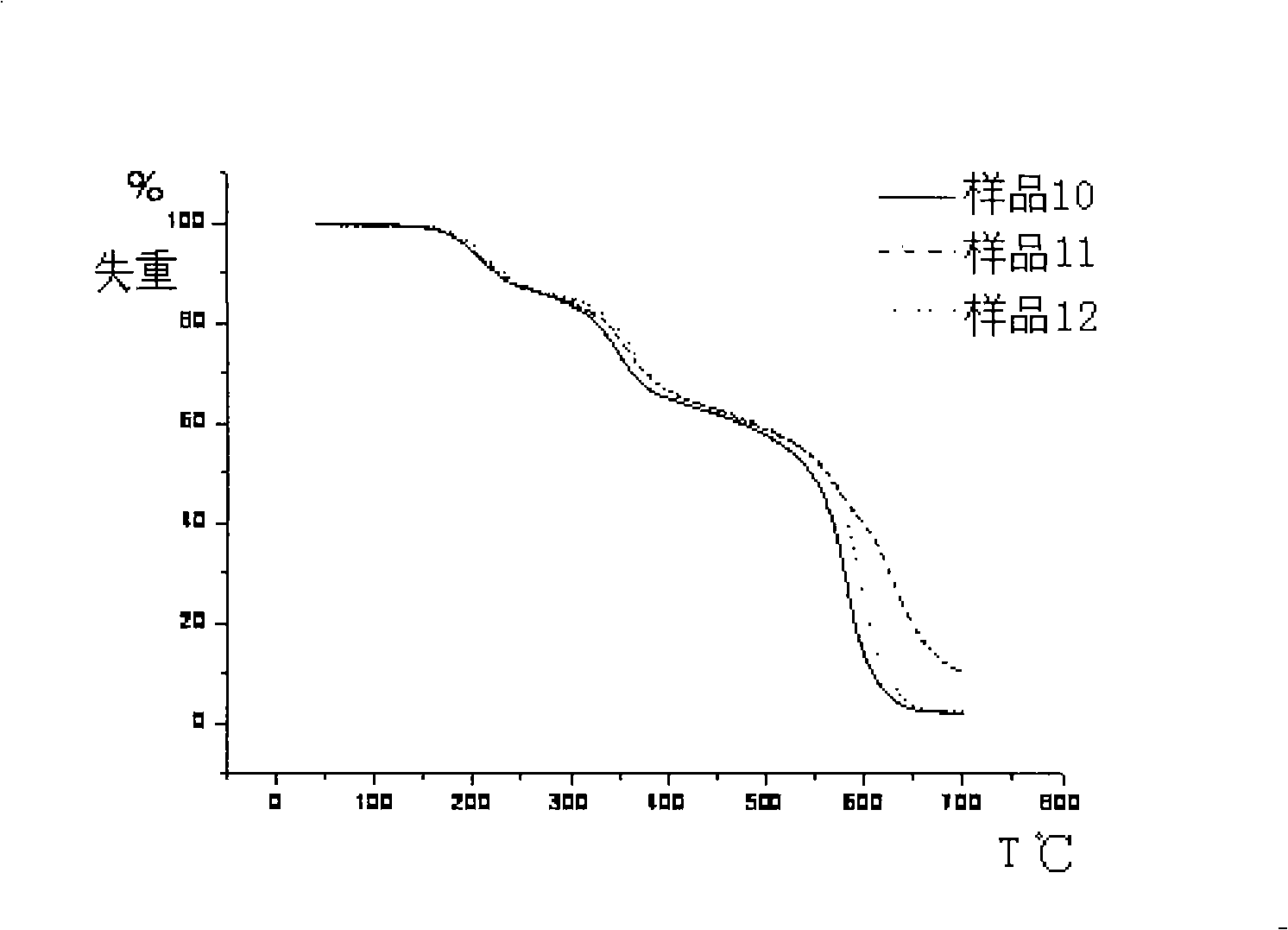

Polyurethane acid imide foam material and preparation thereof

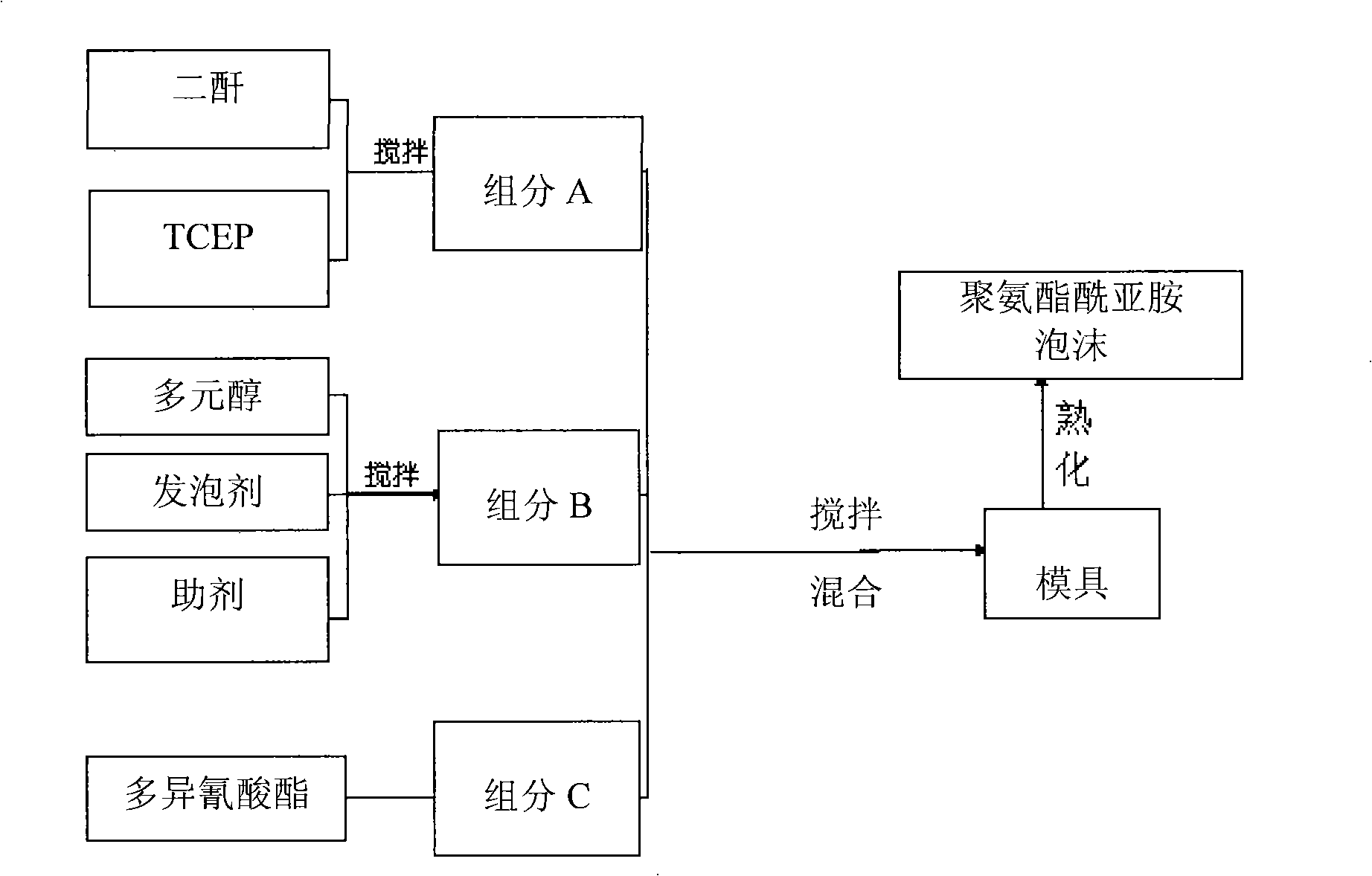

The invention discloses a foaming material of polyurethane-imide and a preparation method thereof. In the method, after a component A, a component B and a component C are uniformly mixed, a one-trip foaming technique is adopted to carry out preparation and obtain the foaming material of polyurethane-imide, wherein, the component A consists of pyromelliticdianhydride and triguaiacyl ( Beta-chloroethyl) phosphate; the component B includes hydroxyl terminated polysiloxane, PCDL, benzoic anhydride polyester polyols, tributyl amine, the dipropylene glycol liquid of DABCO, water, silicon oil and DMMP; the component C is WDP. The method selects a liquid compound with the effect of a solvent as a special functional addition agent to solve the technical problem of uneven material mixing in the existing preparation method, thus being suitable for the one-trip foaming technique; in addition, the technique is simple and easy to be industrialized. The method can be utilized to prepare the foaming material with excellent thermal stability and flame retardance. The working temperature of the foaming material can achieve more than 150 DEG C; and the oxygen index can reach 30 to 40.

