Polyurethane acid imide foam material and preparation thereof

A technology for polyurethane imide and foam material, applied in the field of polyurethane imide foam material and its preparation, can solve the problems of lack of modern production mature technology, achieve good thermal stability and flame retardant performance, simple process and easy industrialization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

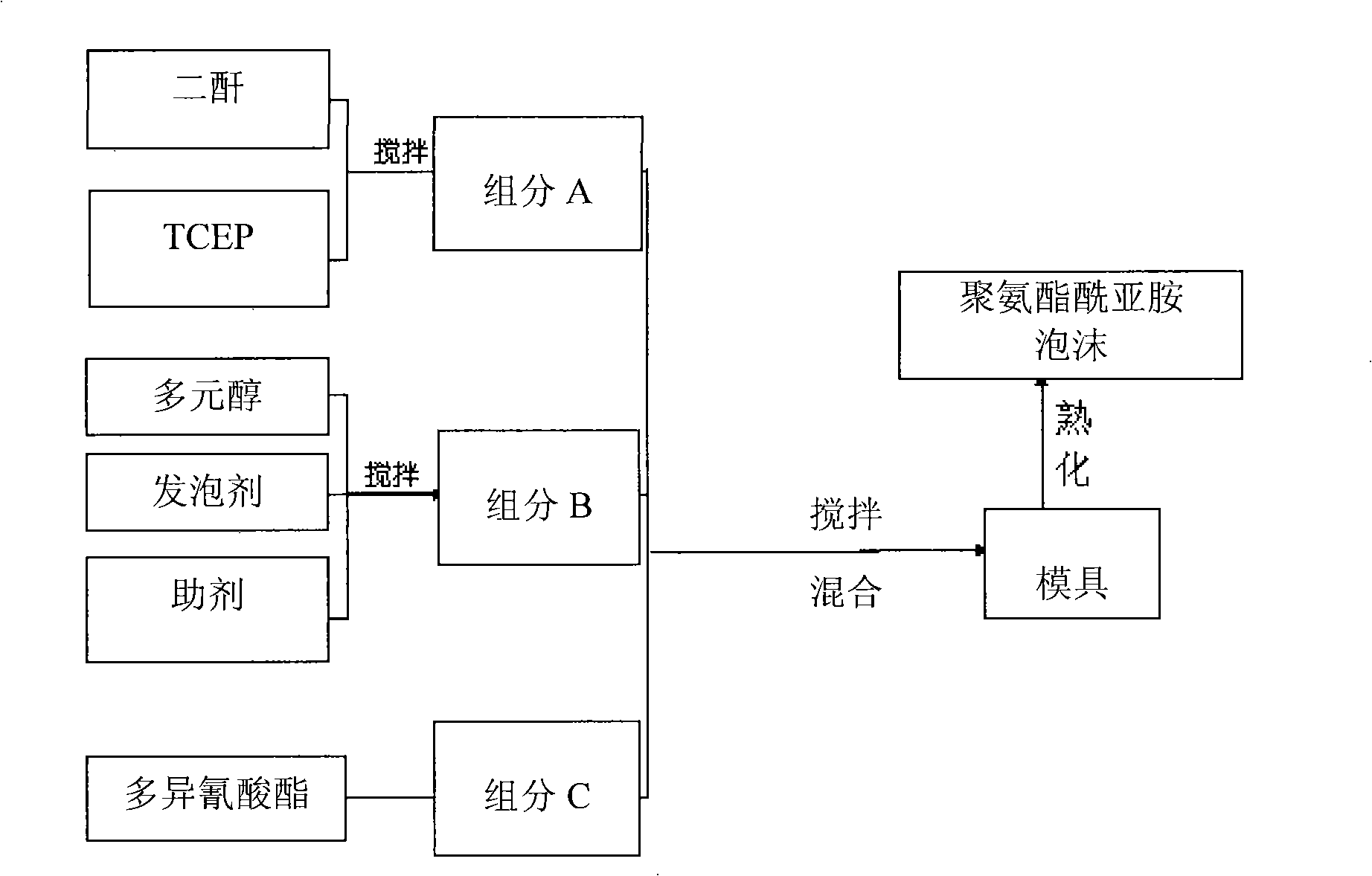

[0024] Embodiment 1, prepare polyurethane imide foam material

[0025] As shown in Table 2, each component was weighed respectively to prepare sample 1#-sample 6# of polyurethane imide foam material: pyromellitic dianhydride (PDMA) and tris (β-chloroethyl) phosphate (TCEP) is mixed and stirred to form a paste, and then the paste and polyphenyl polymethylene polyisocyanate (PAPI) are added to component B at one time, and after mixing, follow the conventional one-step foaming process. The mixed material is poured into a mold for foaming, matured, and then released from the mold to obtain a polyurethane-imide foam material.

[0026] The consumption list of each component in the table 21#-6# sample

[0027]

[0028] The performance of 3# and 4# polyurethane imide foam material that present embodiment makes is as shown in table 3, and the thermogravity curve that measures by thermogravimetry (TG) is as follows figure 2 shown.

