Low-temperature heat-seal acrylic emulsion and preparation method thereof and application thereof

An acrylic emulsion, low-temperature heat-sealing technology, applied in transportation and packaging, flexible coverings, coatings, etc., can solve the problems of unsatisfactory, high sealing temperature, etc., achieve good uniformity, high heat-sealing strength, and eliminate foam Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

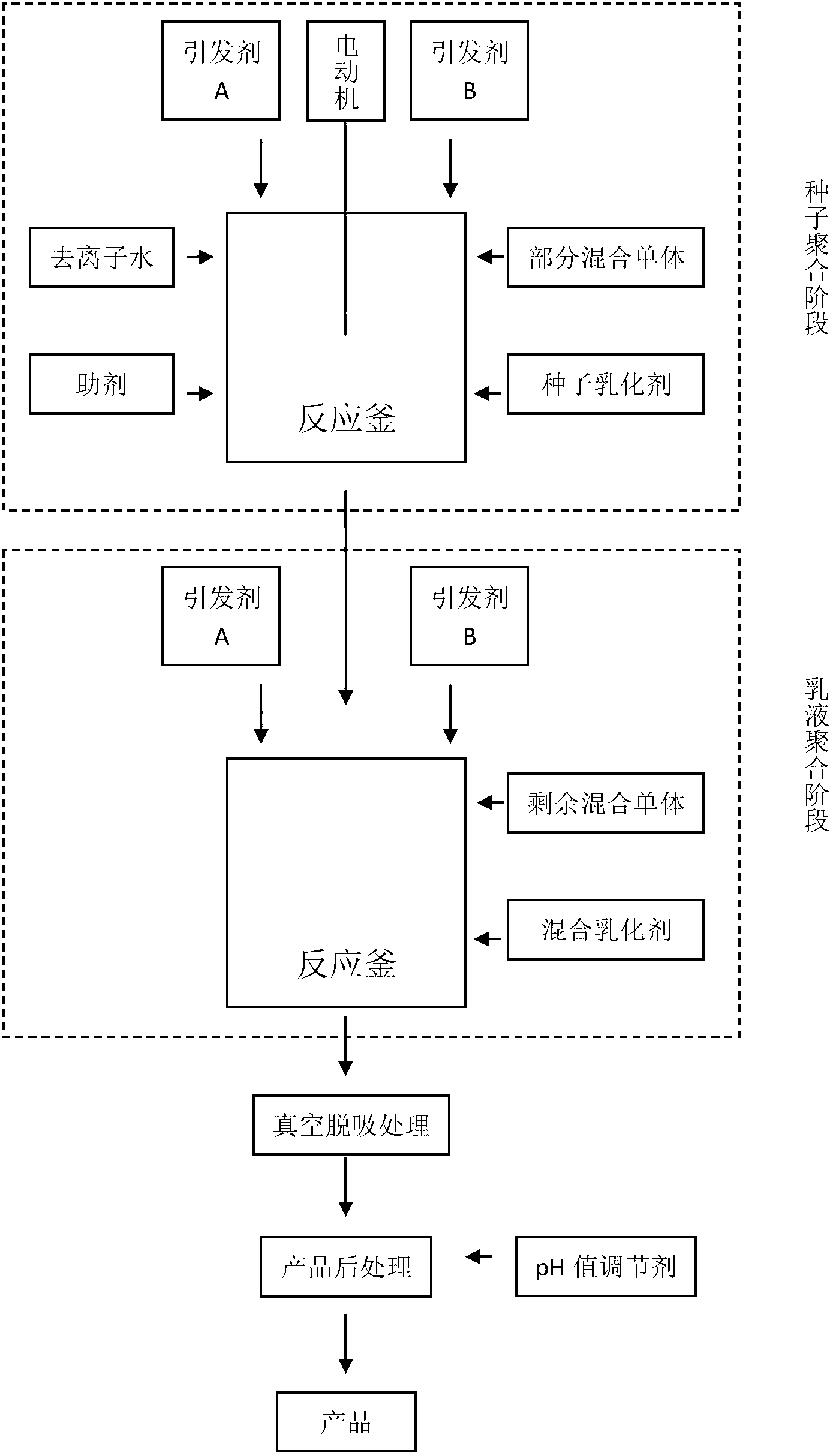

Method used

Image

Examples

Embodiment 1

[0050] 1. Raw material preparation: Mix 37.5kg of 2-ethylhexyl acrylate, 10kg of acrylonitrile and 2.5kg of methacrylic acid, stir for 2 hours to make a mixed monomer; add 160g of tert-butyl hydroperoxide to 8kg of deionized water Stir and mix in tert-butyl hydroperoxide solution; Add 160g of sodium formaldehyde sulfoxylate into deionized water 8kg and stir and mix to make sodium formaldehyde sulfoxylate solution; 2A-1 is 340g, secondary chain Dissolve 1.2kg of sodium alkylsulfonate in water, add water to 10kg, and carry out cold dispersion for 2 hours to make a mixed emulsifier solution;

[0051] 2. Seed polymerization: 50kg of deionized water, 24g of ammonium acetate, 5g of ferrous chloride, 45g of sodium paraffin sulfonate and 140g of MA-80 were used to seal the kettle, replace it with nitrogen for 3 times, and then vacuumize it. Inhale 5% mixed monomer as seed monomer, cold disperse for 0.5h, heat up to 47°C, pump in initiator tert-butyl hydroperoxide solution and sodium f...

Embodiment 2