Owner:BEIJING RADIATION APPL RES CENT

Process for preparing 3,3',4,4'-tetracarboxydiphthalic ether dianhydride

The method for preparation of 3, 3' ,4, 4'-diphenyloxide tetracarboxylic dianhydride belongs to the organic synthetic field. The purpose of this invention is to provide a method for preparation of 3, 3' ,4, 4'-diphenyloxide tetracarboxylic dianhydride, in which its preparation technology is simlple, process flow is short, cost is low, three wastesquantity is few, and its solvents can be retrieved and reused and its products can be easily purified. It includes the following steps: produing the corresponding 4-halogenated potassium phthalate or natrium phthalate by the reaction between 4-halogenated benzoic anhydride and caustic potash or caustic soda; condensing the product of the former step and 4-halogenated benzoic anhydride in the non-polar solvent of dichlorobenzene or trichlorobenzene with organophosphorus compound and / or copper compound as its phase transfer catalyst to obtain monoether anhydride; hydrolyzing the obtained monoether anhydride in the organic acid to prepare monoether acid, afterwards, and closing loop and dehydrating them in the miscible liquids of ethyl acetate and acetic anhydride to prepare purified monoether anhydride. The method for preparation of monoether anhydride can easily control reaction conditions, and is of good stability, especially, is of no strict demand for water.

Owner:HEILONGJIANG INST OF PETROCHEM

Method for preparing BDO/succinic acid diester and phthalandione diester with by-product from benzoic anhydride preparation

InactiveCN101343210AEmission reductionProcess is easy to controlOrganic compound preparationCarboxylic acid esters separation/purificationDistillationWastewater

The invention discloses a method for using by-products of phthalic anhydride to prepare BDO / succinic acid diester and phthalic acid diester, wherein, the by-products comprise at least one of wastewater, waste residues and phthalic anhydride residues, a preparation method thereof includes the major steps of esterification, distillation, reduction, etc., thereby obtaining a phthalic acid diester product, and also a BDO or succinic acid diester product. The method can fully recycle phthalic anhydride, phthalic acid, maleic anhydride, fumaric acid, maleic acid, succinic acid, etc. in the by-products such as wastewater, waste residues and phthalic anhydride residues in the production process of phthalic anhydride, thereby obtaining products such as chemical intermediate BDO or succinic acid diester and phthalic acid diester with great market demands, and maximally reducing the discharge of wastes; and the preparation method has advantages of simple and controllable technical process and rather low cost.

Owner:隆鑫

Composite epoxy asphalt pavement material and preparation method thereof

InactiveCN103773039AAccelerated corrosionImprove heat resistanceBuilding insulationsBenzoic acidStearic acid

The invention relates to a composite epoxy asphalt pavement material and a preparation method thereof. The composite epoxy asphalt pavement material is composed of following components in parts by weight: 50-55 parts of coal tar asphalt, 24-29 parts of phenolic resin, 15-17 parts of bisphenol F-type epoxy resin, 3-5 parts of stearic acid diethanolamide, 6-12 parts of benzoic anhydride and 5-9 parts of aluminum carbonate. According to the composite epoxy asphalt pavement material, the composition materials are heated and fused, agitated, crushed and reacted to prepare the composite epoxy asphalt pavement material; the prepared composite epoxy asphalt pavement material has good corrosion resistance and heat resistance; the composite epoxy asphalt pavement material serves as a bonding layer so that the corrosion stability and the heat stability of a road can be improved.

