Slow release, long-acting urea manure and technique of manufacturing the same

A urea and fertilizer technology, applied in the field of nitrogen fertilizers, can solve the problems of reducing fertilizer nitrogen utilization rate, increasing soil pH value, easy leaching of nitrate nitrogen, etc., and achieving improved utilization rate, simple operation, and labor-saving agricultural production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The raw materials for preparing slow-release urea are: based on 100 parts of urea granules, 0.0625 parts of N-butylphosphorothioate, 2 parts of DCD, 5 parts of acrylic resin and ethyl cellulose copolymer, and 500 ml of industrial ethanol solution; The urea granules contain 46.3% nitrogen, have a particle size of 0.5 mm, and have a weight ratio of acrylic resin to ethyl cellulose of 1:0.1.

[0026] Preparation:

[0027] 1) Preparation of suspension solution: Dissolve 5 parts of copolymer of acrylic resin and ethyl cellulose into 500ml of industrial ethanol solution, then mix 0.0625 parts of N-butylthiophosphoric triamide and 2 parts of DCD evenly before adding, The homogeneously stirred copolymer forms a mixed suspension solution, which is ready for use.

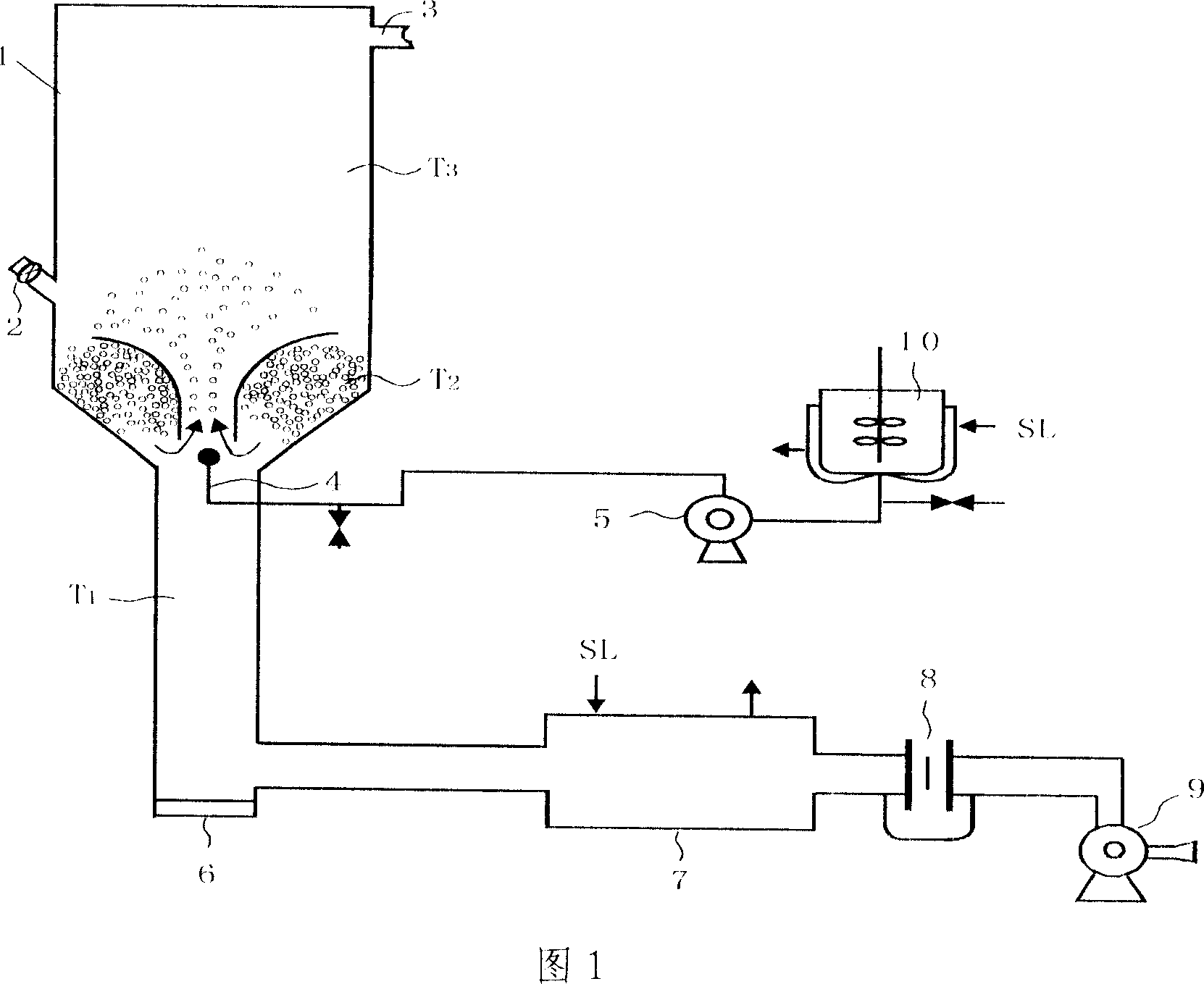

[0028] 2) Utilize the fluidized bed coating technique (see Fig. 1), place the prepared mixed suspension solution in the liquid tank 10, and simultaneously inject 100 parts of urea particles containing 46.3% nitrogen i...

Embodiment 2

[0030] The raw materials for preparing slow-release urea are: based on 100 parts of urea granules, 1 part of N-butyl phosphoric acid triamide, 0.5 part of DCD, 6 parts of acrylic resin and ethyl cellulose copolymer, and 500 ml of ether solution; wherein the urea granules contain Nitrogen 46.3%, particle size 1mm, weight ratio of acrylic resin and ethyl cellulose 1:0.15.

[0031] Preparation:

[0032] 1) Preparation of suspension solution: Dissolve 6 parts of acrylic resin and ethyl cellulose copolymer into 500ml ether solution, then mix 1 part of N-butyl phosphate triamide and 0.5 part of DCD evenly, then add, and stir the copolymer evenly Compose a mixed suspension solution for use.

[0033] 2) The prepared mixed suspension solution is placed in the liquid irrigation 10, and 100 parts of urea particles containing 46.3% nitrogen are injected into the spray tower 1 from the fertilizer feed port 2 for fluidization, and then follow the operation of the fluidized bed The suspens...

Embodiment 3

[0035] The raw materials for preparing slow-release urea are: based on 100 parts of urea granules, 1 part of N-methylpyrrolidone, 2 parts of DCD, 10 parts of acrylic resin and ethyl cellulose copolymer, and 1000 ml of industrial ethanol solution; wherein the urea granules contain nitrogen 46.1%, the particle size is 2mm, and the weight and number ratio of acrylic resin and ethyl cellulose is 1:0.3.

[0036] Preparation:

[0037] 1) Preparation of suspension solution: Dissolve 10 parts of acrylic resin and ethyl cellulose copolymer into 1000ml of industrial ethanol solution, then mix 1 part of N-methylpyrrolidone and 2 parts of DCD evenly, then add, and stir the copolymer to form Mix the suspension solution and set aside.

[0038] 2) The prepared mixed suspension solution is placed in the liquid irrigation 10, and 100 parts of urea particles containing 46.1% nitrogen are injected into the spray tower 1 from the fertilizer feed port 2 for fluidization, and then follow the opera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com