[0062] 1. Raw material preparation: Mix 45kg of 2-ethylhexyl acrylate, 2.5kg of acrylonitrile and 2.5kg of methacrylic acid, stir for 2 hours to make a mixed monomer; add 160g of tert-butyl hydroperoxide to 8kg of deionized water tert-butyl hydroperoxide solution; 160g of sodium formaldehyde sulfoxylate was added into deionized water 8kg and stirred and mixed to make sodium formaldehyde sulfoxylate solution; 2A-1 was 500g, secondary chain Dissolve 1.6kg of sodium alkylsulfonate in water, add water to 10kg, and carry out cold dispersion for 2 hours to make a mixed emulsifier solution;

[0063] 2. Seed polymerization: 50kg of deionized water, 24g of ammonium acetate, 5g of ferrous chloride, 45g of sodium paraffin sulfonate and 140g of MA-80 were used to seal the kettle, replace it with nitrogen for 3 times, and then vacuumize it. Inhale 5% mixed monomer as seed monomer, cold disperse for 0.5h, heat up to 47°C, pump in initiator tert-butyl hydroperoxide solution and sodium formal...

Embodiment 3

[0066] 1. Preparation of raw materials: Mix 40kg of 2-ethylhexyl acrylate, 6kg of acrylonitrile and 4kg of methacrylic acid, stir for 2 hours to make a mixed monomer; add 160g of tert-butyl hydroperoxide into 8kg of deionized water for Stir and mix to make tert-butyl hydroperoxide solution; add 160 g of sodium formaldehyde sulfoxylate into 8 kg of deionized water and stir and mix to make sodium formaldehyde sulfoxylate solution; 2A-1 is 450 g, secondary chain alkyl Dissolve 1.5kg of sodium sulfonate in water, add water to 10kg, and carry out cold dispersion for 2 hours to make a mixed emulsifier solution;

[0067] 2. Seed polymerization: 50kg of deionized water, 24g of ammonium acetate, 5g of ferrous chloride, 45g of sodium paraffin sulfonate and 140g of MA-80 were used to seal the kettle, replace it with nitrogen for 3 times, and then vacuumize it. Inhale 5% mixed monomer as seed monomer, cold disperse for 0.5h, heat up to 47°C, pump in initiator tert-butyl hydroperoxide solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com