Owner:NANTONG SOUTHEAST HIGHWAY ENG

Polyethylene terephthalate composite material for 3D printing and preparation method thereof

The invention provides a polyethylene terephthalate composite material for 3D printing and a preparation method thereof. The preparation method of the composite material comprises the following steps of: dissolving polyethylene glycol into isopropanol; adding benzyl triethylamine bromide, and standing at room temperature; then sequentially adding benzoic anhydride and ethyl alpha-cyanoacrylate, and stirring at room temperature; then adding polyethylene terephthalate granules, heating, stirring, and cooling to room temperature to obtain the polyethylene terephthalate composite material for 3D printing, wherein the content of polyethylene terephthalate is 40%-50%, the content of ethyl alpha-cyanoacrylate is 5%-25%, the content of polyethylene glycol 4000 is 5%-20%, the content of isopropanol is 15%-30%, the content of benzyl triethylamine bromide is 1%-5%, and the content of benzoic anhydride is 1%-5%. The polyethylene terephthalate composite material prepared through the method provided by the invention can be used for 3D printing within a temperature range of 40-60 DEG C without plugging a spray head of a 3D printer.

Owner:TAICANG BIQI NEW MATERIAL RES & DEV

Photosensitive water developing corrosion-resistant composition and photosensitive water developing corrosion-resistant dry film

The invention relates to a photosensitive water developing corrosion-resistant composition and a photosensitive water developing corrosion-resistant dry film. The photosensitive water developing corrosion-resistant composition consists of acrylate, polyvinyl alcohol acrylate-benzoic anhydride half-ester, pentaerythritol triacrylate, monoanhydride half-ester, a photoinitiator, a plasticizer, an inorganic filler, a coloring agent, a tackifier, a leveling defoaming agent, a coupling agent, an emulsifying agent, a polymerization inhibitor and balance of water. As the polyvinyl alcohol acrylate-benzoic anhydride half-ester is used, the photosensitive water developing corrosion-resistant composition can provide water solubility, water developing property, high film-forming property and contact dryness and has high adhesive force when applied to circuit board etching.

Owner:HUIZHOU LIANDA ELECTRONICS MATERIAL

Quick-drying alkide resin and preparation method thereof

The invention relates the method for preparation of alkide resin which possesses easy drying, good water resistance and corrosion resistance, comprising the following characteristics: esterifying and copolymerizing 32í½50wtúÑ fatty acid without conjugate double bonds, 0.5í½1.5wtúÑ maleic acid, 12.5í½16.5wtúÑ benzoic anhydride, 11í½14wtúÑ pentaerythritol or glycerin, 28í½50wtúÑ vinyltoluene. The method not only reduces the cost of production, but also makes the molecular weight distribution of production more homogeneous, and makes the resin easier drying, better water resistance and corrosion resistance. So the range of use of alkide resin is extended.

Owner:JIANGSU SANMU GROUP CORPORATION

Polyimide modified polyisocyanurate foam and preparation method thereof

The invention discloses a polyimide modified polyisocyanurate foam material and a preparation method thereof. A polyimide precursor prepared by esterification reaction of aromatic dianhydride and aromatic diamine with fatty alcohol is compounded with polyester polyol, polyether polyol, a surfactant, a foaming agent, a catalyst, and the like to form a foam combination solution, the solution chemically reacts with polyisocyanate to foam, and then the polyimide modified polyisocyanurate foam is endued with properties such as high-temperature resistance and flame retardance. The modified polyisocyanurate foam material comprises (1) the foamable polyimide precursor, (2) benzoic anhydride polyester and sucrose polyether polyol, (3) a polyisocyanate curing agent, and (4) an organosilicon foam stabilizer, the organic fluorinated surfactant, the trimerization catalyst and the foaming agent. According to the foam material and the preparation method, a one-step foaming technology is adopted, and the technology is simple and convenient and low in cost; and the foam is temperature-resistant, flame-retardant and low in smoke density, so that the popularization and application are facilitated.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

Heat-resisting and acid-alkali-resisting modified plastic material

InactiveCN106750924AExcellent heat resistance, acid and alkali resistanceWell mixedPolyesterToluene diisocyanate

The invention discloses a heat-resisting and acid-alkali-resisting modified plastic material. The heat-resisting and acid-alkali-resisting modified plastic material is prepared from polypropylene, modified polyethylene resin, phenol formaldehyde resin, coumarone indene resin, phenol formaldehyde resin, trimethyl phosphate, benzoic anhydride polyester polyol, diethylenetriamine, dolomite powder, aluminum dihydrogen phosphate, nano titanium dioxide, stearic acid, zinc borate, magnesium aluminate, magnesium oxide, antimony trioxide, zirconium oxide, triphenyl phosphite, toluene diisocyanate, tetrabutyl titanate, dioctyl phthalate, tricresyl phosphate, pentaerythritol stearate, glycerol and a modification auxiliary agent. The modified plastic material disclosed by the invention has excellent heat-resisting and acid-alkali-resisting performance.

