Citric acid monohydrate crystal and production method thereof

A technology of citric acid and crystals, applied in the field of citric acid monohydrate crystals, which can solve the problems of uneven particle size and wide particle size distribution of citric acid monohydrate crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

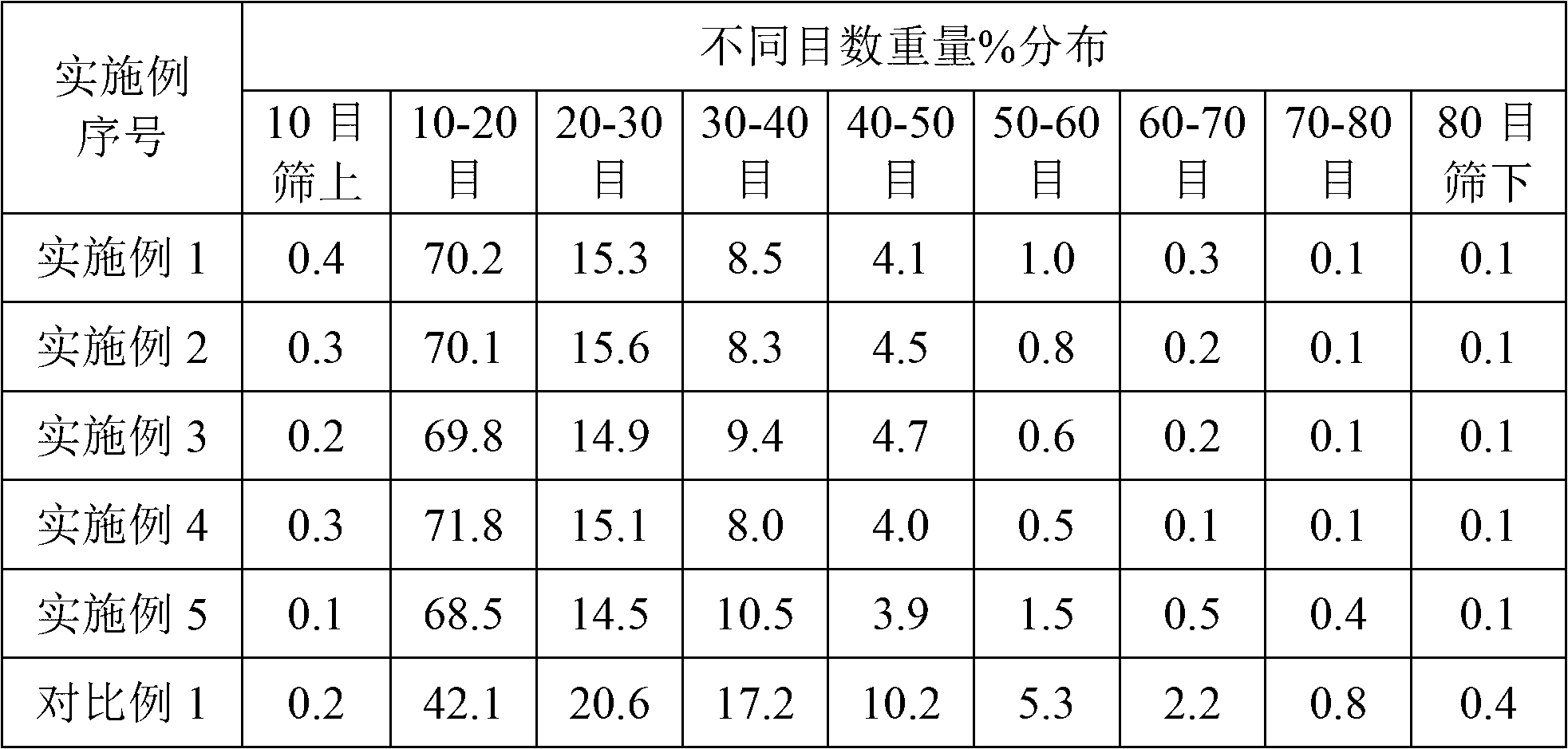

Examples

Embodiment 1

[0037] will be 13m 3 The concentration of citric acid is 38.7% by weight, the purity of citric acid is 99% by weight, and the density is 1147kg / m 3 The citric acid solution was heated and concentrated at 60° C. until the concentration of citric acid was 72% by weight to obtain a citric acid concentrate. Put the citric acid concentrate in the crystallization tank, control the temperature difference between the cooling water passing into the jacket of the crystallization tank and the citric acid concentrate in the crystallization tank to be 15°C, and control the cooling rate to 10°C / h, when the temperature drops to 36.6°C At this time, the temperature difference between the cooling water passed into the jacket of the crystallization tank and the citric acid concentrate in the crystallization tank is controlled to be 10°C, the cooling rate is controlled to be 6°C / h, and the temperature is lowered to 10°C, and the obtained citric acid crystal slurry is Carry out centrifugation, c...

Embodiment 2

[0039] will be 13m 3 The concentration of citric acid is 38.7% by weight, the purity of citric acid is 99% by weight, and the density is 1147kg / m 3 The citric acid solution was heated and concentrated at 60° C. until the concentration of citric acid was 72% by weight to obtain a citric acid concentrate. Put the citric acid concentrate in the crystallization tank, control the temperature difference between the cooling water in the jacket of the crystallization tank and the citric acid concentrate in the crystallization tank to be 15°C, and control the cooling rate to 10°C / h, when the temperature drops to 36.6°C At this time, the temperature difference between the cooling water passed into the jacket of the crystallization tank and the citric acid concentrate in the crystallization tank was controlled to be 10°C, the cooling rate was controlled to be 4°C / h, and the temperature was lowered to 15°C, and the obtained citric acid crystal slurry was Carry out centrifugation, control...

Embodiment 3

[0041] will be 13m 3 The concentration of citric acid is 38.7% by weight, the purity of citric acid is 99% by weight, and the density is 1147kg / m 3 The citric acid solution was heated and concentrated at 80° C. until the concentration of citric acid was 70% by weight to obtain a citric acid concentrate. Put the citric acid concentrate in the crystallization tank, control the temperature difference between the cooling water in the jacket of the crystallization tank and the citric acid concentrate in the crystallization tank to be 15°C, and control the cooling rate to 10°C / h, when the temperature drops to 36.6°C At this time, the temperature difference between the cooling water passed into the jacket of the crystallization tank and the citric acid concentrate in the crystallization tank was controlled to be 4°C, and the cooling rate was controlled to be 2°C / h; the temperature was lowered to 10°C, and the obtained citric acid crystal slurry was Carry out centrifugation, control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com