Preparation method of carbon nano-enzyme co-doped with active metal and nitrogen element and application thereof as nano biological probe for detecting hydrogen peroxide

A technology of active metals and nitrogen elements, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve problems such as poor catalytic activity, unfavorable large-scale production and commercial application of carbon nanozymes, etc. Achieve the effect of fast reaction speed, good enzyme catalytic activity and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

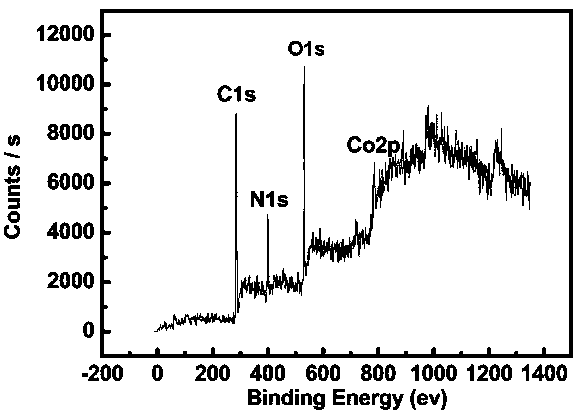

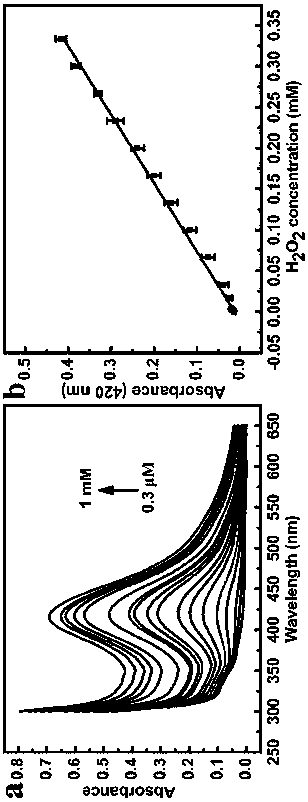

[0023] Step S1: Dissolve 7g of cobalt nitrate hexahydrate and 4.5g of disodium edetate in 20mL of deionized water respectively to form uniform cobalt nitrate solution and disodium edetate solution, then add the cobalt nitrate solution dropwise to Add 10 mL of methanol to the disodium EDTA solution under vigorous stirring, filter the resulting reaction solution, wash the obtained filter cake with deionized water to remove impurities, and dry at 60°C to obtain a solid powder;

[0024] Step S2: put the dried solid powder in step S1 into a quartz tube of a tube furnace, and thermally polymerize at 300° C. for 2 hours under a nitrogen atmosphere to obtain a brown-black product;

[0025] Step S3: Grind the brown-black product obtained by thermal polymerization and disperse it in deionized water under ultrasonic treatment, filter the supernatant brown solution after centrifugation with a microporous filter to remove large particles, and then dry it at 100°C after dialysis 6h to get a...

Embodiment 2

[0032] Step S1: Dissolve 20mg of nickel acetate and 4.5g of disodium edetate in 1mL and 10mL of deionized water respectively to form a uniform solution of nickel acetate and disodium edetate, then add the nickel acetate solution dropwise to Add 10 mL of ethanol to the disodium EDTA solution under vigorous stirring, filter the resulting reaction solution, wash the obtained filter cake with deionized water to remove impurities, and dry at 60°C to obtain a solid powder;

[0033] Step S2: put the dried solid powder in step S1 into a quartz tube of a tube furnace, and thermally polymerize at 450° C. for 30 minutes under a nitrogen atmosphere to obtain a brown-black product;

[0034] Step S3: Grind the brown-black product obtained by thermal polymerization and disperse it in deionized water under ultrasonic treatment, filter the supernatant brown solution after centrifugation with a microporous filter to remove large particles, and then dry it at 180°C after dialysis 1.5h to obtain ...

Embodiment 3

[0036]Step S1: Dissolve 0.2g of cerium sulfate and 4.5g of disodium edetate in 5mL and 20mL of deionized water respectively to form a uniform solution of cerium sulfate and disodium edetate, then add the cerium sulfate solution dropwise Add 10 mL of methanol to the disodium edetate solution under vigorous stirring, filter the resulting reaction solution, wash the obtained filter cake with deionized water to remove impurities, and dry at 60°C to obtain a solid powder;

[0037] Step S2: put the dried solid powder in step S1 into a quartz tube of a tube furnace, and thermally polymerize at 180° C. for 8 hours under a nitrogen atmosphere to obtain a brown-black product;

[0038] Step S3: Grind the brown-black product obtained by thermal polymerization and disperse it in deionized water under ultrasonic treatment, filter the supernatant brown solution after centrifugation with a microporous filter to remove large particles, and then dry it at 60°C after dialysis 10h to obtain the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com