Owner:TIANCHANG KANGNING PLASTIC TECH

Method for preparing C5 hydrocarbon resin from methyl tetrahydro benzoic anhydride production waste liquor

The invention relates to a method for preparing C5 petroleum resin by using the waste liquor in the methyl tetrahydrophthalic anhydride production. The method comprises the following steps: firstly, the waste liquor in the methyl tetrahydrophthalic anhydride production is separated for colloid removal to obtain cis-1,3-pentadiene material A, and the cracked C5 fraction is separated for dicyclopentadiene removal to obtain decyclization C5 material B; secondly, the materials A and B are fed according to the weight ratio of 1:0.1-5, and the intermittent cationic polymerization reaction is performed to the materials A and B in the C5 light oil solvent under the catalysis of catalyst (aluminium trichloride); and thirdly, after the polymerization reaction is finished, the catalyst is removed by a third-order continuous water-washing method to obtain the C5 petroleum resin. The prepared C5 petroleum resin is shallow coating color, high in softening point and stable in quality index and is especially used for road marking, and the method utilizes the waste liquor in the methyl tetrahydrophthalic anhydride production, improves the utilization value of the waste liquor, realizes the automation by adopting the continuous water-washing process and reduces the consumption of the water and the materials when improving the water-washing efficiency.

Owner:NINGBO YONGHUA RESIN +1

Preparation method of polyurethane curing agent

The invention discloses a preparing method of polyurethane hardener, which comprises the following steps: (1) adopting C16-18 saturated fatty acid as modifier; making benzene carbonic acid as molecular weight controller; dissolving benzoic anhydride, pentaerythrite and adjuvant in the solvent under 150-200 deg.c to proceed catalyzing reaction; preparing modified polyester polyatomic alcohol of fatty acid; (2) catalyzing modified polyester polyatomic alcohol of fatty acid, toluene diisocyanate and adjuvant in the solvent under 50-90 deg.c to obtain the product.

Owner:HANGZHOU PAINT

Premixed polyether, raw material composition, polyurethane foam, and preparation method and application thereof

ActiveCN104558476AGood physical and mechanical propertiesStrong impact resistanceLife-savingPolyesterFoaming agent

The invention discloses premixed polyether, a raw material composition, polyurethane foam, and a preparation method and application thereof. The premixed polyether comprises the following ingredients in parts by weight: 30-50 parts of polyether polyol A, 40-60 parts of polyether polyol B, 5-15 parts of polyester polyol C, 2.0-2.5 parts of a surfactant, 0.1-0.3 part of a catalyst A, 0.6-1.5 parts of a catalyst B, 0.3-0.6 part of a catalyst C, 18-22 parts of a foaming agent and 1.5-2.2 parts of water, wherein the polyether polyol A is polyether polyol which is prepared by adopting sorbitol as an initiator for polymerizing with oxyalkylene; the polyether polyol B is polyether polyol NJ6209 and / or polyether polyol SA380; the polyester polyol C is benzoic anhydride polyester polyol. The polyurethane foam prepared by adopting the premixed polyether is high in percentage of close area and low in water absorption, and the entire polyurethane foam has relatively high physical strength.

Owner:SHANGHAI DONGDA POLYURETHANE

Process for esterification production of phthalate

InactiveCN1884250AGood colorHigh volume resistivityOrganic compound preparationCarboxylic acid esters preparationLithium hydroxideSodium aluminate

The invention relates to a process for preparing phthalate, comprising following steps: (1) taking benzoic anhydride and relative excess alcohols as raw material, stirring and heating for dissolution, getting monoesters; (2) adding solid aluminum oxide into said alcohols solution, acting with caustic soda solution, getting sodium aluminate, adding lithium hydrate into said reactant of benzoic anhydride and alcohols for bi-esters action; filtering lithium compounds from reactants after reaction and getting coarse ester; (3) neutralizing said coarse ester to be alkalinity, washing alkalinity, dewatering and dealcoholizing, getting phthalate. The process is characterized by good color of product and high volume electrical resistivity.