[0029] Table 33# and 4# performance list of sam...

Embodiment 2

[0032] Embodiment 2, prepare polyurethane imide foam material

[0033] Weigh each component respectively according to the consumption shown in table 4, prepare the sample 7#-sample 15# of polyurethane imide foam material: combine pyromellitic dianhydride (PDMA) and tris (beta-chloroethyl) phosphoric acid After the ester (TCEP) is mixed and stirred to form a paste, the paste and polyphenyl polymethylene polyisocyanate (PAPI) are added to component B at one time, and after mixing, follow the conventional one-step foaming process. The mixed material is poured into a mold for foaming, matured, and then released to obtain a polyurethane-imide foam material.

[0034] The dosage list of each component in the table 47#-15# sample

[0035]

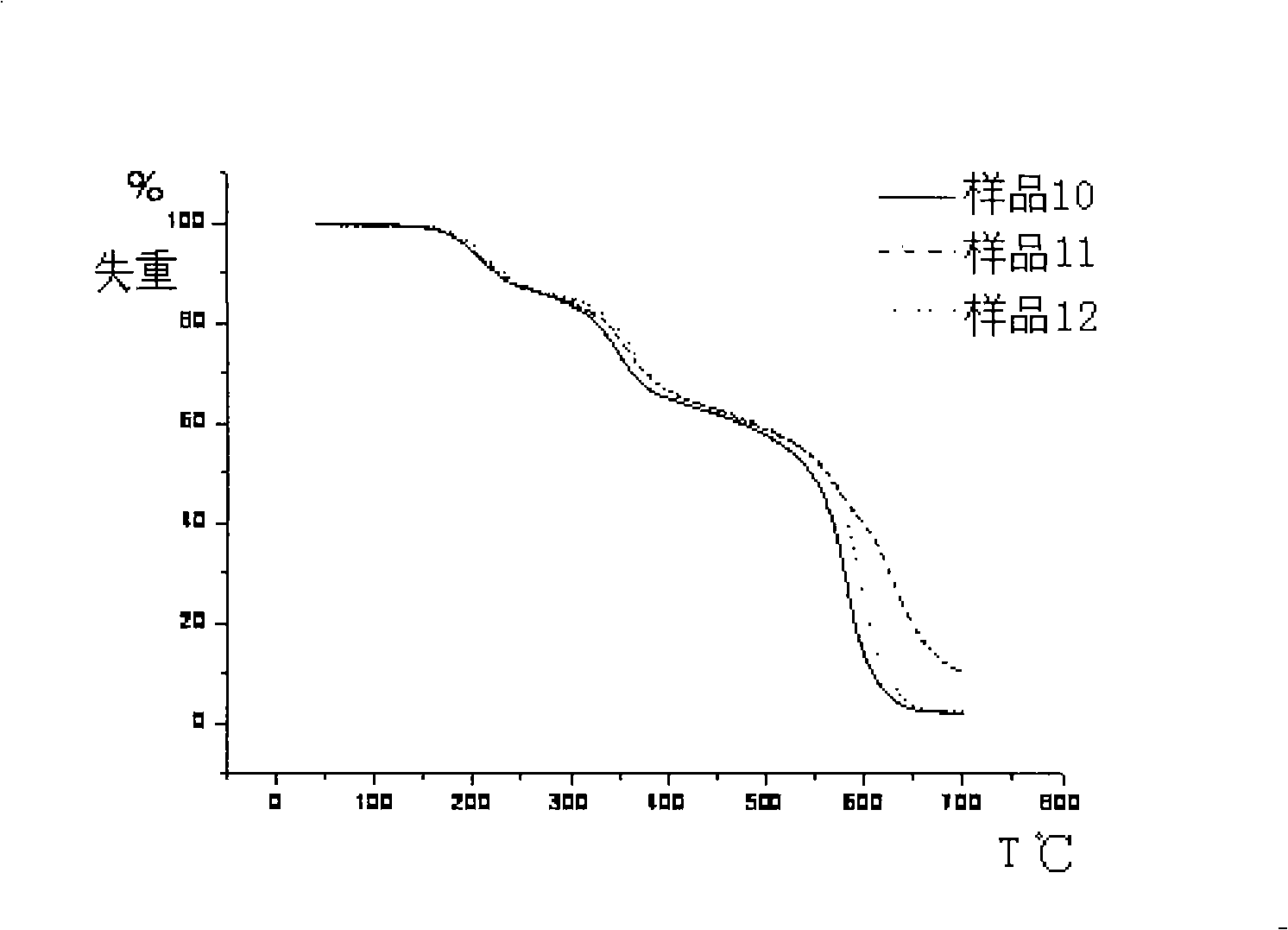

[0036] The performance of the polyurethane imide foam material (sample 10#, sample 11# and sample 12#) that present embodiment makes is as shown in table 5, and the thermal weight loss curve measured by thermogravimetric analysis (TG) is as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com