Rollscale impurity-removing system and process

A technology of iron scale and impurity, which is applied in the rolling iron scale impurity removal system and process field under high temperature conditions, to achieve the effect of improving the grinding process conditions, increasing product output, and prolonging the life of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

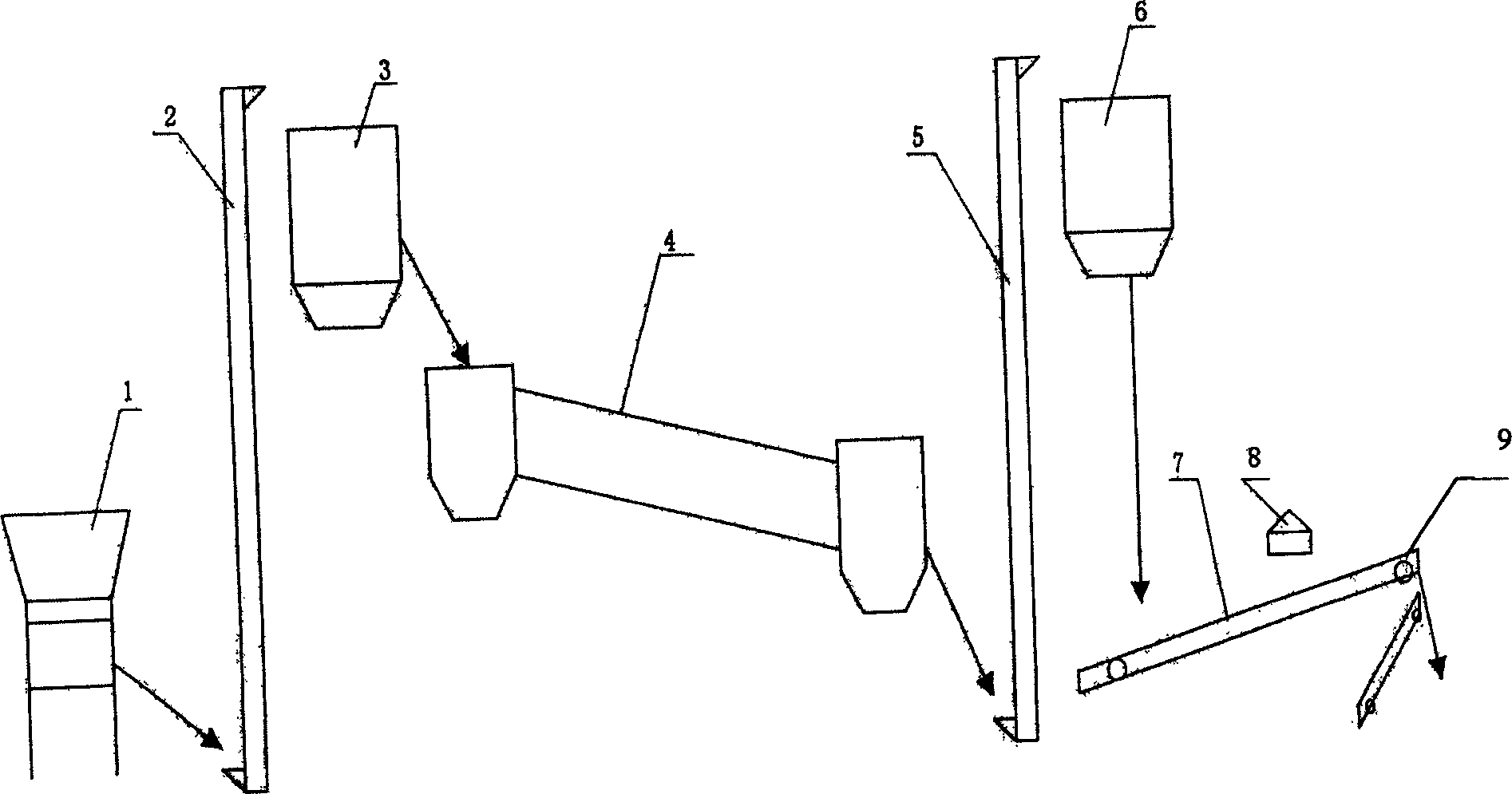

[0012] Embodiment 1: referring to accompanying drawing, during production, iron scale raw material is loaded into grid sieve 1, and iron scale raw material is sorted into sieve upper material and sieve lower material and enters respective lower hoppers, and sieve upper material is impurity, and sieve lower material is made of 1 # Elevator 2 into 1 # Silo 3, 1 # The iron scale raw material in the silo 3 is sent to the drying kiln 4 for drying. The drying temperature is 200°C for 30 minutes. The temperature control is based on the effective removal of oil and water impurities. After drying, the high-temperature iron scale passes through 2 # Elevator 5 into 2 # The silo 6 is evenly fed to the belt conveyor 7. The iron scale raw material is on the belt conveyor 7. When passing through the iron remover 8, metal iron impurities are removed, and when passing through the high-temperature resistant magnetic roller 9, small particles and micro-particle impurities are removed. When the...

Embodiment 2

[0013] Example 2: The drying temperature is 160°C, and the drying time is 40 minutes; the magnetic field strength of the high temperature-resistant magnetic roller is 2400 Gauss, and the working temperature is 240°C. All the other are identical with embodiment 1. After the impurity removal process is used, (1) the silicon dioxide content is reduced to 0.29%; (2) the product quality of iron oxide powder is improved, Fe 2 o 3 The average value of the percentage content is increased from 98% to 99.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com