Owner:池青松

Method for preparing unsaturated polyester resin from wastes of benzoic anhydride production process and distillation fraction

The invention discloses a manufacturing method for producing an unsaturated vibrin by utilizing the wastes and the distilling fractions generated during a phthalic anhydride production process, which belongs to the composing manufacture industry of a macromolecule compound. In the invention, the wastes, the distilling fractions, diethylene glycol, glycol and a catalyst are firstly fed into a reaction kettle and mixed uniformly; the temperature is gradually raised; when the temperature of the reaction kettle is raised to 200 DEG C, the temperature is controlled to be 200 to 220 DEG C for about 3 to 8 hours; when an acid value achieves to 35 to 40, vacuumizing is carried out for 1 to 2h; then a polymerization inhibitor and cinnamene are added into a diluting kettle; the adding amount of the polymerization inhibitor is 100 to 200ppm; when the acid value of the reaction kettle reaches a theoretical value (30 to 35), the temperature is reduced to 150 to 170 DEG C; then the unsaturated vibrin in the reaction kettle is transferred into the diluting kettle for dilution, adjusted into a proper viscosity and packaged. The technique of the method of the invention is simple and changes wastes to be valuable as well as changes the harm into benefit; in addition, the method of the invention can generate excellent economic benefits, reduce the pollution of the wastes to the environment and is beneficial to environment protection.

Owner:中山联成化学工业有限公司

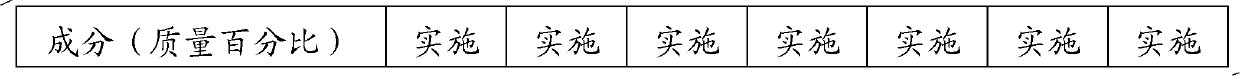

Synthesis method of fluopyram

The invention discloses a synthesis method of fluopyram and belongs to the technical field of fine chemical engineering. The synthesis method comprises the following steps: by taking 2,3-dichloro-5-trifluoromethylpyridine as a raw material, performing condensation and hydrolysis decarboxylation with ethyl cyanoacetate in the presence of an alkali so as to obtain 2-acetonitrile-3-chloro-5-trifluoromethylpyridine; performing catalytic hydrogenation reduction so as to obtain 2-ethylamino-3-chloro-5-trifluoromethylpyridine, performing protection by using o-trifluoromethyl benzoic anhydride or o-trifluoromethyl benzoic acid-trimethylacetic anhydride, so as to obtain a target product, namely fluopyram. The synthesis method is reasonable and simple and convenient in route selection and is applicable to industrial amplification, the synthesis method breaks through a conventional process, a step that hydrogenation reduction is implemented and at the same time amino is protected by using other acylation reagents firstly, and acylation of the amino with o-trifluoromethyl benzoyl chloride is implemented later is avoided, a step that hydrogenation is implemented and at the same time protectionis implemented to obtain the target product amide is implemented instead, and process procedures can be simplified.

Owner:DALIAN JOIN KING FINE CHEM CO LTD

Preparation method for benzoyldiphenyl phosphine oxide derivatives

ActiveCN105198927AReduce wasteHigh yieldGroup 5/15 element organic compoundsDiphenylphosphine oxideBenzoic anhydride

A provided preparation method for benzoyldiphenyl phosphine oxide derivatives comprises the following steps: mixing a diphenylphosphine oxide derivative, a first solvent and a catalyst under an oxygen-free condition, so as to obtain a first reaction solution; dissolving a benzoic anhydride derivative in a second solvent, so as to obtain a second reaction solution; and mixing the first reaction solution and the second reaction solution to perform a nucleophilic reaction, so as to obtain the corresponding benzoyldiphenyl phosphine oxide derivative with the structure shown as a formula I. The provided preparation method for the benzoyldiphenyl phosphine oxide derivatives employs a one-step reaction, reaction steps are reduced, and further waste caused by incapability of 100% utilizing the raw materials and intermediates in the multiple reaction steps is reduced, and the yield of the final product is increased. Raw material waste reduction during reaction and selection on reaction conditions enable the yield of the preparation method is substantially improved, and the yield is between 80%-91%.

Owner:QINGDAO FUSILIN CHEM SCI & TECH +1

PU board for automobile

The invention discloses a PU board for an automobile. The PU board for the automobile is prepared from the following raw materials in parts by weight: 5 to 7 parts of polyether polyol, 5 to 8 parts of benzoic anhydride polyester polyol, 3 to 8 parts of graphite, 3 to 8 parts of activated carbon, 6 to 9 parts of kieselguhr, 3 to 5 parts of stearic acid, 10 to 15 parts of natural organic fiber, 5 to 10 parts of ceramic fiber, 1 to 3 parts of mineral fiber, 2 to 6 parts of foaming agent, 1 to 3 parts of plasticizer and 2 to 6 parts of flame retardant. The PU board for the automobile has the advantages that the weight is light, the strength is great, the stability is enhanced, the sound absorbing effect is remarkably improved and the peculiar smell can be removed.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

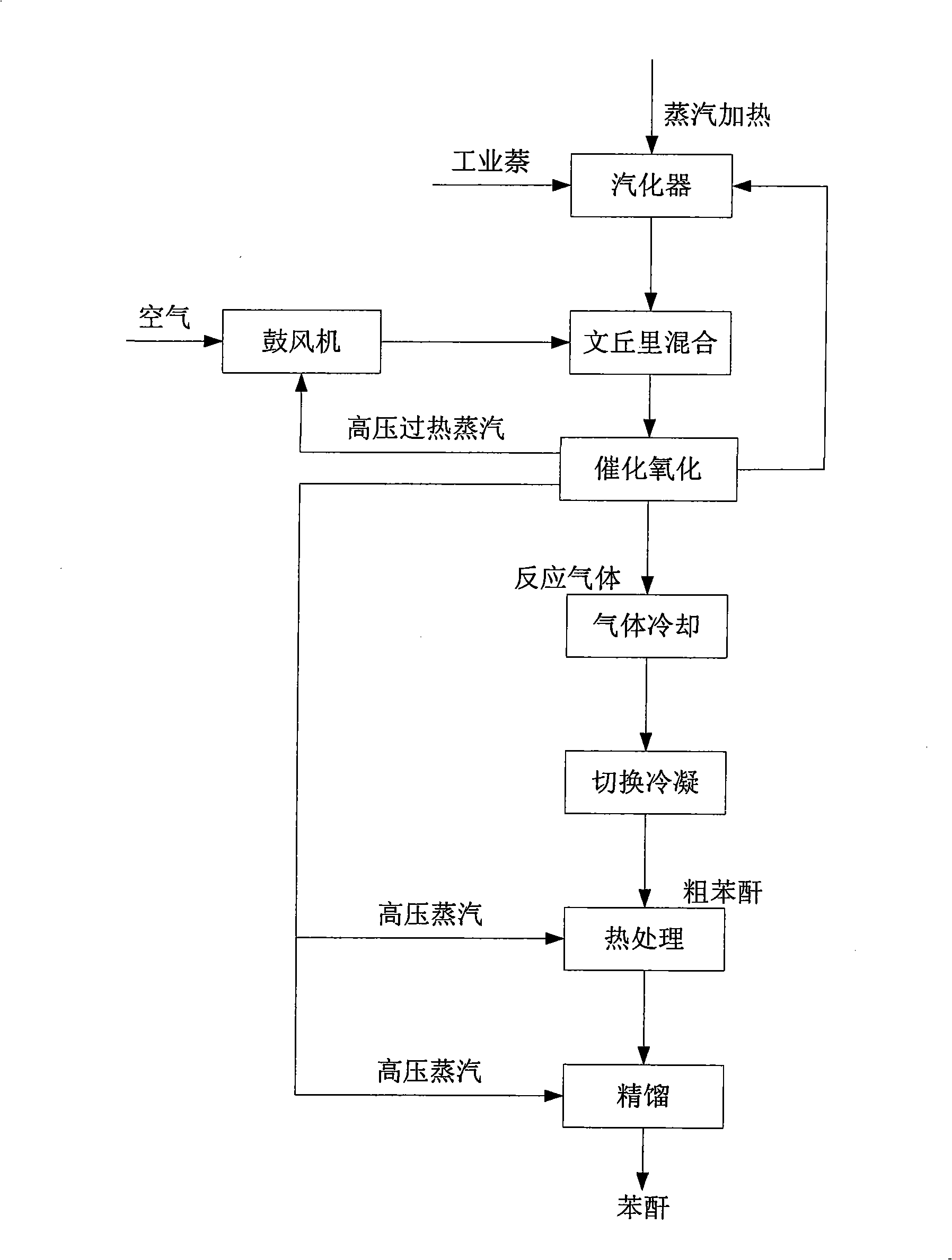

Industrialized production process of benzoic anhydride

ActiveCN101298446AAvoid cloggingEasy to controlOrganic chemistryChemical/physical/physico-chemical nozzle-type rreactorsBenzoic anhydrideFixed bed

A method for manufacturing phthalic anhydride by industrial naphthalene includes the following steps: 1) the industrial naphthalene is heated in a carburetor until being completely vaporized; 2) the vaporized naphthalene enters a naphthalene-air mixer by a venturi tube and is fully mixed with the reaction air; 3) the fully mixed naphthalene-air mixing air enters a fixed bed vapor phase reactor for reaction, and then the phthalic anhydride is obtained. The method can be used for leading the industrial naphthalene to be completely vaporized and fully mixed with the air, thereby improving the yield of the phthalic anhydride and simultaneously being capable of solving the problem that the nozzle in the conventional ejection type vaporization technique is easy to be plugged.

Owner:山西宏特煤化工有限公司

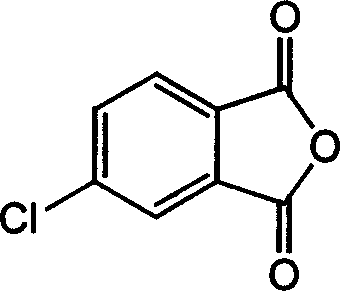

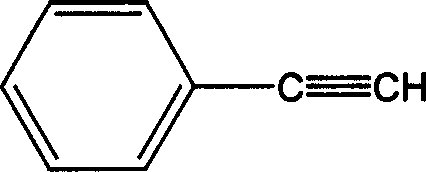

4-phenylacetylene benzoic anhydride preparation method

The invention relates to a process for preparing 4-phenylacetylene- benzoic anhydride from 4-chlorophthalic anhydride as raw material, at the presence of 4 (triphenylphosphine) fertilizer as catalyst, copper chloride as catalyst promoter, and tertiary amine as absorbent of reaction by-product through coupling reaction in nonprotonic solvent with phenylacetylene.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High-yield synthesis method of sofosbuvir and sofosbuvir prepared with method

ActiveCN105646626AOvercome the conditionsOvercome by-productsSugar derivativesSugar derivatives preparationSodium methoxidePhosphorus tribromide

The invention relates to a high-yield synthesis method of sofosbuvir and sofosbuvir prepared with the method. The method comprises steps as follows: (a) cytidine and benzoic anhydride are dissolved in a first organic solvent for a reaction; TIDPSCl2 is added for a reaction; (b) a product and dimethyl phthalate are dissolved in a second organic solvent for a reaction; (c) a Grignard reagent is dissolved in tetrahydrofuran, and the temperature is reduced to subzero 35 DEG C to subzero 20 DEG C; tetrahydrofuran containing a third product is dropwise added and has a reaction, and a fourth product is obtained through purification; (d) the fourth product is dissolved in acetic acid containing tetrabutylammonium fluoride and has a reaction, and a sixth product is obtained through purification; (e) the sixth product is dissolved in the second solvent, phosphorus tribromide is added and has a reaction, and a seventh product is obtained through purification; (f) the seventh product is dissolved in methanol containing sodium methoxide and has a reaction, and an eighth product is obtained through purification. Accordingly, the reaction steps are reduced, the cost is greatly reduced, and the yield of the product is increased.

Owner:GUIZHOU INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com